Ultrasonic vibration cutting device

A technology of ultrasonic vibration cutting and cutting blades, which is applied in turning equipment, tool holder accessories, metal processing equipment, etc., can solve the problems of cutting difficult-to-machine materials, achieve low cutting temperature, low cutting surface roughness, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

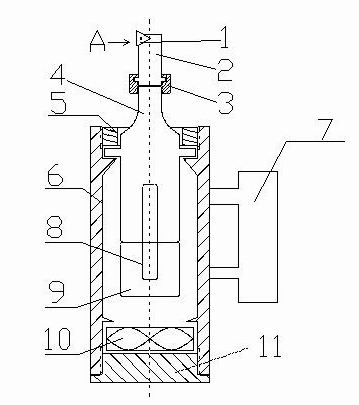

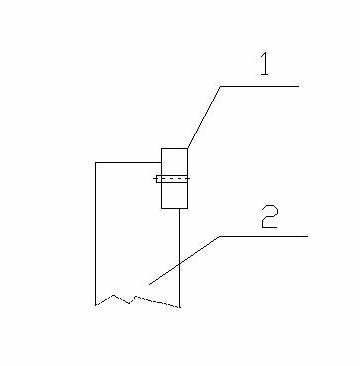

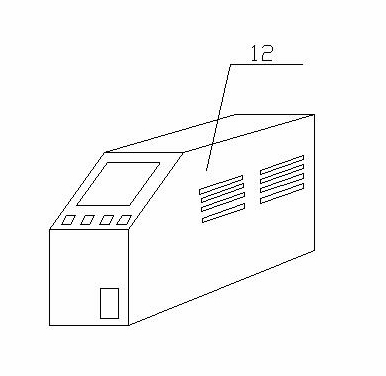

[0017] figure 1 figure 2 image 3 Middle: Ultrasonic vibration cutting device, mainly composed of cutting blade 1, cutting tool head 2, lock nut Ⅰ 3, horn 4, lock nut Ⅱ 5, shell 6, fixed chuck 7, screw rod 8, transducer 9 fan 10. The rear cover 11 and the digital power control box 12 are composed. The shell 6 is cylindrical. The upper part of the cylindrical inner diameter is provided with threads, and the lower part of the inner diameter thread of the cylinder is provided with a triangular boss. The plane of the triangular boss is upward, and the lower part of the cylindrical inner diameter is Also be provided with screw thread, the upper part of screw thread is also provided with triangular boss, the triangular boss plane of lower part is downward, and cylinder outer middle part is provided with fixed chuck 7, and shell 6 bottom is connected back cover 11, and back cover 11 is the intersection of cylinder and round cake. Combined body, the cylindrical part is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com