Semi-automatic assembly equipment of fire extinguisher pressure gauge

A technology for assembling equipment and pressure gauges, which is applied in metal processing equipment, assembly machines, manufacturing tools, etc., can solve the problems of manual assembly, high production cost, and high work intensity, so as to improve production efficiency, product quality, and market competition Reasonable effect of force and structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

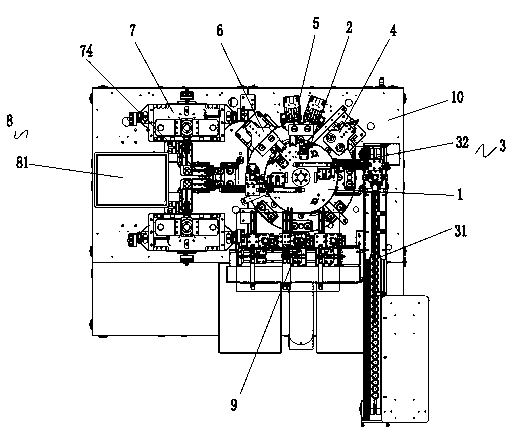

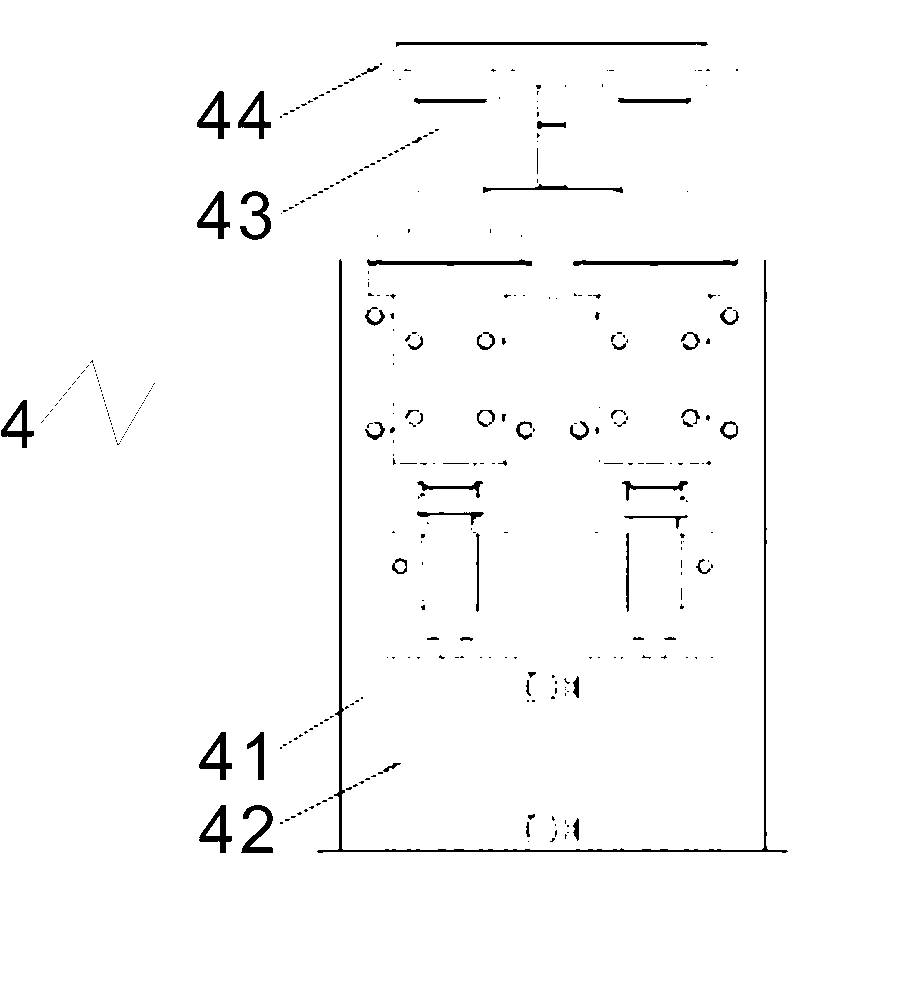

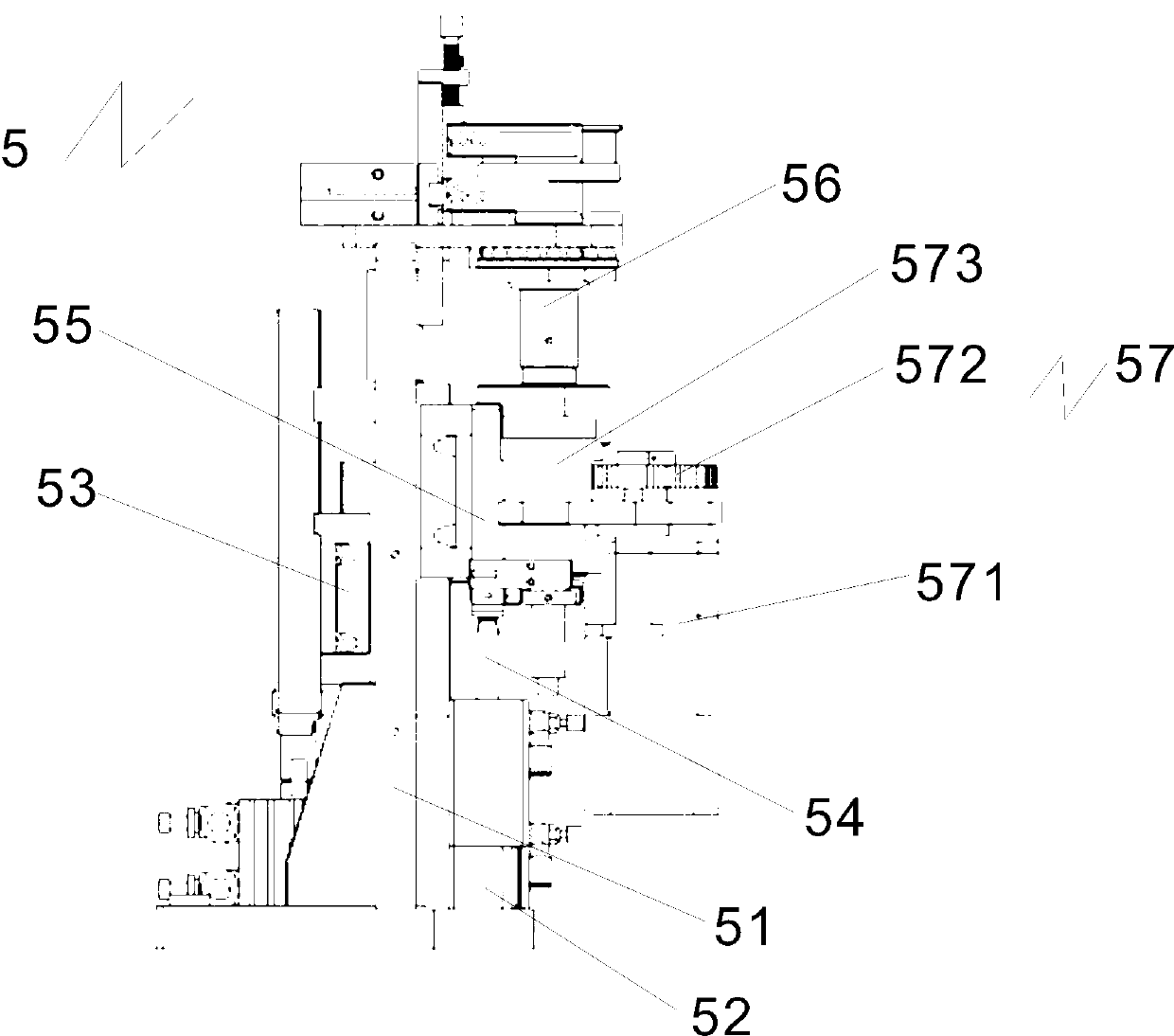

[0026] as attached Figure 1~6 As shown, a fire extinguisher pressure gauge semi-automatic assembly equipment includes a frame and a workbench 10 arranged on the frame. A turntable 1 is arranged on the workbench 10, and a fixture 2 for placing the pressure gauge is arranged on the turntable 1. Among them, a pressure gauge feeding mechanism 3, a pressure impact mechanism 4, a pointer swing angle adjustment mechanism 5, a retesting pressure maintaining mechanism 6, a riveting mechanism 7, a good product unloading mechanism 8, and a defective product unloading mechanism are also arranged on the workbench 10. 9. The above mechanisms are respectively connected to and controlled by the main control circuit.

[0027] In this example, the pressure gauge feeding mechanism 3 includes a delivery cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com