Automatic pushing type soil pressure balance pipe jacking machine

An earth pressure balance and self-propelled technology, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of inability to adjust the cutting size of the cutter head and poor adaptability, and achieve the effect of expanding the cutting range and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

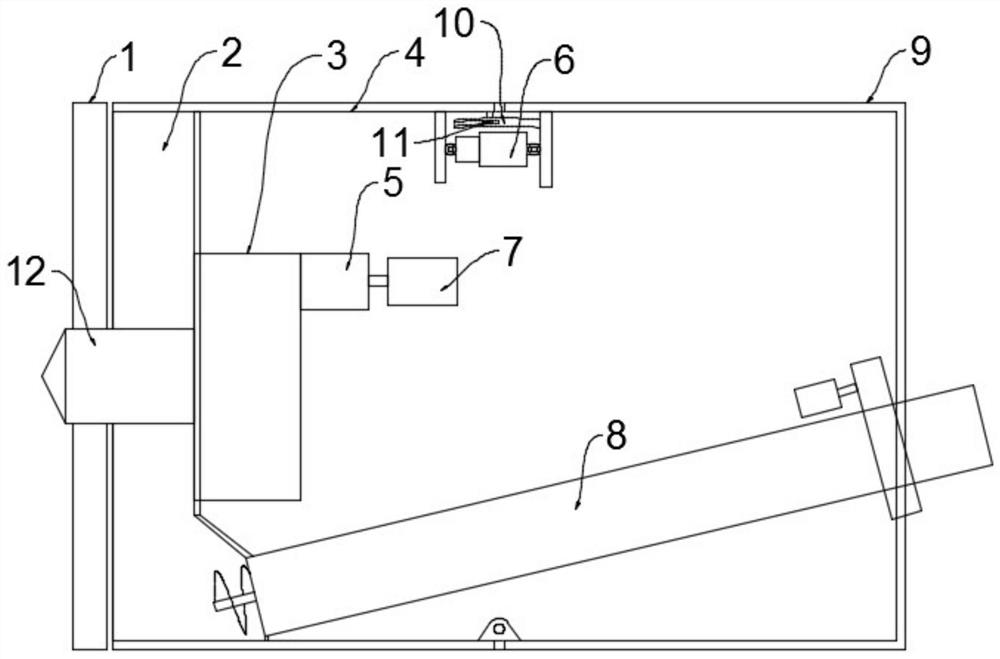

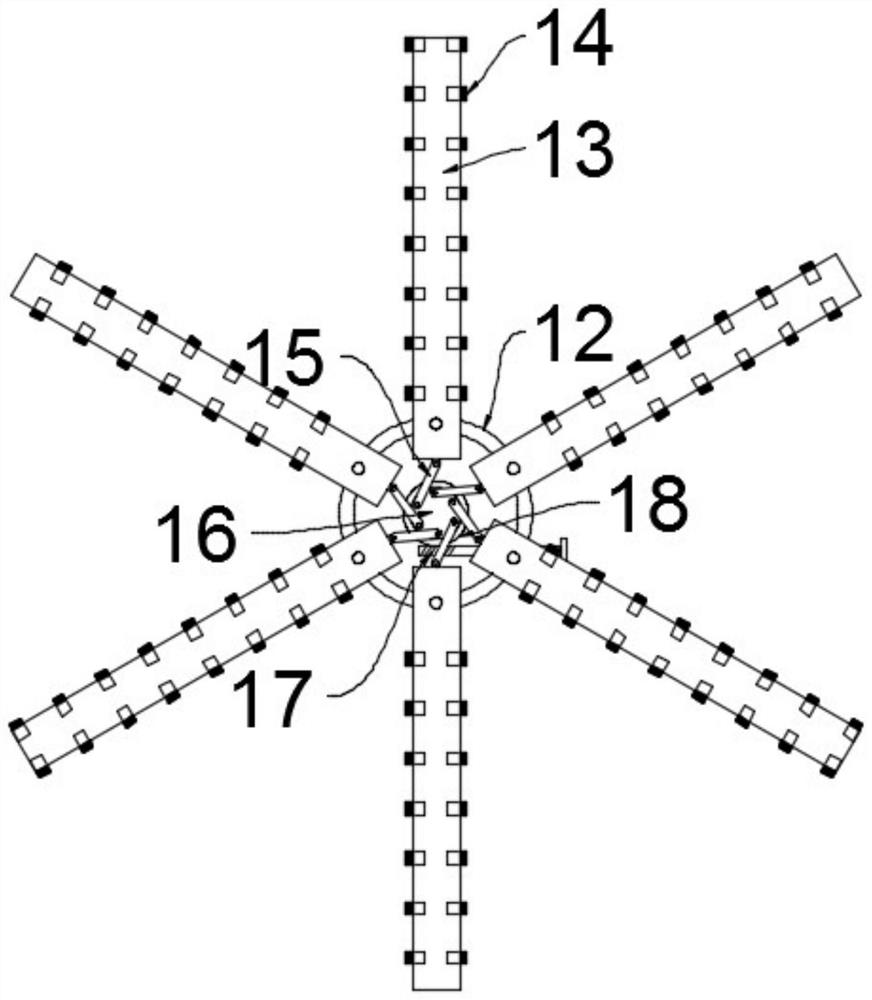

[0025] see Figure 1~2 , in an embodiment of the present invention, a self-propelled earth pressure balance pipe jacking machine includes an installation shell, a cutter head 1, a power unit that drives the cutter head 1 to rotate, and a delivery unit for outputting soil. The center of one end of the installation shell A main shaft 12 is installed for rotation, and the main shaft 12 is located on the shaft section outside the installation shell, and a plurality of cutter heads 1 are fixedly installed in the circumferential direction at equal intervals. The cutter head 1 includes a mounting plate 13 and two groups of tools installed symmetrically and equidistantly on the mounting plate 13. 14. Further, the cutter 14 of the adjacent cutter head 1 is misplaced to expand the effective cutting area. The power unit is installed in the installation shell and driven to connect the main shaft 12. The power unit includes a cutter head drive motor 7, a planetary reducer 5 and The power b...

