Sublevel open-stoping mining method with subsequent backfilling for long-hole caving in thin ore bodies

A technology for backfill mining and thin ore body, which is applied in the fields of backfill, surface mining, mining equipment, etc., and can solve the problems of surrounding rock fragmentation, increased ore dilution loss, and low safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

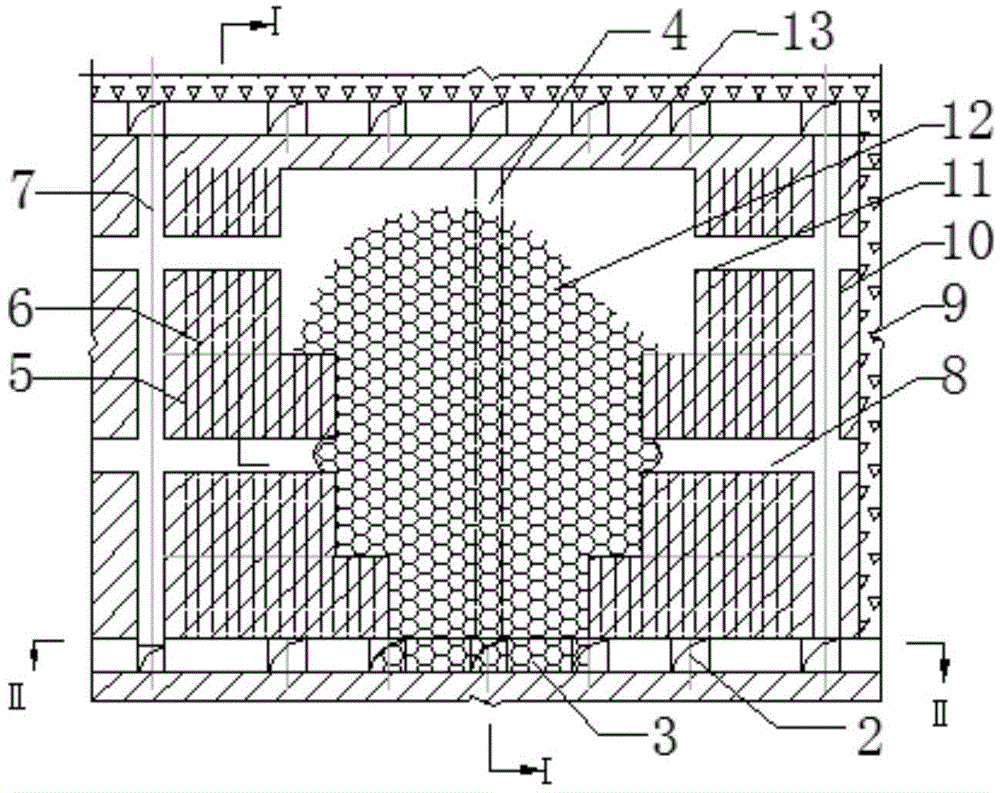

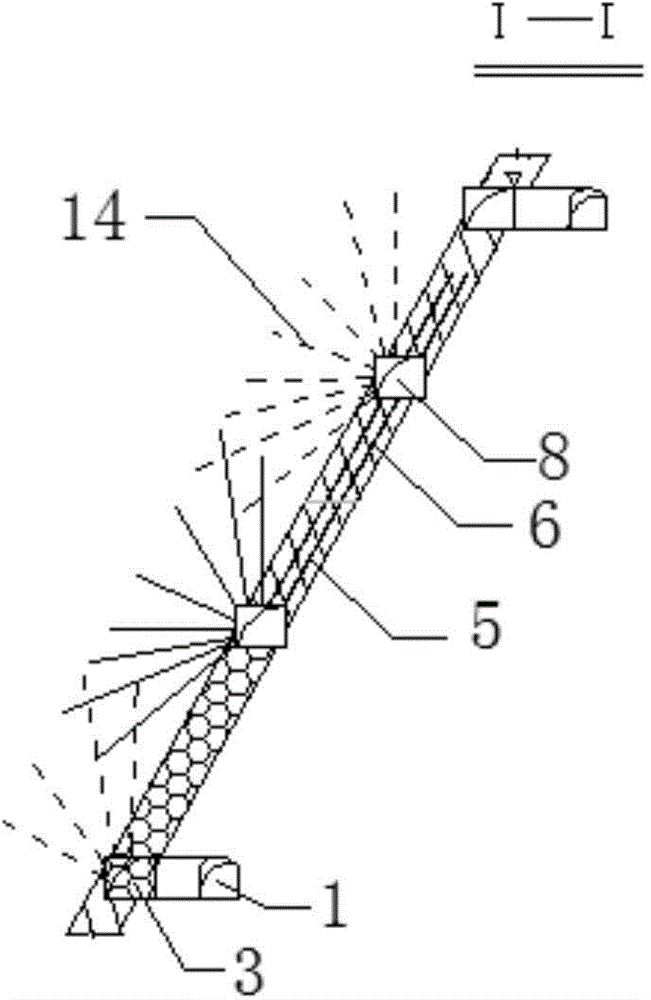

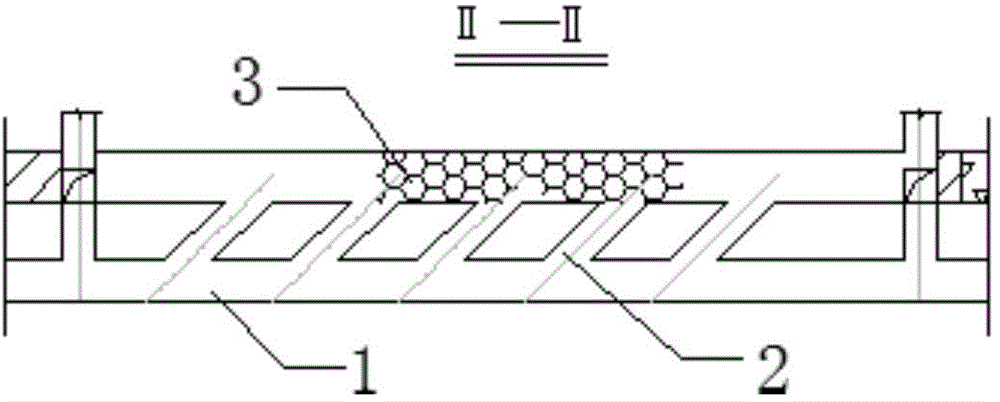

[0034] The XX gold deposit is a fine-grained epithermal gold deposit of medium-low temperature. The dip angle of the ore body is 50°-56°, and the average thickness is 4.32m. The surrounding rocks of the roof and floor are mainly siltstone and mudstone, and the overall stability of the ore rock is poor. Originally, the method of mining with shallow holes was adopted, and then the method of mining with middle and deep hole collapsed in sections and then filled was adopted. The ore block is arranged along the strike, the length of the ore block is 50m, and the width is the thickness of the ore body; the height of the stage is 40m, divided into 3 sections along the vertical direction, and the section height is 10-15m; Drill upward parallel (or fan-shaped) medium-deep holes, drill upward parallel (or fan-shaped) medium-deep holes from the segmented rock drilling level entry, and downward parallel (or fan-shaped) medium-deep holes, the hole depth is 8-15m, the hole diameter is 65m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com