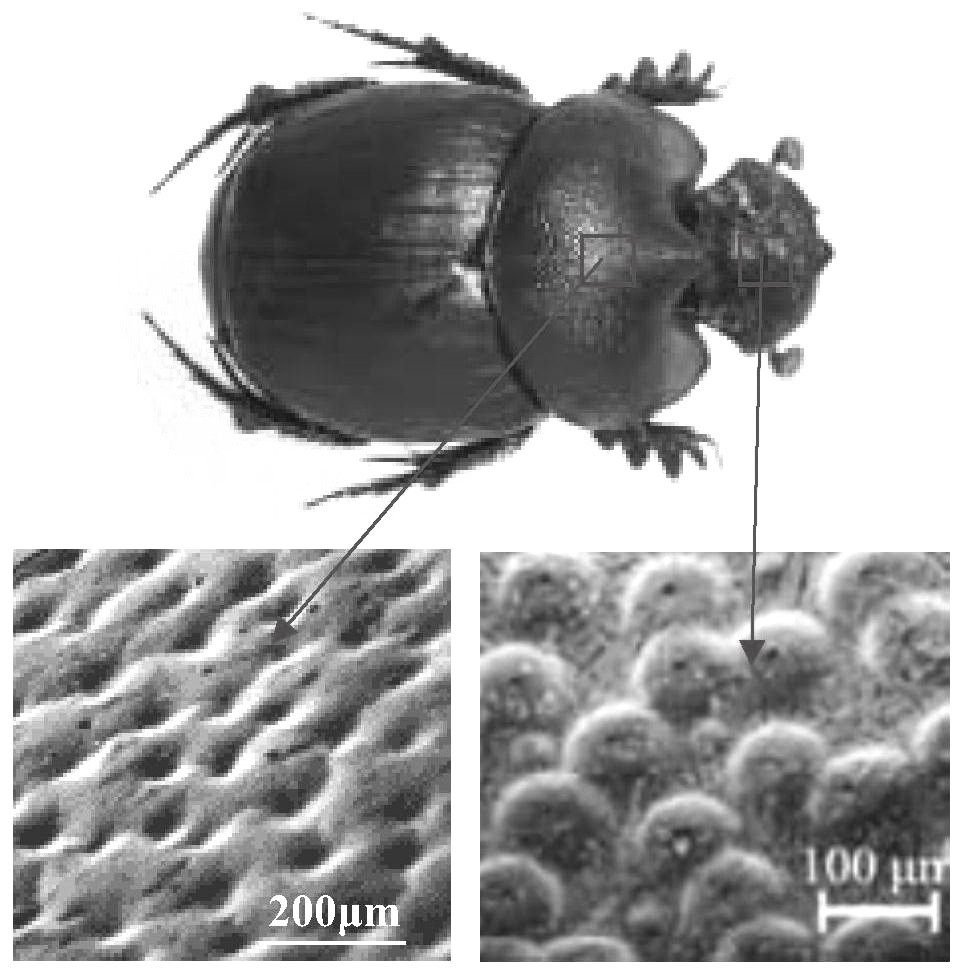

Bionic bone cutting tool based on dung beetle surface microstructure and preparation method of bionic bone cutting tool

A cutting tool and microstructure technology, which is applied in the field of bone cutting tools, can solve the problems of mechanical and thermal damage to surrounding tissue, blood vessel and nerve tissue, hinder postoperative recovery of patients, and bone cell necrosis, so as to improve the quality of the cutting surface and improve the Effect of surface quality and crack suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also proposes a method for preparing a bionic bone cutting tool based on the surface microstructure of the dung beetle, which includes the following steps:

[0040] 1) Remove the oxide layer on the surface of the tool body, and then perform ultrasonic cleaning, nitrogen drying, and vacuum drying;

