Separated full-automatic drilling and riveting bracket system

An automatic drilling and riveting machine, fully automatic technology, applied to other manufacturing equipment/tools, large fixed members, metal processing machinery parts, etc., can solve the center of gravity deviation of the X-axis sliding table, difficult installation and debugging, large footprint, etc. problems, to achieve the effect of reducing installation height, good production continuity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

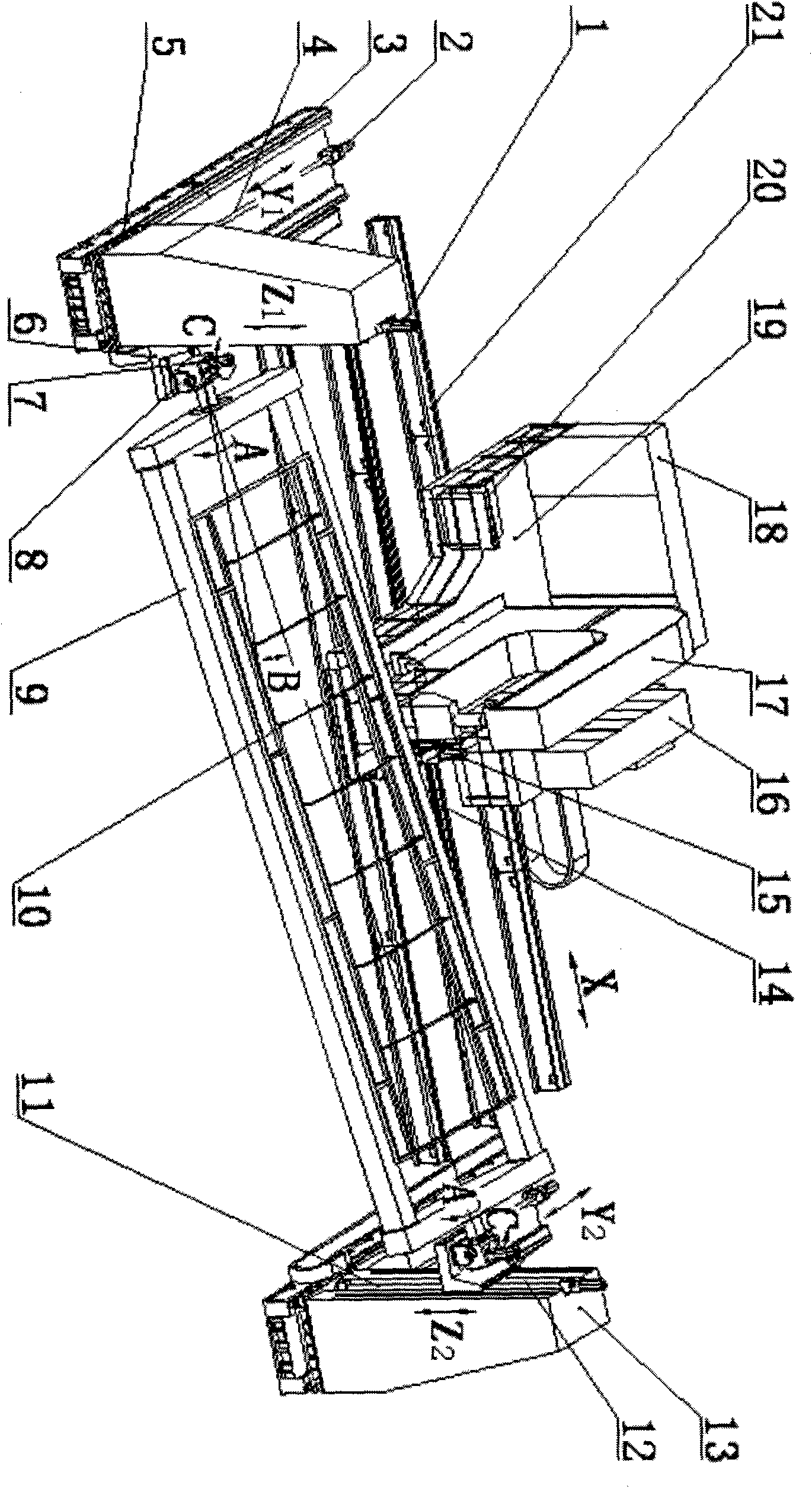

