Hammer-type straw pulverizer

A straw pulverizer and hammer technology, applied in agricultural machinery and implements, cutting equipment, applications, etc., can solve the problems of inconsistent straw shape, waste, environmental dust pollution, etc. The effect of knife efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following describes the specific implementation of the present invention in further detail through the description of the embodiments with reference to the accompanying drawings. The purpose is to help those skilled in the art have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and Contribute to its implementation.

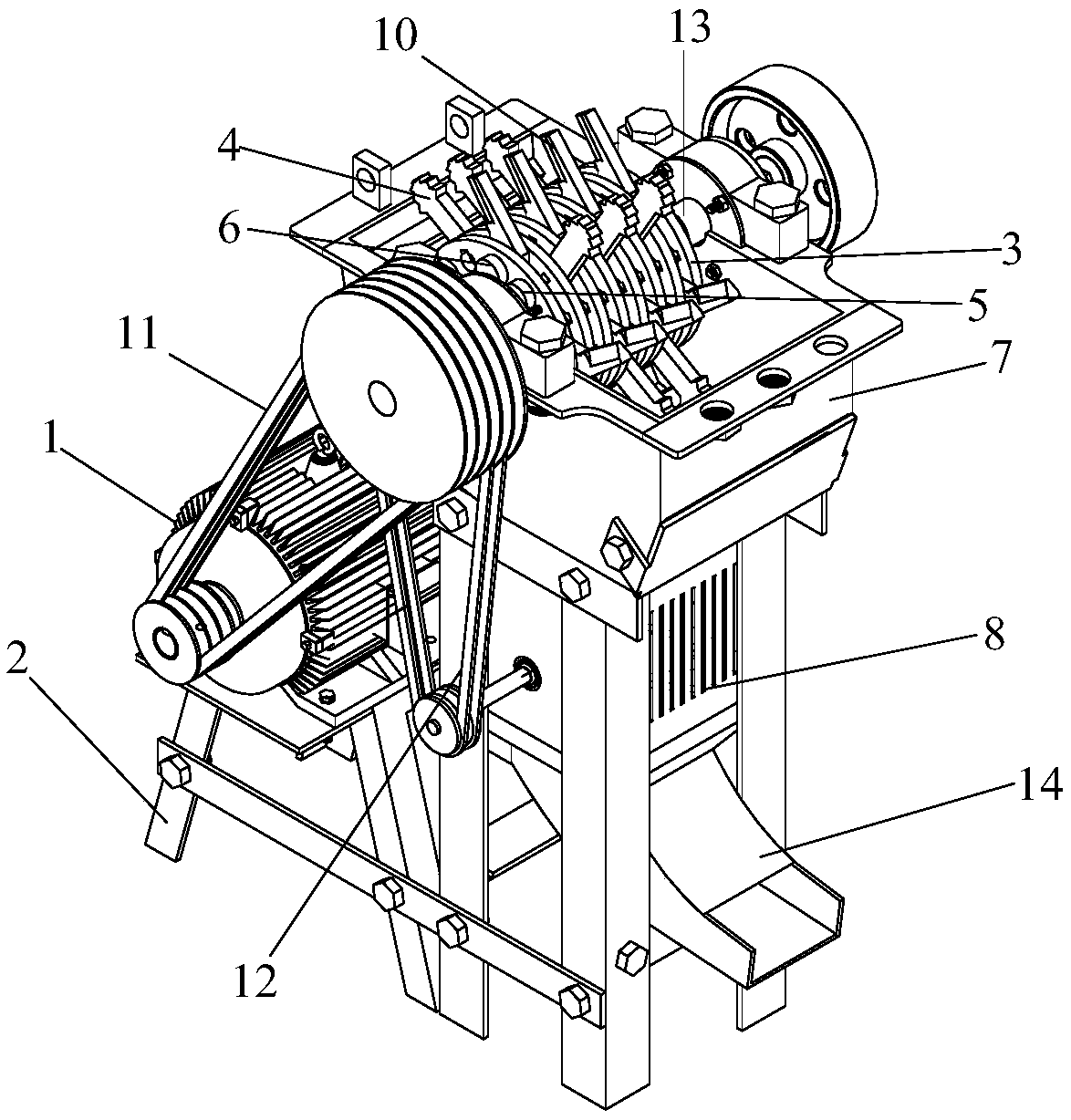