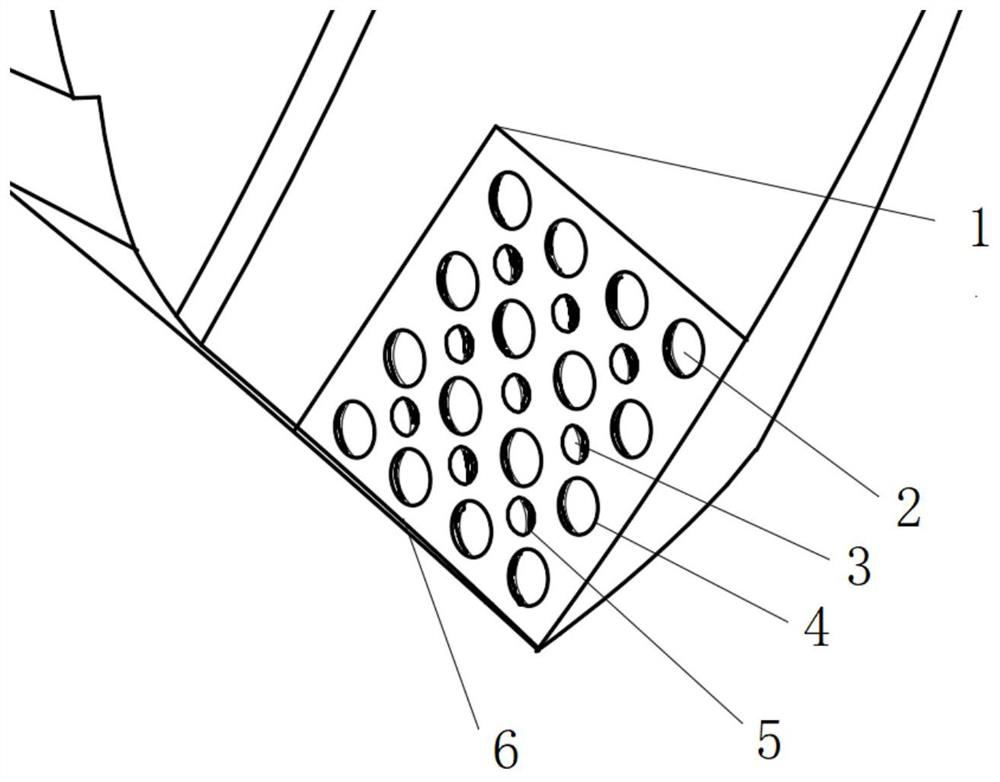

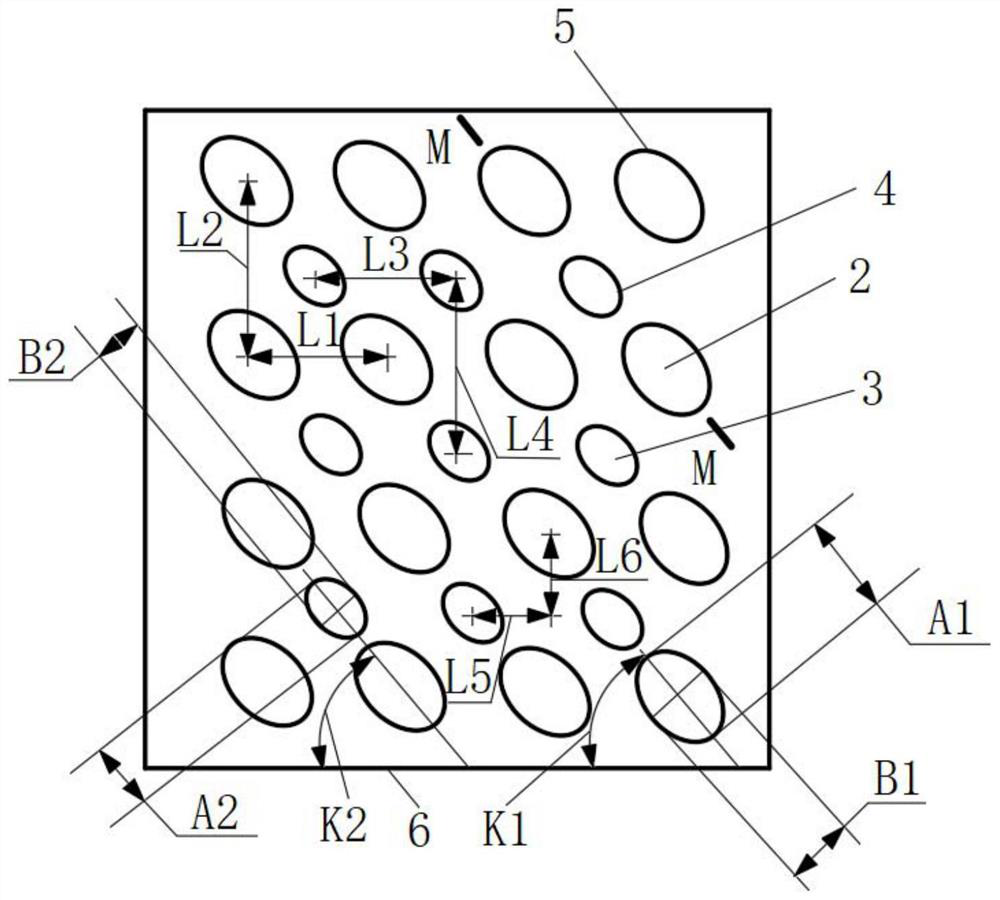

[0041] 2) Processing several semi-ellipsoidal convex hulls 2 in the chip contact area 1, the angle K1 between the extension line of the major axis A1 of the ellipse and the cutting chisel edge 6 is 0°-90°, preferably 45°, adjacent The lateral spacing L1 of the convex hull of the semi-ellipsoid is 155.1-201.4 μm, preferably 180 μm, the longitudinal spacing L2 is 88.4-133.6 μm, preferably 120 μm, and the height value H1 is 27.6-47.35 μm, preferably 37.5 μm;

[0042] 3) A number of semi-ellipsoid pits 3 are processed in the chip contact area 1, the adjacent transverse distance L3 is the same as L1, the longitudinal distance L4 is the same as L2, and the ang...

Embodiment 1

[0046] A bionic bone cutting tool based on the microstructure of the dung beetle surface. The tool body is a milling cutter, and its material is cemented carbide. Laser processing technology is combined with acid etching on the chip contact area of the tool rake face 1.5mm×1.5mm The structure described above is processed in the square area, and the steps of its preparation method are as follows:

[0047] 1) Pre-treatment: Remove the oxide layer on the surface of the tool body through micro-sandblasting. After the micro-sandblasting treatment, pour a certain amount of organic solution into the beaker, put the beaker into the ultrasonic cleaning machine, and then put the tool body into the beaker. The organic solution uses absolute ethanol and acetone in turn to clean the tool body Ultrasonic cleaning was carried out for 20 minutes. After cleaning, rinse the tool body with deionized water, and dry it with nitrogen after cleaning. Finally, put the dried tool body in a vacuum ...

Embodiment 2

[0054] A bionic cutting tool based on the microstructure of the dung beetle surface and its preparation method. The structure and preparation method are the same as those in Embodiment 1, except that the tool body is a drill bit.

[0055] The bionic bone cutting tool that imitates the surface of the dung beetle studied in the present invention is a novel, bionic bone cutting tool. The so-called bionic bone cutting hand tool refers to a bone cutting hand tool that uses a specific processing technology to process a micro-nano-scale texture array of a bionic surface structure in the chip contact area of the rake face. During dry cutting, due to the existence of the micro-nano scale texture array on the rake face of the tool, the chip contact length during the cutting process is reduced, the frictional resistance is reduced, and the cutting temperature is reduced. In addition, the edges of convex and pit microstructures are prone to produce "derivative cutting" (secondary cuttin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis | aaaaa | aaaaa |

| Short axis | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com