Automatic focus numerical control laser cutter

A digitally controlled laser and automatic focusing technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of limited cutting range of plates, small adjustable focus, and low accuracy, so as to improve stability and Accuracy, expanded cutting range, stable and high-precision focusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

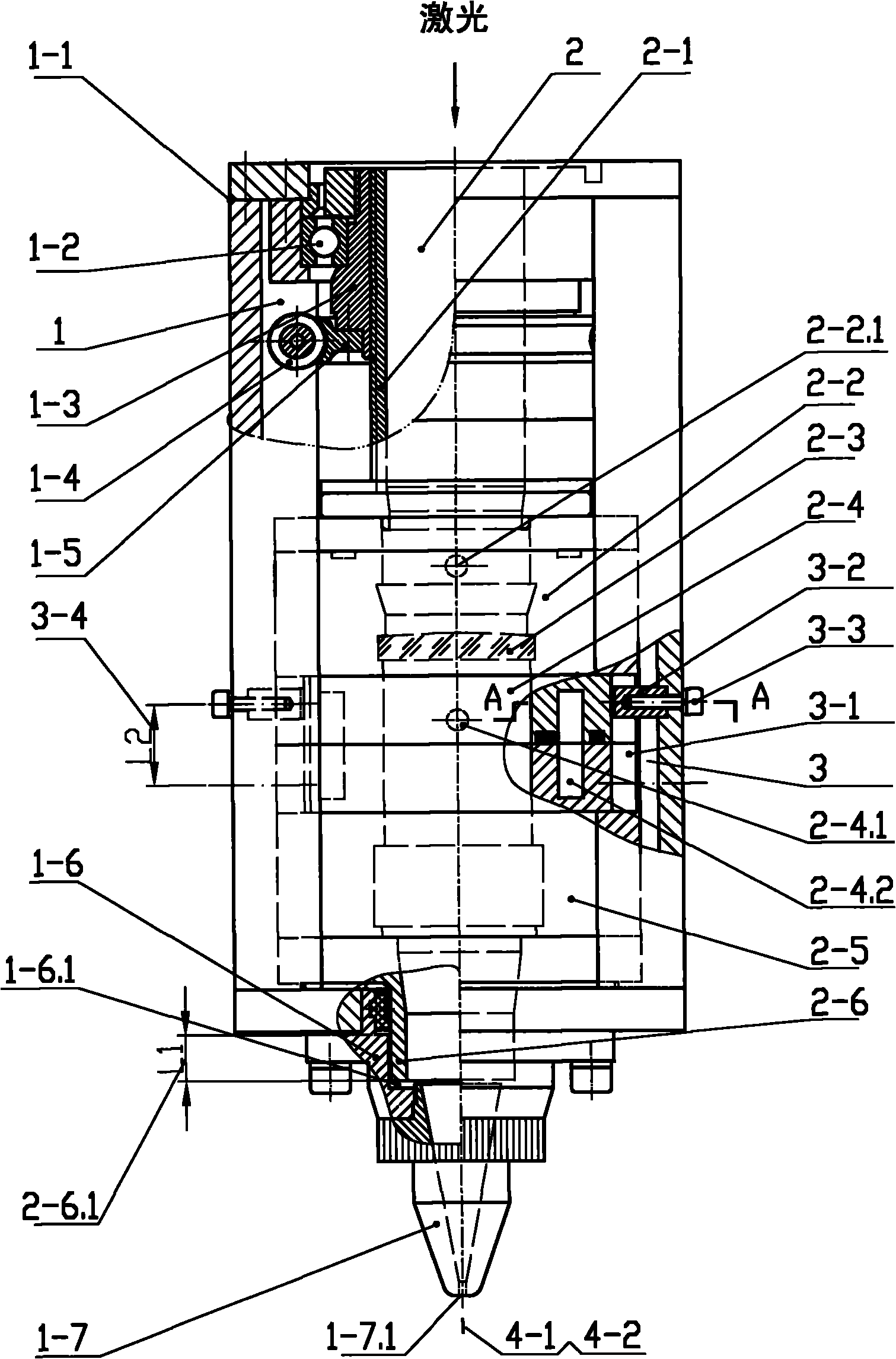

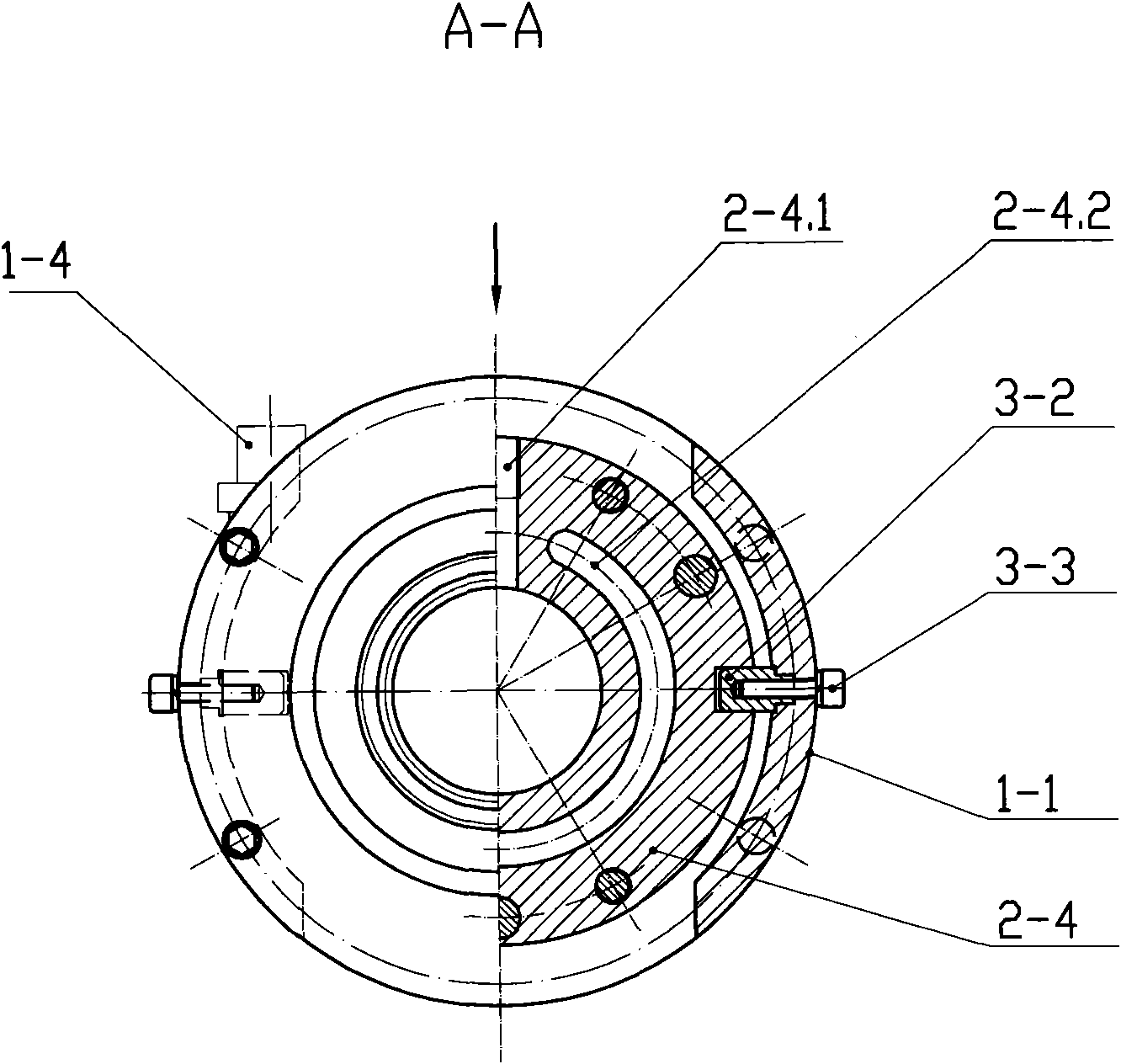

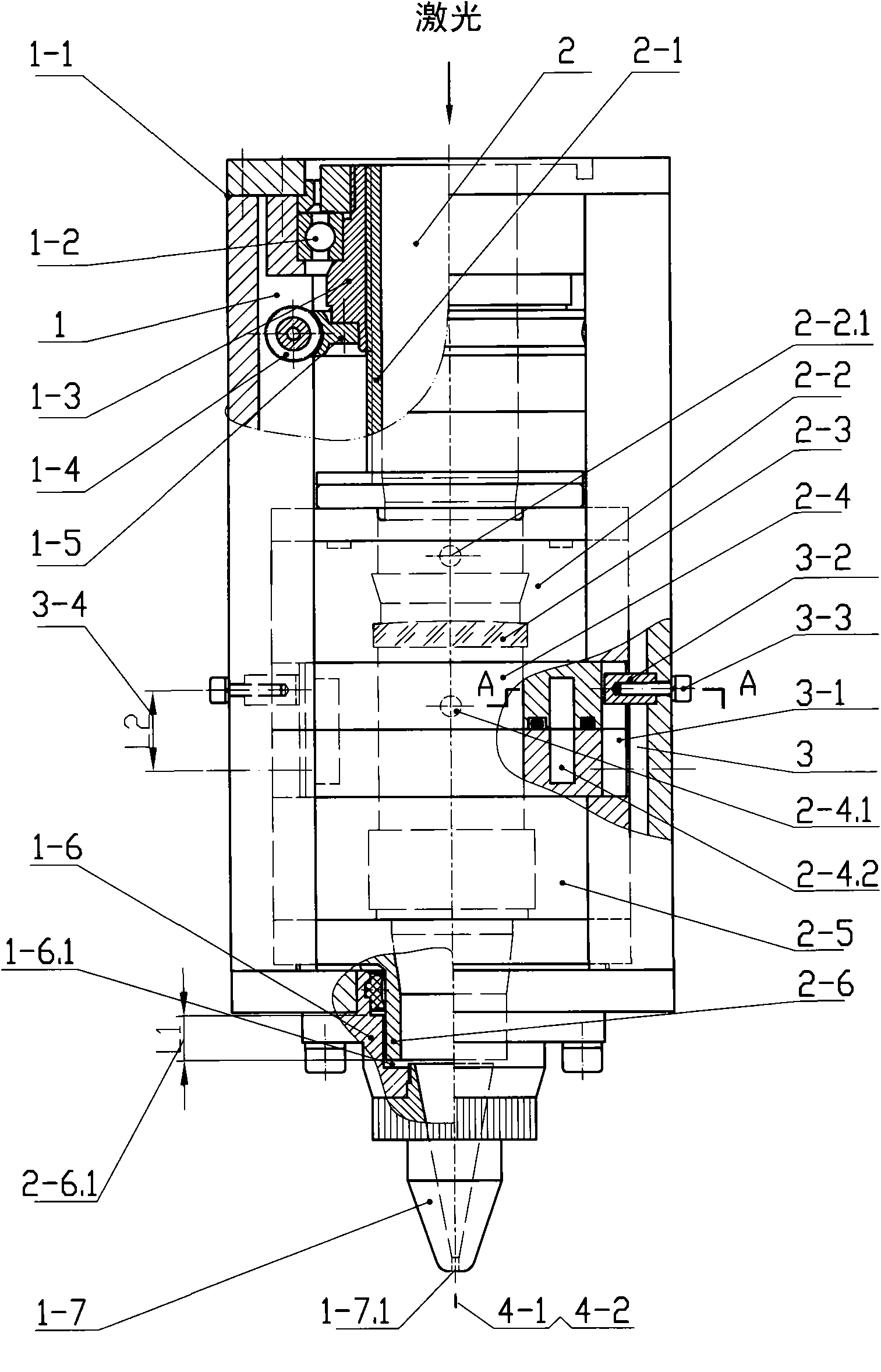

[0014] Such as figure 1 As shown, the automatic focusing CNC laser cutter of the present invention includes a frame mechanism 1, a focusing mechanism 2, a mirror seat mechanism, and a guiding mechanism 3 composed of a guiding groove 3-1, a guiding key 3-2, and a locking screw 3-3. ; The frame mechanism 1 includes a fixed sleeve 1-1, a connecting seat 1-6 and a nozzle 1-7; -3 and a trapezoidal threaded sleeve 2-1; the mirror base mechanism includes an upper mirror base 2-2, a focusing lens 2-3, a water air base 2-4, a lower mirror base 2-5 and a ventilation base 2-6, The upper mirror base 2-2 is provided with air blowing holes 2-2.1 and air blowing grooves, and the water air base 2-4 is composed of upper and lower parts. The parts are positioned by positioning pins and connected by screws; the lower end of the trapezoidal threaded sleeve 2-1 is connected with the upper lens base 2-2 through the transition flange; the guide mechanism 3 is set in the water air base 2-4 and cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com