Orientation order distribution of diamond in tool bit realization method

A technology of directional arrangement and diamond, which is applied in the field of preparation of diamond tool heads, can solve the problems of not having industrialized production conditions, not being effectively solved, and high maintenance and manufacturing costs, so as to avoid adverse effects, low equipment maintenance costs, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

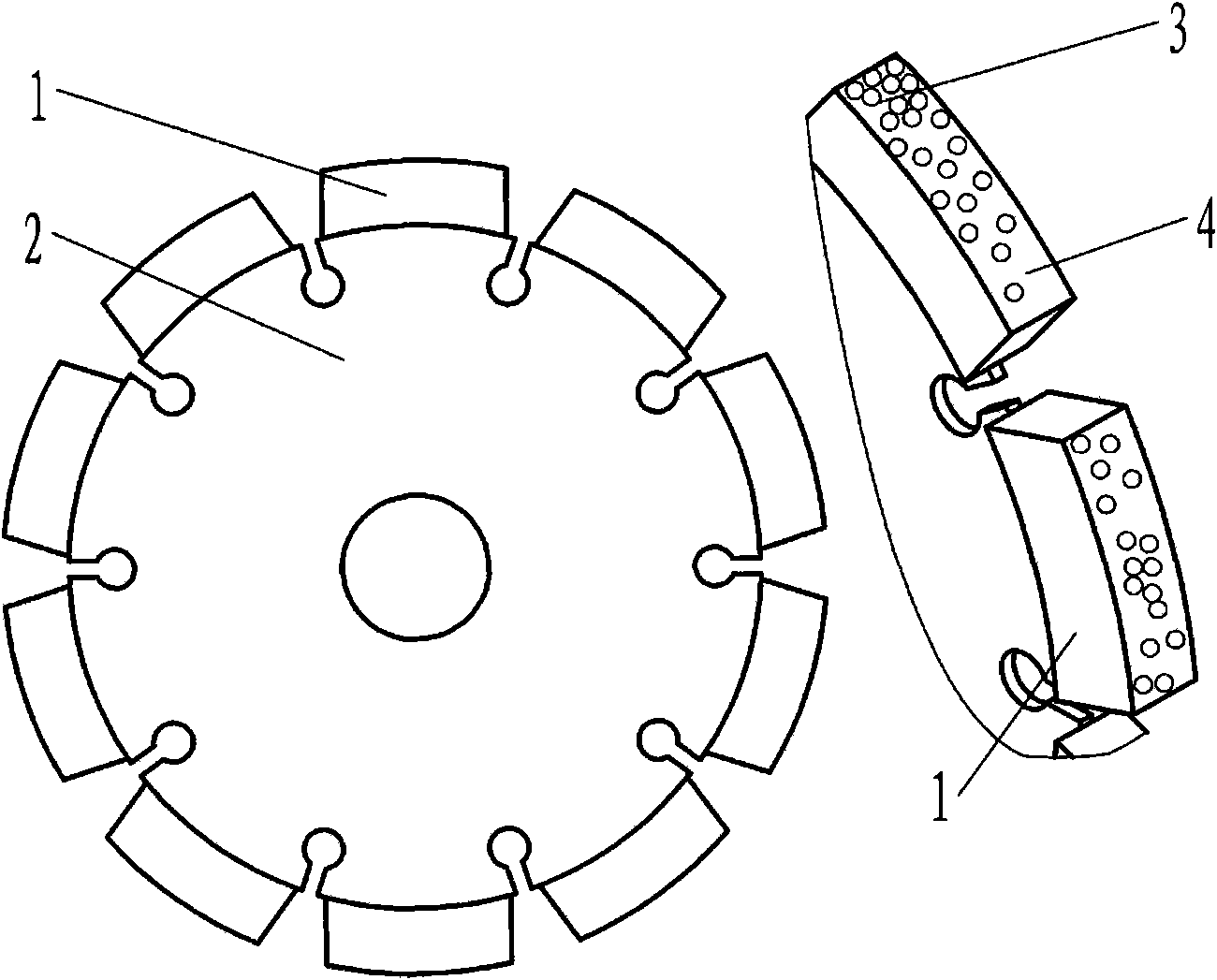

[0044] In traditional diamond tools, diamonds are randomly distributed in the cutter head, such as figure 1 As shown, the effective utilization rate of such diamonds is very low, which limits the improvement of tool sharpness and life. An effective way to