Annular super-hard abrasive wire and method for manufacturing same

A superabrasive and the technology of the production method are applied in the direction of manufacturing tools, sawing machine tool manufacturing, metal sawing equipment, etc., which can solve the problems of wide kerf, low efficiency, and poor cutting surface quality, and achieve smooth cutting surface, The effect of uniform thickness and low cutting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

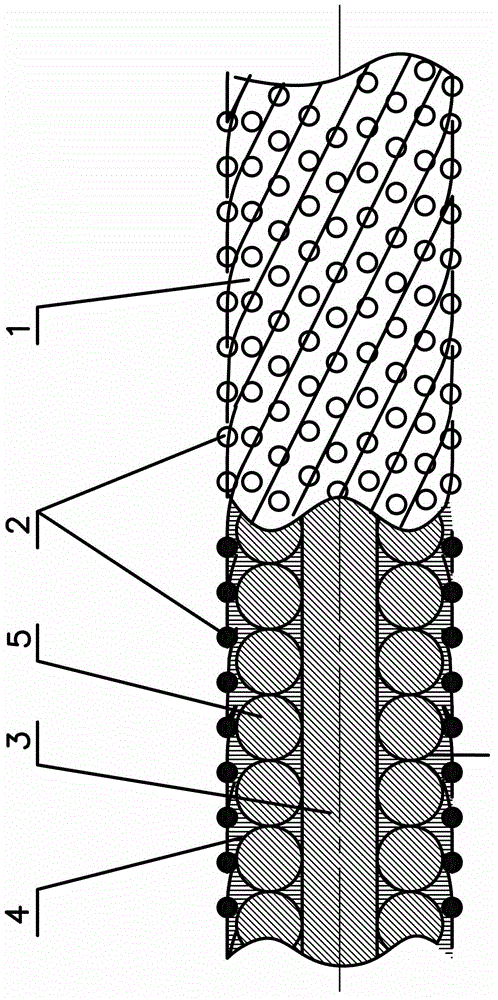

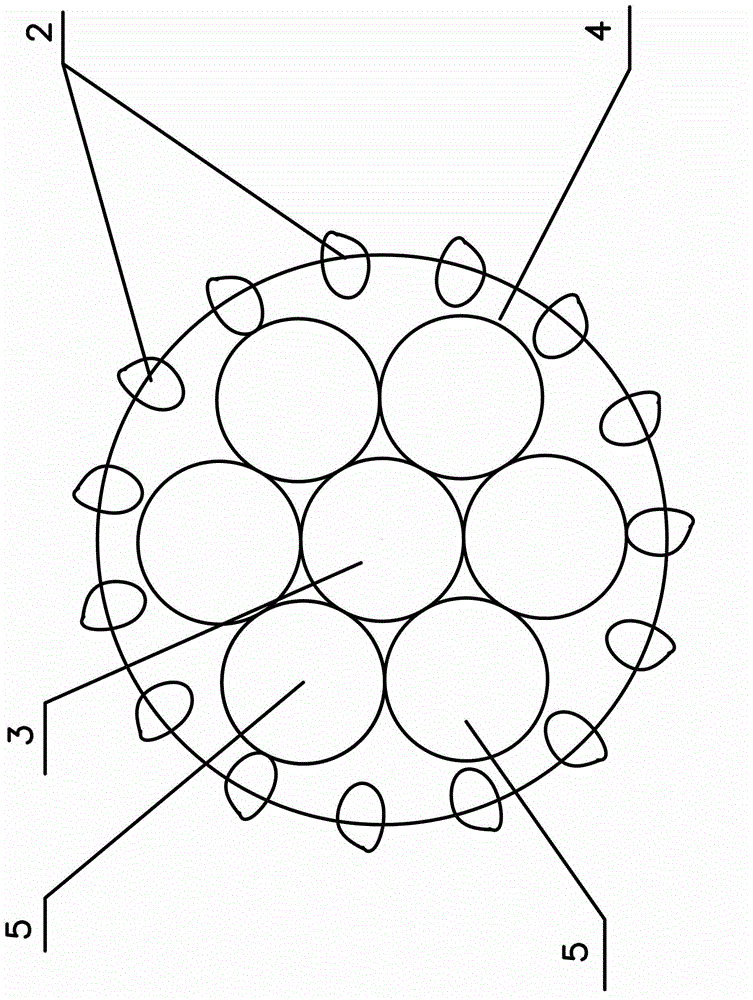

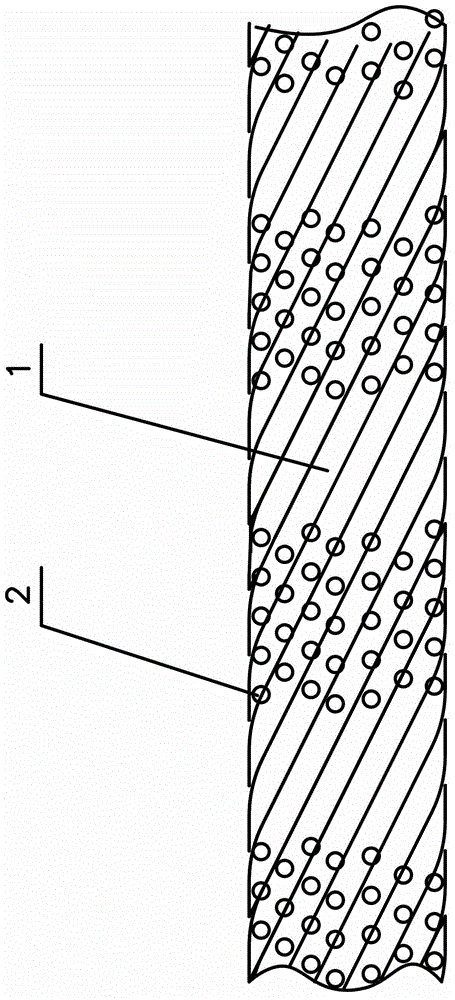

[0032] The matrix of the annular superabrasive wire of the present invention is a wire rope 1 of 0.1 mm to 6 mm, and the wire rope 1 is a section of metal wire or non-metal wire, or a multi-strand metal filament or multi-strand metal wire twisted on the core wire 3. Strands of non-metallic filaments, such as figure 1 As shown, the silk rope 1 adopts a 1×7 rope (a core wire 3 in the middle and six metal or non-metal strands 5 twisted on it), and the two ends of the silk rope 1 are connected to form a circular silk rope 1; the superabrasive particles 2 are uniformly coated and consolidated on the surface of the silk rope 1 to form a superabrasive layer, and the superabrasive layer is a single particle thickness layer; the superabrasive layer can be a continuous layer, or Can be a discontinuous layer, such as image 3 As shown; the particle diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com