Powdery material belt conveyor and conveying method thereof

A technology for belt conveyors and powdery materials, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems affecting the working environment of workers, the heavy load of conveyor belts, and the impact on service life, so as to avoid chaos Flying and dust cleaning is convenient, and the transmission process is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

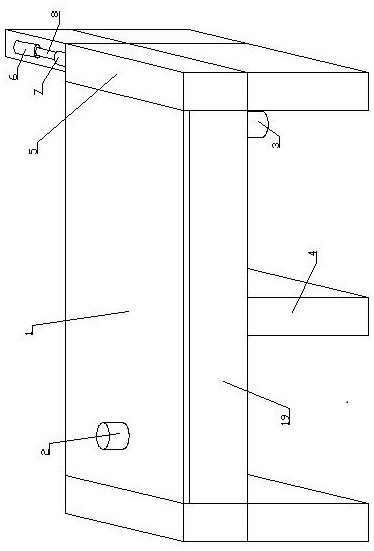

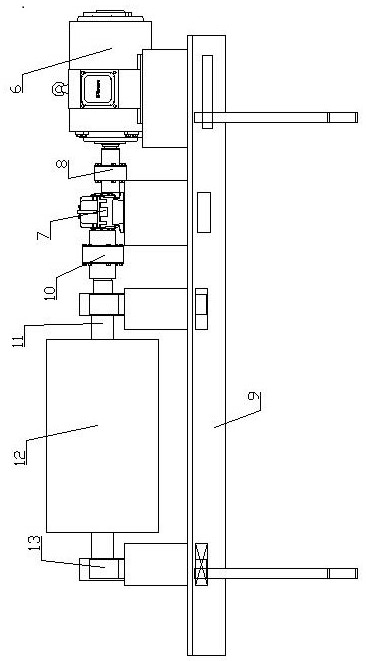

[0032] Belt conveyors for powdery materials, such as Figure 1~7 As shown, it includes a transmission mechanism, a protection mechanism, a slip detection mechanism and a conveyor belt 18. The front end of the conveyor belt 18 is provided with a feed port 2, and the rear end of the conveyor belt 18 is provided with a discharge port 3. The material falls from the feed port 2 onto the conveyor belt 18 and is transported to the discharge port 3 under the action of the conveyor belt 18 .

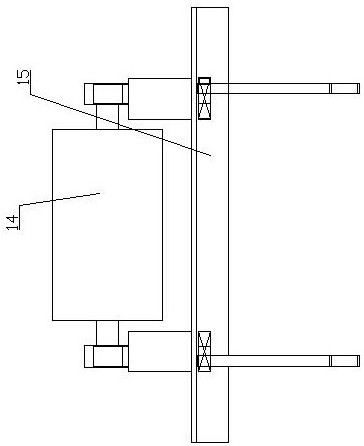

[0033] Wherein, the transmission mechanism is used to realize the transmission of the conveyor belt 18, and the transmission mechanism includes a speed reducer 7, a first coupling 8, a second coupling 10, a motor 6, a driven roller 14 and an output shaft 11 connected with the motor 6 The drive drum 12, the conveyor belt 18 is set between the driven drum 14 and the drive drum 12, the output shaft 11 of the motor 6 is connected with the reducer 7 through the first coupling 8; the output shaft 11 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com