Antiloading composition for an abrasive article and abrasive article having an antiloading coating

A technology of abrasive products and compositions, applied in coatings, abrasives, manufacturing tools, etc., can solve the problems of cutting ability and performance degradation of abrasive products, achieve the effect of reducing peeling and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

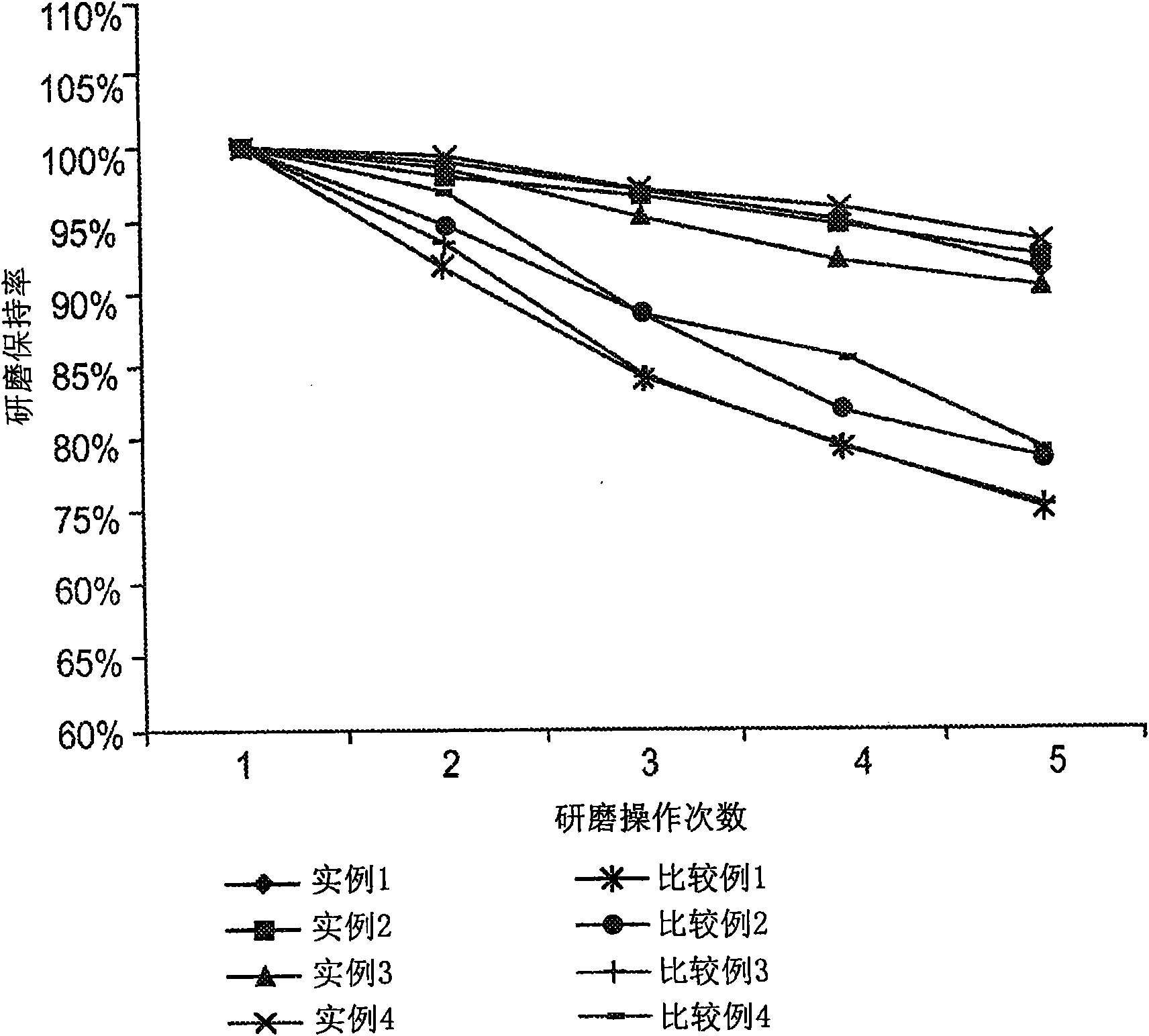

Examples

example 1

[0039] Method of making anti-fill composition

[0040] Calcium 12-hydroxystearate ("CS-6", manufactured by NITTO CHEMICAL INDUSTRY CO.LTD., solid content: 30%) and methylcellulose ("Metolose SM-15", manufactured by SHIN-ETSU CHEMICAL CO.LTD. manufactured, solid content: 8%) was mixed with water and dispersed with a stirrer at 500 rpm for 30 minutes to obtain an anti-caking composition.

