A kind of aggregate screening equipment for concrete

A screening equipment and concrete technology, which is applied in the fields of screening, solid separation, packaging, etc., can solve the problems of poor screening effect, time-consuming, easy falling of materials, etc., and achieve the effect of avoiding random flying and increasing the efficiency of screening and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

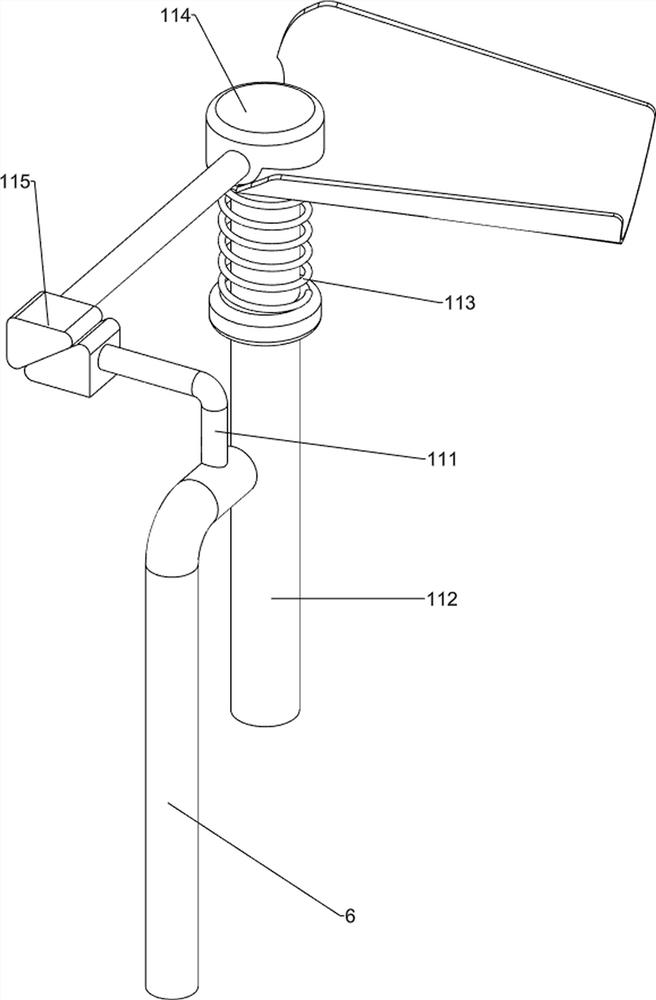

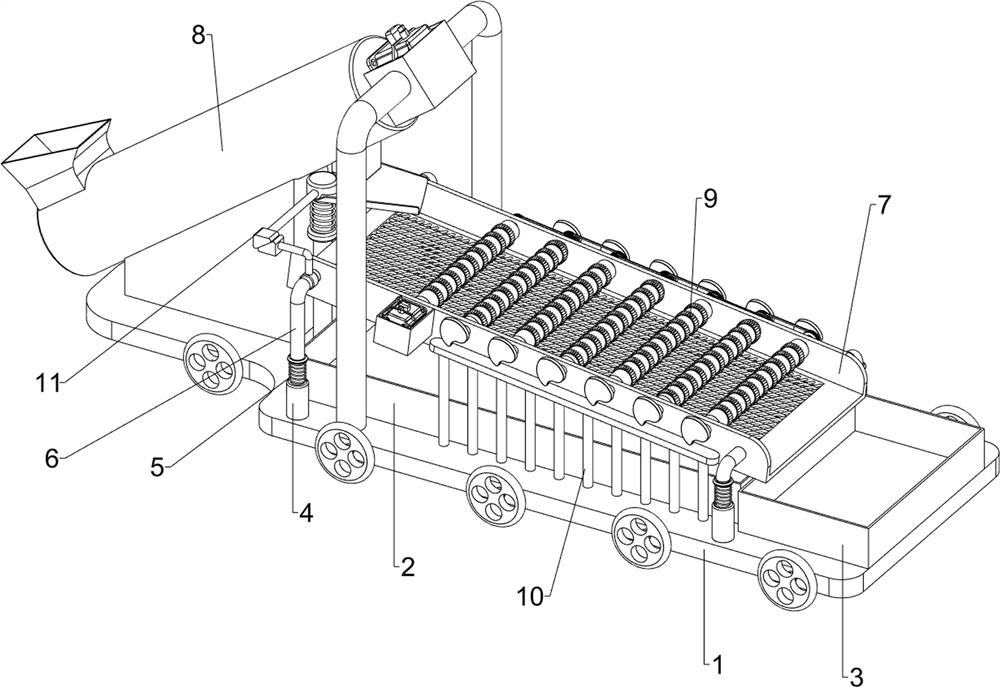

[0049] A kind of aggregate screening equipment for concrete, such as figure 1 , Figure 4 and Figure 6 As shown, it includes a base 1, a collection frame 2, a material receiving frame 3, a hollow column 4, a first spring 5, a telescopic rod 6, a screening frame 7, a feeding mechanism 8 and a brushing mechanism 9, and the top of the base 1 is provided with a Collecting frame 2, base 1 top front side is provided with receiving frame 3, receiving frame 3 is positioned at collecting frame 2 right ahead, base 1 top front and rear both sides are left and right symmetrical all are provided with hollow column 4, rear hollow column 4 tops are arranged The sliding type is provided with a telescopic rod 6, and the lower part of the telescopic rod 6 is covered with a first spring 5. A screening frame 7 is arranged between the telescopic rods 6 on the left and right sides. The side is provided with feeding mechanism 8.

