Preparation for free-cutting adnic alloy

A nickel-copper alloy and easy-cutting technology, which is applied in the field of preparation of free-cutting nickel-copper alloys, can solve the problems of steel cutting performance, poor fluidity, and easy-cutting uniformity, so as to reduce cutting force and cutting temperature, and reduce surface Effect of roughness and improved chip control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In the nickel-copper alloy, after refining at 1600° C. for 20 minutes, add carbon and nickel-magnesium alloy for deoxidation, and finally add 0.06% (sulfur weight) MnS to the nickel-copper alloy liquid.

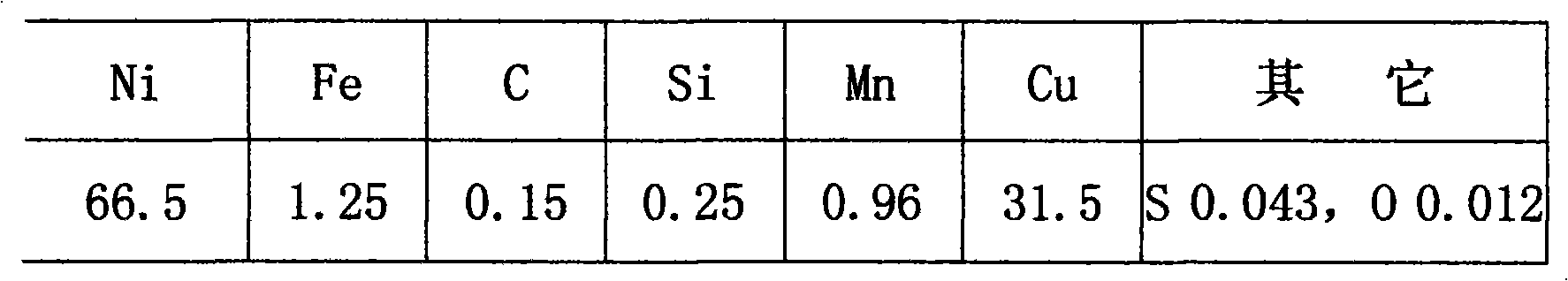

[0021] Analysis results of cast alloy ingot composition:

[0022]

[0023] Results Forging process, sample turning performance is good;

Embodiment 2

[0025] In the nickel-copper alloy, after refining for 20 minutes, add calcium-silicon alloy for deoxidation, and finally add 0.07% (sulfur weight) FeS to the nickel-copper alloy liquid.

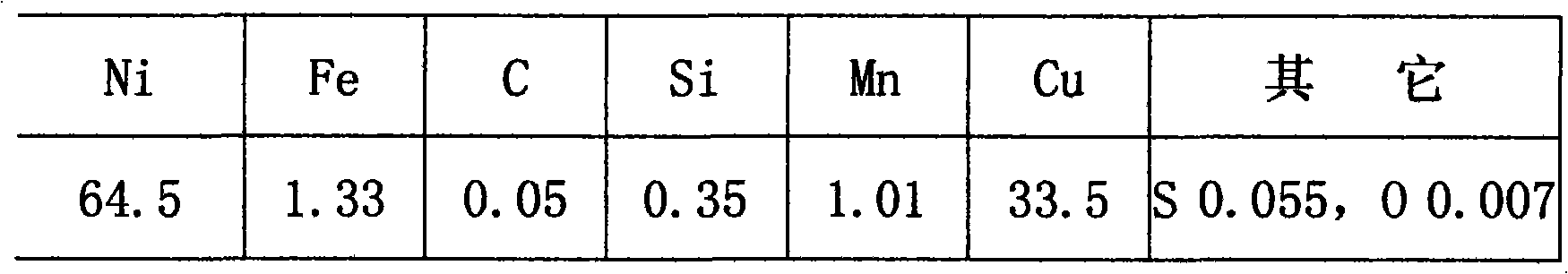

[0026] Analysis results of cast alloy ingot composition:

[0027]

[0028] Results Hot-rolled processing, the turning performance of the sample is good;

Embodiment 3

[0030] In the nickel-copper alloy, add carbon, after refining for 15 minutes, add copper-zirconium alloy for deoxidation, and finally add 0.07% (sulfur weight) high nickel matte to the nickel-copper alloy liquid.

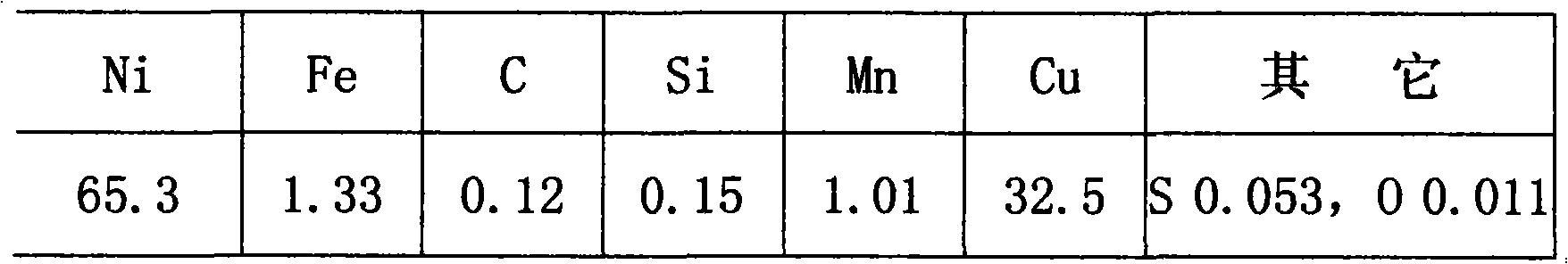

[0031] Analysis results of cast alloy ingot composition:

[0032]

[0033] Castings are processed directly, and the sample turning performance is good;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com