Cutting tool with coating

A cutting tool and coating technology, applied in the field of coated cutting tools, can solve problems such as weak bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

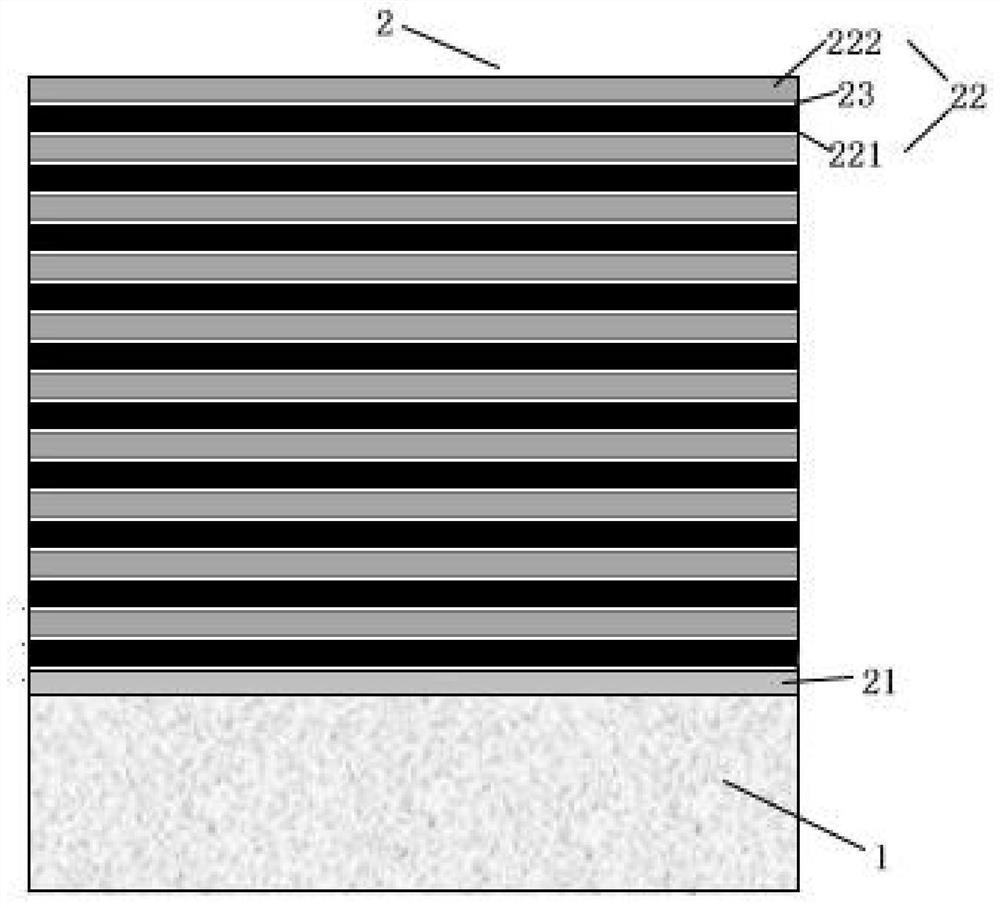

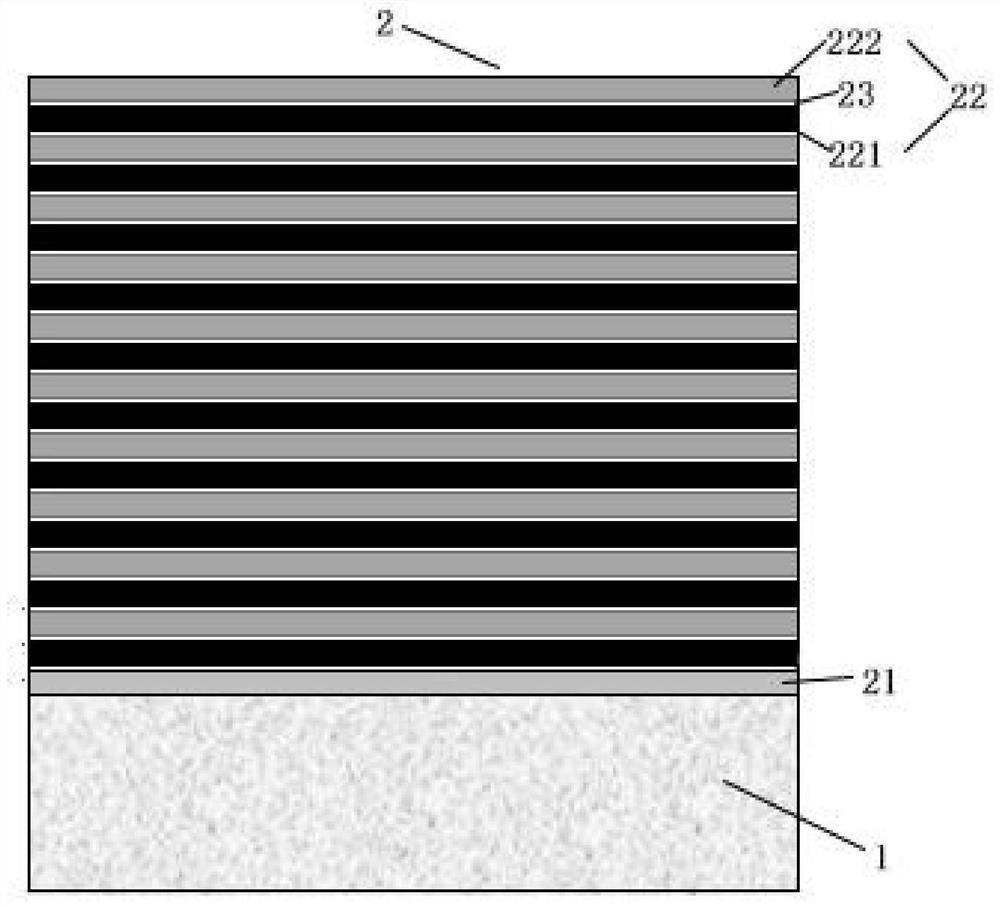

[0027] A multi-layer wear-resistant coating 2 with a total thickness of 20 μm was coated on the cemented carbide indexable insert SNGX1206ANN-MM4 as the substrate by CVD technology.

[0028] The cemented carbide composition is 12% Co, 1.5% cubic carbide and the balance WC.

[0029] The multilayer wear-resistant coating 2 sequentially includes from the inside to the outside: at least one layer of titanium compound layer 21 and at least one layer of periodic coating 22, and the periodic coating 22 is formed by alternate deposition of AlTiN layer 221 and AlTiSiN layer 222, repeating the cycle for 12. The coating surface roughness of the multi-layer wear-resistant coating 2 is Ra≤0.2 μm.

[0030] The titanium compound layer 21 is prepared by CVD technology, and the titanium compound layer 21 constitutes the first hard layer adjacent to the cemented carbide substrate 1 . The titanium compound layer 21 is made of one or more of TiN, TiC, and TiCN, preferably TiN, and has a thickne...

Embodiment 2

[0036] A multi-layer wear-resistant coating 2 with a total thickness of 0.5 μm was coated on the cemented carbide indexable insert SNGX1206ANN-MM4 by CVD technology.

[0037] The cemented carbide composition is 12.5% Co, 1.2% cubic carbide and the balance WC.

[0038] The repetition period of the periodic coating 22 is 8, and the coating surface roughness of the multilayer wear-resistant coating 2 is Ra≤0.1.5 μm.