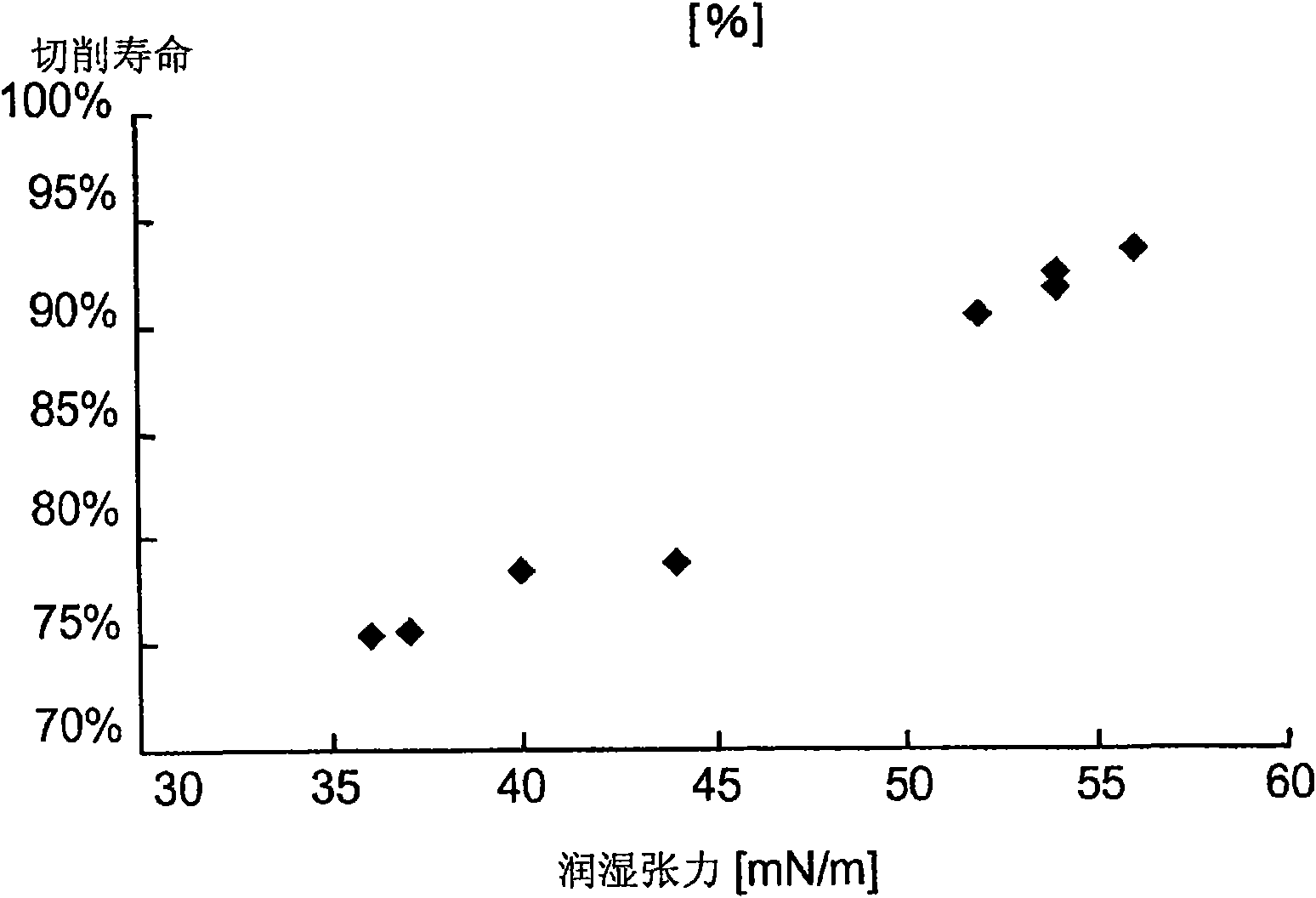

[0041] Measurement of wetting tension

[0042] The wetting tension of the coating formed from the obtained anti-filling composition was measured according to JIS K 6768 "Test Method for Wetting Tension of Plastic, Film and Sheet (Method for Determination of Wetting Tension of Plastics, Films, and Sheets)", JIS K The disclosure of 6768 is incorporated herein by reference. Accordingly, the film thickness of the anti-fill coating was measured to be 35 micrometers (μm). In addition, the coating amount and suitable drying conditions of the anti-caking composition are determined according to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wetting tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com