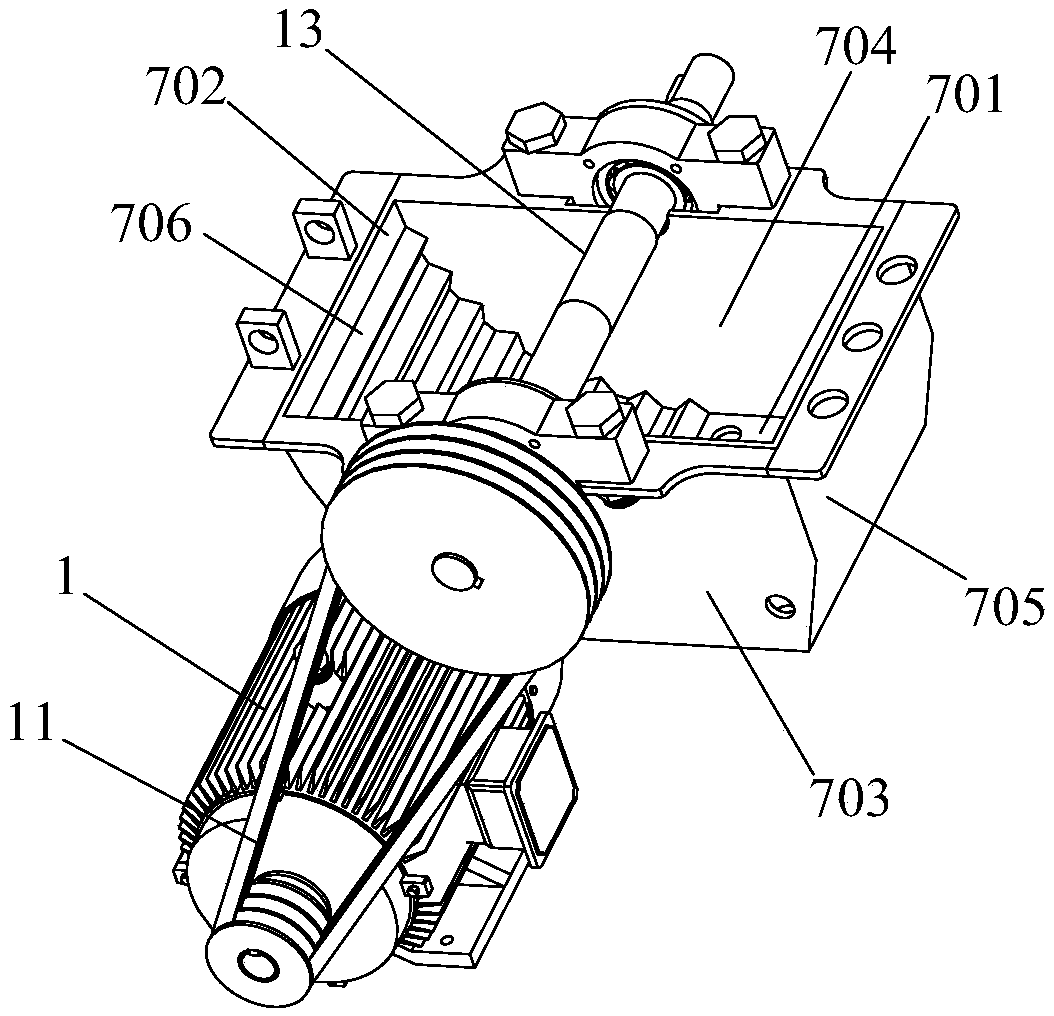

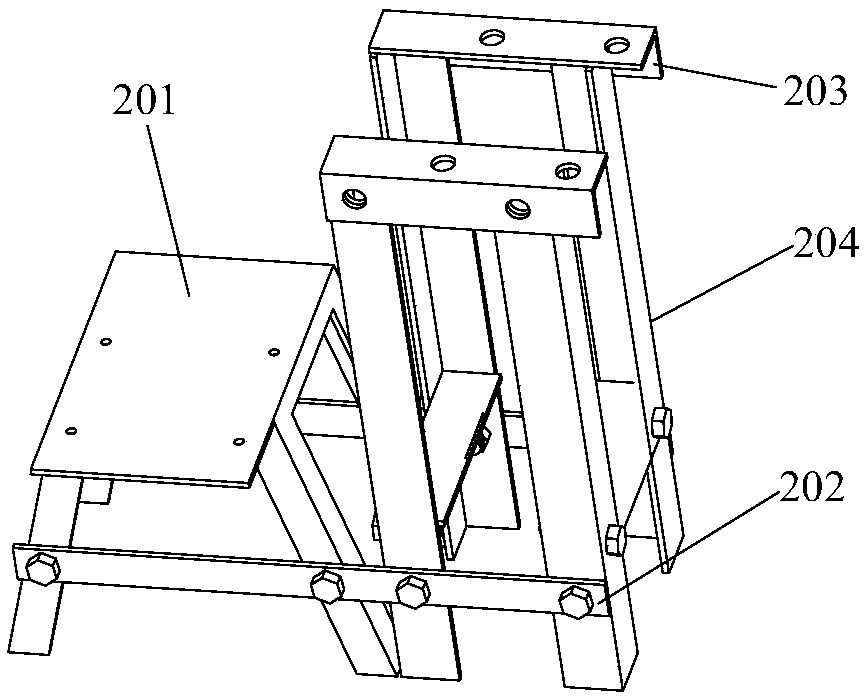

[0030] Such as figure 1 As shown, the present invention provides a hammer-type straw pulverizer, which includes a frame 2, a power device, a main shaft, a cover (not shown in the figure), a pulverizing chamber 7, and a pulverizing chamber 7 rotatably arranged in the pulverizing chamber 7. The hammer holder 3, the first crushing tool 4, the second crushing tool 10, the first crushing tool 4 and the hammer holder 3 form a detachable connection, and the first crushing tool 4 and the hammer holder 3 are kept facing each other during operation A fixed first quick-change device 5 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com