Multifunctional processing equipment for hollow glass

A processing equipment and multi-functional technology, applied in the field of multi-functional processing equipment, can solve the problems of affecting the drilling effect of glass, increase the working time, and increase the cutting cost, so as to improve practicability and flexibility, improve work efficiency, reduce The effect of handling and fixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

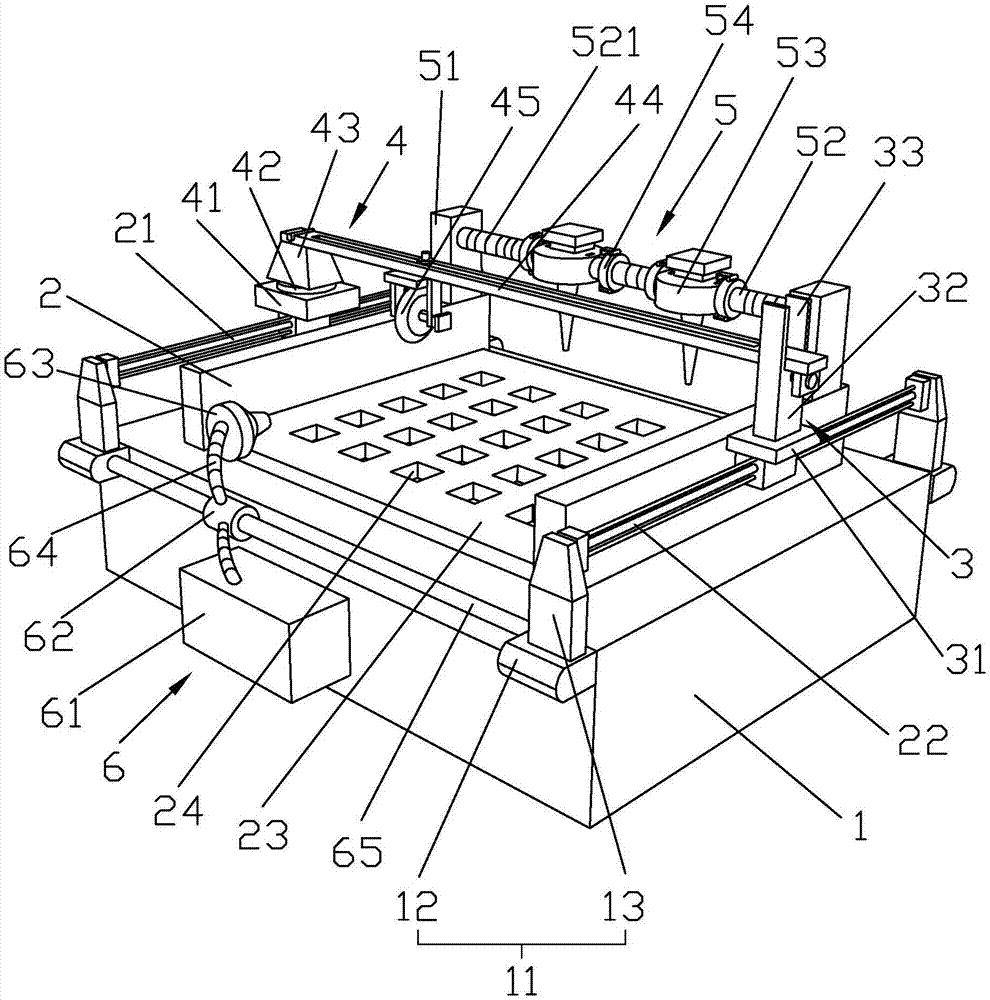

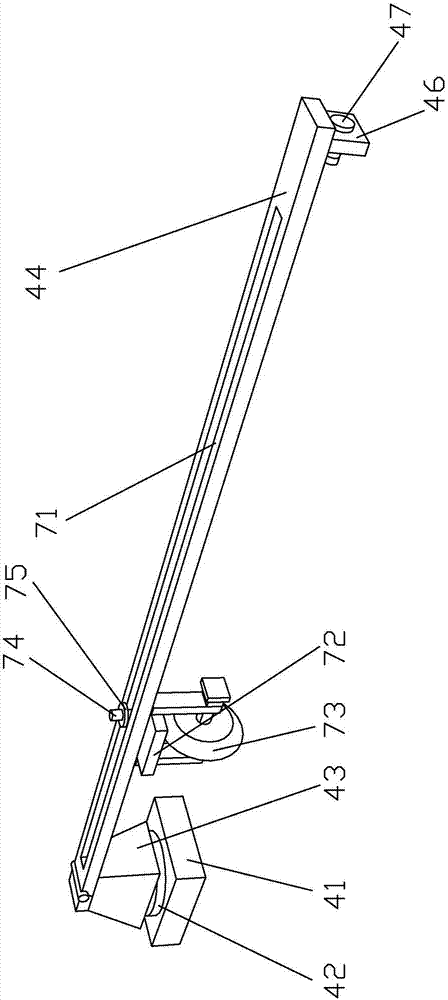

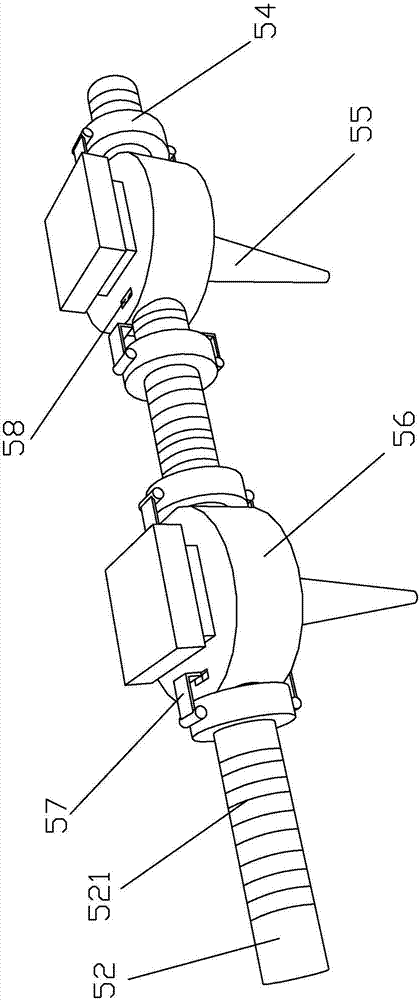

[0023] Such as Figure 1-3As shown, it is a multifunctional processing equipment for insulating glass of the present invention, including a machine base 1, a machine table 2, a first rodless cylinder 21, a second rodless cylinder 22, a cutting device 4 and a drilling device 5 , the cutting device 4 and the drilling device 5 are installed on the machine base 1 at the same time, so that the glass can be cut and drilled on the same machine 2 without changing the position, reducing the time and steps of handling and fixing, Improved work efficiency. The base 1 is provided with a mounting frame 11, and the first rodless cylinder 21 and the second rodless cylinder 22 are symmetrically installed on the left and right sides of the frame 1 through the mounting frame 11 respectively. On a peripheral angle, the mounting frame 11 includes a fixed base 12 and a support plate 13, the fixed base 12 is connected with the base 1, the support plate 13 is vertically arranged on the fixed base 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com