Adjustable track automatic gas cutting machine

A gas cutting machine, adjustable technology, applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of slag hanging, poor stability, uneven cutting edge, etc., achieve automatic stable feeding, and improve cutting quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

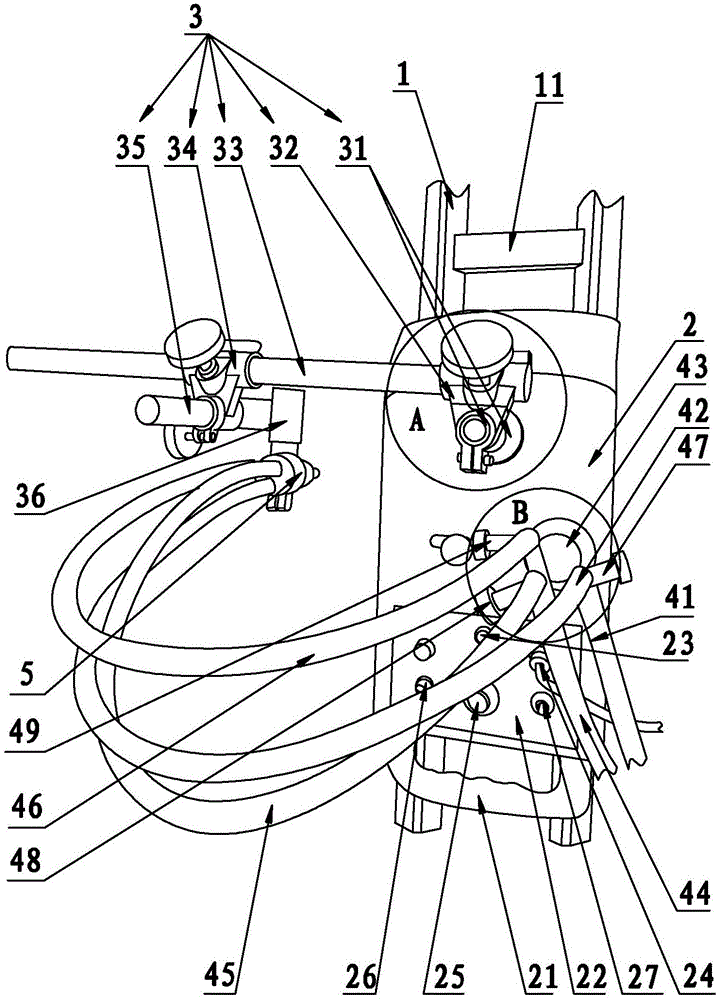

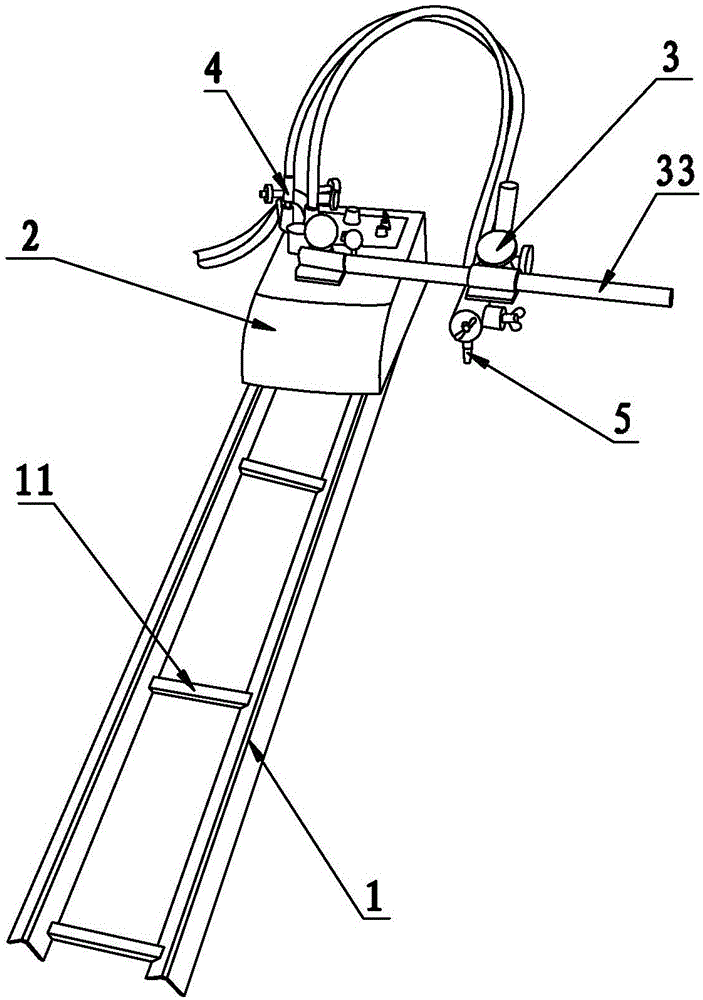

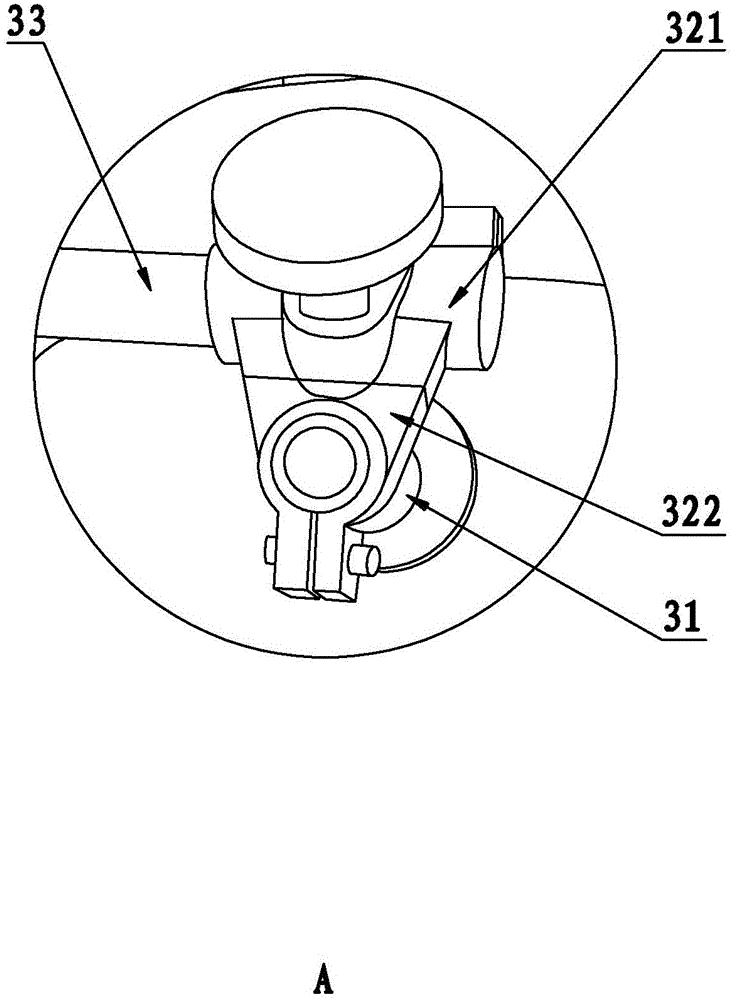

[0032] Such as Figure 1-4 As shown, an adjustable track automatic gas cutting machine includes a guide rail 1, a gas cutting machine body 2, an adjustment mechanism 3, an air intake control mechanism 4 and a gas cutting nozzle 5, two guide rails 1 are arranged side by side on the left and right, and the two guide rails A connector 11 is fixedly installed in one room, and the structure of the cross section of the guide rail 1 is triangular;

[0033] The bottom of the gas cutting machine body 2 is equipped with rollers that are compatible with the two guide rails 1, and drive shafts are installed between the left and right side-by-side rollers, and a driving device is connected between the front and rear two drive shafts; The rear end of machine body 2 is fixedly installed with a handle 21, and the rear portion of described gas cutting machine body 2 top surface is equipped with controller 22, and indicator light 23, power cord 24, regulator are installed on the control panel o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com