Riveting machine

A riveting machine and rivet technology, applied in the field of flywheel assembly equipment, can solve the problems of difficulty in guaranteeing riveting quality and low production efficiency, and achieve the effects of high assembly efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

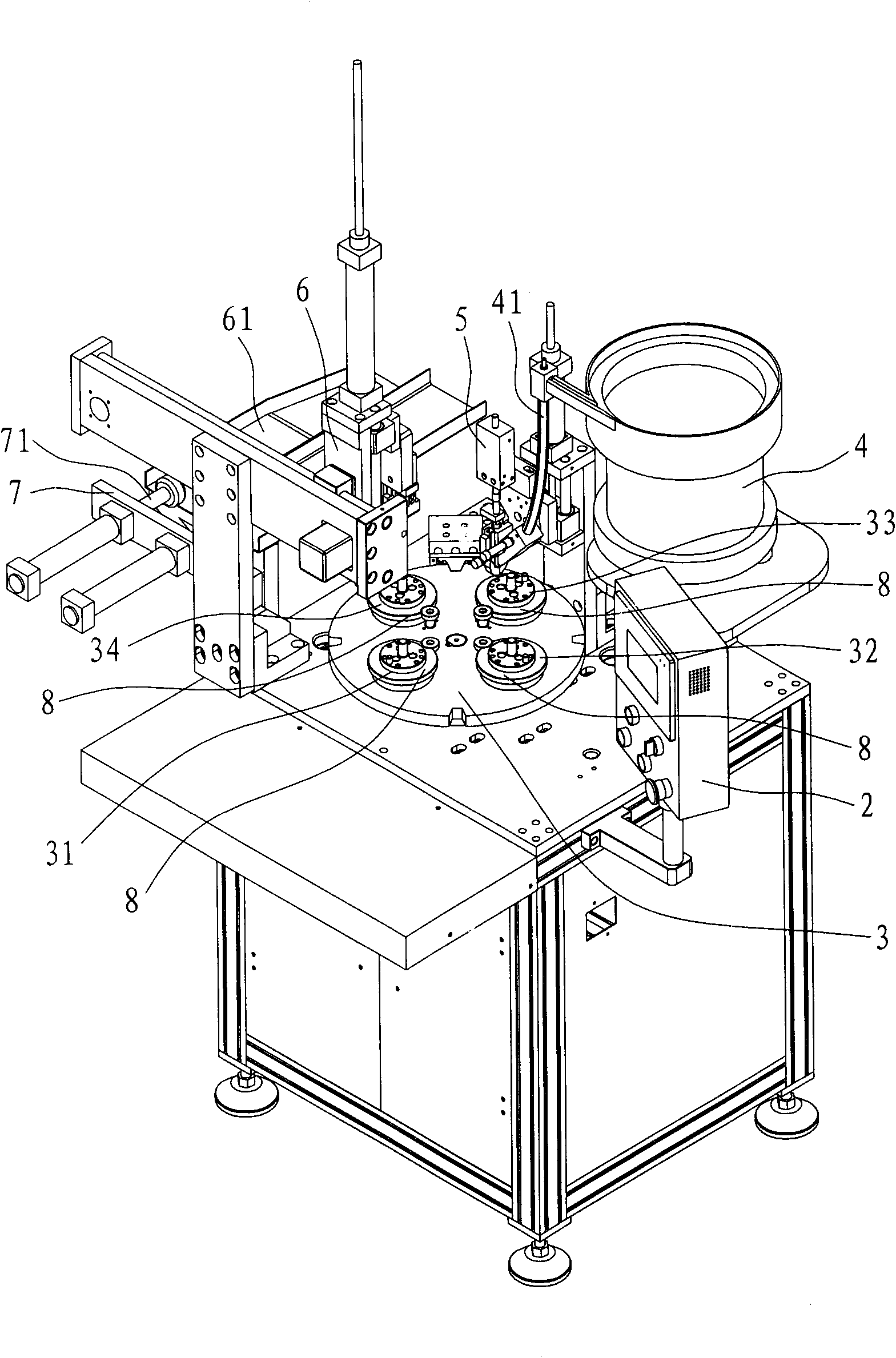

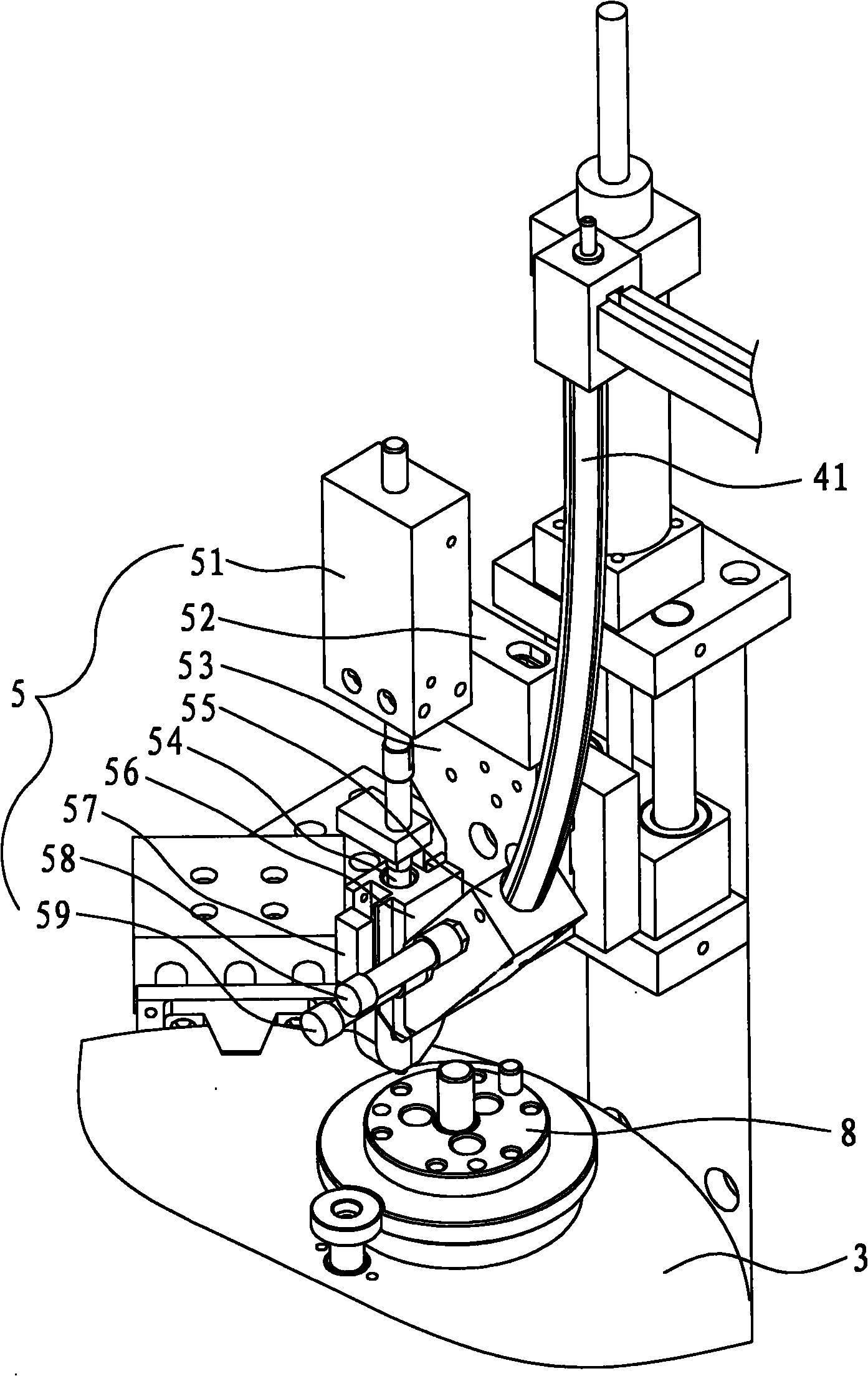

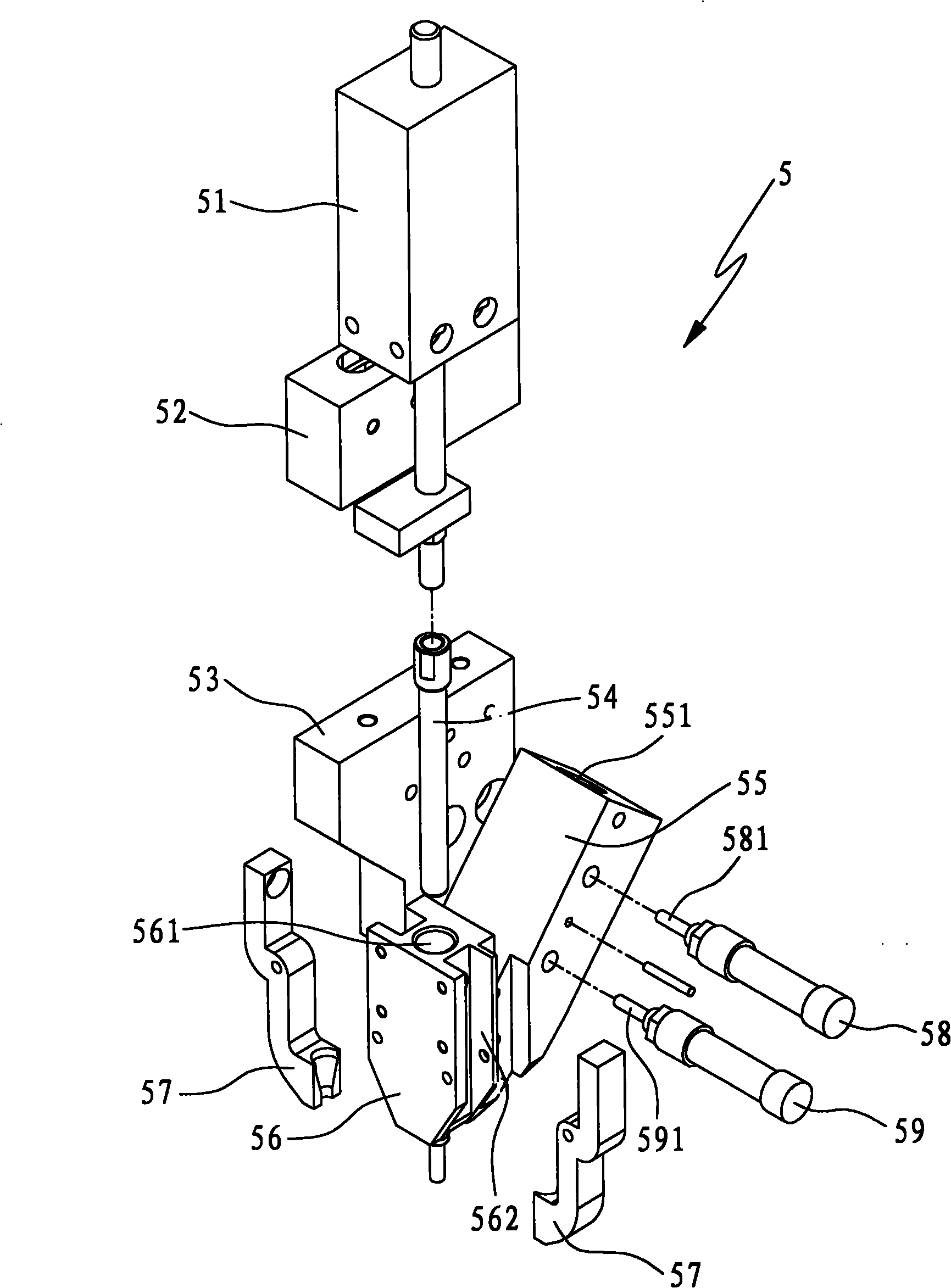

[0012] Such as figure 1 As shown, the present invention is a riveting machine, which is mainly composed of a machine platform 1, a control panel 2, a station turntable 3, a vibrating mechanism 4, a riveting mechanism 5, a blanking mechanism 6, and a pushing mechanism 7.

[0013] The station turntable 3 is installed on the machine platform 1 and can rotate intermittently around its center line. On the station turntable 3, a feeding station 31, an empty station 32, a riveting station 33, and a lower station are distributed equidistantly on the station turntable 3. The material station 34 is all equipped with a tool fixture 8 for clamping the workpiece on the above-mentioned four stations. The functions of each station are: (1) The feeding station, which performs the feeding operation. The operator puts the flywheel base and flywheel housing on the loading tooling to prepare for the next station action. (2) Riveting station, this station drives rivets into the workpiece holes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com