Paper stripping device for paper-covered copper wire

A technology of stripping paper and copper wire, which is applied in circuit/collector parts, electrical components, inductor/transformer/magnet manufacturing, etc. It can solve the problems of uneven cut surface, unable to protect paper-coated copper wire, and easy to be torn. To achieve the effect of smooth and complete cut surface, wide application range, and favorable peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

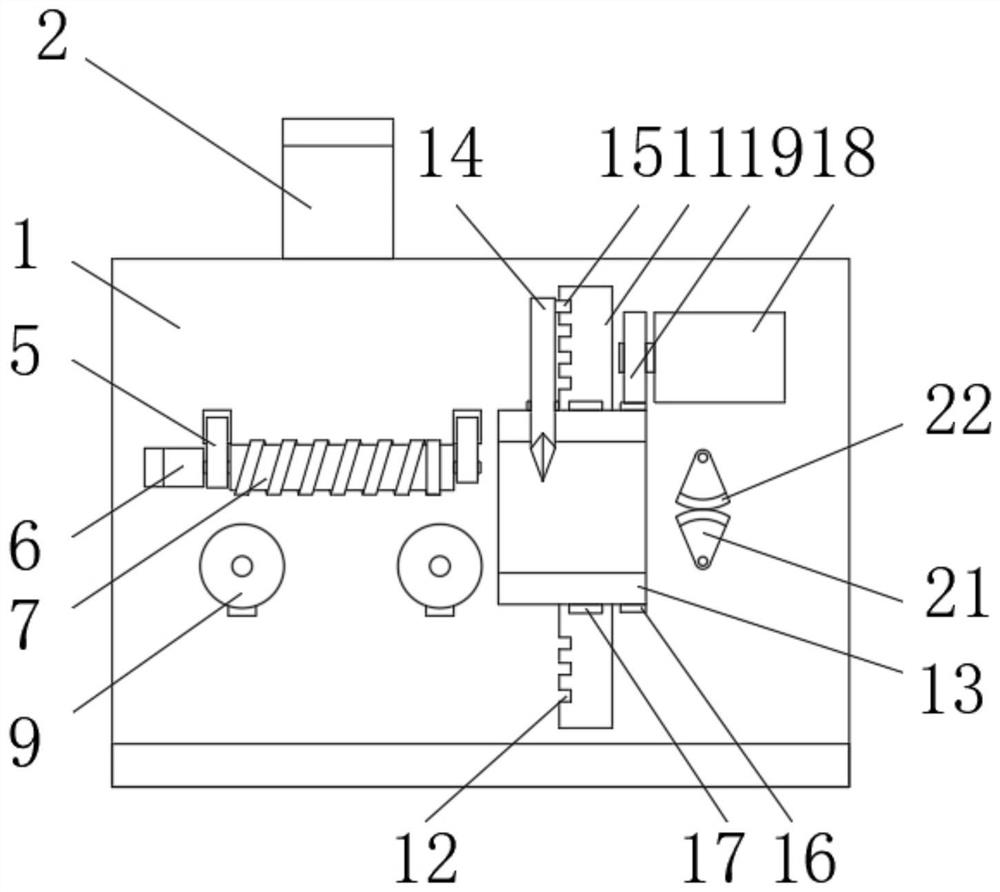

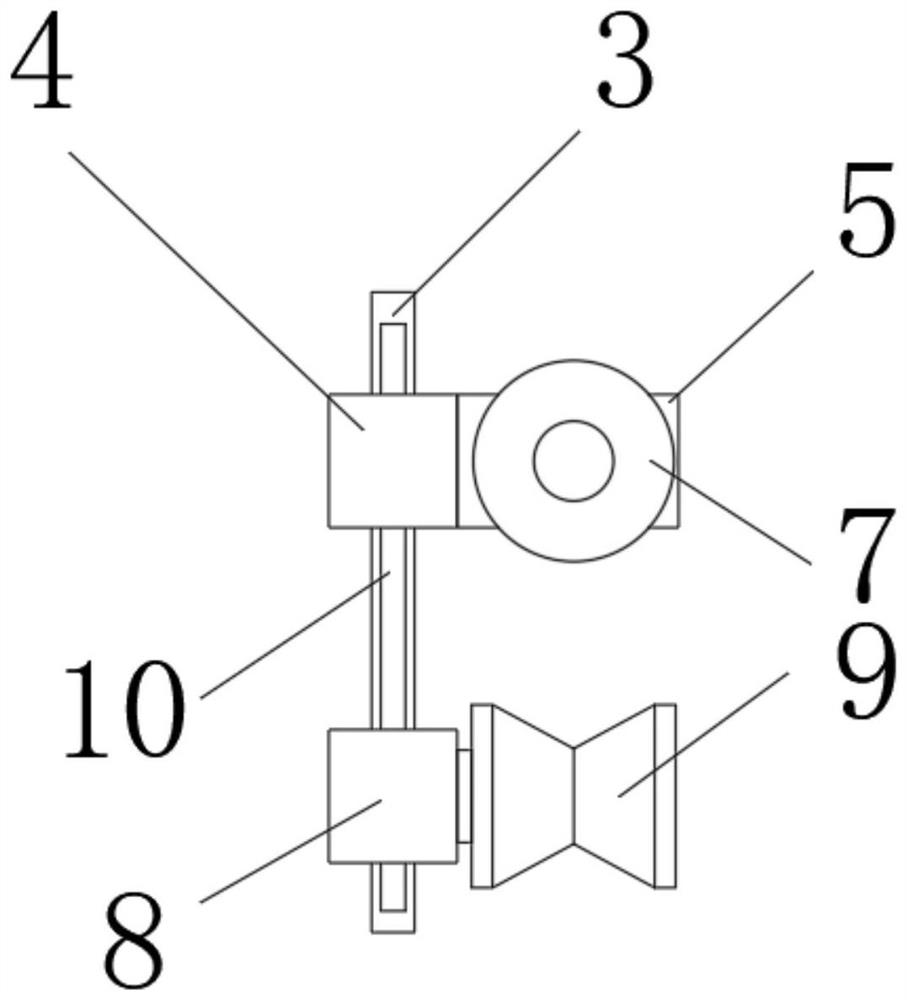