Embodiment 2

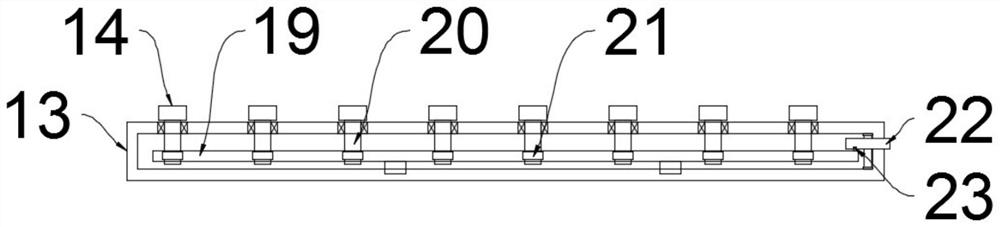

[0029] see Figure 3-5The difference between the embodiment of the present invention and embodiment 1 is that, further, since the cutters 14 are installed at intervals, the effective cutting area when the cutter head 1 rotates is smaller, and the mounting plate 13 is provided with a mounting cavity The end of the mounting plate 13 away from the main shaft 12 is rotated with a roller 22, the roller 22 is in contact with the soil, and the friction between the soil and the roller 22 makes the roller 22 rotate when the cutter head 1 rotates. Install the installation shaft 20 of the tool 14, the installation shaft 20 runs through the installation plate 13 and extends to the outside of the installation plate 13, the end of the installation shaft 20 located outside the installation plate 13 is detachably mounted with the tool 14, and the installation shaft 20 is fixedly equipped with a gear 21. There is a double-sided rack 19 between the front and rear symmetrical two sets of install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com