Air controlled multi-plane special-shaped foam no-die cutting mahcine

A die cutting machine and multi-plane technology, applied in metal processing and other directions, can solve the problems of inability to cut special-shaped foam, low production efficiency, and high production cost, and achieve the effects of easy operation, improved production efficiency, and avoidance of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

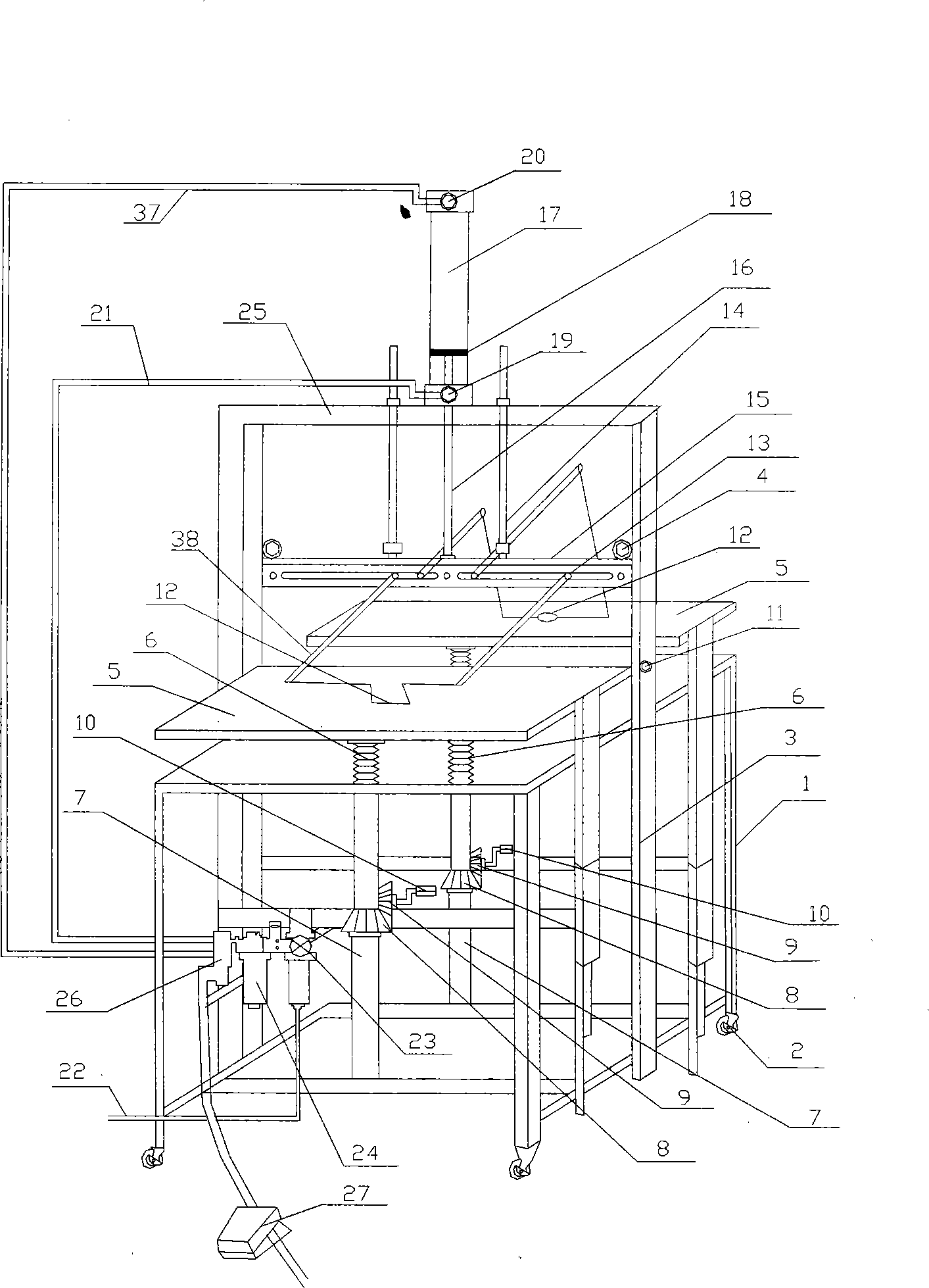

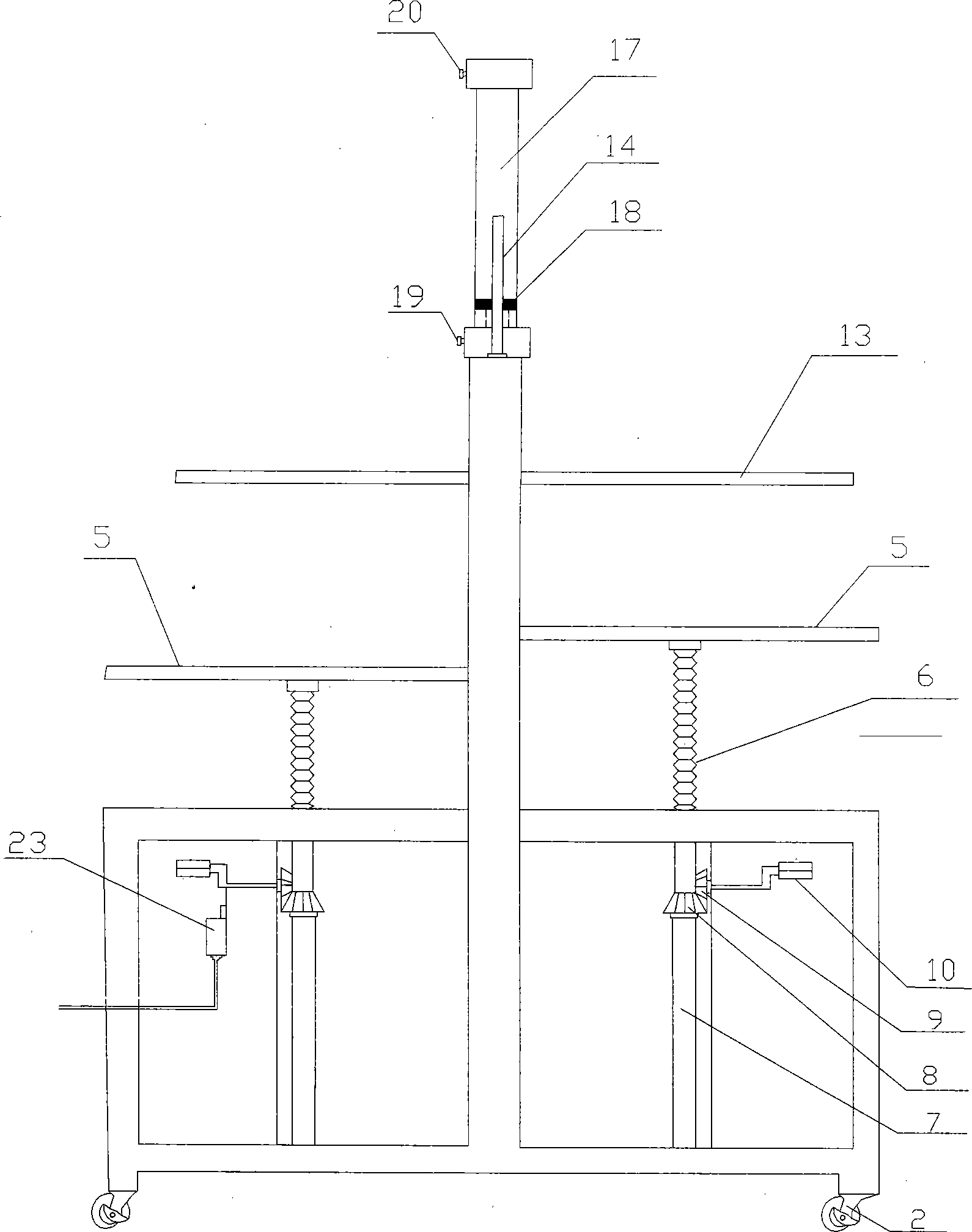