[0039] The titanium compound layer 21 is prepared by CVD technology, and the titanium compound layer 21 is made of TiN with a thickness of 0.05 μm.

[0040] The composition of the AlTiN layer 221 is Ti 0.96 al 0.04 N, the thickness is 0.2μm, and the nanohardness is greater than 35GPa. AlTiN coating was prepared by CVD technology, at 700°C, 4mbar pressure, using 98.0at% hydrogen, 0.10at% TiCl 4 , 0.30at% AlCl 4 , 0.7at% NH 3 , the rest of the inert gas constitutes the gas mixture.

[0041] AlTiSiN layer 222 is Si x N y The amorphous-wrapped high-alumina fc...

Embodiment 3

[0045] A multi-layer wear-resistant coating 2 with a total thickness of 15 μm was coated on the cemented carbide indexable insert SNGX1206ANN-MM4 by CVD technology.

[0046] The cemented carbide composition is 11.5% Co, 1.7% cubic carbide and the balance WC.

[0047] The repetition period of the periodic coating 22 is 10, and the coating surface roughness of the multilayer wear-resistant coating 2 is Ra≤0.18 μm.

[0048] The titanium compound layer 21 is prepared by CVD technology, and the titanium compound layer 21 is made of TiN with a thickness of 0.1 μm.

[0049] The composition of the AlTiN layer 221 is Ti 0.83 al 0.17 N, the thickness is 0.2μm, and the nanohardness is greater than 35GPa. The AlTiN layer 221 has a face-centered cubic (FCC) crystal structure and crystal growth assumes a (111) direction. AlTiN coating was prepared by CVD technology, at 800°C, 4mbar pressure, using 96.0at% hydrogen, 0.13at% TiCl 4 , 0.35at% AlCl 4 , 0.8at% NH 3 , the rest of the inert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com