Patents

Literature

31results about How to "Reduce inventory quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

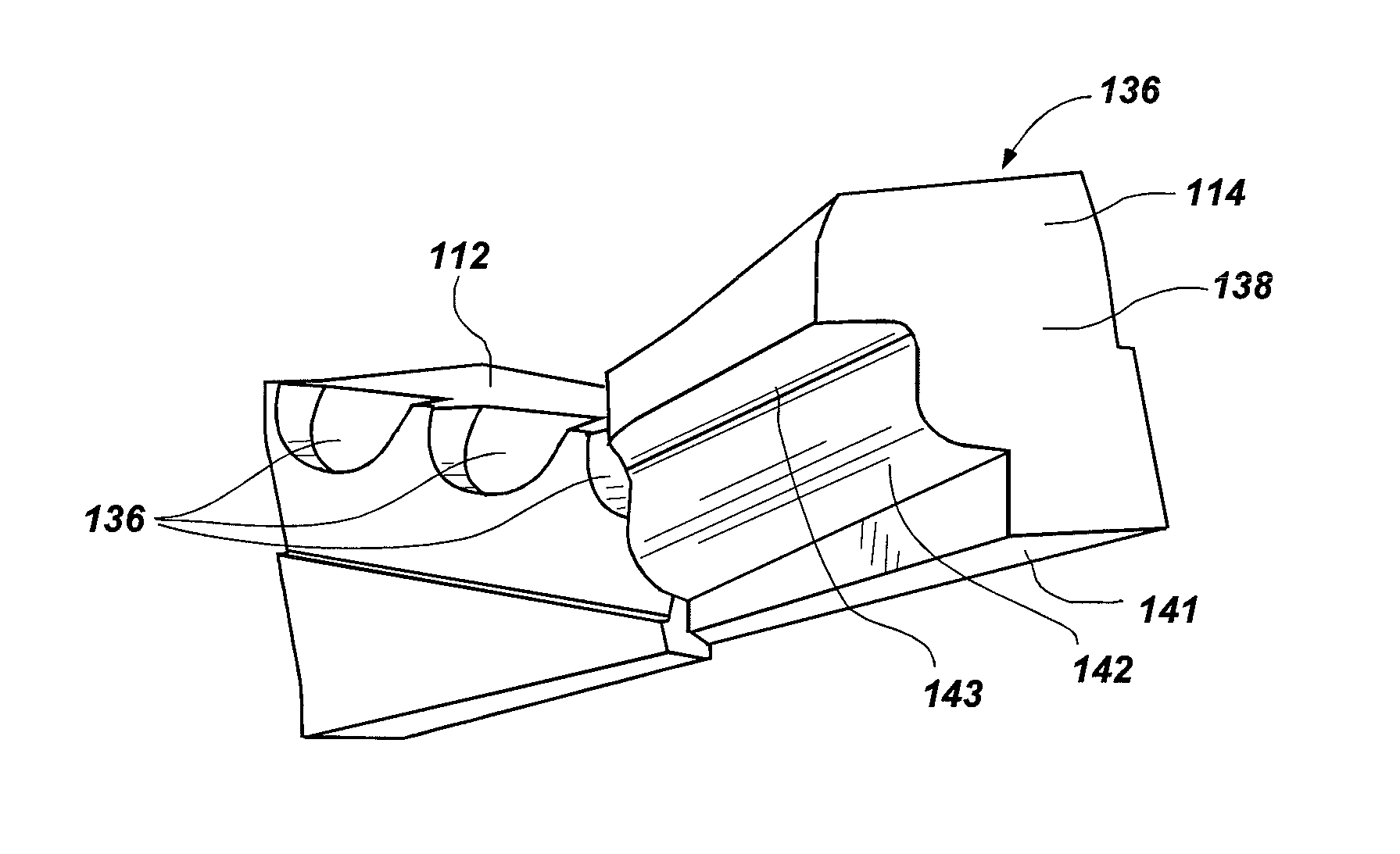

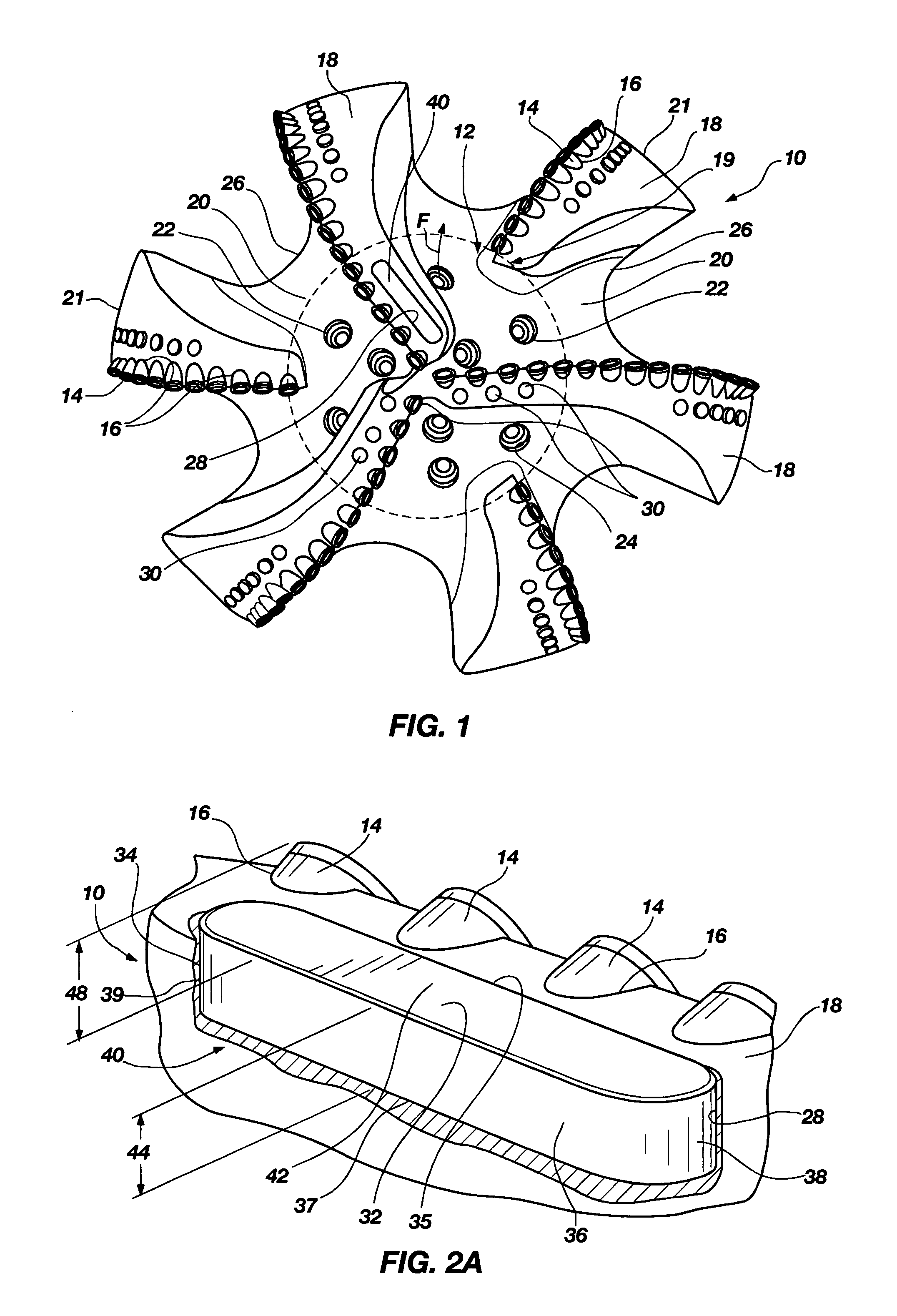

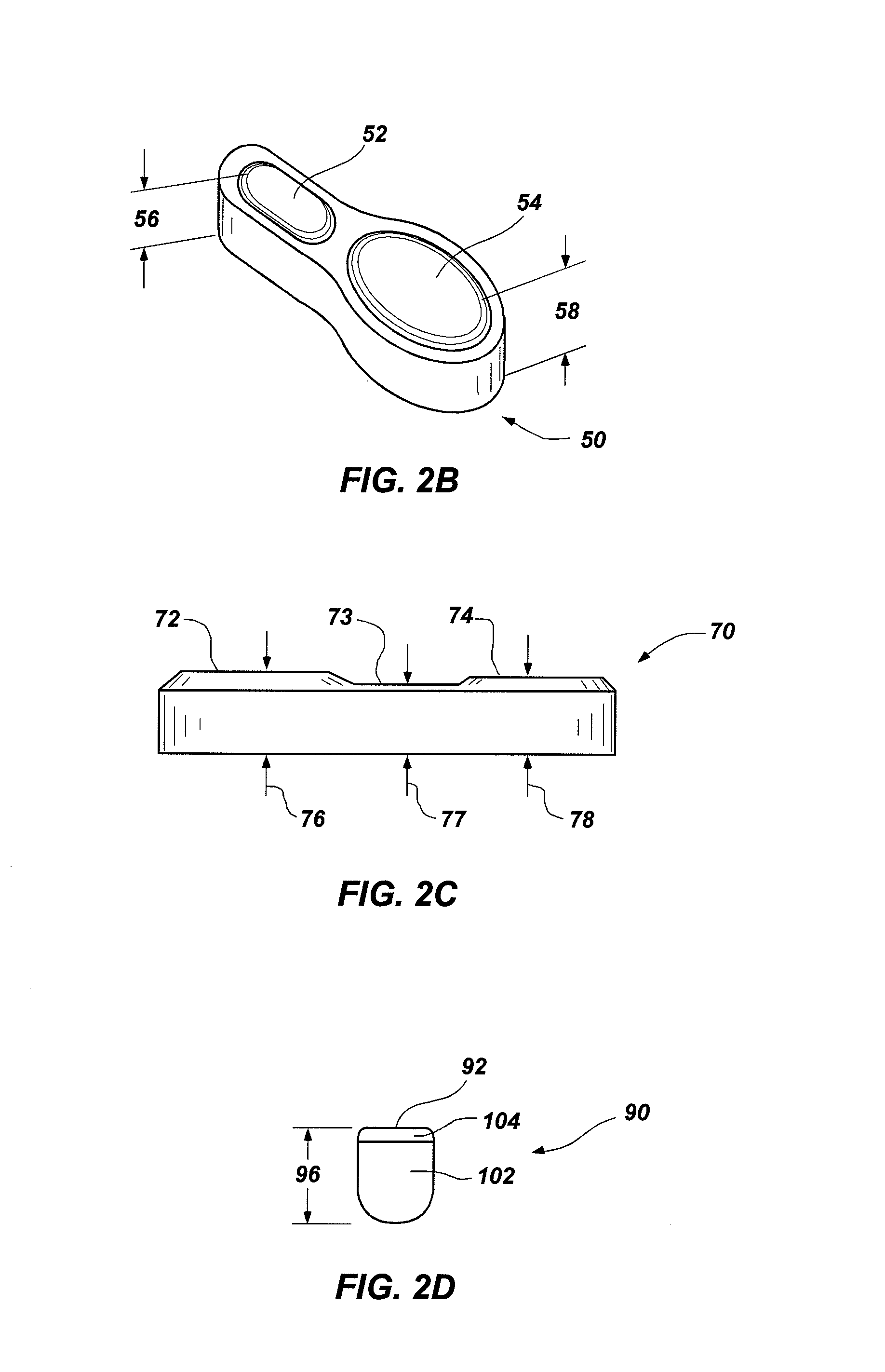

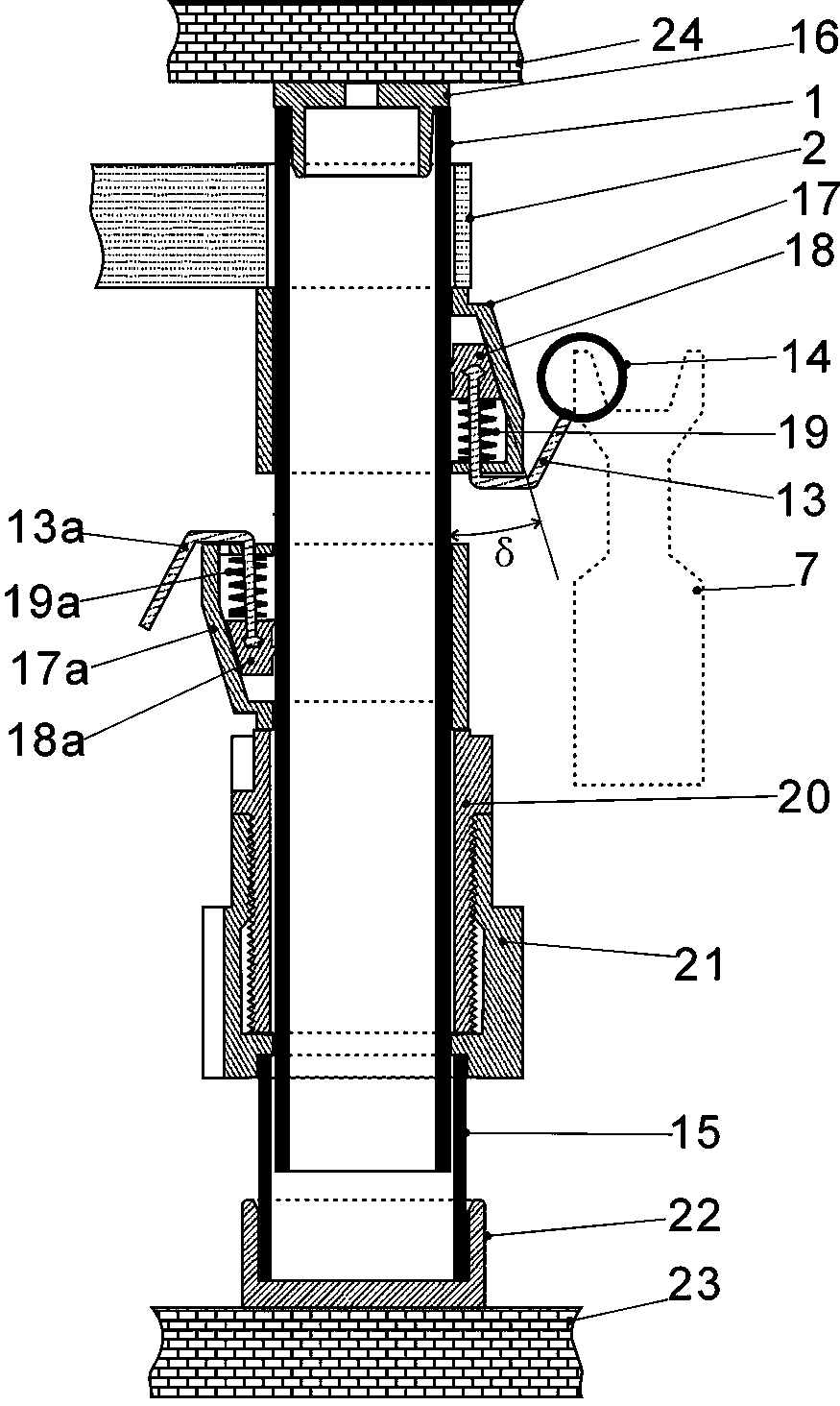

Interchangeable bearing blocks for drill bits, and drill bits including same

ActiveUS7814997B2Reduce complexityReduce inventory quantityDrill bitsDrilling rodsEngineeringRubbing

A bearing block is provided that may be used with a drag bit body or frame to limit depth of cut of cutters on a bit. The bearing block is designed so that it may be interchangeably replaced or repaired without necessitating alteration to a standardized bit frame. The interchangeable bearing block may be used to provide a target depth of cut (TDOC) and / or a selected contact or rubbing area to support weight on bit and limit depth of cut (DOC) for improving drilling performance of a bit. The interchangeable bearing block brings manufacturing selectability by providing a customizable product in terms of depth of cut selection and cutter penetration control for different formations, which is suitable for use with a common bit frame. A rotary drill bit assembly, a unitary cone insert bearing block for a drill bit, and a bit frame are also provided.

