Automatic riveting machine for multi-layer circuit board

A multi-layer circuit board and riveting machine technology, which is applied to metal processing machinery parts, large fixed members, and other manufacturing equipment/tools, etc., can solve the problems of difficult fine-tuning, large stroke of the conveying platform, high machine price, etc., and achieve practical cost , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

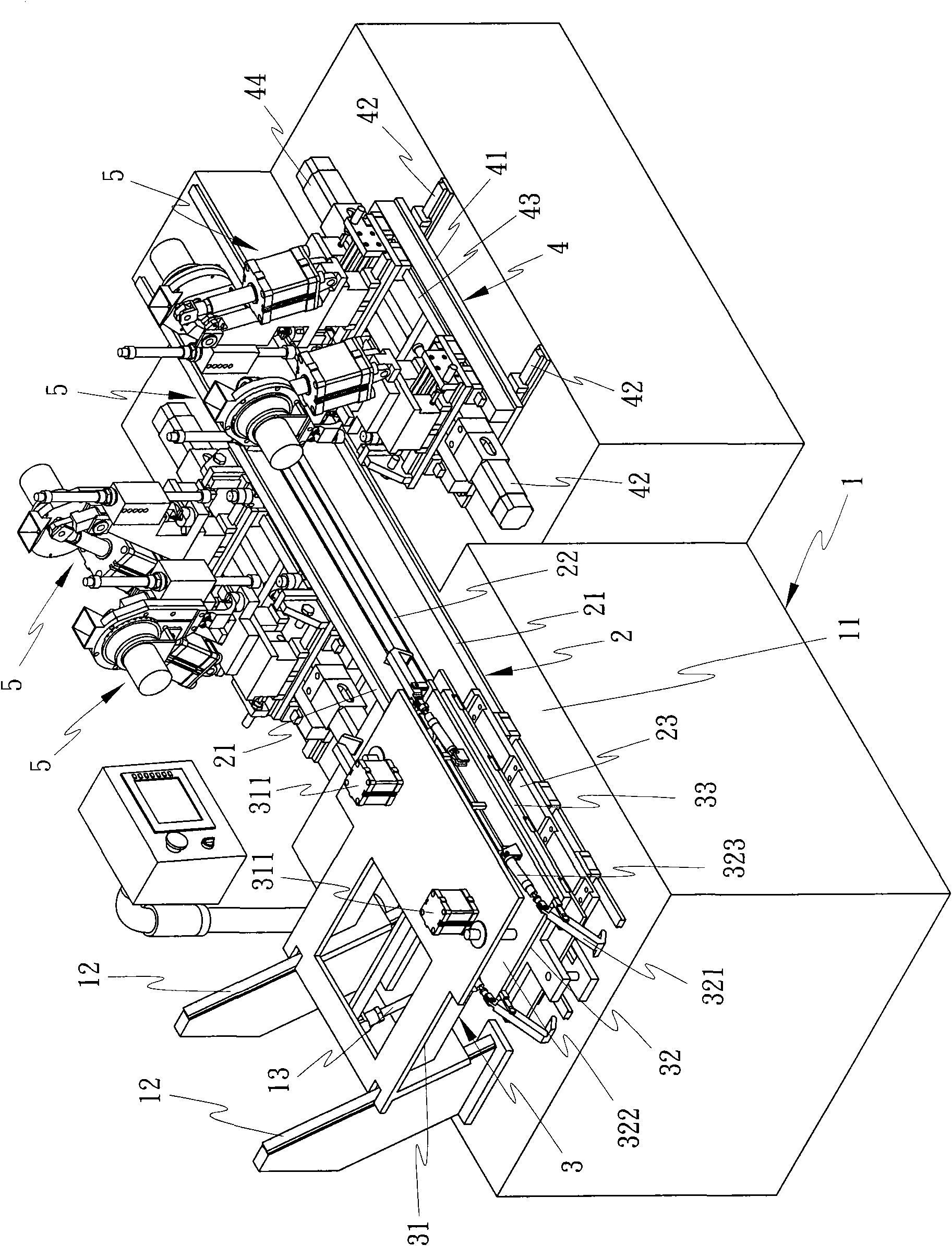

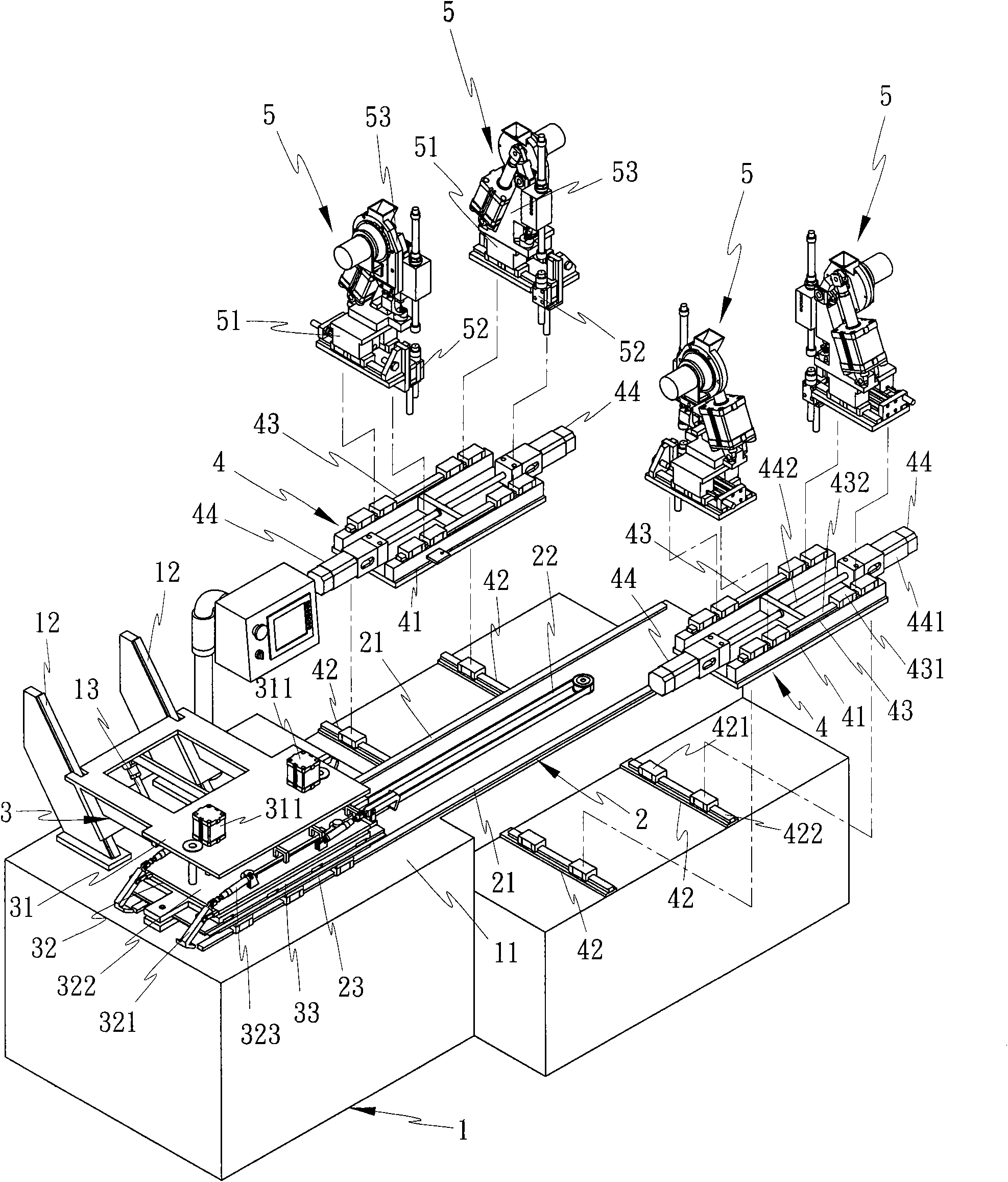

