Redwood furniture tenon mortise cutting device

A technology for cutting devices and mahogany furniture, which is applied in wood processing equipment, manufacturing tools, and dovetail processing, etc., and can solve the problems of reduced processing efficiency and unfavorable mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

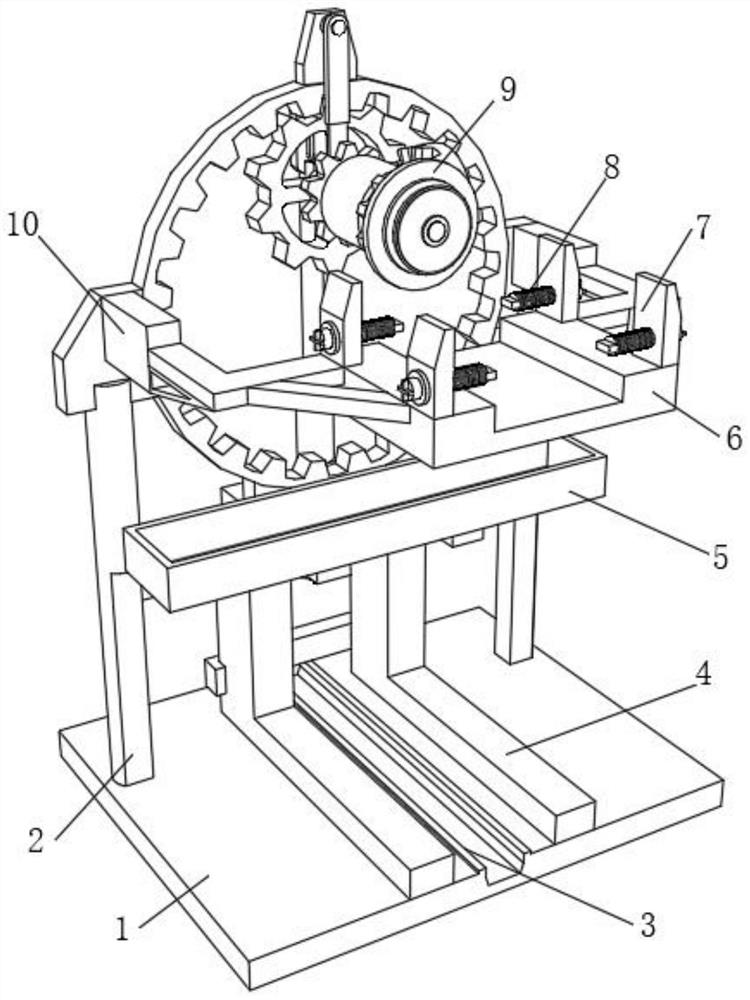

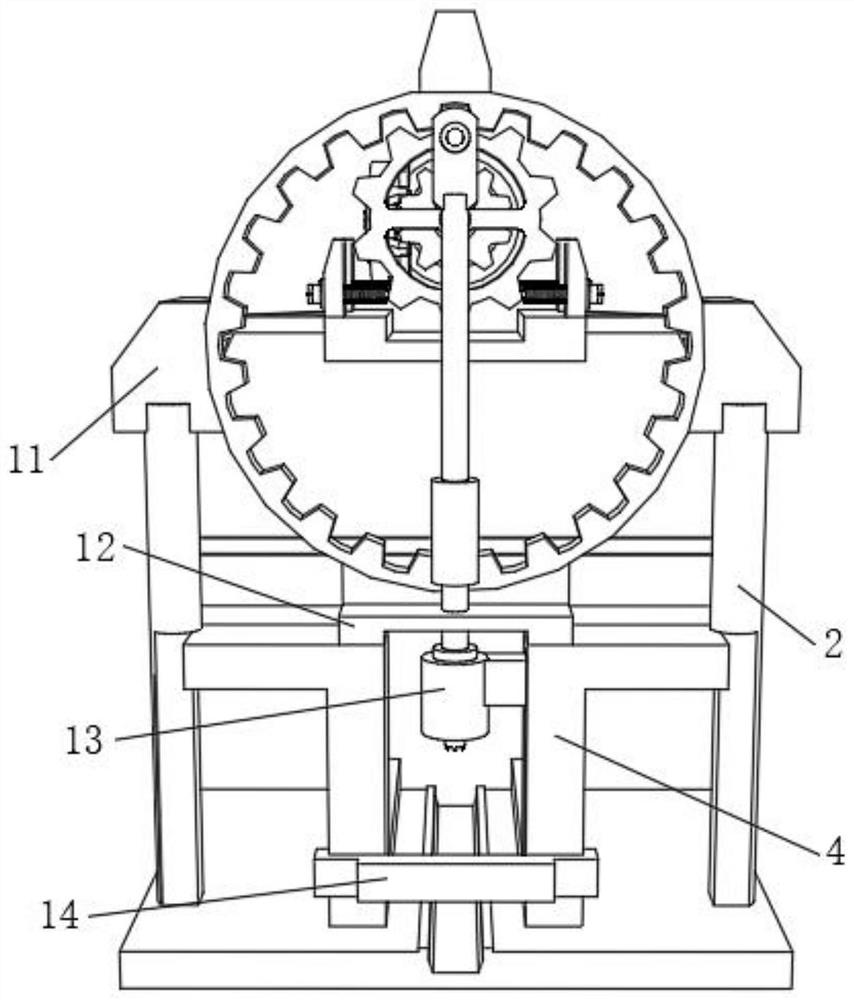

[0032] A mahogany furniture mortise and mortise cutting device, such as Figure 1-5 As shown, including the base 1, the outer walls on both sides of the top of the base 1 are respectively fixed with supporting columns 2 by bolts, and the top outer walls of the two supporting columns 2 are connected with mounting seats 11 by threads, and the two mounting seats 11 are opposite to each other. The side is provided with the same circumferential cutting mechanism, and the bottom outer wall of the circumferential cutting mechanism is fixed with a connecting plate 12 by bolts, and the top outer wall of the connecting plate 12 is fixed with a waste tank 5 by bolts, and the outer walls on both sides of the bottom of the connecting plate 12 are respectively fixed by bolts. The limiting plate 4 is fixed, and the outer walls of one side of the two limiting plates 4 are fixed with the same baffle plate 14 by bolts, and the base 1 is provided with a first timber tank 3 near the top outer wall...

