Automatic control system for cross-cut shear blade gap

A technology of automatic control and cutting edge clearance, applied in the field of cross-cutting shears, can solve the problems of large amount of equipment modification, abnormal collapse of cross-cutting shears, and difference in cutting quality, so as to reduce deviation and improve The effect of cut surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

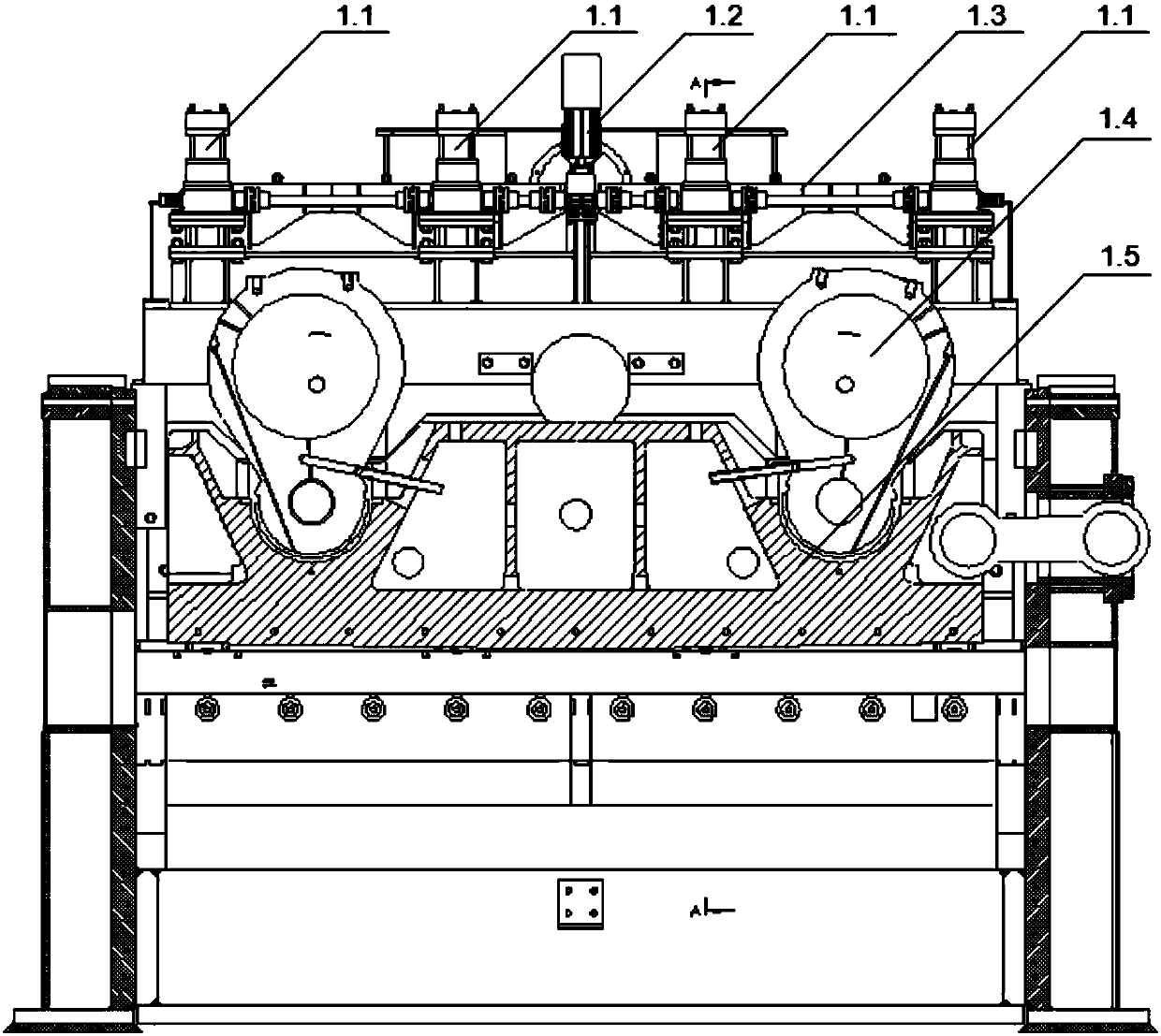

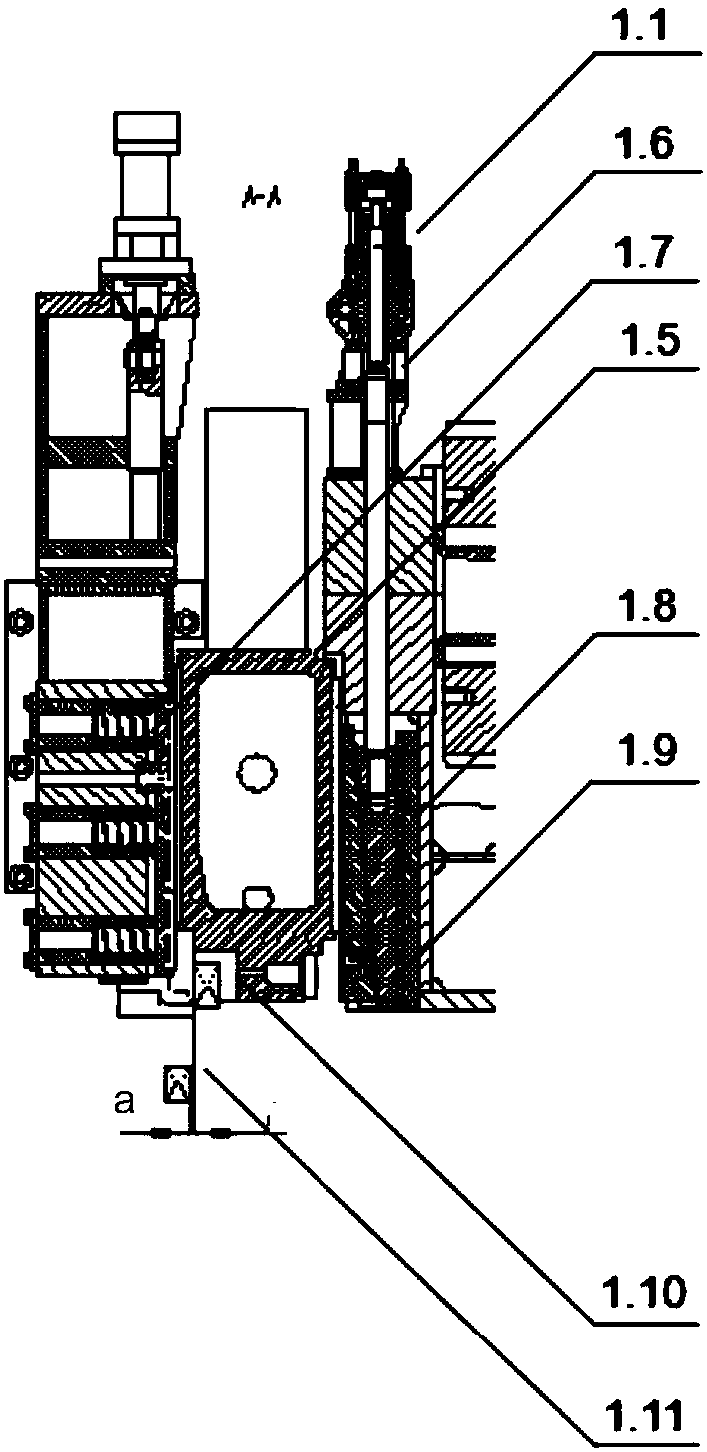

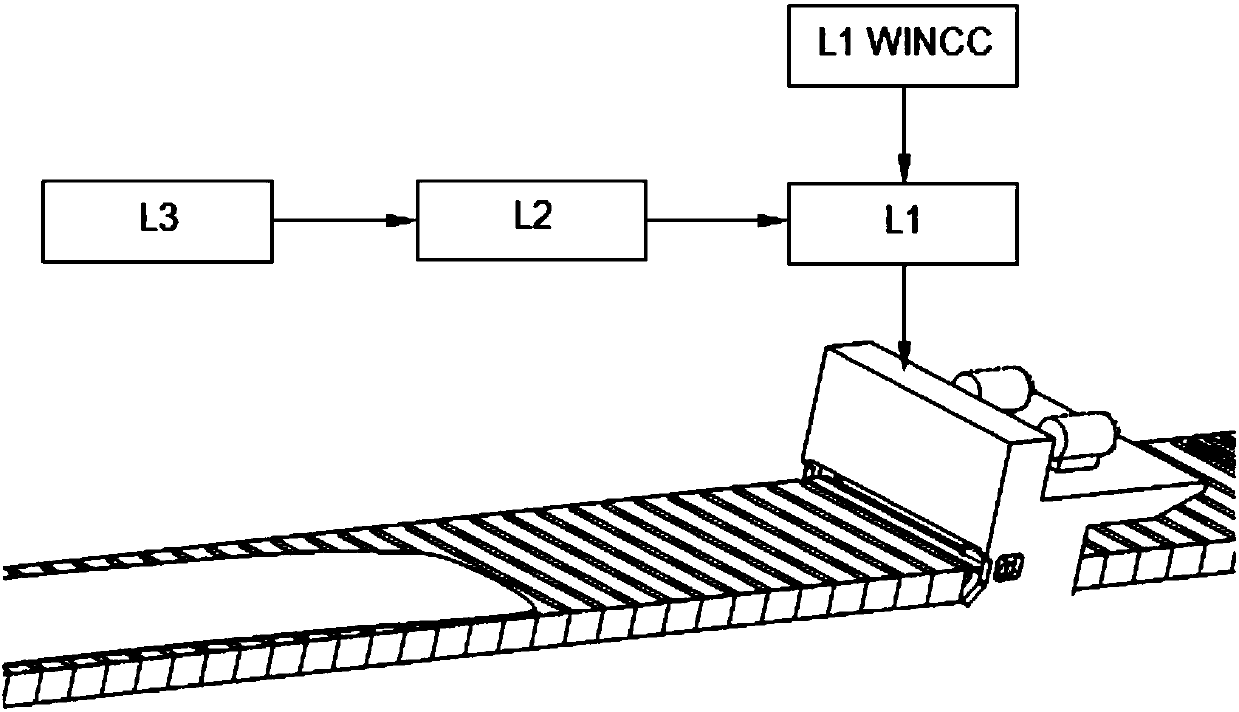

[0028] refer to image 3 As shown, in order to solve the problem of unreasonable setting of the gap between the cutting blades of the cross-cutting shears, the automatic control system for the gaps between the cutting blades of the cross-cutting shears of the present invention mainly includes: a production control computer L3, a process automation computer L2 and a basic automation computer L1, wherein:

[0029] The production control computer L3 sends the original PDI data of the steel plate to be sheared (here mainly refers to the three-dimensional size, tensile strength, etc. of the steel plate) to the process automation computer L2;

[0030] The process automation computer L2 automatically calculates the optimal cutting edge gap value according to the received original data of the steel plate combined with the static param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com