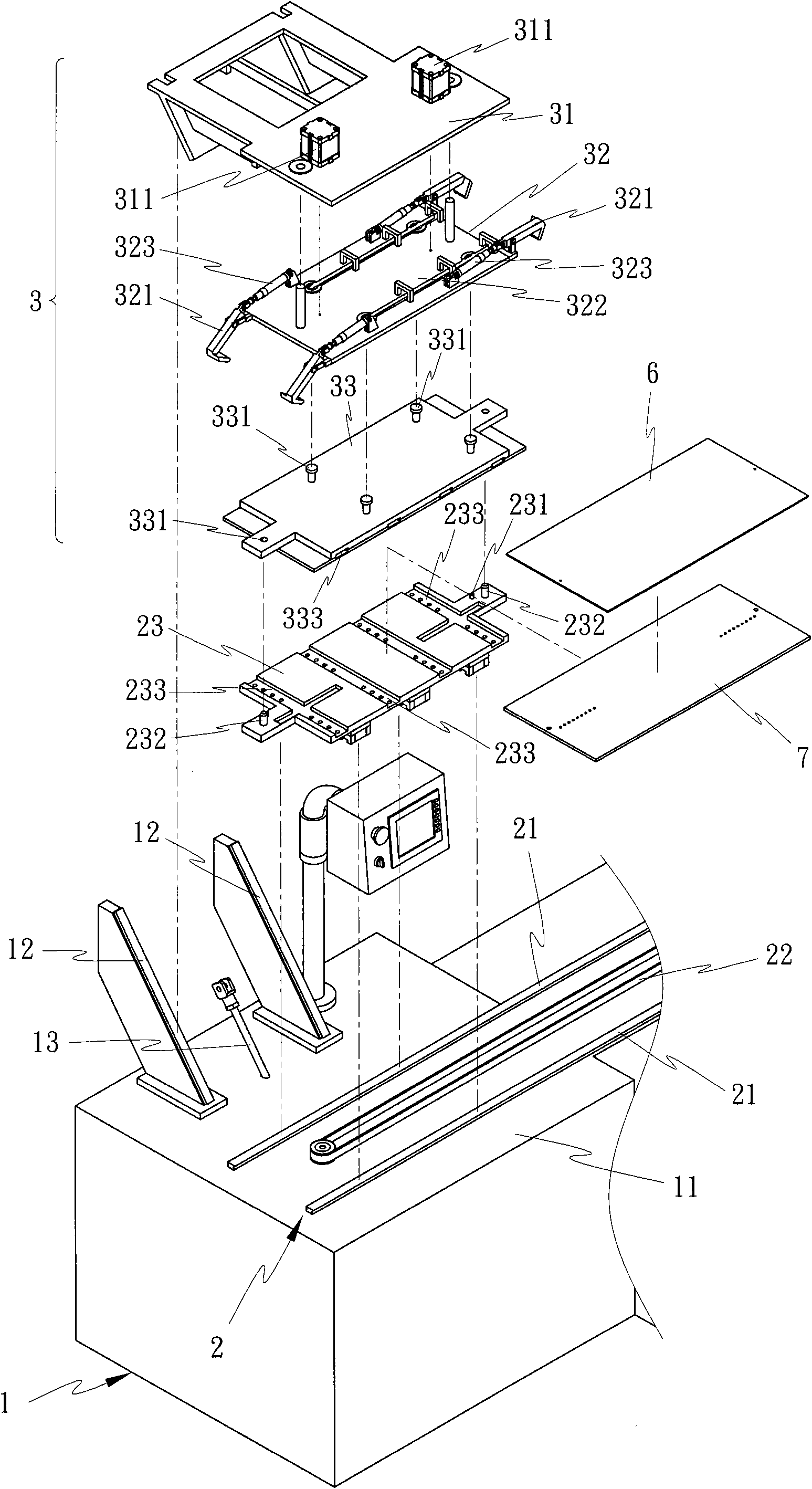

[0025] As shown in the accompanying drawings, the preferred embodiment of the automatic riveting machine for multilayer circuit boards of the present invention includes a machine platform 1, a conveying mechanism 2, a grabbing mechanism 3, a two-way sliding mechanism 4 and at least one drilling riveting Institution 5 consists of:

[0026] machine 1, such as figure 1 and figure 2 As shown, it is a structural machine platform, which forms a table 11 at the upper end, and combines two lifting rails 12 on the table surface 11 at the front end; a pneumatic cylinder is arranged inside the machine platform 1, and the piston shaft 13 of the pneumatic cylinder extends out of the table surface 11. The piston shaft 13 is combined with the lifting platform 31 of the grabbing mechanism 3 .

[0027] Conveying mechanism 2, such as Figure 1 to Figure 3 As shown, it has two sets of transverse rails 21 combined on the table 11 of the machine platform 1, a transverse transmission belt set 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com