[0050] First, the staff pushes the equipment to the place where a...

Embodiment 2

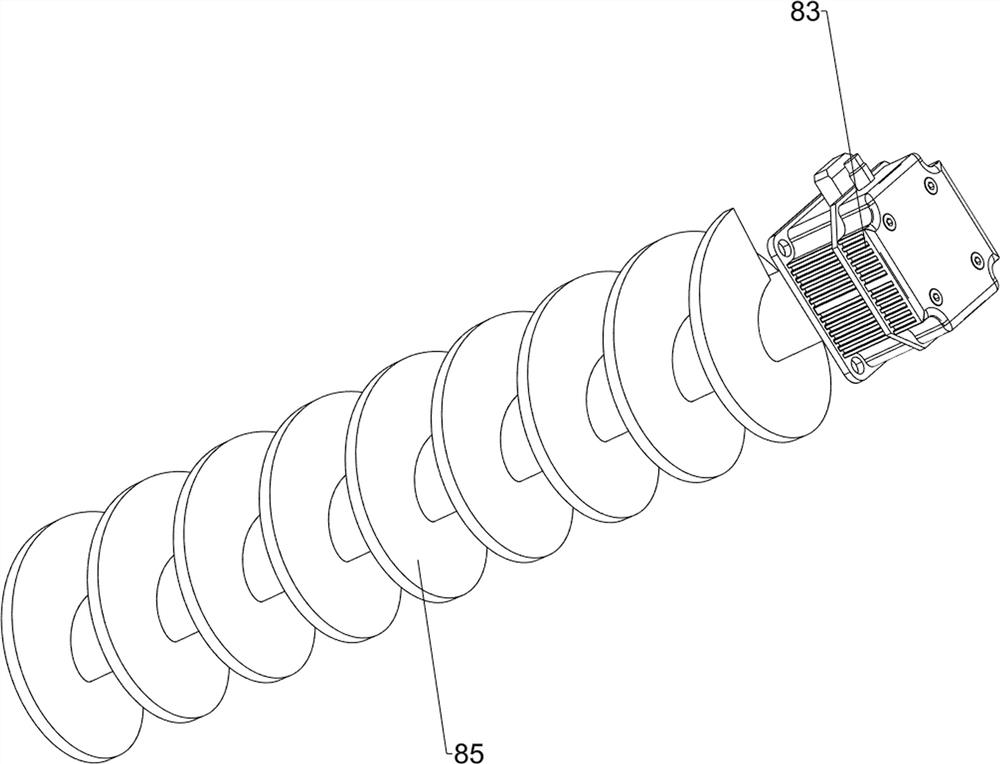

[0052] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the feeding mechanism 8 includes a support frame 81, a first support 82, a first motor 83, a first mounting frame 84, and a screw rod 85. The top of the base 1 is provided with a support frame 81, and the top of the support frame 81 is provided with a first mounting frame. Frame 84, base 1 top side rear part is provided with first support 82, and first support 82 is positioned at support frame 81 front, and first support 82 top inner side is placed with first motor 83, and the output shaft of first motor 83 is provided with screw rod 85, the screw rod 85 is located inside the first installation frame 84.

[0053]The feeding mechanism 8 is used for conveying aggregates for concrete, and conveys the aggregates for concrete poured into the bottom of the first installation frame 84 to the top thereof. First, the staff needs to pour the aggregates for concrete into the bottom of th...

Embodiment 3

[0057] On the basis of Example 2, such as Figure 5 and Figure 6 As shown, it also includes a shaking mechanism 10. The shaking mechanism 10 includes a second bracket 101, a clapping rod 102 and a cam 103. The left and right sides of the pushing roller 93 are provided with cams 103, and the top of the base 1 is symmetrically provided with a second Both the bracket 101 and the top of the second bracket 101 are provided with a clapping rod 102 , and the clapping rod 102 is in contact with the cam 103 .

[0058] The shaking mechanism 10 can further assist the falling of the finer concrete aggregates on the screening frame 7. After the second motor 92 starts, it will drive the pushing roller 93 to rotate, and then drive the cam 103 to rotate. Since the cam 103 is an irregular object , the rotation of the cam 103 will beat the clapping rod 102, and then the screening frame 7 can be shaken up and down, and the telescopic rod 6 will move up and down, so that some thinner concrete b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com