Liquid crystal glass substrate double-cutter wheel cutting device and method

A technology of liquid crystal glass substrate and cutting device, applied in glass cutting device, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of inability to obtain cutting effect, unstable laser processing, easy to produce fragments, etc., and achieve high cutting surface quality, Simple structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

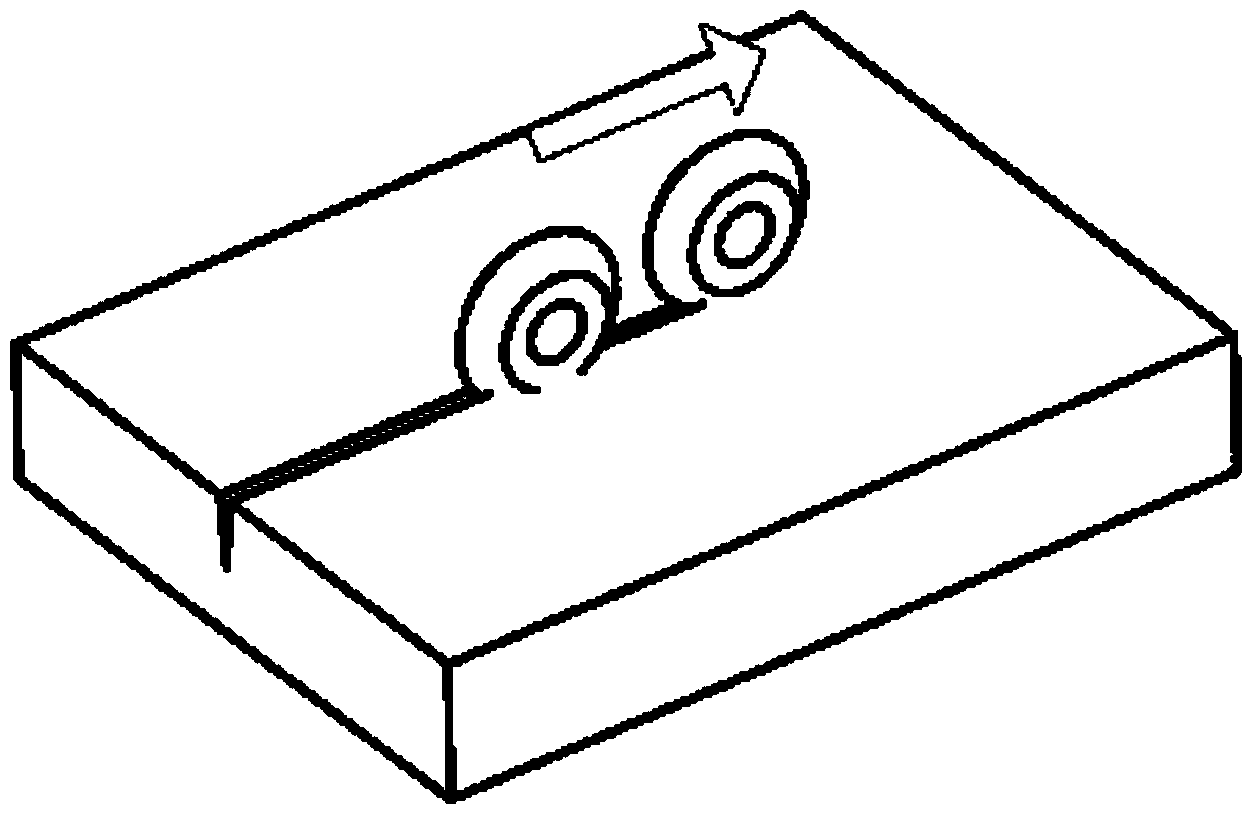

[0030] like figure 1 As shown, the double cutter wheel cutting method for liquid crystal glass substrates uses two cutter wheels to cut the liquid crystal glass substrate successively along the feeding direction indicated by the arrow. Feed cutting, followed by the following wheel (the left wheel) cutting with a higher cutting feed. The cutting feed mentioned here refers to the depth that the knife wheel cuts into the liquid crystal glass substrate.

