Machining tool and machining method for precise step holes of aluminum alloy thin-wall casing

A stepped hole and aluminum alloy technology, applied in metal processing equipment, cutting tools for lathes, metal processing machinery parts, etc., can solve the problems of increased workshop management difficulty, high repair rate, equipment bottlenecks, etc., to increase the cutting range , Guarantee processing quality and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

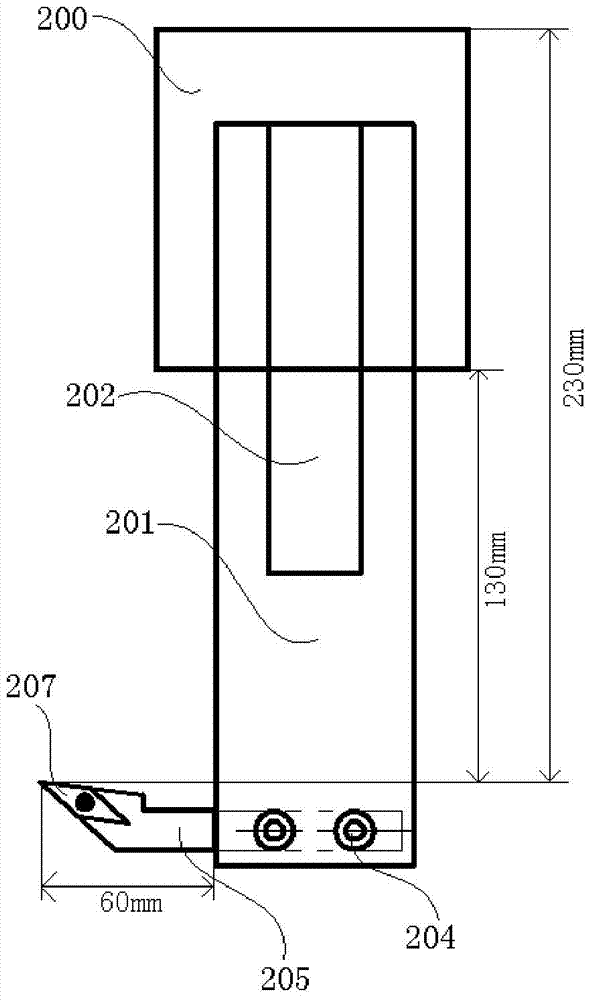

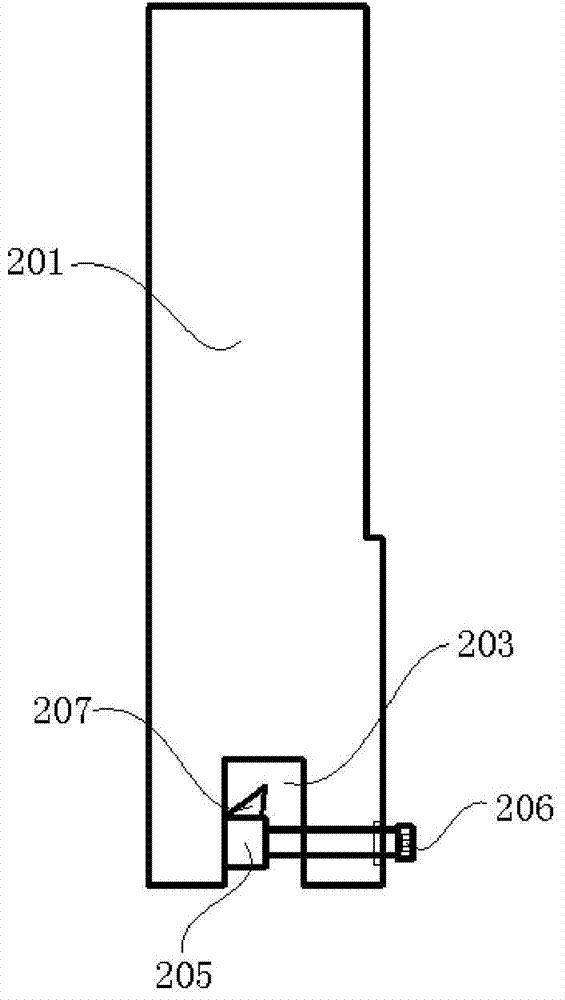

[0027] Please refer to figure 2 and image 3 , the present embodiment provides a machining tool for machining a precision stepped hole in an aluminum alloy thin-wall casing, including a turning tool holder 201 , a turning tool 205 and a turning blade 207 .

[0028] One end of the turning tool holder 201 is provided with a fixing groove 202 connected with the machine tool holder part 200 , and the other end is provided with a turning tool groove 203 and one or more screw holes 204 perpendicular to the length direction of the turning tool groove 203 .

[0029] One end of turning tool 205 stretches into turning tool groove 203, and turning tool 205 is fixed in turning tool groove 203 by screw 206 through screw hole 204.

[0030] The turning blade 207, the turning blade 207 is detachably fixedly arranged on the opposite end of the turning tool 205 extending into the turning tool groove 203.

[0031] In a specific embodiment, the length of the turning tool bar seat 201 is 220-24...

Embodiment 2

[0035] Please refer to Figure 4 , the present embodiment provides a method for processing a precision stepped hole in an aluminum alloy thin-wall casing, comprising the following steps:

[0036] Step 401: Place the thin-walled receiver on the fixture with the big end facing down and the small end facing up.

[0037] Step 402: Align the screw holes on the clamp fixing surface of the large end of the thin-walled receiver with the screw holes on the clamp fixing surface, and fix the thin-wall receiver on the clamp by screws.

[0038] Step 403: Select a suitable tool to process the outer circle and the stepped end face of the small end. After the thin-walled casing is clamped, the outer circle and the stepped end surface of the small end are located on the outside, therefore, there are many kinds of tools suitable for processing the small end in step 403, and only need to select according to the current conventional tool selection requirements That's it. Please refer to Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com