Coated tip for processing aluminum materials and preparation method thereof

A technology of coating inserts and coatings, applied in metal processing equipment, tools for lathes, turning equipment, etc., can solve the problem of difficult to find coated inserts, and achieve the effect of shortening polishing time and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

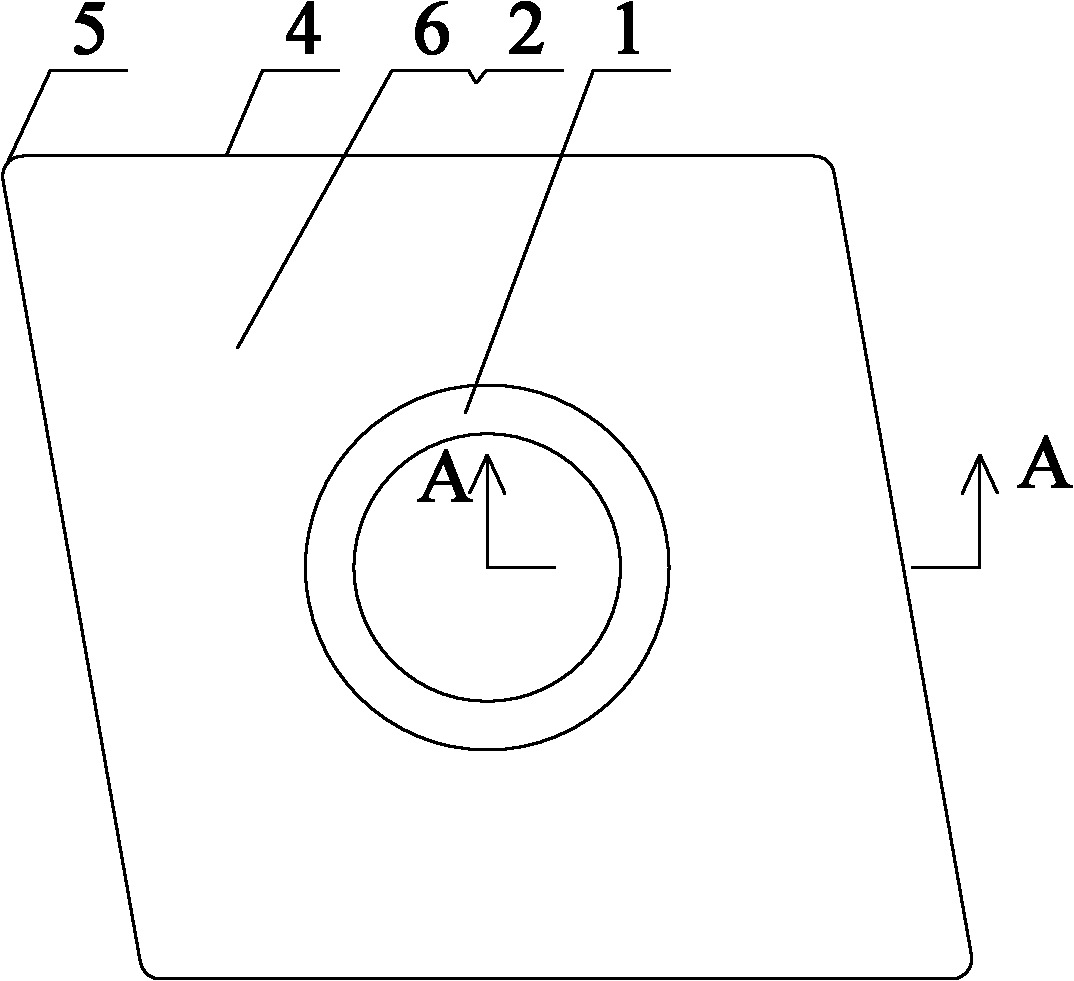

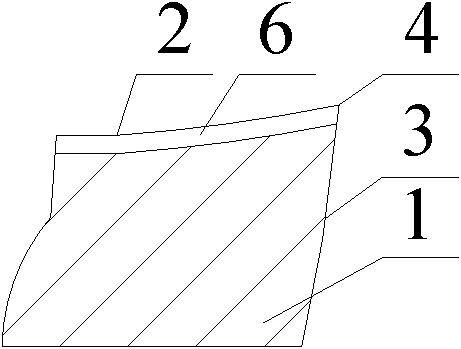

[0023] a kind of like Figure 2 ~ Figure 3 The shown coated insert for processing aluminum of the present invention comprises a hard alloy substrate 1 in an approximate cuboid shape, and the cemented carbide substrate 1 is provided with a rake face 2 (i.e. a top surface) positioned at its top. ) and the flank 3 (that is, the four sides) on its side, the rake face 2 intersects with each flank 3 to form an edge 4, which is linear without passivation treatment The extended sharp edge, the rake face 2 and any two adjacent flank faces 3 intersect to form a tip 5, the rake face 2 is coated with a polished titanium nitride coating 6, and the coating thickness is 5 μm, The grain size is 20nm, the rake face 2 is golden yellow, the flank face 3 is a cemented carbide grinding surface formed after grinding, and the flank face 3 presents the true color of cemented carbide.

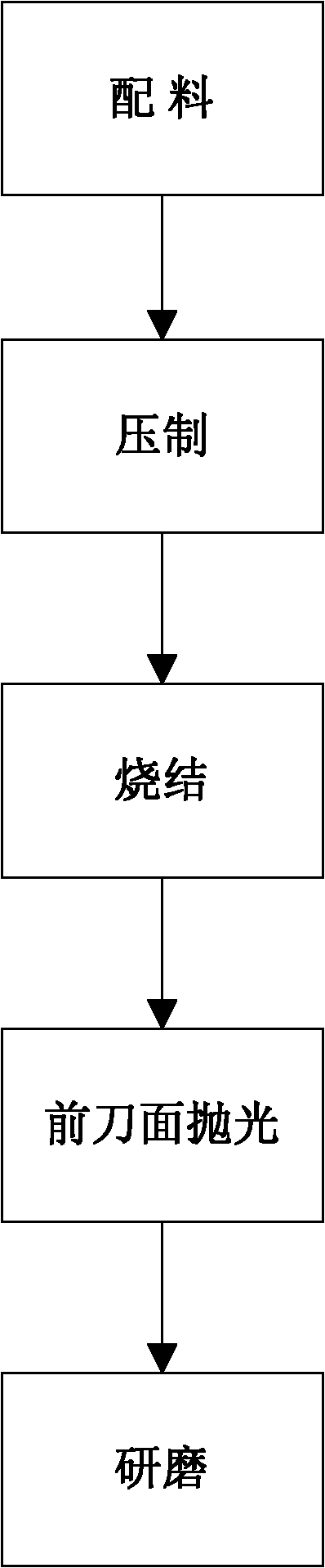

[0024] The technical process of the coating blade preparation method for processing aluminum in this embodiment is ...

Embodiment 2

[0030] A coated blade for processing aluminum of the present invention, the coated blade comprises a nearly cuboid-shaped cemented carbide substrate, the cemented carbide substrate is provided with a rake face (i.e. a top surface) at its top and a The flank flank (that