Automatic cutting equipment for bar type material continuous discharging system

A technology of automatic cutting and discharging system, applied in metal processing and other directions, can solve the problems of difficult adjustment of manual operation process, unfavorable industrial expansion, failure to meet positioning requirements, etc., to improve the low efficiency of manual operation and the automation of equipment. High level, easy maintenance and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

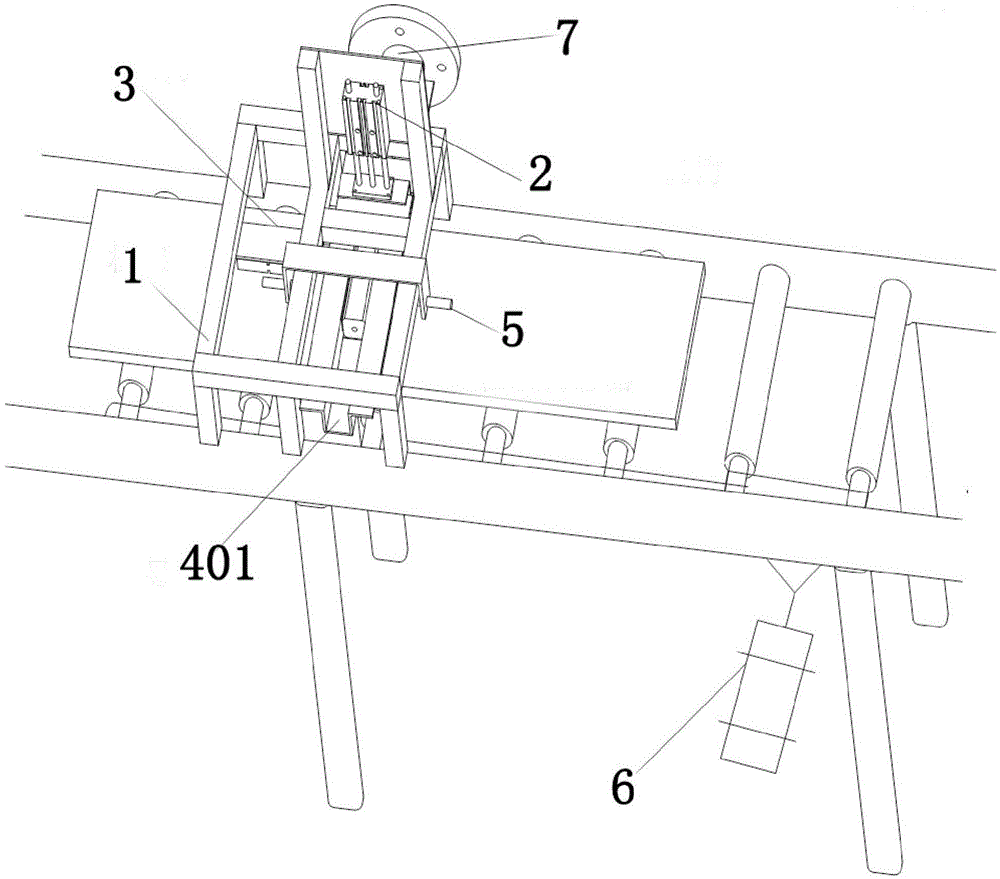

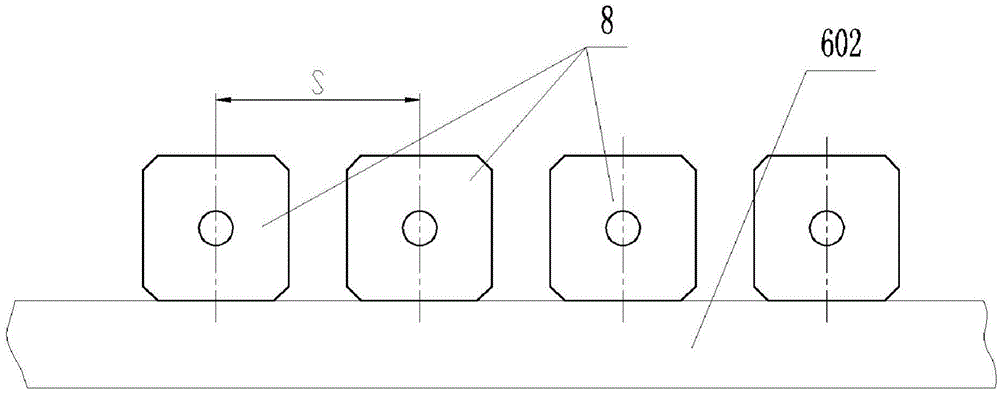

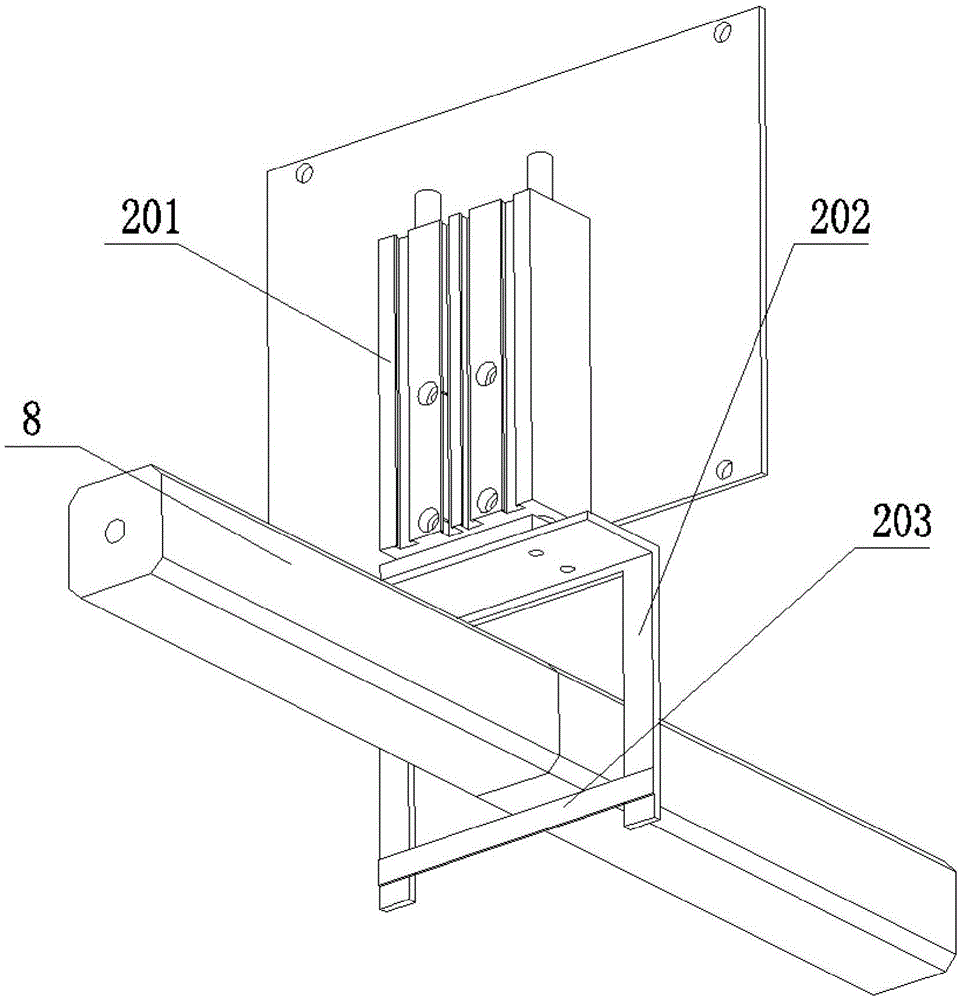

[0031] as attached figure 1 As shown, the present invention is mainly made of frame 1, automatic cutting mechanism 2, support mechanism 3, guide groove, position sensor 5, transmission mechanism 6 and electric control system. The frame is fixed on the transmission mechanism or on the continuous discharge system, and is mainly used to install the dynamic cutting mechanism, support mechanism, guide groove and position sensor; the automatic cutting mechanism is fixed on the frame and is located in the discharge of the continuous discharge system. Port 7 is used to automatically cut off the rod-shaped material at the discharge port; the support mechanism is located in front of the discharge port and below the automatic cutting mechanism, and is used to support and blank the material 8 at the discharge port; the guide groove is fixed on the support On the frame above the mechanism, it is used to guide the rod-shaped material at the discharge port; the position sensor is fixed at t...

Embodiment 2

[0043] An automatic cutting method for an automatic cutting device of a continuous discharge system for rod-shaped materials according to the present invention comprises the following steps:

[0044] 1) In the initial state, the cutter of the automatic cutting mechanism is in the incision position, the support plate of the support mechanism is in the support position, and the continuous carbon rod processed by the carbon rod extrusion molding equipment advances along the guide groove on the support mechanism;

[0045] 2) The position sensor detects the length of the material. When the front end of the material reaches the set point, the position sensor outputs a signal to the input port of the logic control unit;

[0046] 3) The logic control unit issues instructions to the automatic cutting mechanism, and the cutting cylinder drives the cutter to perform external or internal cutting actions, thereby cutting off the material;

[0047] 4) After the material is cut off, the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com