System for removing slab burrs

A slab and burr technology is applied in the field of devices for efficiently removing slab burrs by ion arc, which can solve the problems of slow flame cutting speed, secondary slag pollution, inability to meet the real-time requirements of on-site production lines, etc., and achieves excellent cutting surface quality, The effect of high deburring rate and real-time efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

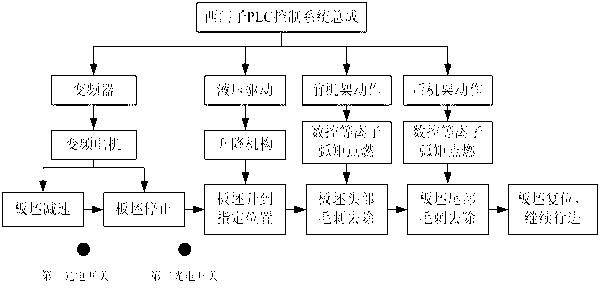

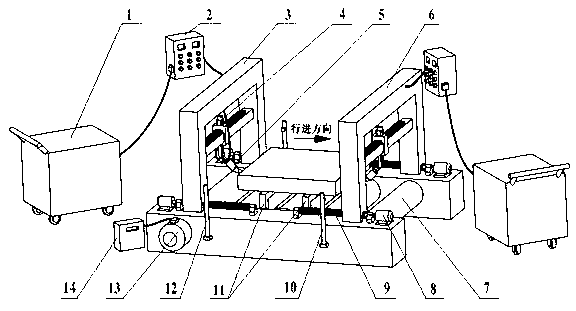

[0015] Depend on figure 1 and figure 2 It can be seen that the system for removing burrs from slabs in the present invention consists of three parts: CNC plasma arc cutting device, slab positioning device and Siemens PLC control system assembly. The CNC plasma arc cutting device is composed of two sets of identical components, that is, the plasma power supply 1, the control cabinet 2, the first servo motor 4 (connected to the reducer), the plasma gun body 5 and its walking mechanism, etc., and the plasma power supply 1 is connected to the control The cabinet 2 is connected to the servo motor 4 and the plasma gun body 5 again. Considering the continuous working time of the plasma gun body 5 and the service life of the electrode tungsten rod, a water cooling system is used on the gun body. In order to ensure the working stability of the cutting system, two control cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com