is, the four sides), the rake face and each flank intersect to form an edge, which is a sharp edge that extends linearly without passivation treatment, and the rake face It intersects with any adjacent two flanks to form a tool tip. The rake face is coated with a polished titanium boride coating. The thickness of the coating is 4.5 μm and the grain size is 24nm. The rake face is gray. The cutter face is a cemented carbide grinding surface formed after grinding, and the flank face presents the true color of cemented carbide.

[0031] The technical process of the coating blade preparation method for processing aluminum in this embodiment is as follows Figure 4 As shown, it includes batching, pressing, sintering,...

Embodiment 3

[0037] A coated blade for processing aluminum of the present invention, the coated blade comprises a nearly cuboid-shaped cemented carbide substrate, the cemented carbide substrate is provided with a rake face (i.e. a top surface) at its top and a The flank flank (that is, the four sides), the rake face and each flank intersect to form an edge, which is a sharp edge that extends linearly without passivation treatment, and the rake face It intersects with any adjacent two flank faces to form a tool tip. The rake face is coated with a polished composite coating of titanium nitride and titanium boride. The total thickness of the composite coating is 12 μm, and the grain size of titanium nitride is The thickness is 22nm, the thickness is 5μm as the surface layer, and the titanium boride is used as the bottom layer, the thickness is 7μm, the grain size is 26nm, the rake surface is golden yellow, the flank surface is the grinding surface formed after grinding, and the flank surface a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com