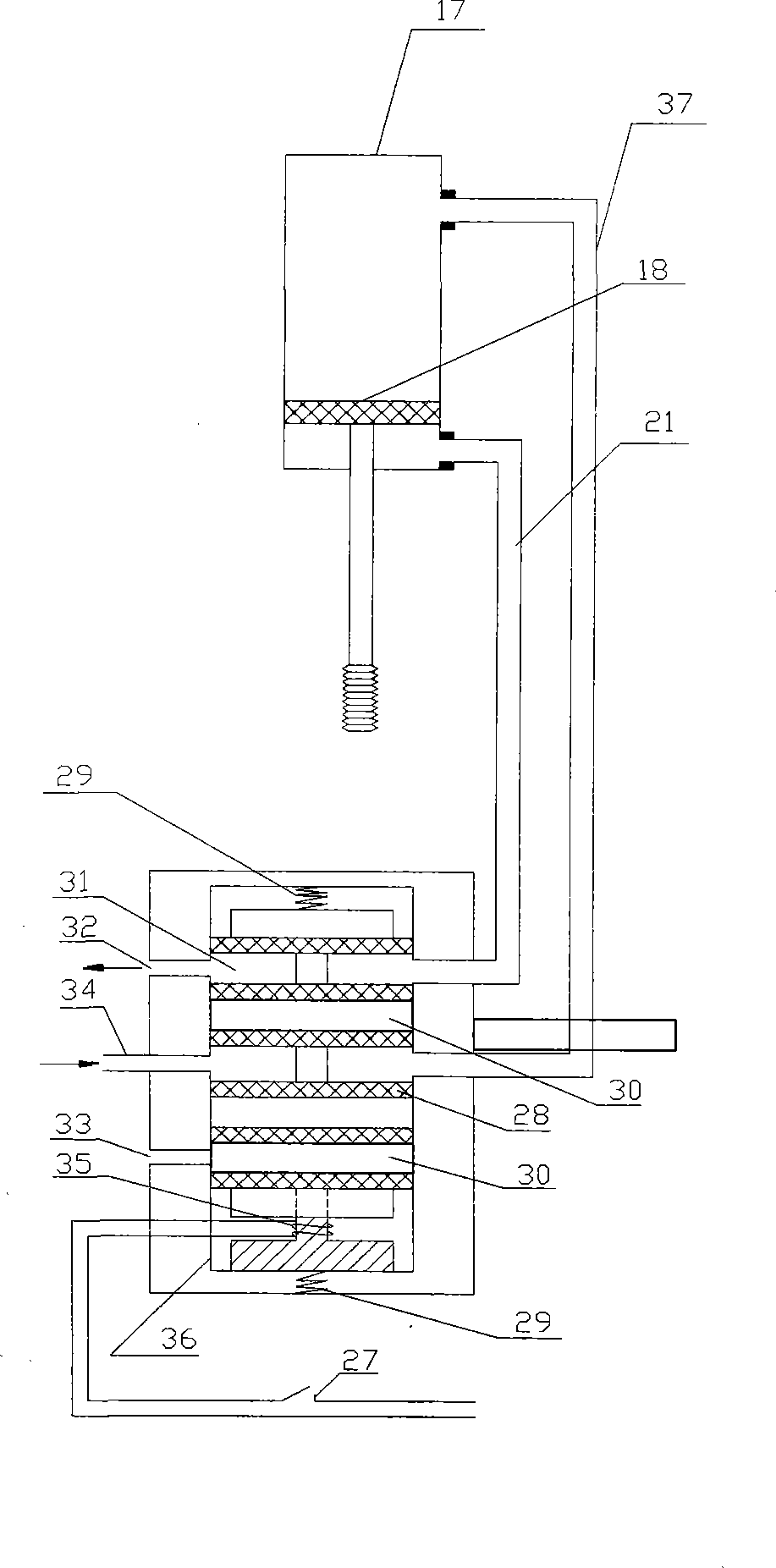

[0011] Below in conjunction with two plane embodiment drawings of the present invention, the present invention is described in detail:

[0012] exist figure 1 , figure 2 Among them, two independent worktables (5) are arranged on both sides of the track, and the center of the back of each worktable is provided with a lifting screw (6), a lifting coil (7), a driven bevel gear (8), Active bevel gear (9) lifting handle (10). Universal rollers (2) are installed on the bottom of the frame (1), and rails (3) are installed at the center of both sides of the frame (1), and the rail wheels (4) are fixed on the rail wheel linkage rod (15) , the insulating rod (13) is fixed under the rail wheel linkage rod (15), the heating wire (12) is installed under the insulating rod (13), and the cylinder (17) is fixed at the center of the cross arm (25) on the top of the track (3) place, the bottom end of the piston connecting rod (16) is fixed on the rail wheel linkage shaft (15), and is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com