Edge material shearing device for plastic sheets

A shearing device, a technology for plastic sheets, applied in the direction of metal processing, etc., can solve the problems of plastic sheets that cannot be cut by longitudinal cutting, unsmooth cutting edges, and broken finished sheets, so as to shorten labor time, improve labor efficiency, and save labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

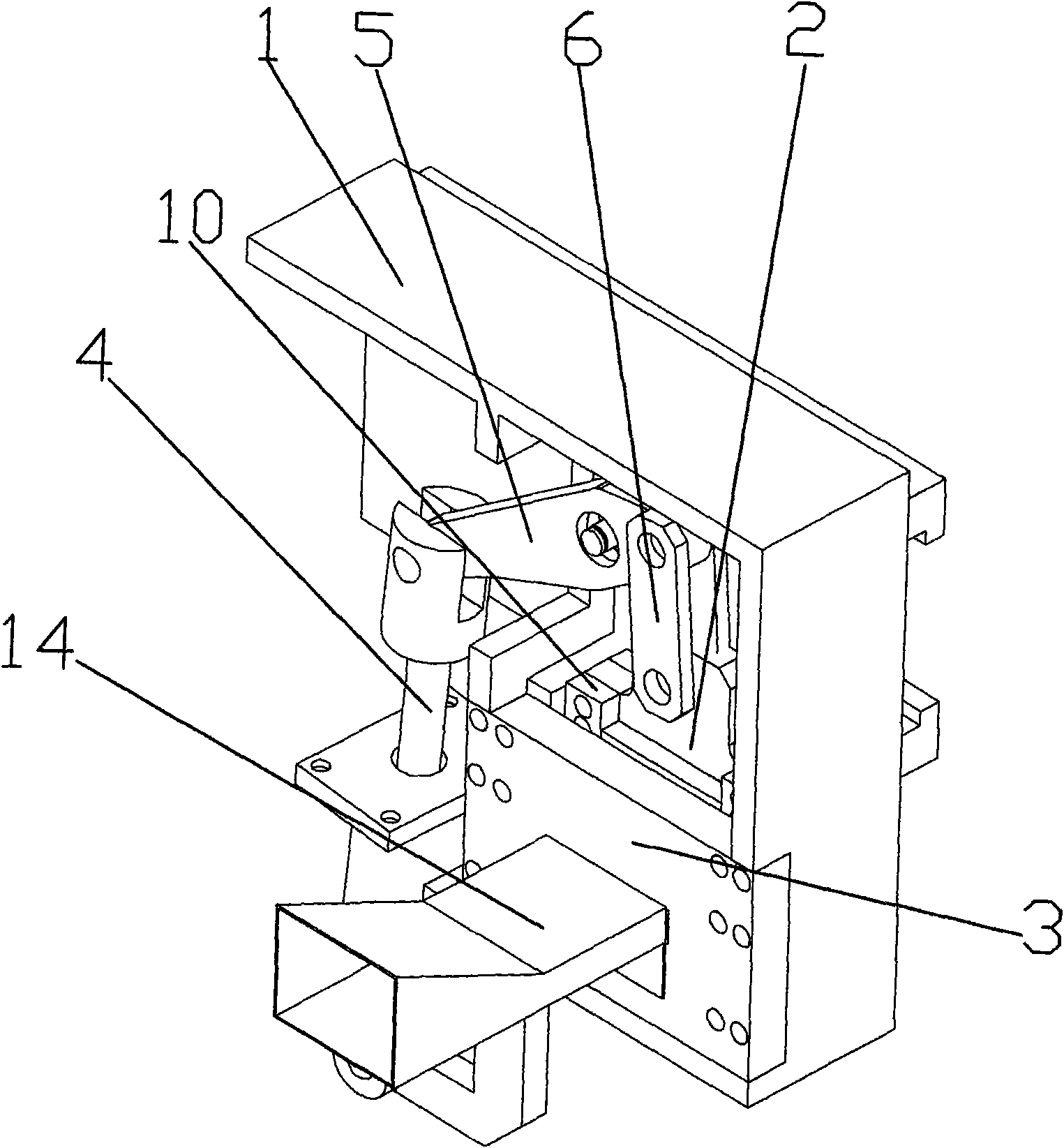

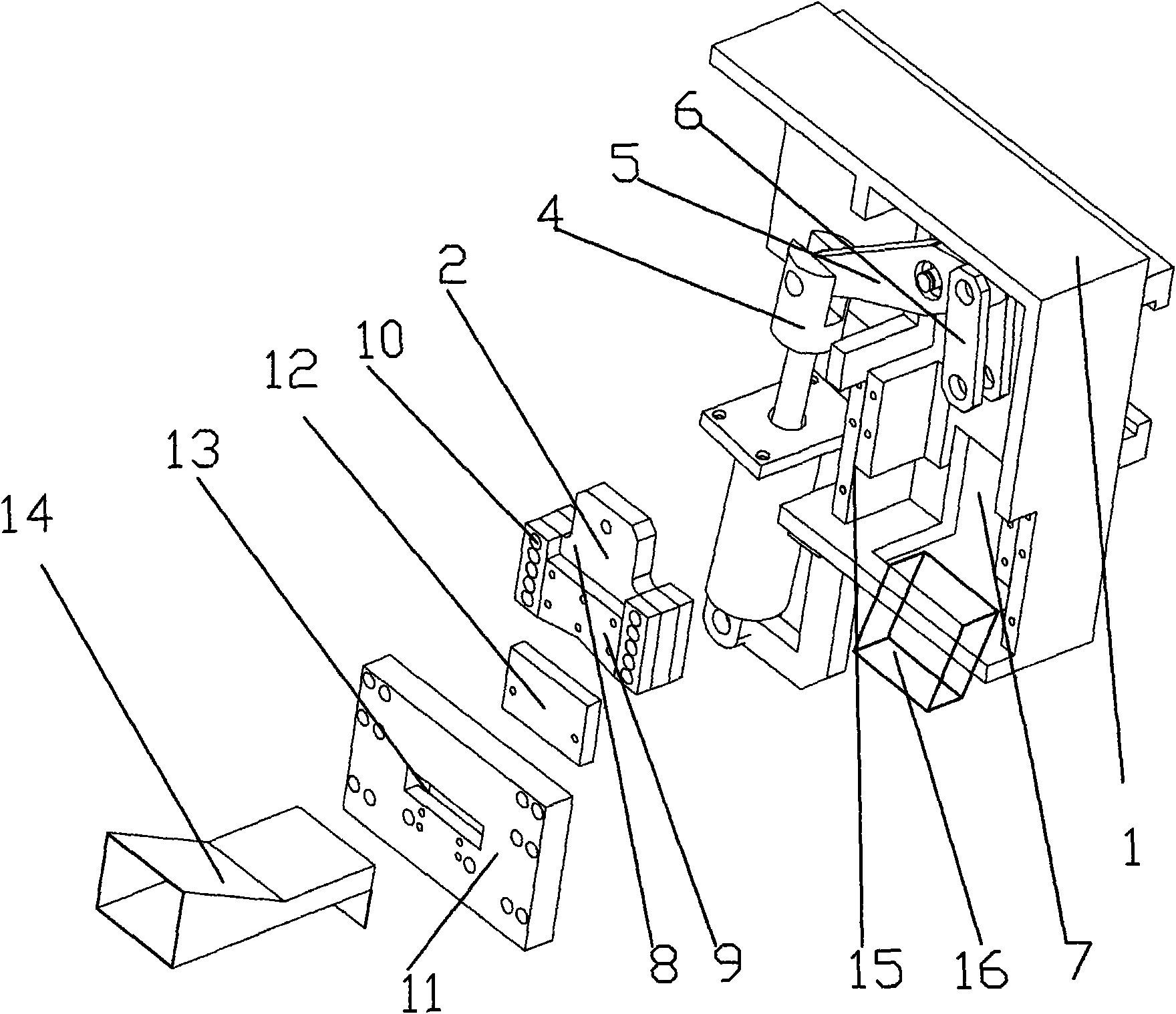

[0018] as attached figure 1 as well as figure 2 A kind of cutting device for plastic sheet material edge shown, it comprises machine base 1, upper knife device 2 and lower knife device 3, is provided with air cylinder 4 on the machine base 1, and the push rod of air cylinder 4 is connected with a lever mechanism 5, The machine base has a concave cavity, the lever mechanism 5 is fixed in the cavity of the machine base 1, the connecting rod 6 of the lever mechanism 5 is fixedly connected with the upper knife device 2, and the knife edge shape of the described upper knife device 2 is a dovetail Shape, the lower knife device 3 is arranged below the upper knife device 2, which includes the lower knife 12 and the lower knife installation assembly 11, the lower knife 12 is fixed on the rear end surface of the lower knife installation assembly 11, and the lower knife installation assembly 11 is provided with A through hole 13, the through hole 13 is located above the lower knife 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com