Production line of square coaming of freezer liner

A production line and coaming technology, which is applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of lack of fully automated freezer liner coaming production line, manual intervention, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

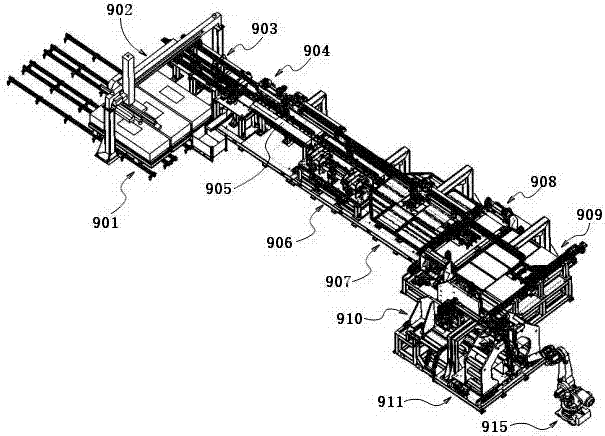

[0036] Such as figure 1As shown, a production line for a freezer liner mouth-shaped coaming, including a sheet material bin 901, a feeding table 903, a punching unit 904, a first transition table 905, a long side folding machine 906, a 90-degree turning table 907, a double The edge folding machine 908 with different ends, the second transition table 909, the first bending machine 910, and the second bending riveting machine 911. A first suction cup manipulator 902 is provided between the sheet material bin 901 and the loading platform 903 . The suction cup track of the first suction cup manipulator 902 spans over the sheet stock bin 901 and the feeding platform 903 . The sheet material warehouse 901 is used for storing processed straight sheet materials. The feeding table 903, the punching unit 904, the first transition table 905, the long side folding mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com