Milling cutter

A technology of milling cutters and blades, which is applied in the field of forming milling cutters, can solve the problems of complex contour lines of cutting blades, reducing the service life of forming milling cutters, easy wear or cracking of blades, etc. Avoid the effect of chattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

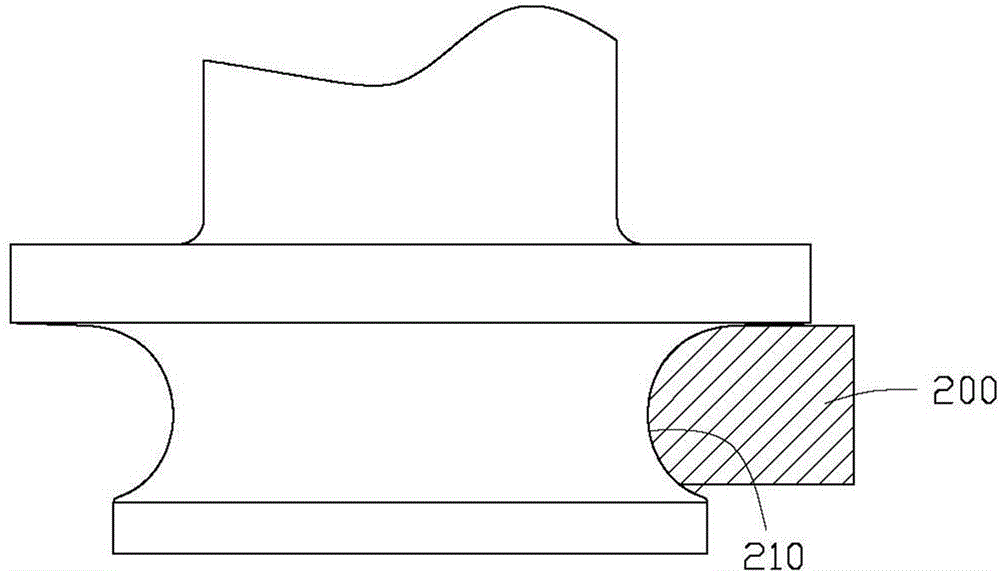

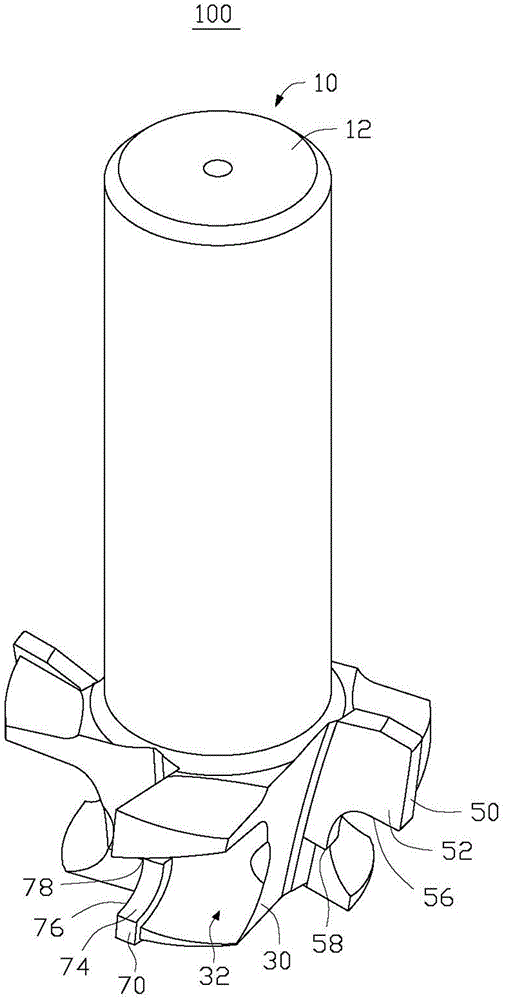

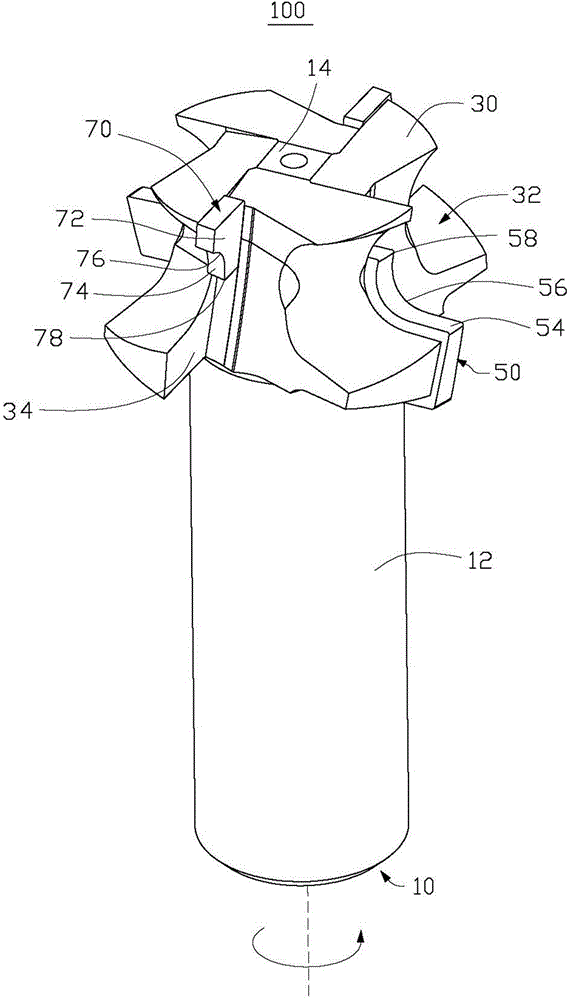

[0032] see Figure 2 to Figure 6 , the milling cutter 100 of the first embodiment of the present invention is used to process the workpiece 200 (see reference Figure 5 ) to perform milling, and process the workpiece 200 into a predetermined outer contour. Specifically, the workpiece 200 is roughly plate-shaped (not shown in the figure), the outer contour is formed around the edge of the workpiece 200 , and the cross-section of the outer contour is roughly an arc-shaped contour line 210 . Further, the outline 210 includes a first portion 212 and a second portion 214 continuous with the first portion 212 . In this embodiment, both the first portion 212 and the first portion 212 are partially arc-shaped.

[0033] see again figure 2 , The milling cutter 100 includes a handle 10 , a blade supporting portion 30 mounted on the handle 10 , and a first blade 50 and a second blade 70 mounted on the blade supporting portion 30 .

[0034] The handle 10 is substantially cylindrical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com