increase the cutting speed of the tool and obtain high cutting life at the same time is to realize the directional and orderly arrangement of diamonds in the cutter head. The object of the present invention is to provide a method for properly arranging diamonds in the three-dimensional space of the diamond cutter head with high efficiency and low cost. The present invention will be described in detail with reference to the accompanying drawings.

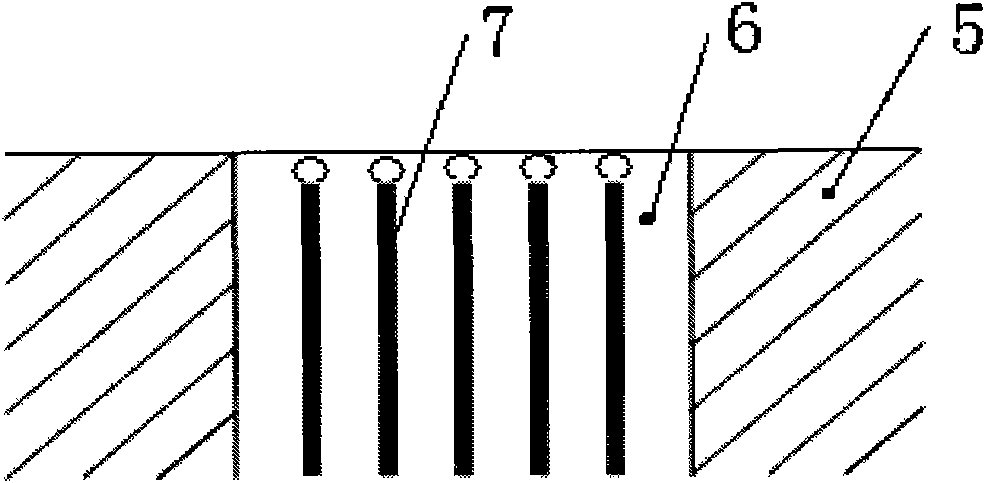

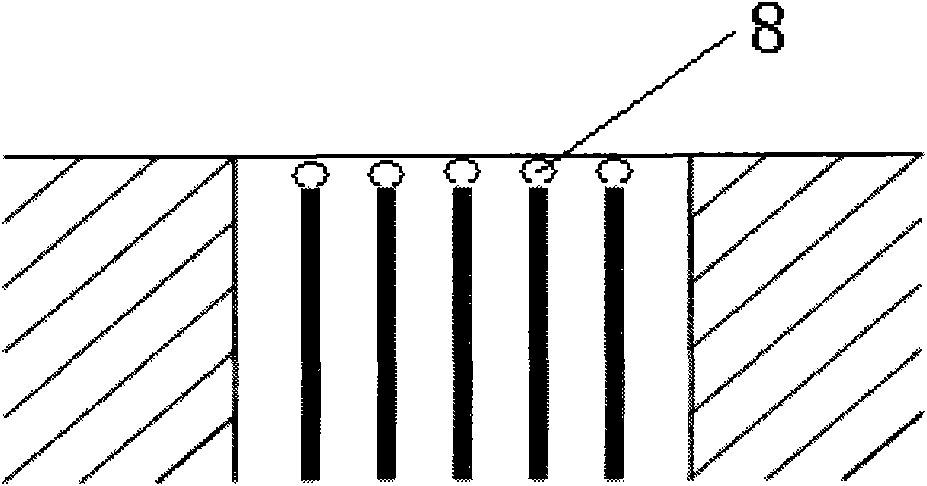

[0045] The present invention obtains the orientation and orderly arrangement of diamonds in three-dimensional space by pressing a single layer of diamonds in which the cutter h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com