Automatic riveting machine

A riveting machine and automatic technology, applied in the field of automatic riveting machines, can solve the problems of reduced work efficiency, inaccurate positioning of silver points, low work efficiency, etc., and achieve the effect of improving work efficiency and good riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

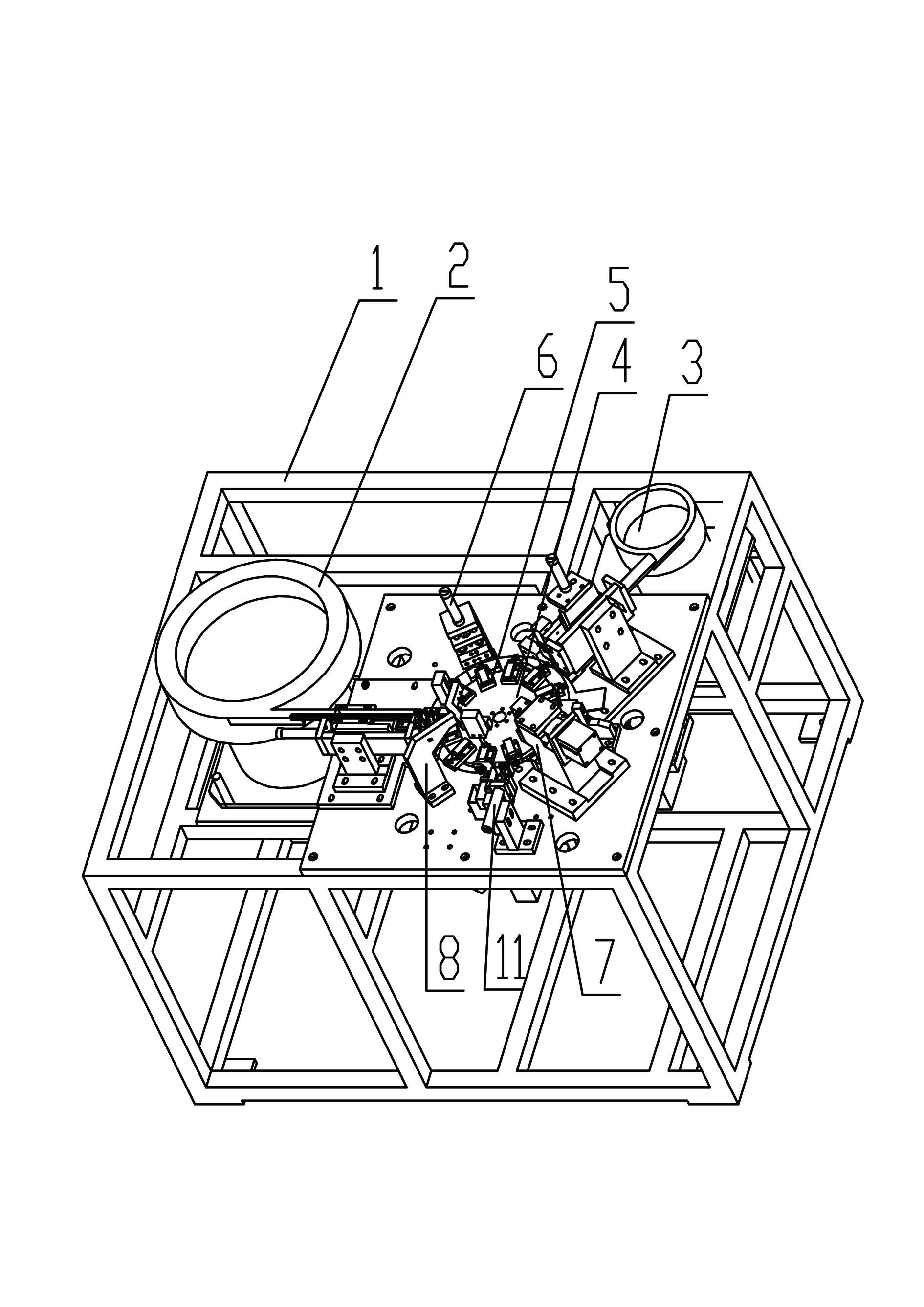

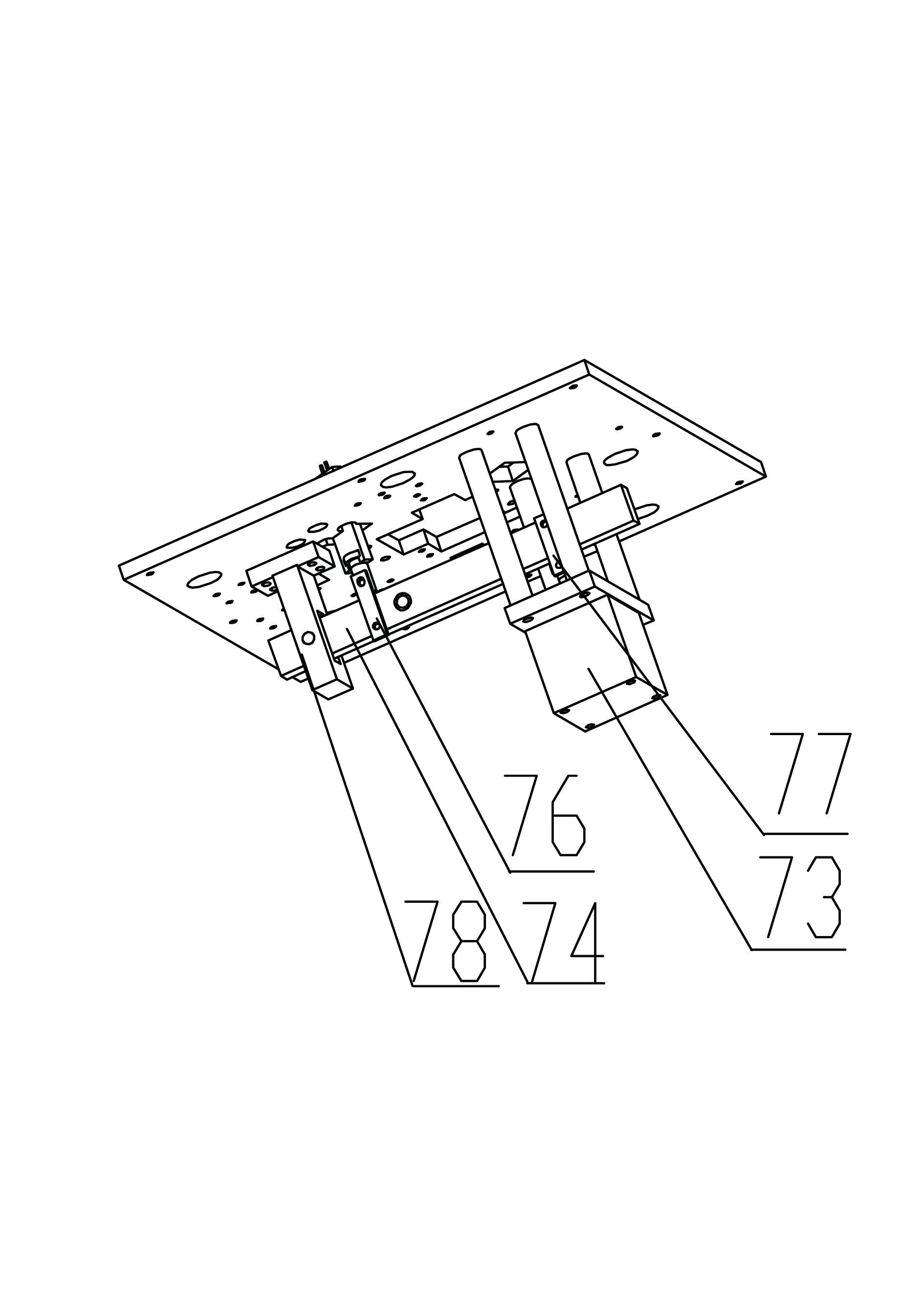

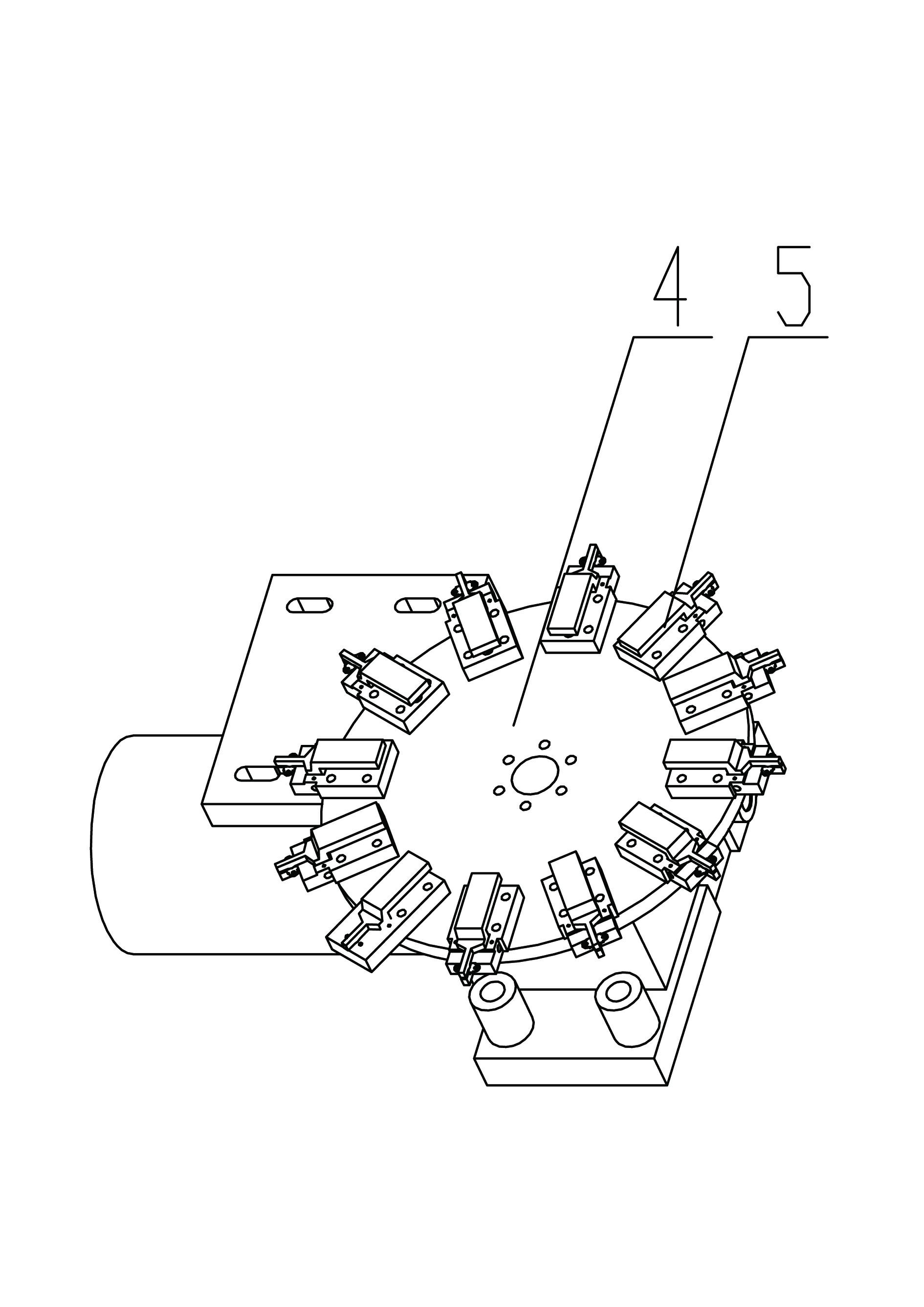

[0019] Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a specific implementation of an automatic riveting machine includes a frame 1, a parts vibrating feeder 2, a silver point vibrating feeder 3, a rotary conveyor 4, a plurality of elastic clamping devices 5, parts Guiding device 6, double-head riveting device 7, parts loosening device 8, parts handling manipulator 9, silver point handling manipulator 10, unloading manipulator 11, frame 1 provides a platform for the automatic riveting machine. Parts vibrating feeder 2 continuously provides parts for the automatic riveting machine, and at the same time cooperates with the parts handling manipulator 9 to transport the parts into the elastic clamping device 5 and clamp them; the silver point vibrating feeder 3 is for automatic riveting The riveting machine continuously provides silver dots, and at the same time cooperates with the silver dot handling manipulator 10 to tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com