Machining method and tool for R groove in guide plate of marine diesel frame

A technology of marine diesel engine and processing method, applied in the direction of tools, manufacturing tools, metal processing equipment, etc. for lathes, can solve the problems of insufficient quality assurance, poor workpiece quality, low processing efficiency, etc., to improve processing efficiency and ensure processing. Quality, the effect of extending cutting life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the drawings and embodiments, but the protection scope of the present invention should not be limited accordingly.

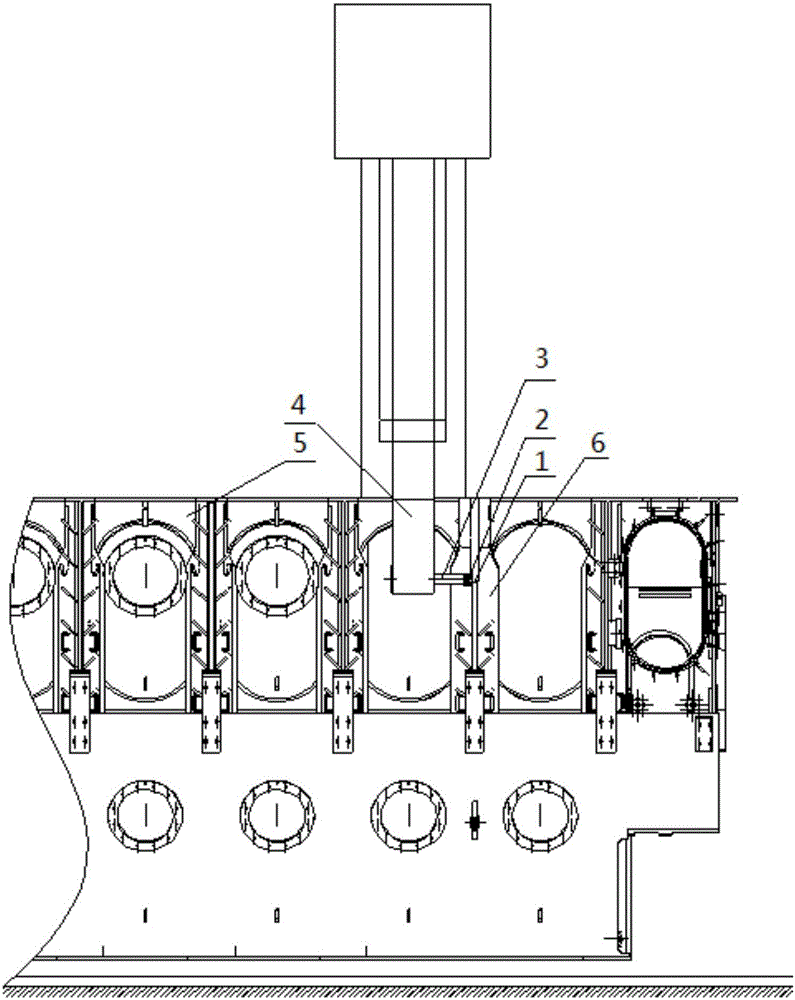

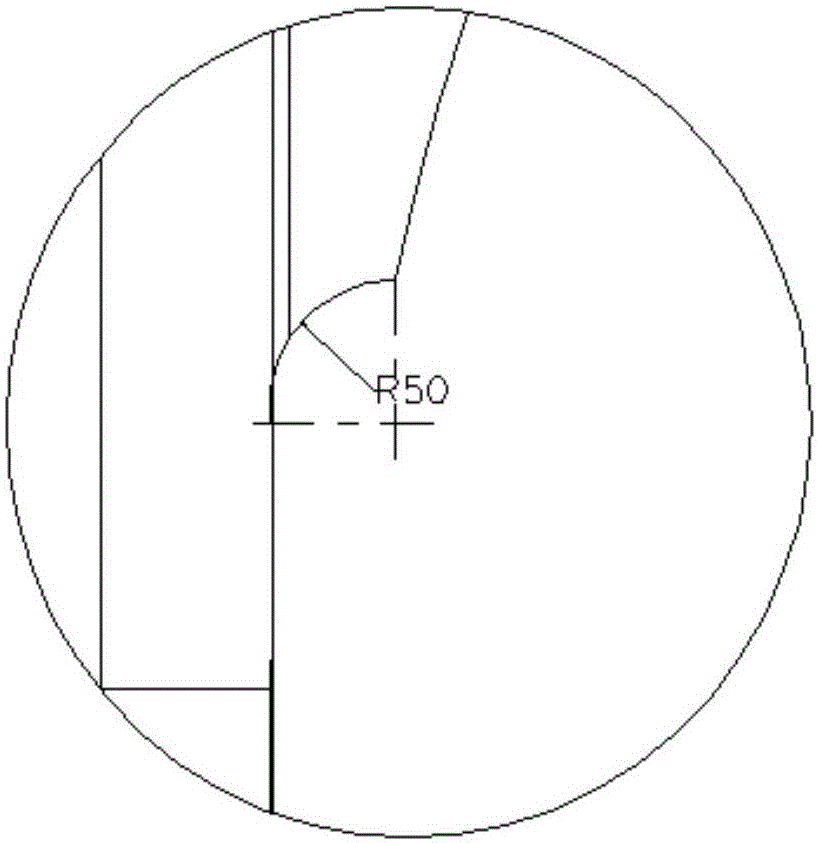

