Efficient grinding equipment for metal casting

A metal casting and high-efficiency technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve problems that affect grinding efficiency and grinding quality, hand numbness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

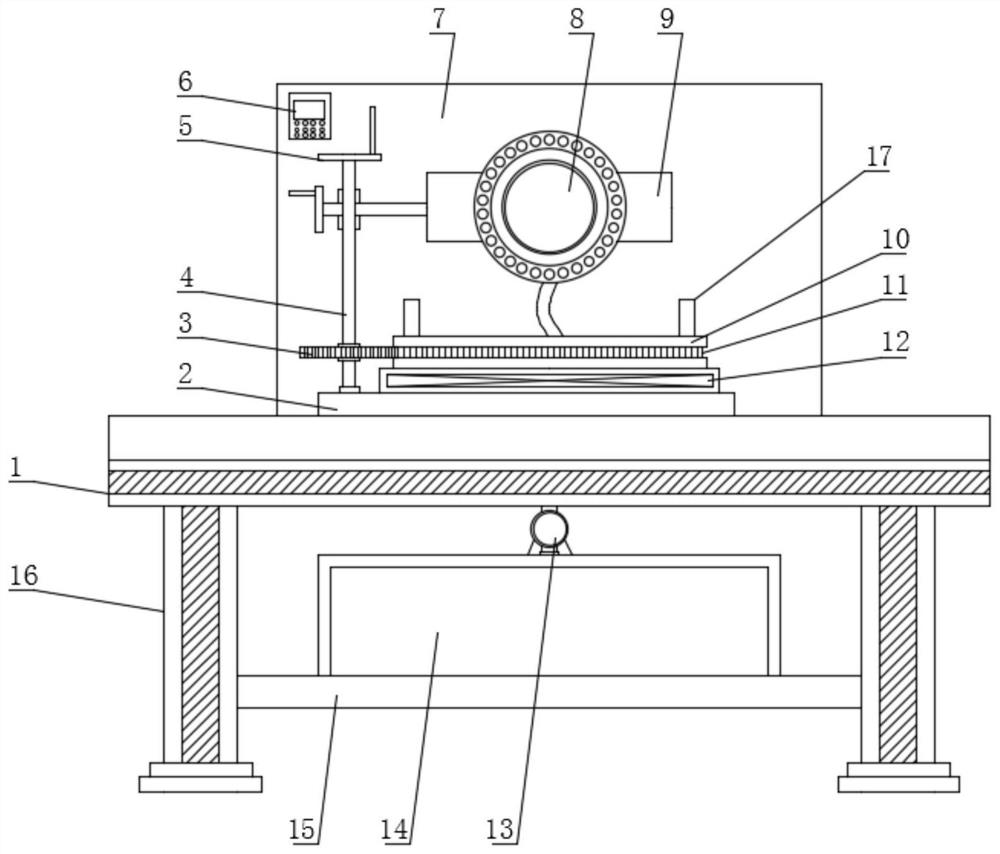

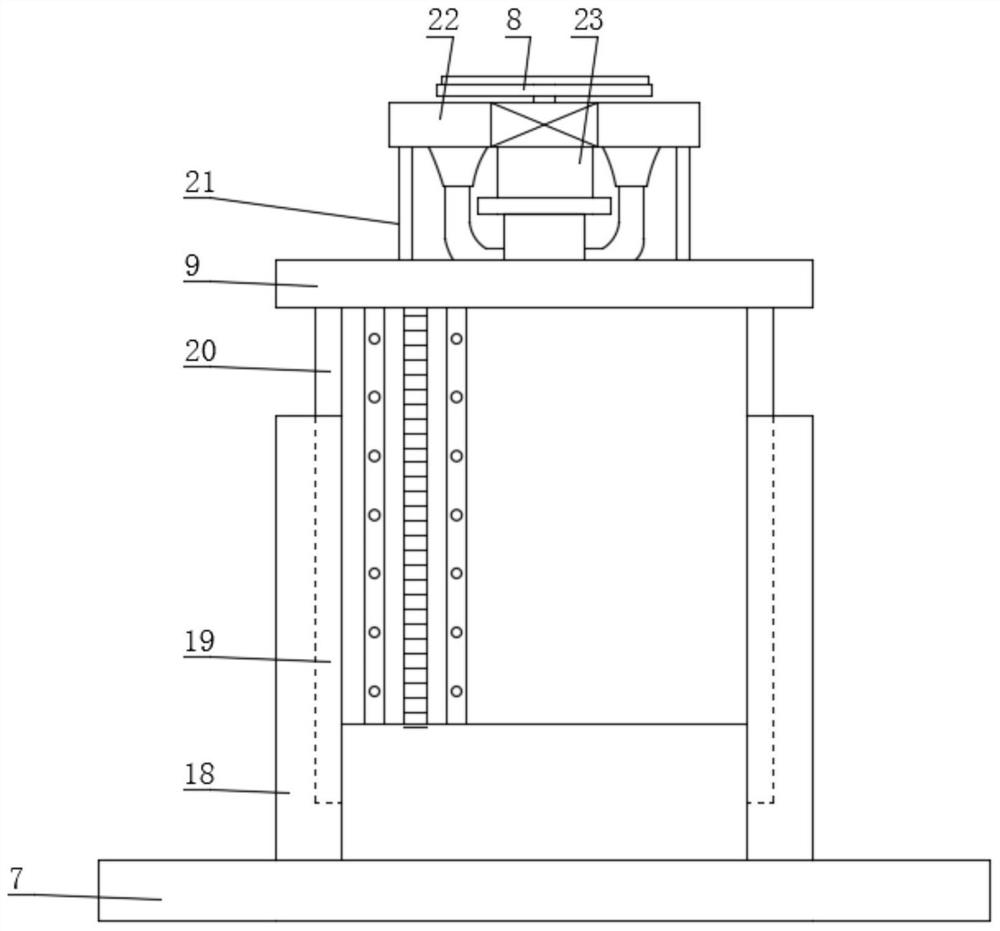

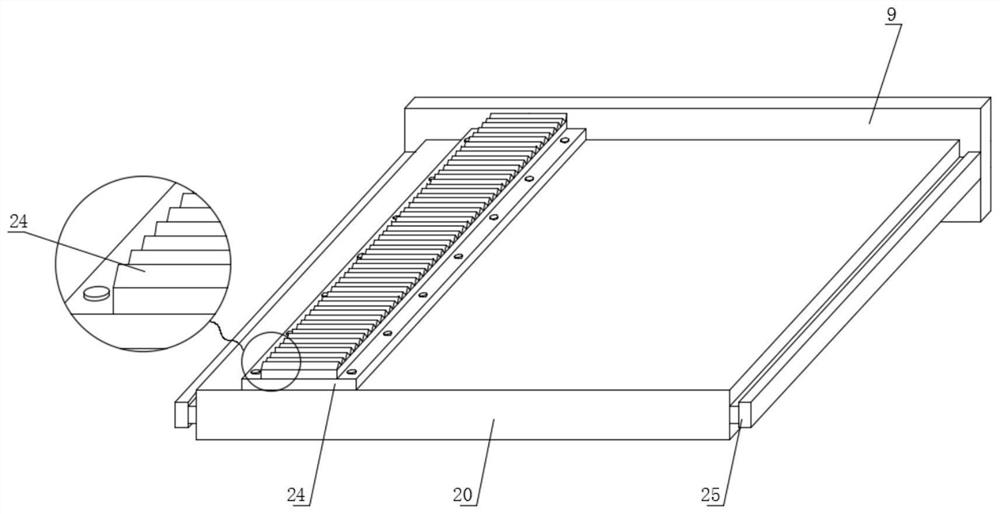

[0037] First embodiment, with reference to figure 1 , 2 , 3 and Image 6 A metal casting 1, a top surface of the device body 1 is mounted near the edge of the vertical back plate 7, the backplate by high polishing apparatus including an apparatus body 7 is attached to the surface symmetrically fixed block 18, the fixing block 18 defines a slide surface 19, an adjustment plate 20 disposed between the two fixing blocks 18, the two ends of the adjusting plate 20 is provided with a slider 25, the adjusting plate 20 through the slide rail 19 and the slider 25 connected to a bottom end regulating plate 20 is provided with a straight surface of the rack 24, the back plate 7 is provided with a support surface of the plate 29, the support surface of the movable plate 29 connected to a second rotating lever 30, the second rotating lever 30 is provided at one end with a second drive gear 32, and the second drive gear 32 engaged with a linear rack 24 is connected to the other end of the second...

Embodiment 2

[0038] According to the second embodiment, with reference to figure 1The upper surface of the apparatus body 1 is provided with a support seat 2, and a rotating base 12 is provided at the top of the support seat 2, and a fixed base 10 is provided at the top of the rotating base 12, and the outer surface of the fixing member