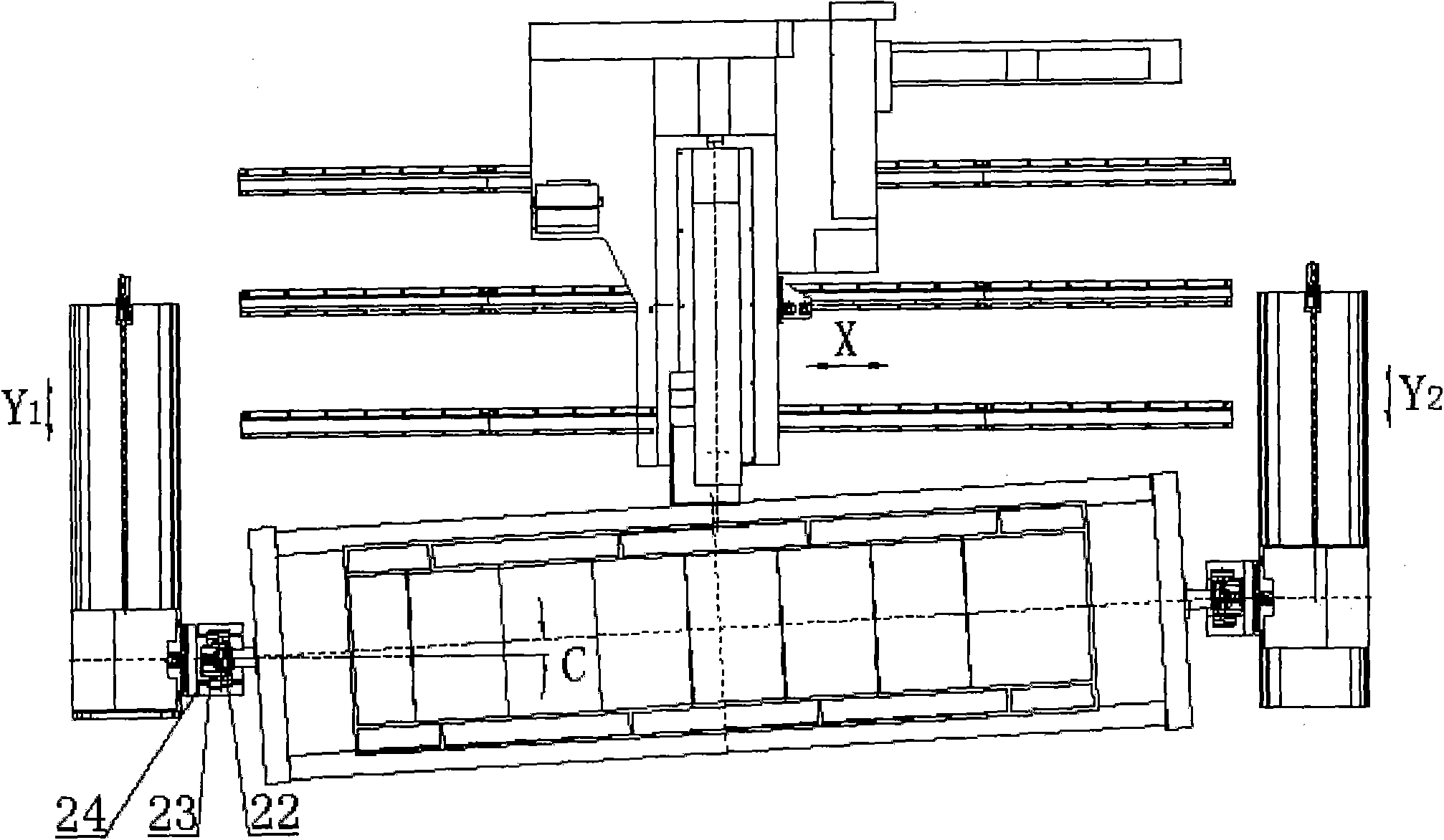

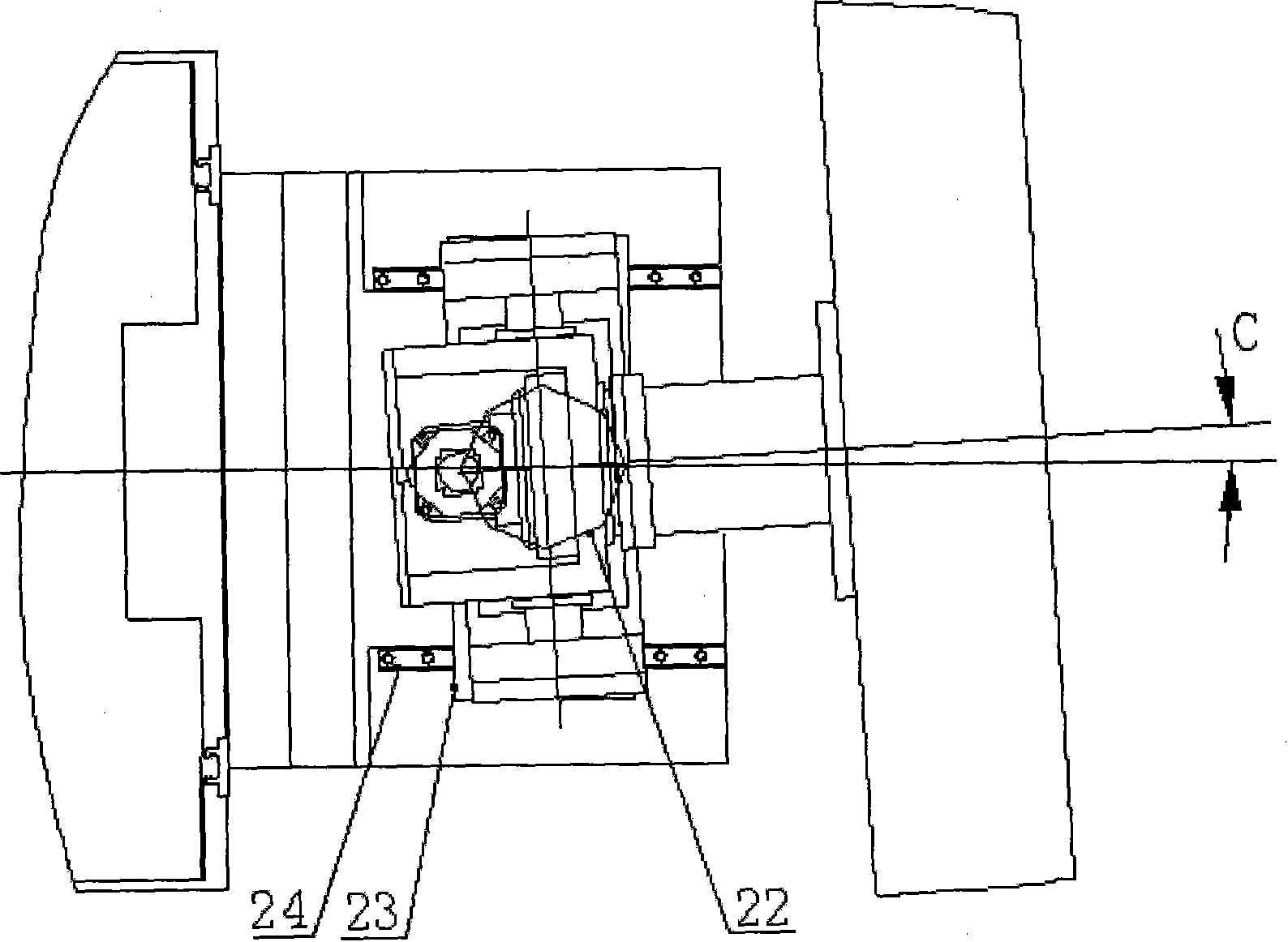

[0018] refer to figure 1 , figure 2 , image 3 , set forth as follows with regard to implementing an embodiment of the present invention:

[0019] The automatic drilling and riveting machine 17, the operating table 20, the control cabinet 18, the automatic nail feeding mechanism 16, and the X-axis motor 15 are installed on the X-sliding table 19, carried and guided by the X-axis guide rail 21, and the rack 14 is driven by the X-axis motor 15 , to form X-axis motion; two Z columns 13 are installed on the Y slides 5 on the left and right sides, the Y-axis screw 4 is driven by the Y-axis motor 2, carried and guided by the Y-axis guide rail 3, and the Y slide 5 is driven to form the Y-axis Movement; the Z sliding table 6 is guided by the Z-axis guide rails 11 installed on the Z columns 13 on the left and right sides, the support frame 9 is installed on the Z sliding table 6, and the Z-axis motor 1 drives the Z-axis screw rod 12 to drive the Z Slide table 6 moves up and down to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com