Contact riveter

A riveting machine and contact technology, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of long operation time, unsafe, and rising operating costs of parts, and achieves improved working environment, high efficiency, Good assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples, but the specific examples do not limit the present invention in any way.

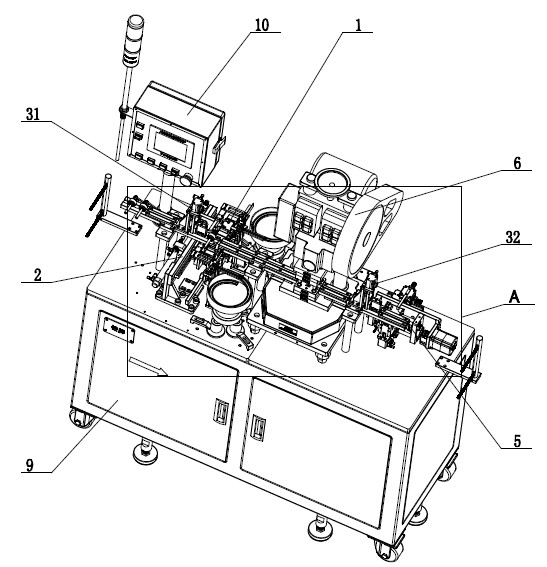

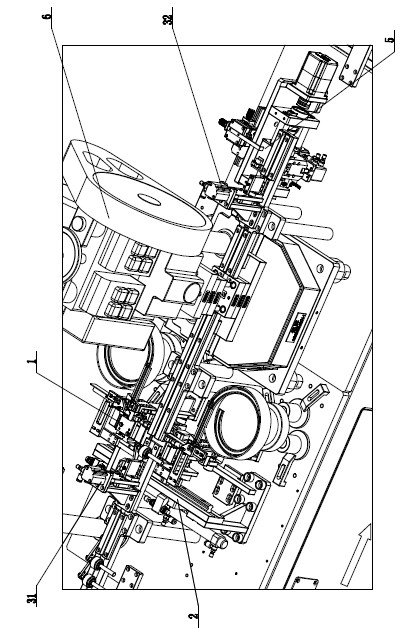

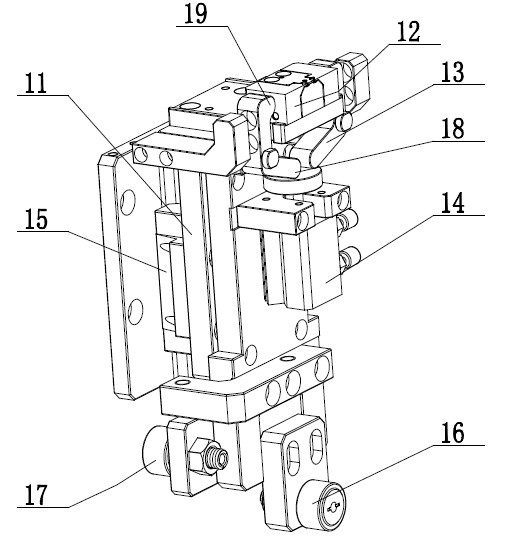

[0031] Such as figure 1 , 2 As shown, the contact riveting machine includes a first strip positioning and pressing device 31, a contact feeding device 2, a contact riveting device 6, a second strip positioning and pressing device 32, a strip Feeding device 5, roll material receiving device (figure omitted), above-mentioned devices are all connected with main control circuit 10, and are controlled by it, and main control circuit 10 is located at an end of body 9. In addition, it also includes a cam jacking device 4 arranged under the contact clamping device 1 of the contact feeding device 2 . Here, the structure of the first strip positioning and pressing device 31 is exactly the same as that of the second strip positioning and pressing device 32 .

[0032] Among them, the material belt conveying track ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com