Medium deep hole presplitting blasting mining method of steeply inclined thin-to-ultrathin-lode ore body

A pre-split blasting, steep tilting technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of endangering safety, poor ore output, and non-releasing, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

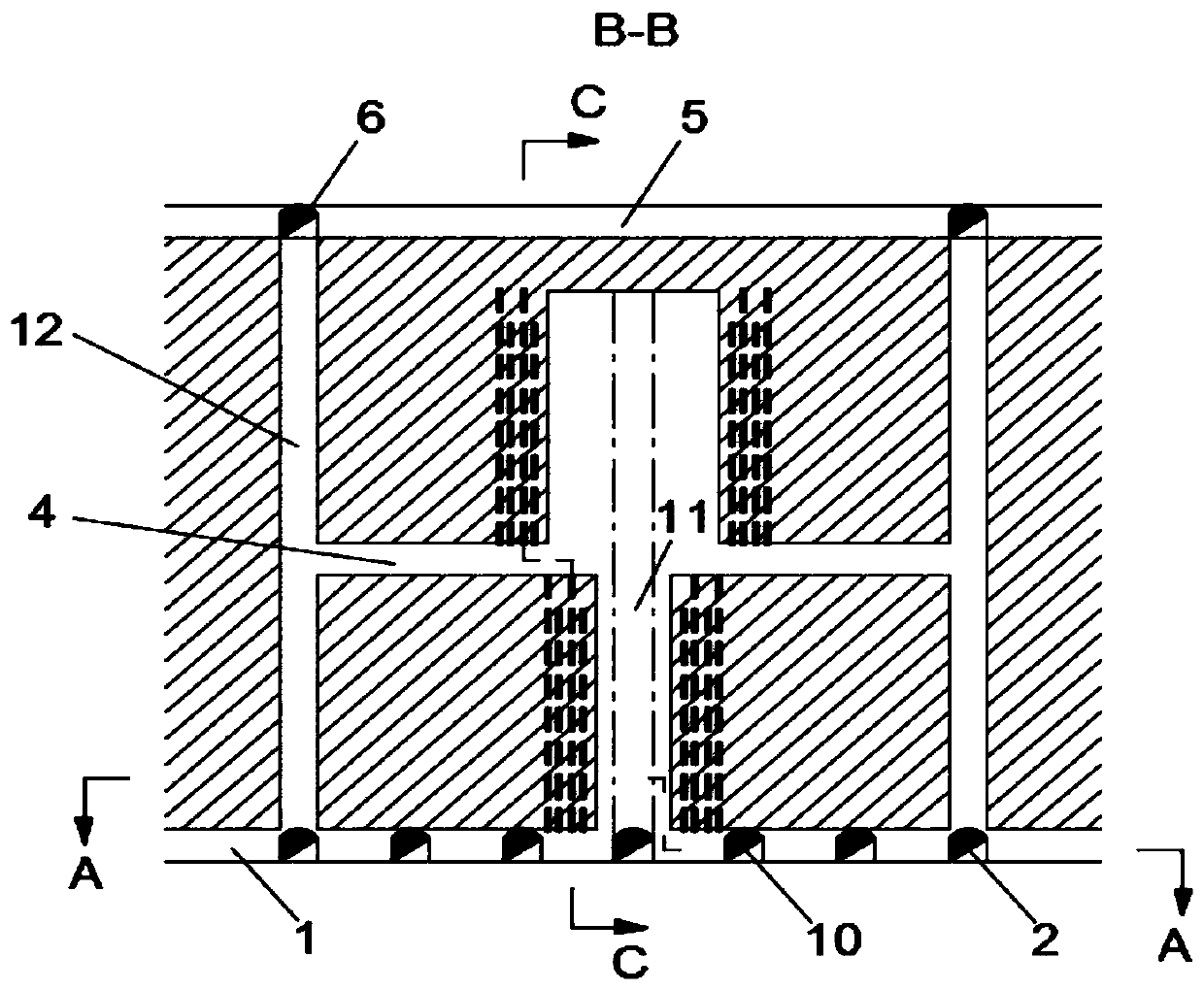

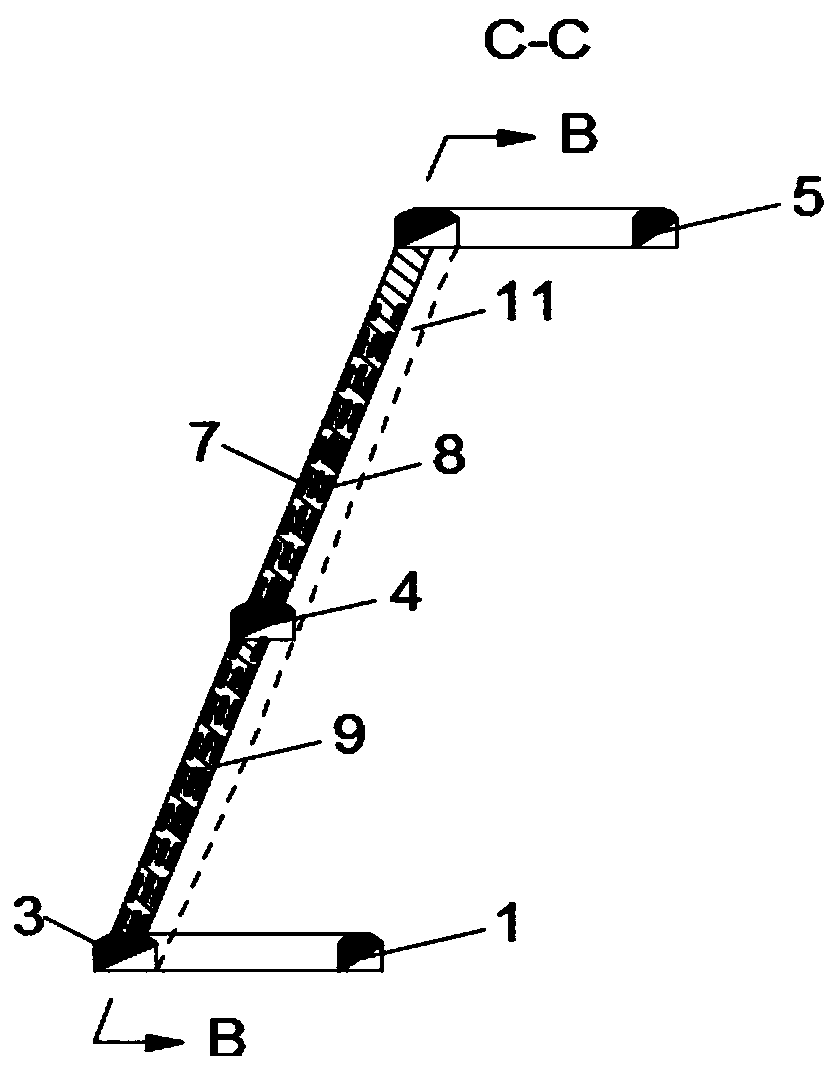

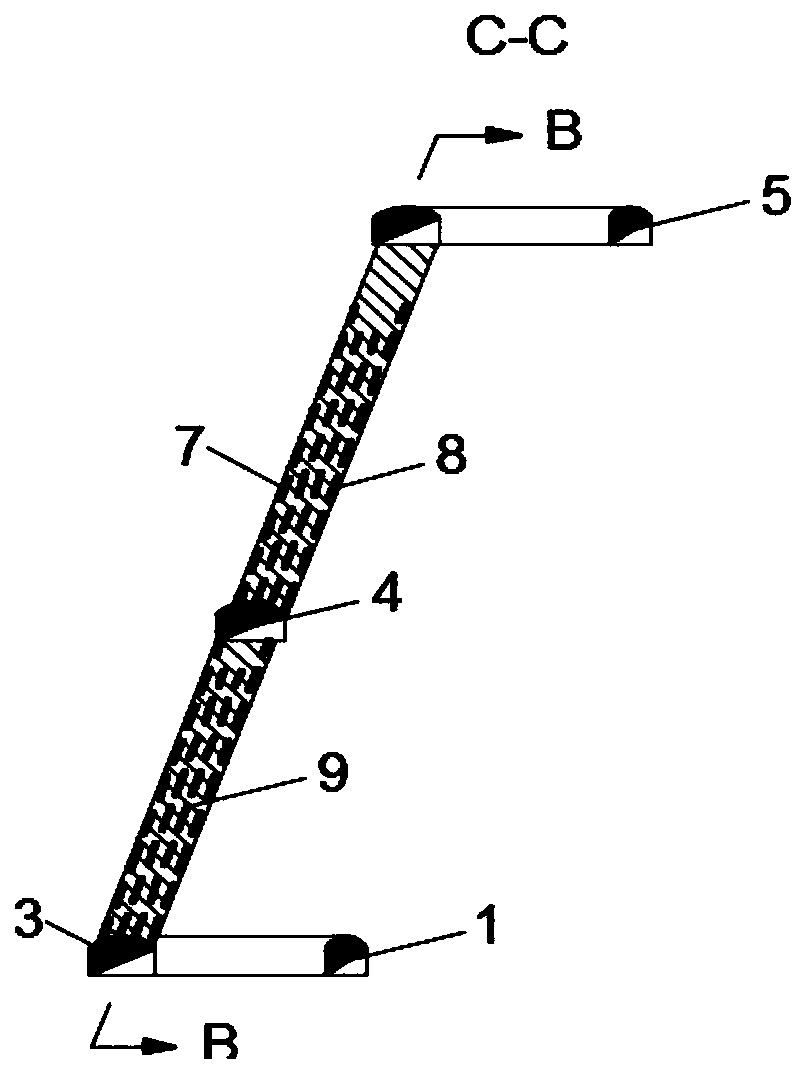

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, the medium and deep hole pre-splitting blasting mining method of steeply inclined thin vein to extremely thin vein ore body of the present invention, main steps are as follows:

[0021] Firstly, excavate the bottom-drawing roadway 3 along the vein and the stratified rock drilling roadway 4 in the vein along the strike in the ore body vein similar to the mine house method in the stage, and excavate the flat-bottomed structure at an interval of 8m in the vertical direction to excavate the ore and penetrate the vein 10 . The bottom-drawing roadway 3 and the layered rock drilling roadway 4 fully expose the boundary line between the upper and lower wall roof surrounding rocks of the ore vein and the ore body, so as to drill along the boundary line to predict the ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com