Owner:BAKER HUGHES HLDG LLC

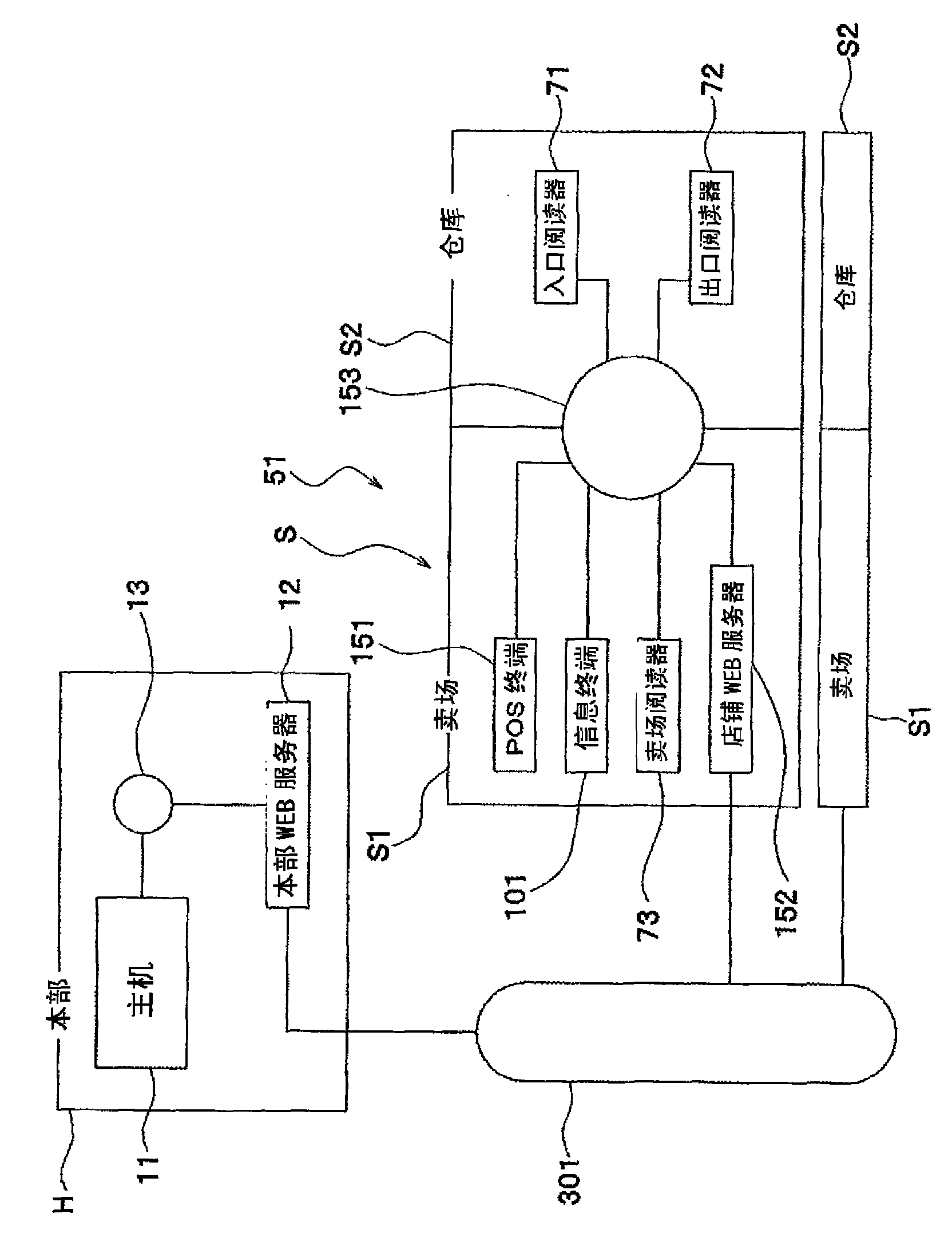

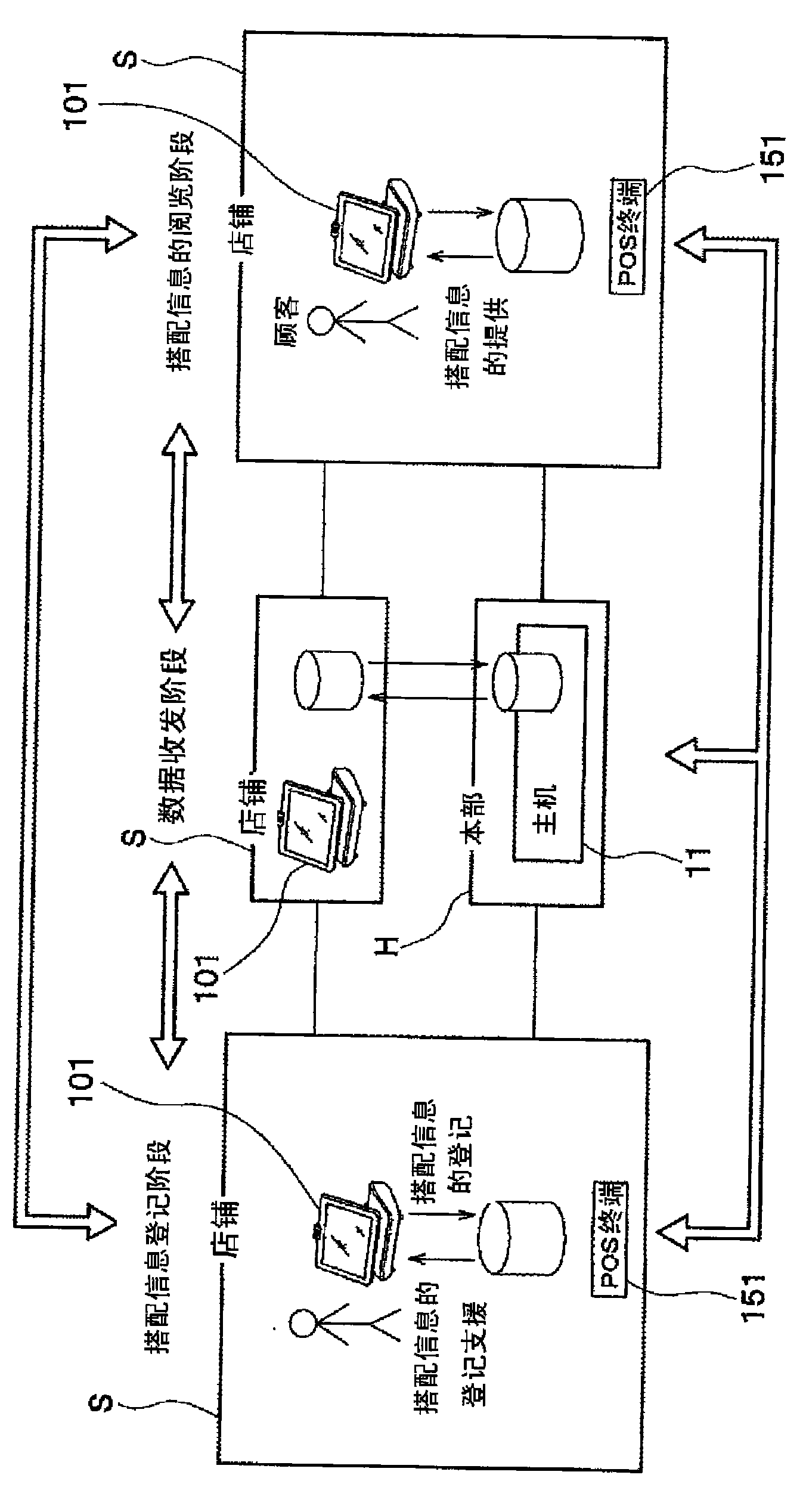

Information providing device, computer-readable recording medium, and store system

InactiveCN101604333AInventory Quantity IncreaseThe number of displays increasedBuying/selling/leasing transactionsMarketingLiquid-crystal displayDatabase

The invention discloses an information providing device, a computer-readable recording medium, and a store system. An information terminal displays a coordinate screen acquired from a coordinate database on a liquid crystal display, acquires data of an article code of clothes coordinated in the coordinate image from the coordinate database, acquires data of inventory status and display status associated with the acquired article code from an inventory database which stores and saves an article code of an individual article in association with inventory status of the article in a warehouse and display status of the article in a sales floor, and displays an inventory screen which reports a place where the article exists as an article inventory list on the liquid crystal display.