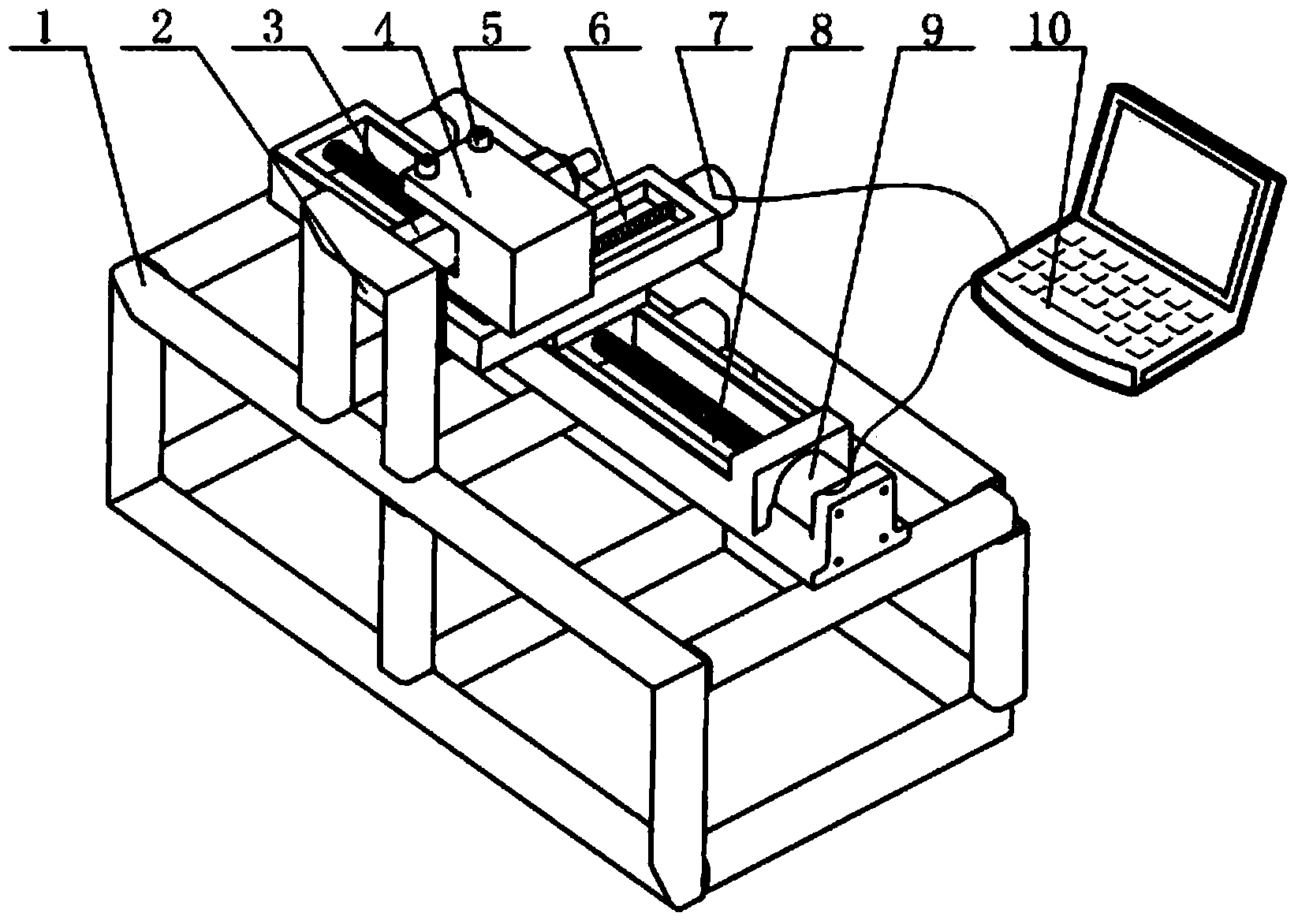

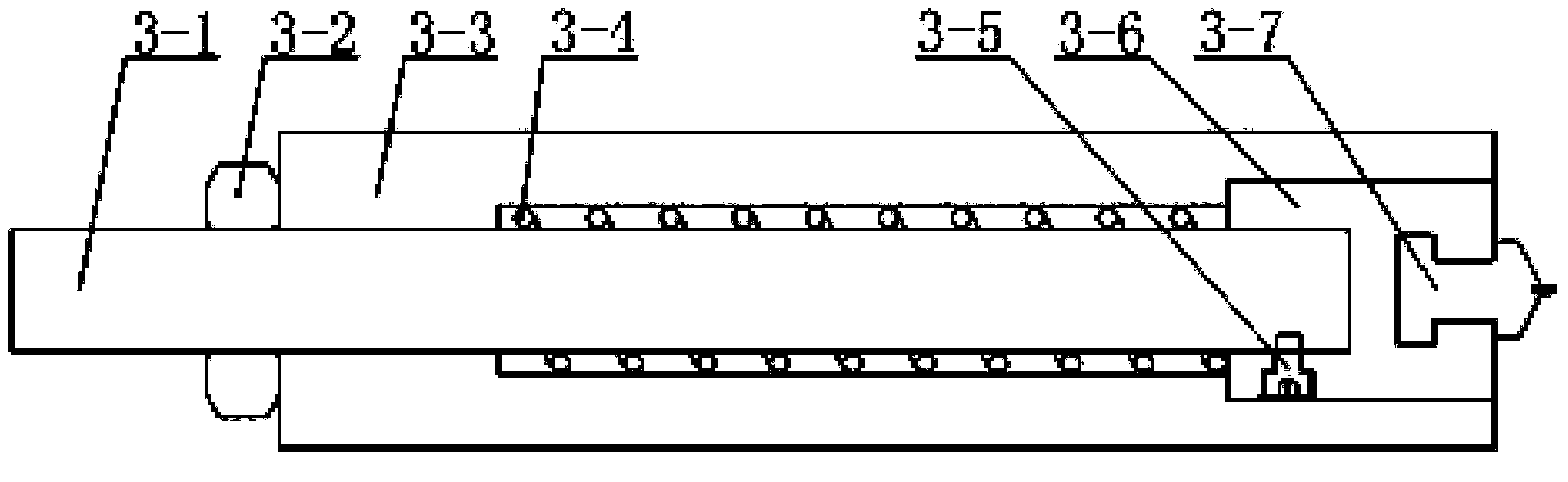

[0031] like figure 2 As shown, the liquid crystal glass substrate double-knife wheel cutting device is composed of a support frame, a knife wheel fixture, a knife holder, a locking screw, a Y-axis screw, a Y-axis drive motor, an X-axis screw, an X-axis drive motor and a control computer. composition. Wherein, the Y-axis screw, the Y-axis driving motor, the X-axis screw, and the X-axis dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com