Centrifugal water removal automatic cleaning and dust removal device

An automatic cleaning and dust removal device technology, which is applied in the direction of combined devices, vacuum cleaners, cleaning equipment, etc., can solve the problems of secondary pollution, impact on the user's respiratory tract, cumbersome use process, etc., to prevent secondary pollution, remove water and dust twice pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

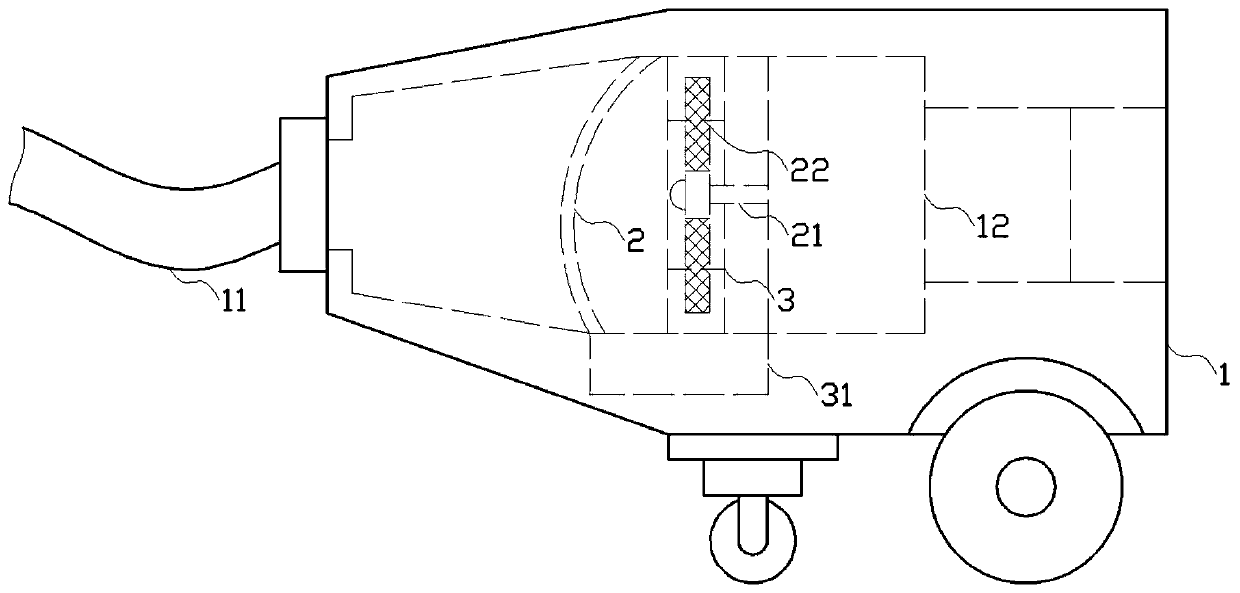

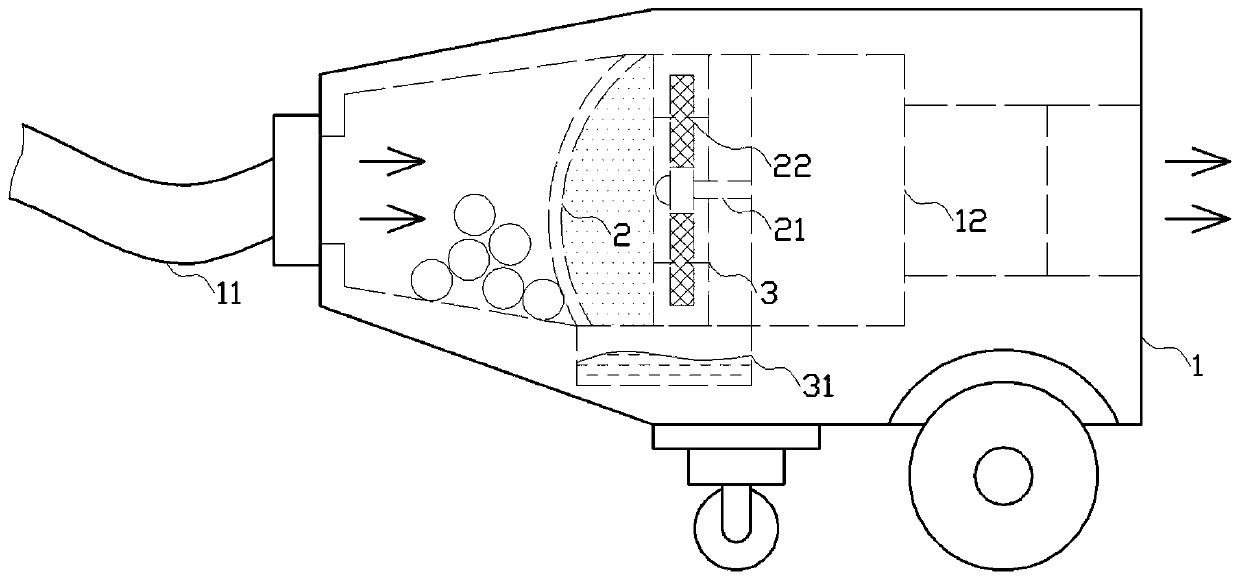

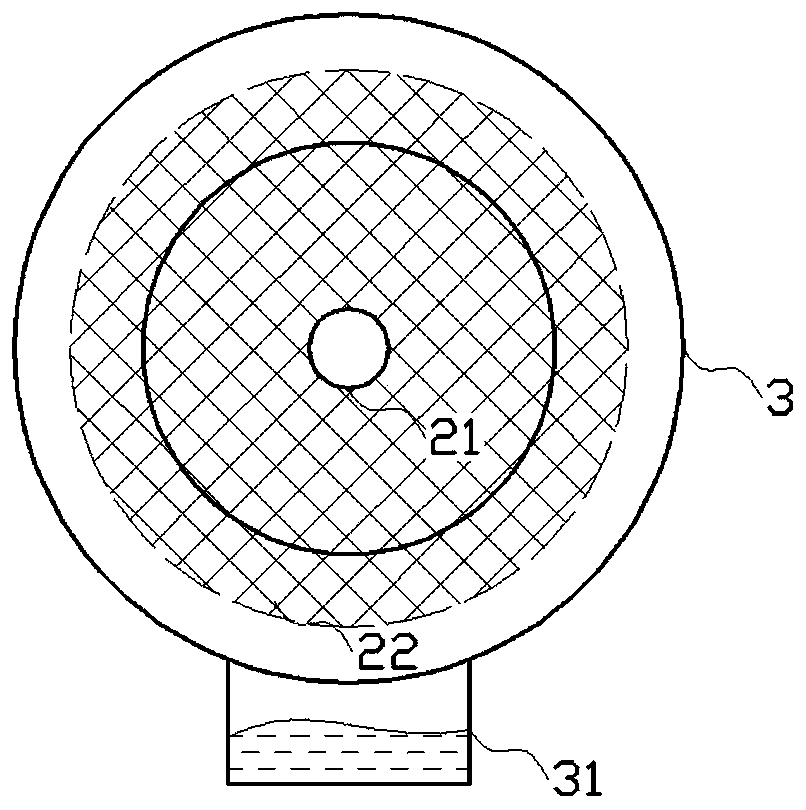

[0013] like figure 1 , figure 2 , image 3 As shown in the embodiment, the centrifugal dewatering and automatic cleaning and dedusting device is a kind of dust and accumulated water sucked into the vacuum cleaner through the fan, and then the dust, accumulated water and sundries are separated through the filter layer, so that the dust and accumulated water enter the secondary Filtration; then the accumulated water is absorbed by the water-absorbing layer and discharged into the water storage box under centrifugal action, so that the dust is separated from the accumulated water; after the device is closed, the dust falls into the water storage box under the action of gravity and merges with the accumulated water, thereby A device for easy cleaning, which includes a vacuum cleaner body 1, a filter module 2 and a separation module 3; A motor module 12 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com