Method and system for controlling power consumption during a rock drilling process and a rock drilling apparatus therefore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

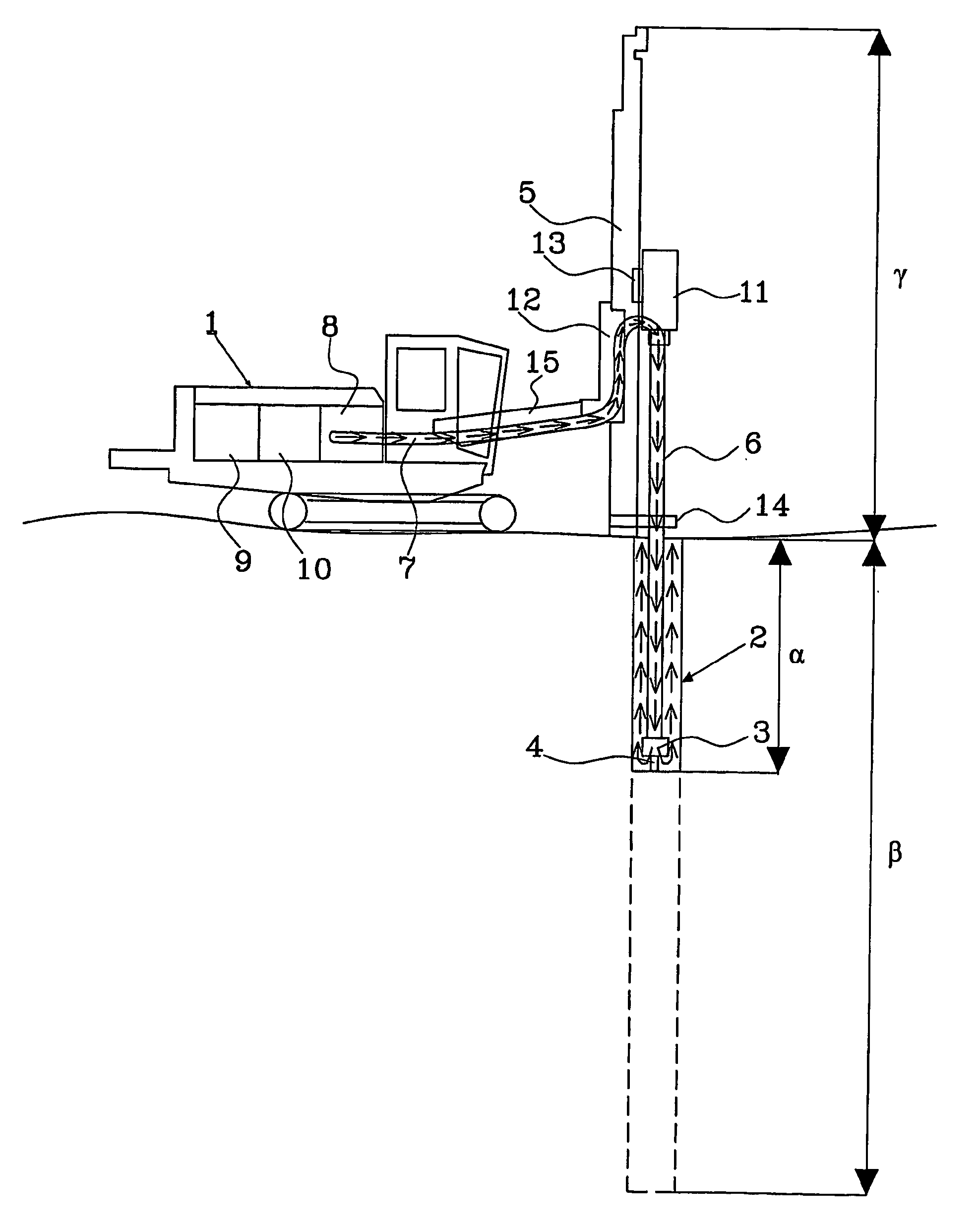

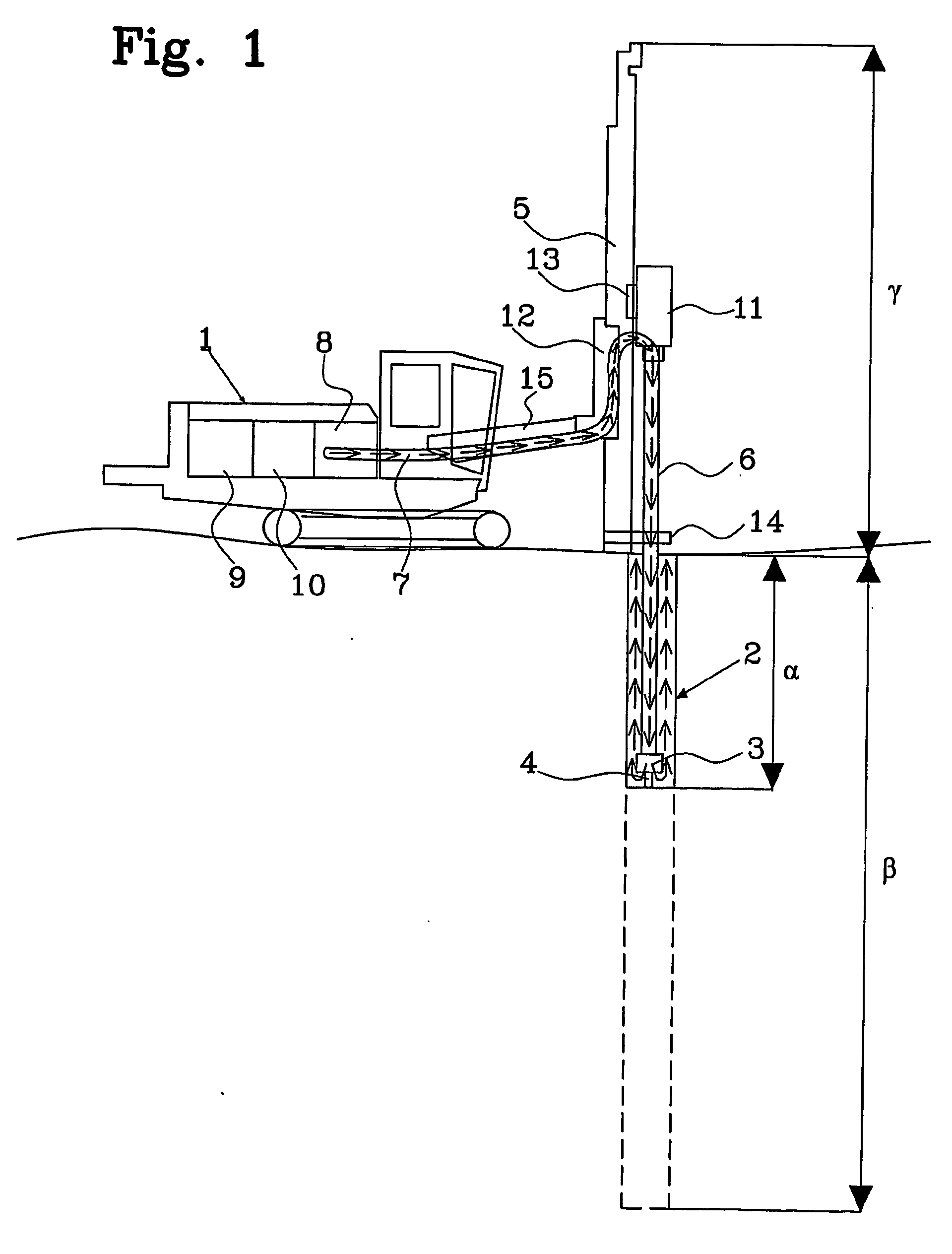

[0023]FIG. 1 depicts an exemplary rock drilling apparatus according to the present invention. In the figure is shown a rock drilling apparatus 1, in this exemplary a surface drill rig. The drill rig 1 is shown in use drilling a hole 2, starting from a ground level, at present having reached a depth α and destined to result in a hole of depth β, for example 30 meters, the finished hole being indicated by interrupted lines. (The shown relation of drill rig height / hole depth is not intended to be exact. The total height γ of the drill might for example be 10 meters.)

[0024] The drill rig 1 is provided with a top hammer 11 mounted via a rock drill cradle 13 on a feed 5. The feed 5 is attached to a boom 15 via a feed holder 12. The top hammer 11 provides percussive action to a drill tool 3 with one or more drill bits 4 via a drill rod 6 supported by a rod support 14. The top hammer 11 is power supplied from a hydraulic pump 10, driven by a diesel engine 9, via a conduit attached to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com