[0026] The present invention proposes a processing method for the R groove of the guide plate of the marine diesel engine frame, please refer to figure 1 with figure 2 , on the CNC gantry milling machine, the boring and milling compound tool 2 is installed on the anti-vibration handle 3, and the anti-vibration tool handle 3 is connected to the power spindle attachment 4, and the boring and milling compound tool 2 is controlled radially and Axial feed to complete the automatic cutting process of the R groove 1.

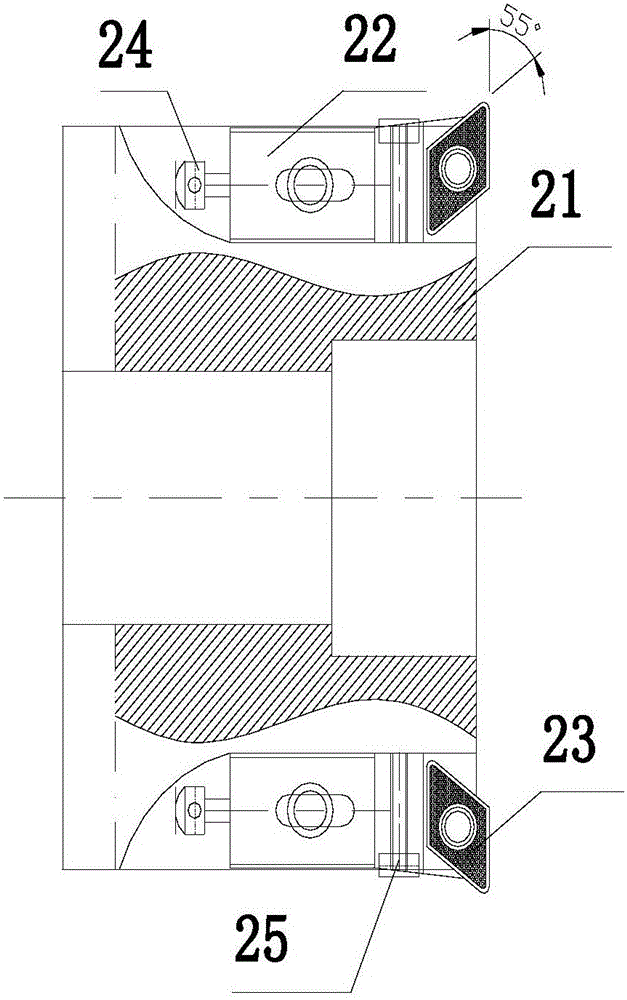

[0027] Please refer to image 3 with Figure 4 , the boring and milling compound tool 2 includes a cutter body 21 and several tool holders 22 and blades 23; On the clamp 22, the knife clamp 22 is provided with adjusting screws 24 and 25, which are used to adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com