Automatic riveting machine

A riveting machine and automatic technology, applied in the field of riveting machines, can solve the problems of safety hazards in safe operation, reduce work efficiency, and low work efficiency, and achieve the effects of convenient and safe operation, novel design, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

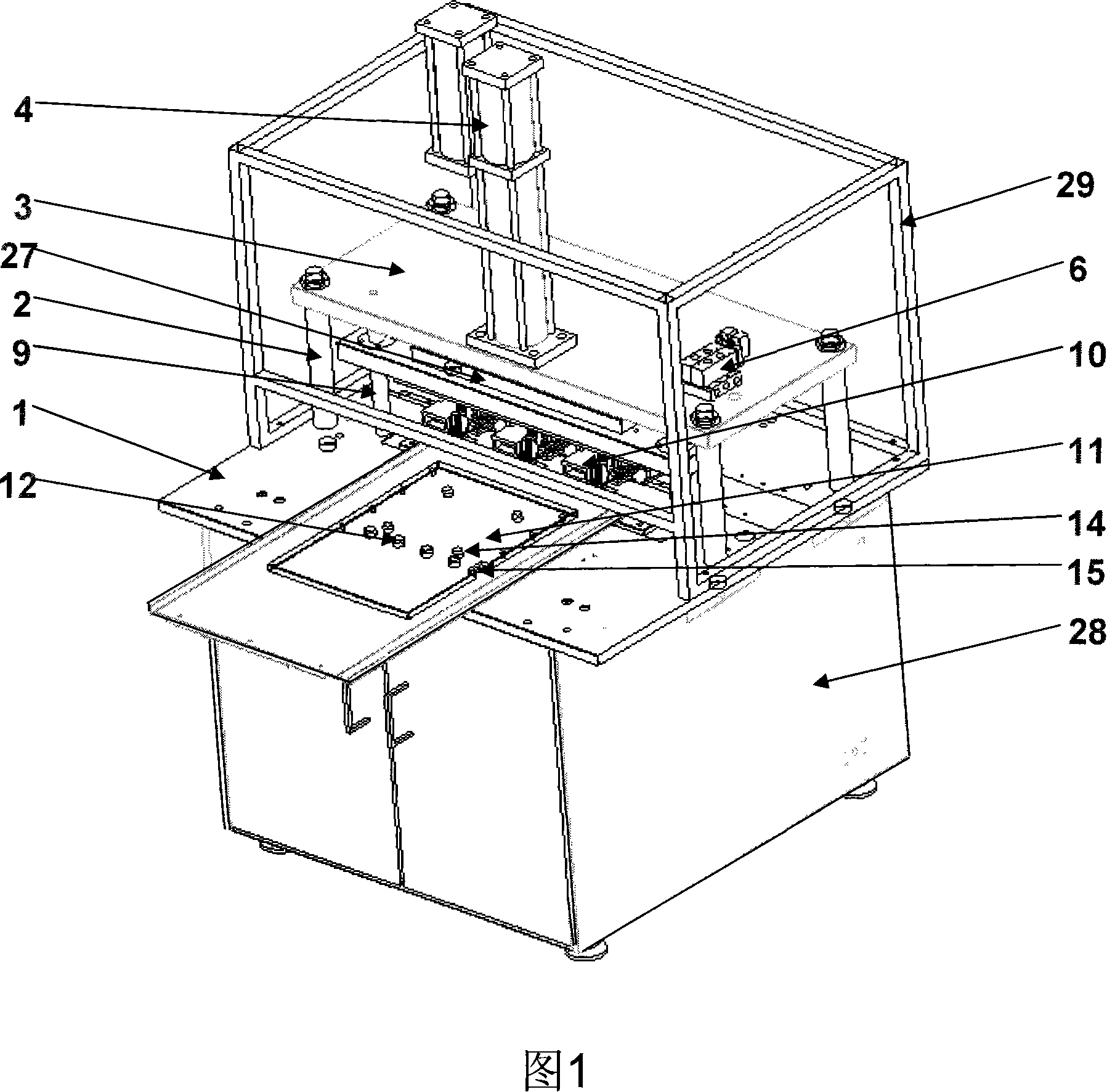

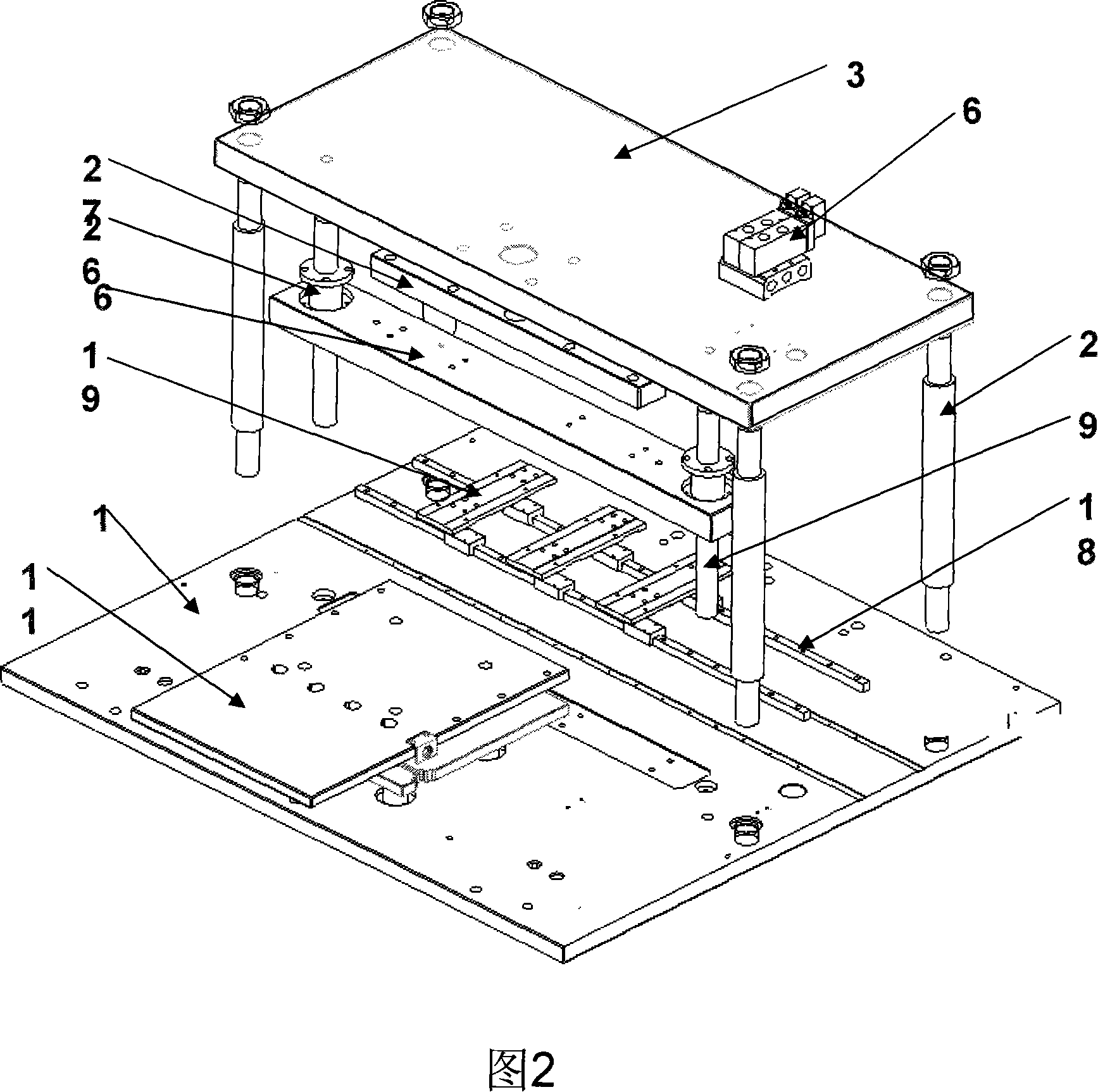

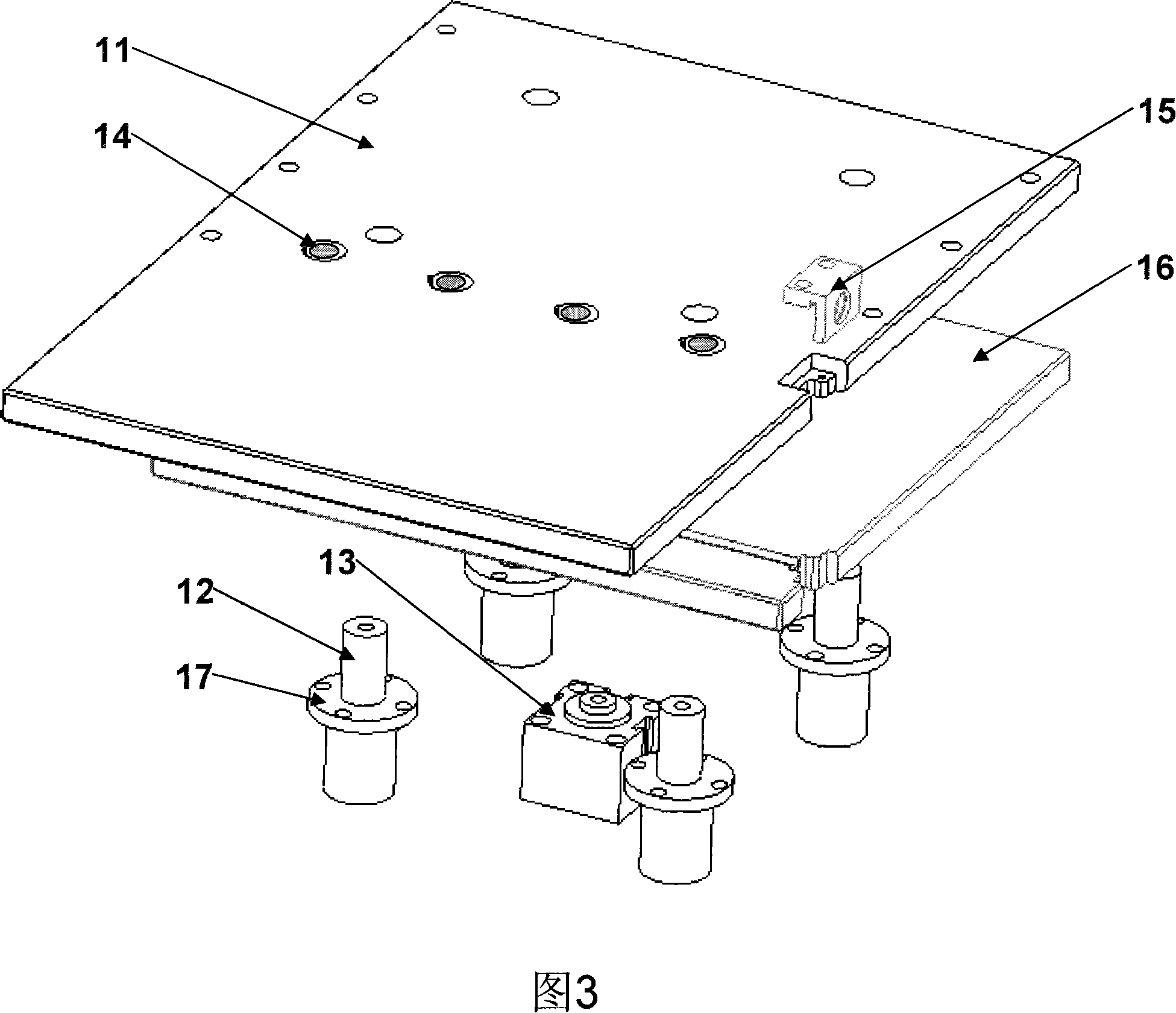

[0023] A kind of automatic riveting machine as shown in Fig. 1, Fig. 2, has working platform 1, is provided with the mold that is used to place rivet above working platform 1 and is used for pressing the power unit of rivet, is provided with above working platform 1 by four A column 2 supports a four-corner upper plate 3, and an air-oil hydraulic cylinder 4 and an air-oil hydraulic cylinder control solenoid valve 6 for controlling the vertical movement of the air-oil hydraulic cylinder push rod 5 are fixedly installed on the upper plate 3; the mold is composed of The upper mold table 7 and the lower mold table 8 are composed, the upper mold table 7 is connected with the ejector pin of the air-oil hydraulic cylinder 4, the lower mold table 8 is fixedly arranged on the working platform 1, and is fixedly arranged between the upper plate 3 and the working platform 1 There is an upper mold table guide post 9, and the two ends of the upper mold table 7 are set on the upper mold table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com