Inverted swing worktable of multi-line cutting machine

A multi-wire cutting machine and worktable technology, which is applied to fine work devices, work accessories, manufacturing tools, etc., can solve problems such as affecting the accuracy of the cutting surface of the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

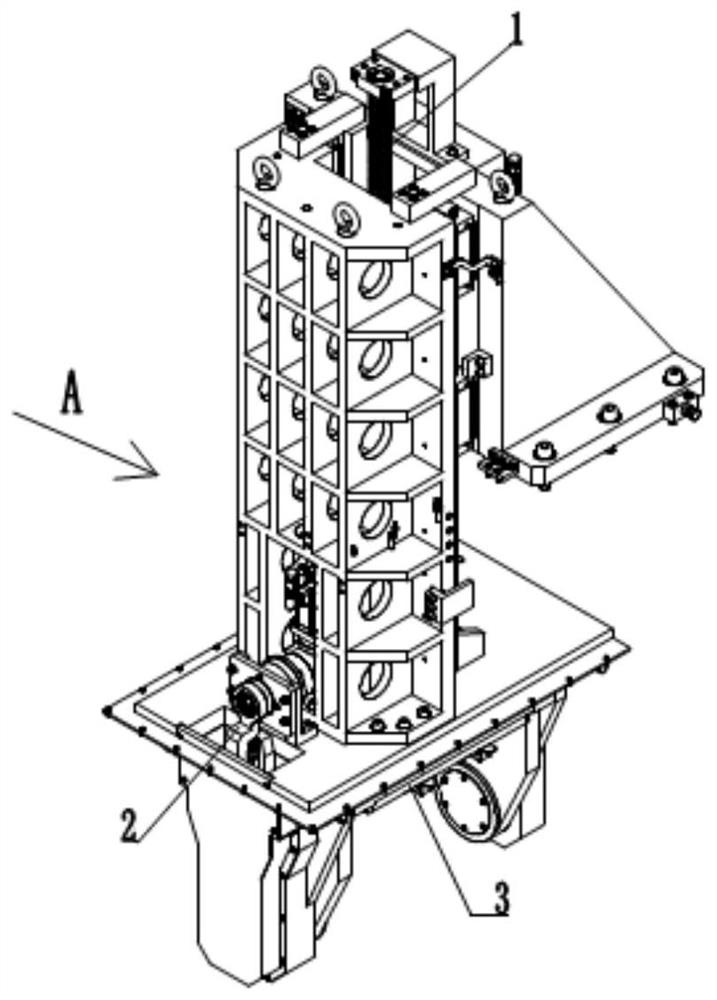

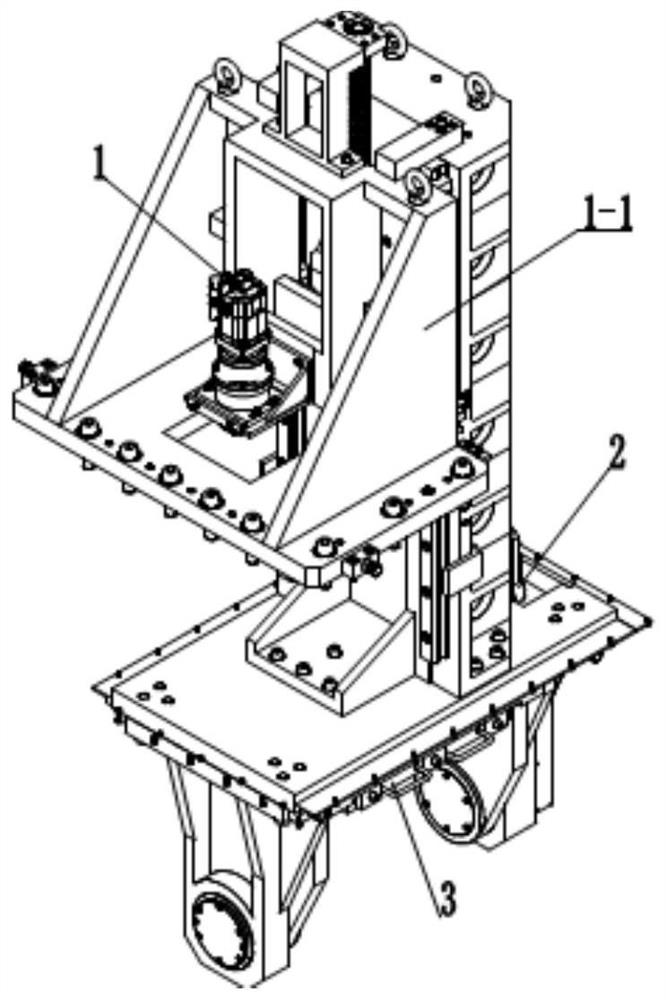

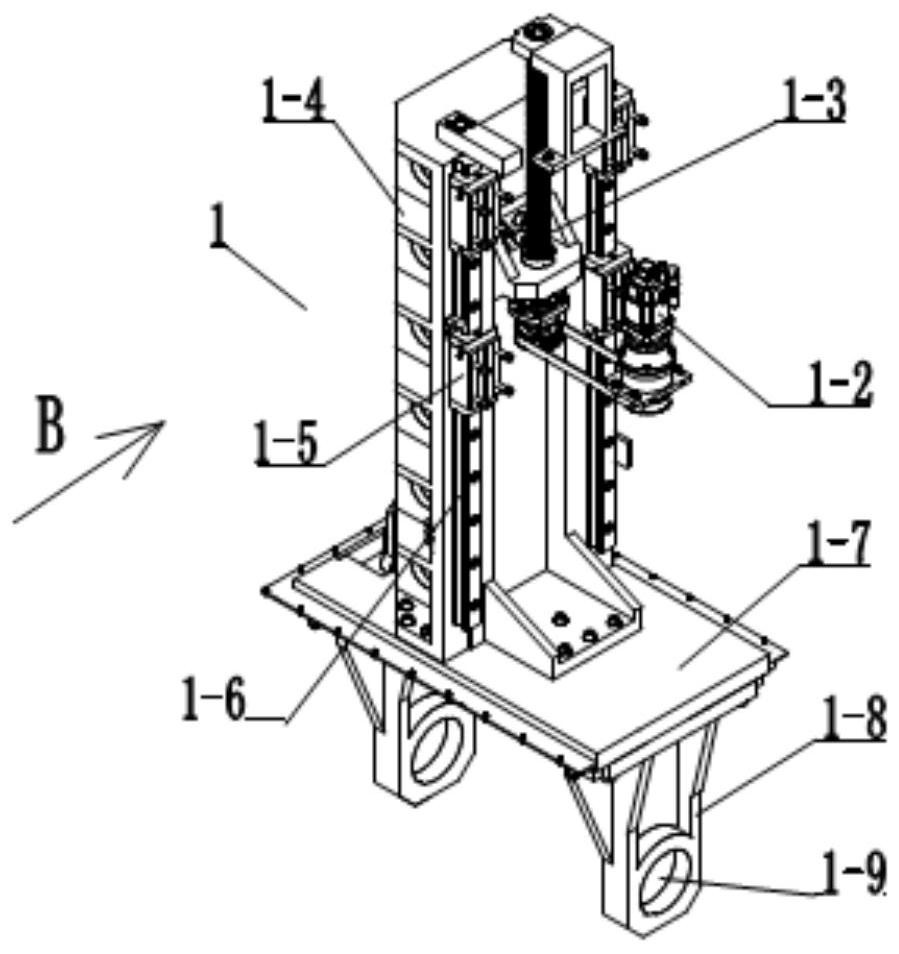

[0031] See Figure 1, figure 2 , the inverted swinging table of the multi-wire cutting machine according to the present invention includes a lifting mechanism 1, a swinging mechanism 2 and a worktable body 3; the lifting mechanism 1 is provided with a fixed part, a driving part and a lifting part, and the fixed The components are installed on the top of the main frame of the multi-wire cutting machine. The driving component is connected between the fixed component and the lifting component. The power provided by the driving component drives the lifting component to move up and down. The swing mechanism 2 is installed on the lifting mechanism 1. On the lifting part: the workbench body 3 is assembled with the swing mechanism 2, and under the joint action of the lift mechanism and the swing mechanism, the compound swing action of the workbench bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com