Embodiment 2

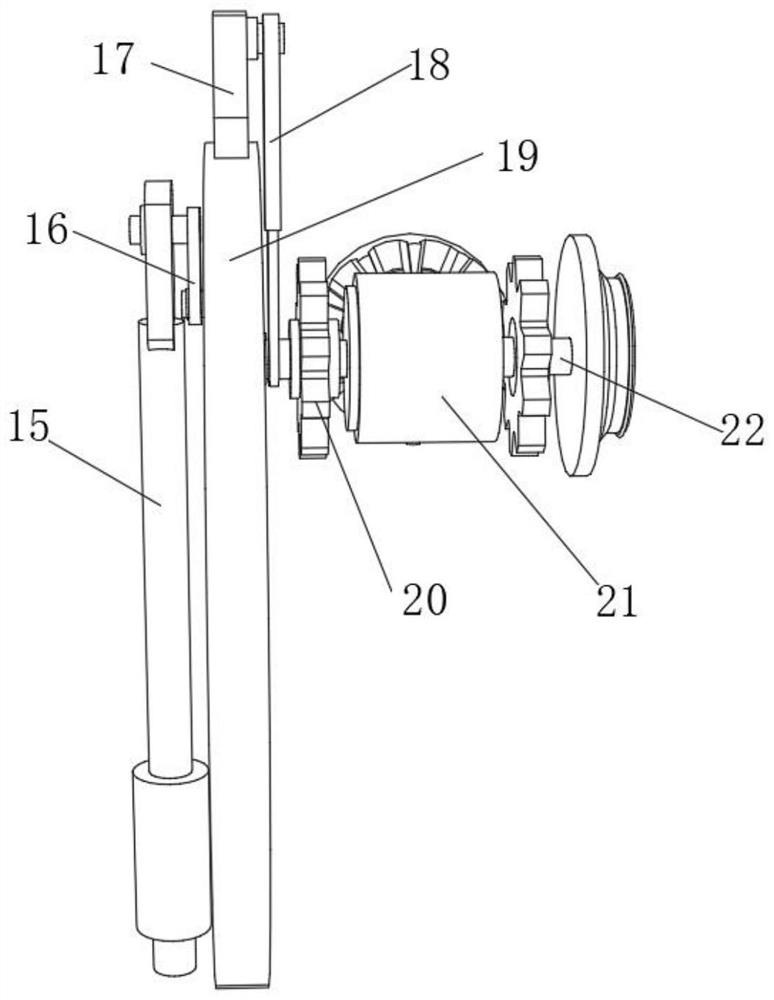

[0037] A mahogany furniture mortise and mortise cutting device, such as Figure 4 As shown, in order to promote the effectiveness of the cutting head 9 on tenon wood processing; this embodiment makes the following improvements on the basis of Embodiment 1: the cutting head 9 includes a retaining ring 23, a cutter wheel 24 and a stepped grinding wheel 25 , and the retaining ring 23 is threaded to one end of the rotating shaft 22, the step type grinding wheel 25 is threaded to one side of the retaining ring 23, and the cutter wheel 24 is threaded to one side of the step type grinding wheel 25; When the rotating cutter wheel 24 performs circumferential cutting on tenon wood, the setting of the retaining ring 23 can effectively avoid the problem of wood chips splashing to the side of the circumferential cutting mechanism during cutting, thereby protecting the normal operation of the circumferential cutting mechanism to a certain extent. The table-shaped grinding wheel 25 can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com