is provided with a driven gear. 11. The top surface activity of the support seat 2 is provided with a first rotational rod 4, and the first drive rod 4 is provided with a first active gear 3, the first active gear 3 to engage the driven gear 11, said The first adjustment wheel 5 is provided with a first adjustment wheel 5, and the top surface of the fastener 10 is provided with a fixing mechanism 17, by providing a support seat 2, a rotating base 12, a first rotating rod 4, a first active gear 3, and the first The mating of the main wheel 5 and the driven gear 11 facilitates the rotation of the fixing mechanism 17, and the grinding disc 8 can be grinded to each...

Embodiment 3

[0039] Example III, reference figure 1 , 4 with Figure 7 The surface of the mounting plate 9 is provided with a dust cover 22 through the fixing rod 21, the dust cover 22 being mounted on the outer surface of the grinding disc 8, the top surface of the dust cover 22, and the bellows 26, which are connected to the bellows 26. At one end of the bellows 26 is connected to a collection tube 27, a blower 13 is provided at one end of the collecting tube 27, and the air blower 13 is provided with a collection box 14 by a collection tube 27, and the dust cover 22 is opened and opened. 33, and there are a plurality of suction ports 33, and the apparatus body 1 is provided with a cross plate 15, the collecting box 14 mounted on top surface of the cross plate 15, by mounting the dust cover 22 outside the surface of the grinding disc 8. However, it can make the dust cover 22 to perform dust dust generated by the grinding disc 8, and improve the absorption quality of the dust cover 22 on the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com