Handheld type composite ultrasonic food splitting tool

An ultrasonic and hand-held technology, applied in the field of hand-held composite ultrasonic food slitting and cutting knives, can solve the problems of difficult operation, difficult cutting of food, and low cutting efficiency, so as to achieve smooth and flat cutting surface, saving manpower and raw material costs, and cutting efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

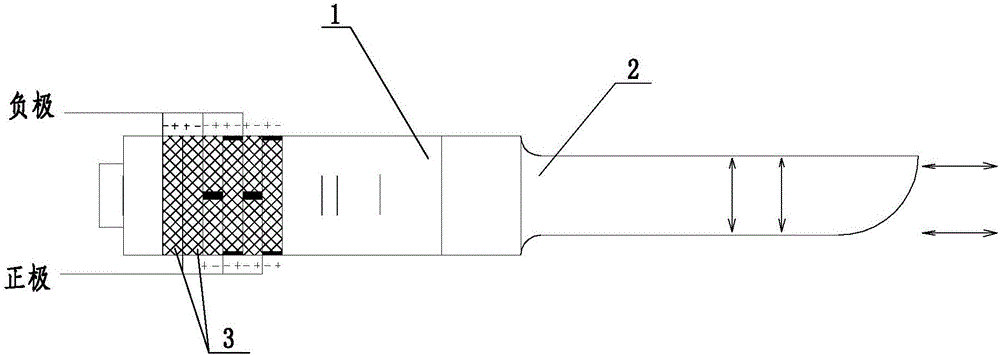

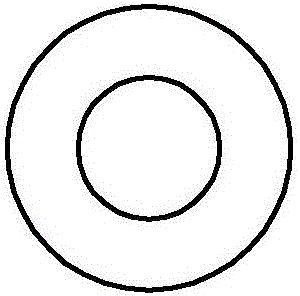

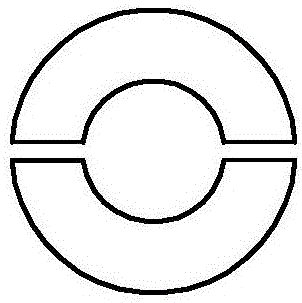

[0010] Such as Figure 1-Figure 3 As shown, the present invention includes an ultrasonic transducer 1 with four piezoelectric ceramics and a titanium alloy cutter 2, each piezoelectric ceramic is an integral structure, and the titanium alloy cutter 2 is fixedly arranged on the ultrasonic transducer 1 through screw fit. Under the action of the drive power supply, the piezoelectric ceramics reciprocate longitudinally, thereby converting electrical energy into mechanical energy; the hand-held composite ultrasonic food cutting knife also includes two piezoelectric ceramics 3, two piezoelectric ceramics 3 are respectively symmetrical split structures and are arranged oppositely. Two piezoelectric ceramics 3 are arranged at the rear end of four piezoelectric ceramics, and the positive and negative poles of the two piezoelectric ceramics 3 and the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com