Method for welding high-strength steel through laser welding machine

A welding method and laser welding machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as fracture, affecting the normal production of the unit, and broken belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

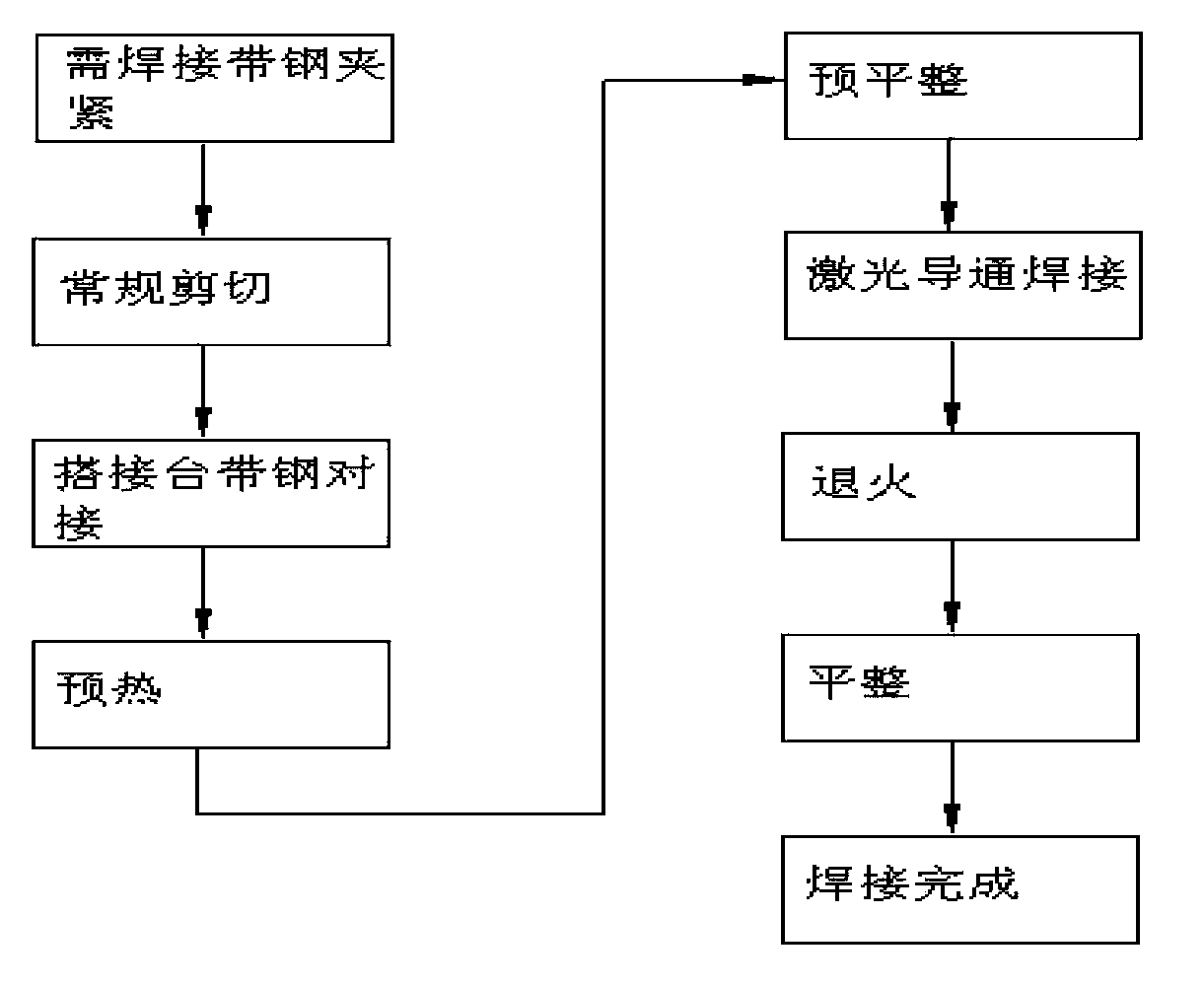

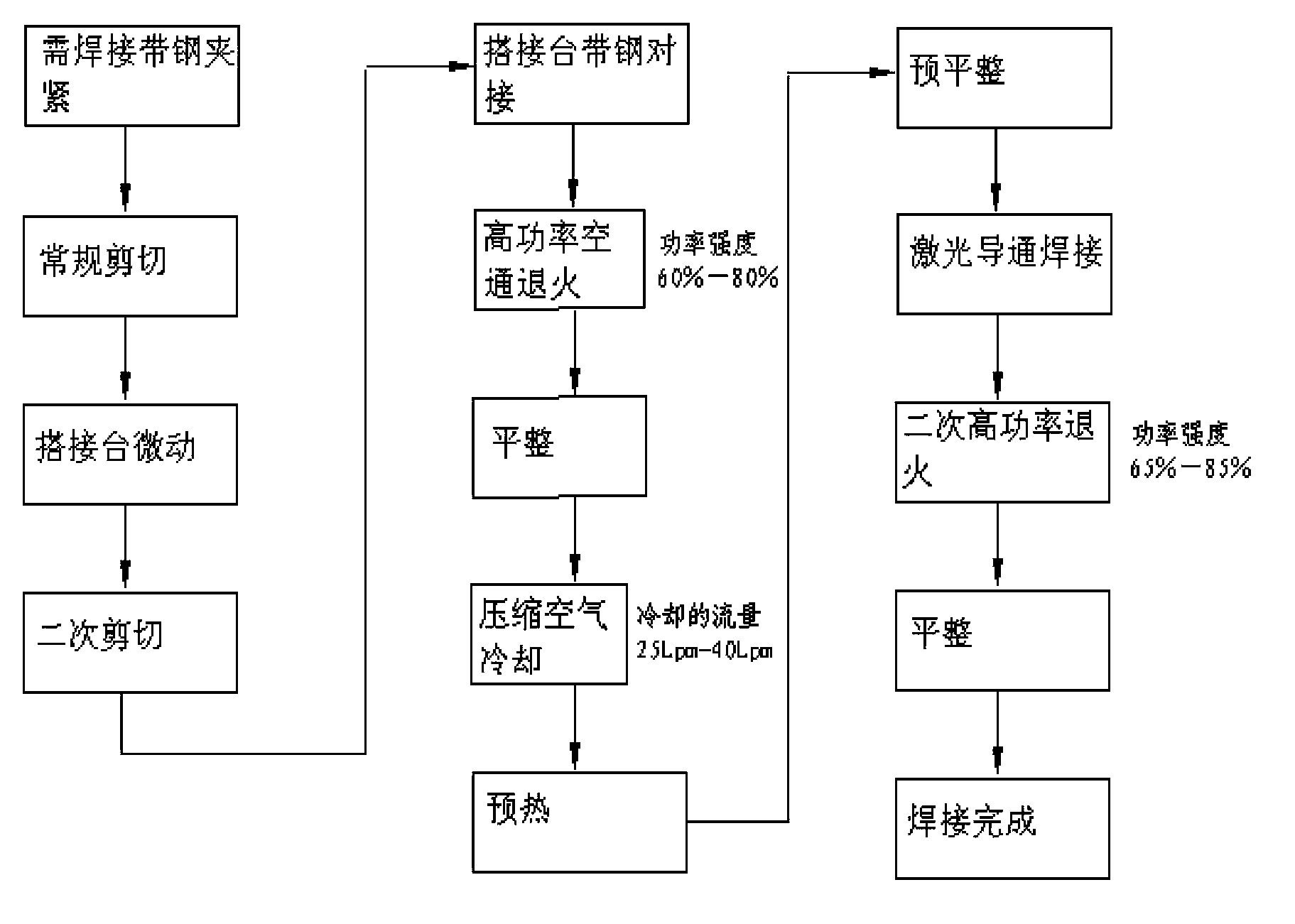

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0014] see figure 2 As shown, the welding method of the laser welder welding high-strength steel of the present invention specifically includes the following steps: clamping the strip steel to be welded, conventional shearing, and micro-movement of the lap table (allowing the clamping of the lap table clamp to be clamped by conventional shearing) Move the leading edge a little forward to determine the shearing amount of the secondary shearing, the moving distance can be set as 0.05mm~0.2mm), secondary shearing (cut off the micro leading edge protruding from the movement of the lapping table), lapping Lap joint, high-power air-through annealing (set the annealing power intensity at 60% to 80% according to the strength of the material, and convert the success rate to 6KW to 8KW, control the moving speed of the welding machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com