[0024] refer to Figure 1-5 , a stripping device for paper-wrapped copper wire, comprising a main body 1, a conveying mechanism 23 is arranged on one side of one end of the main body 1, a cutting mechanism 24 is arranged in the middle of one end of the main body 1, and a stripping mechanism is arranged on the other side of one end of the main body 1 Institution 25.

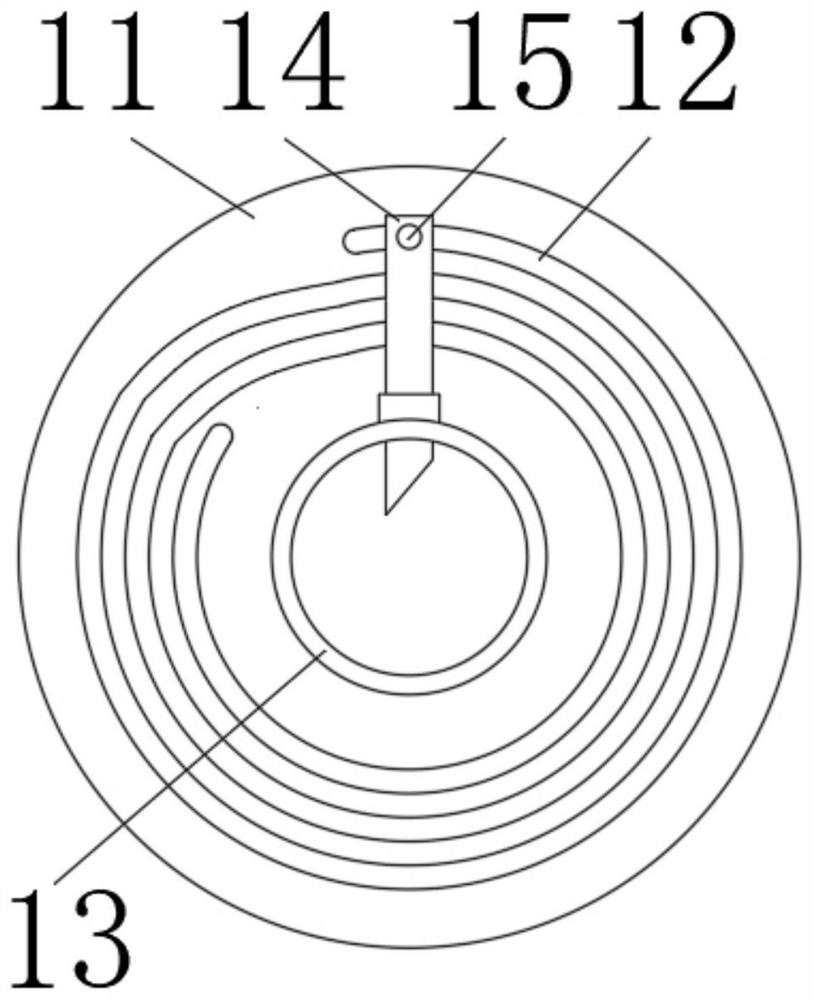

[0025] Through the provided chute 12, slide block 15, rack 16 and first gear 19, according to the engagement of the rack 16 with the first gear 19, the second servo motor 18 can drive the cutting seat 13 to rotate inside the slide block 15, According to the size of the slide block 15 matching the chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com