Owner:TOSHIBA TEC KK

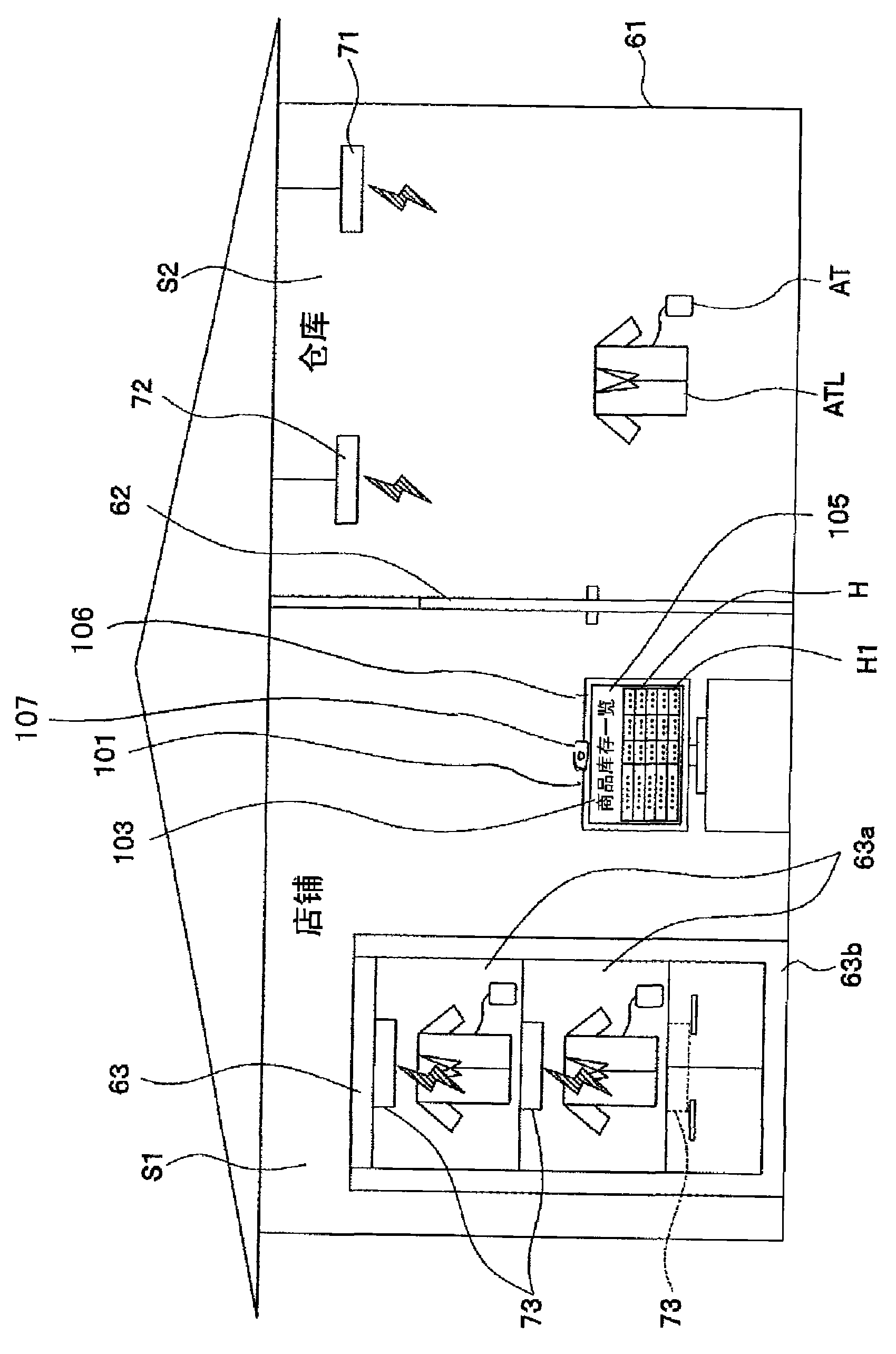

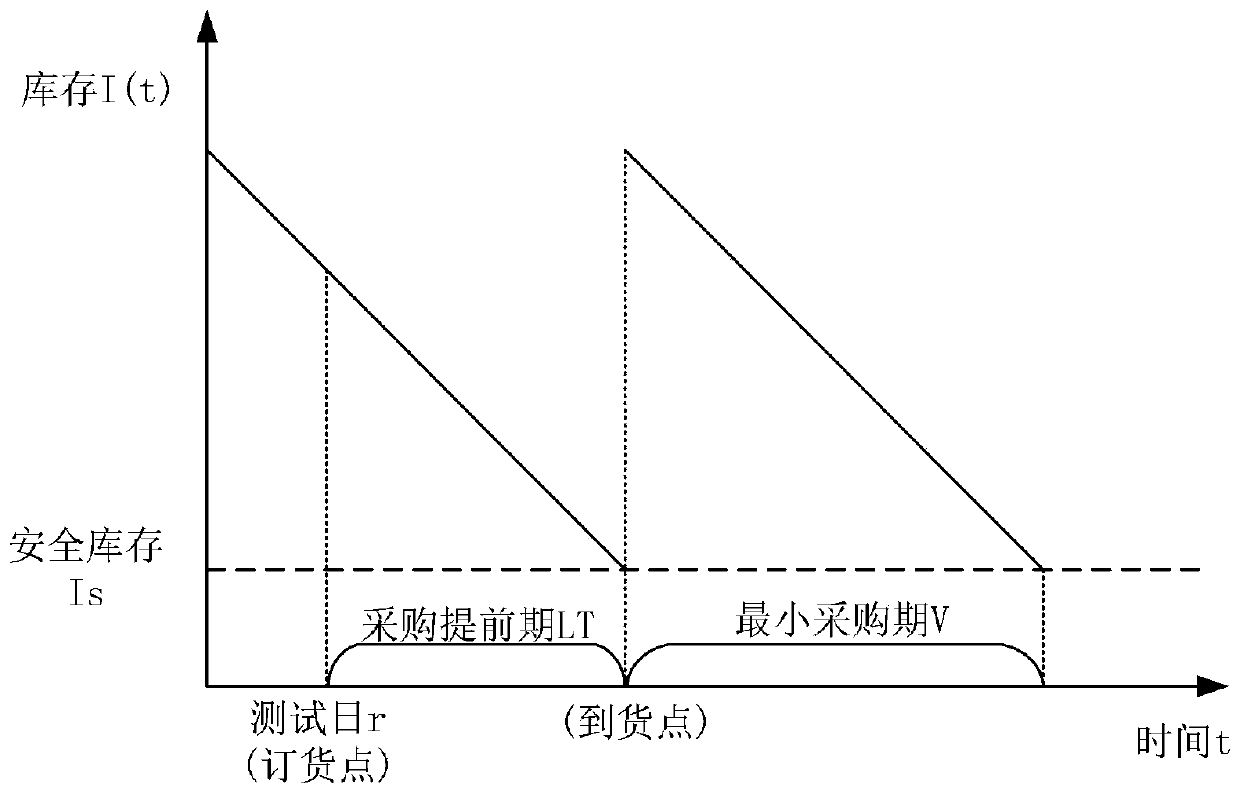

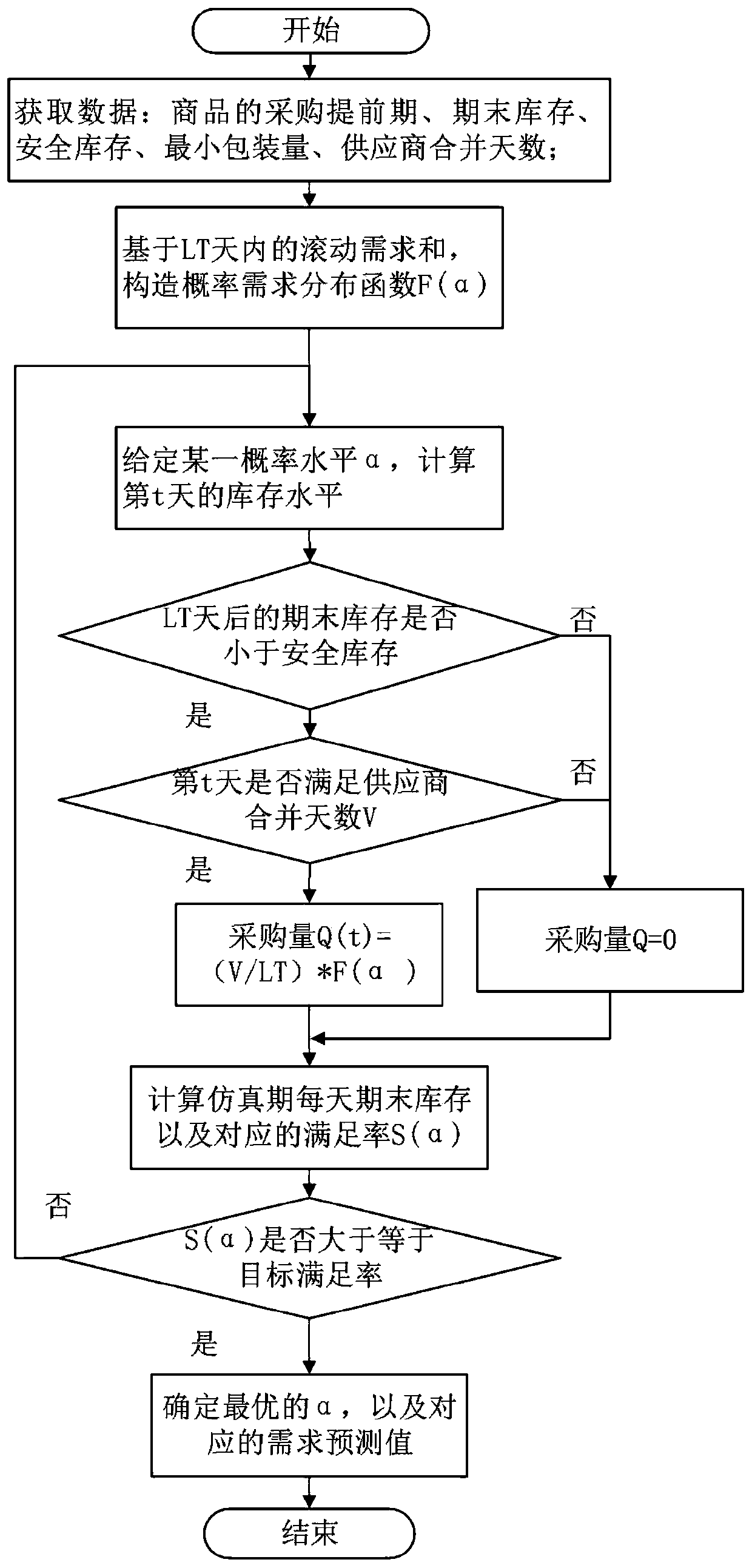

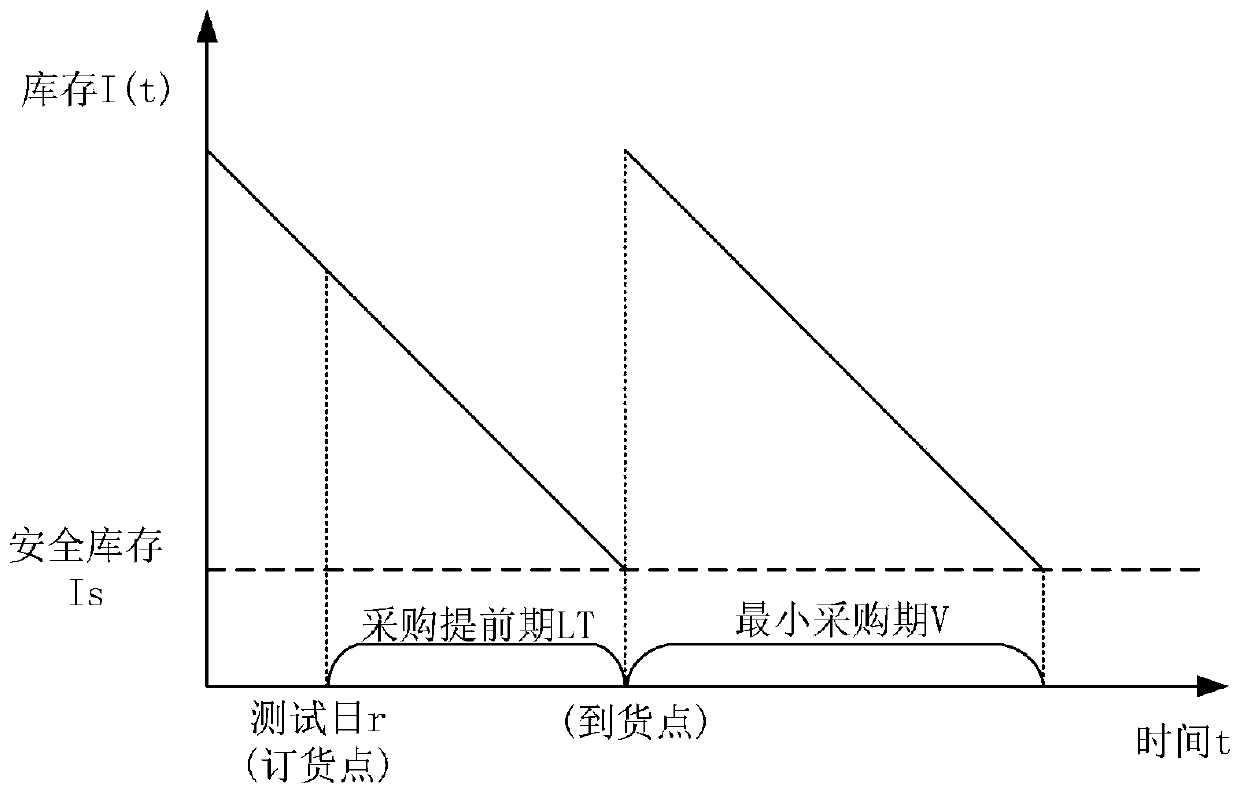

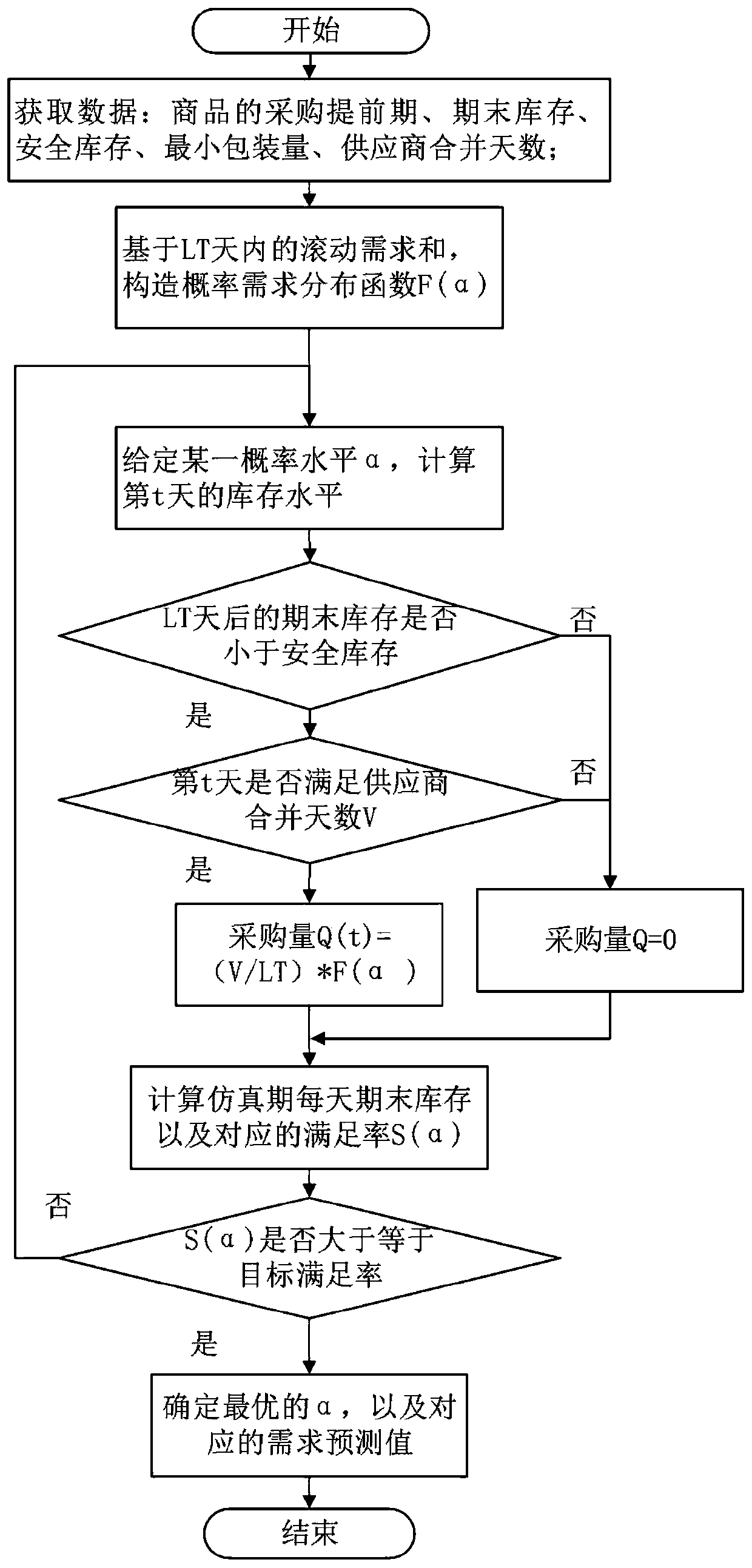

Inventory optimization method based on probability demand distribution

ActiveCN109740793AStrong randomnessReduce inventory quantityForecastingLogisticsGreek letter alphaPurchasing

The invention discloses an inventory optimization method based on probability demand distribution. The method comprises the following steps of: an existing enterprise informatization management platform is relied on. inventory remainders of the commodities are extracted; warehouse entry and exit details, Sales order, purchasing multi-dimensional data such as advanced stage and the like; the methodcomprises the following steps: firstly, constructing probability distribution of warehouse-out quantity in a purchasing advance LT; if the warehouse-out quantity in the LT day is q (q is greater than0); historical warehouse-out frequency distribution is counted; according to the invention, a required probability density function f (q) can be obtained, so that an expected value corresponding to acertain probability value alpha is obtained, wherein 0 < =alpha < = 1. Therefore, a function relationship between the probability value and the demand prediction value is established. And then determining a target satisfaction rate Sopt, calculating a simulation satisfaction rate Si according to the F (alpha) traversal probability value alphai until Si is greater than or equal to the Sopt, and training an optimal probability and a corresponding demand prediction value. According to the method, the prediction idea of demand probability distribution is creatively introduced, and inventory optimization benefit maximization is achieved under the condition that the satisfaction rate is guaranteed for the pain point problems of large commodity demand fluctuation and high prediction difficulty of current enterprises.

Owner:杭州览众数据科技有限公司

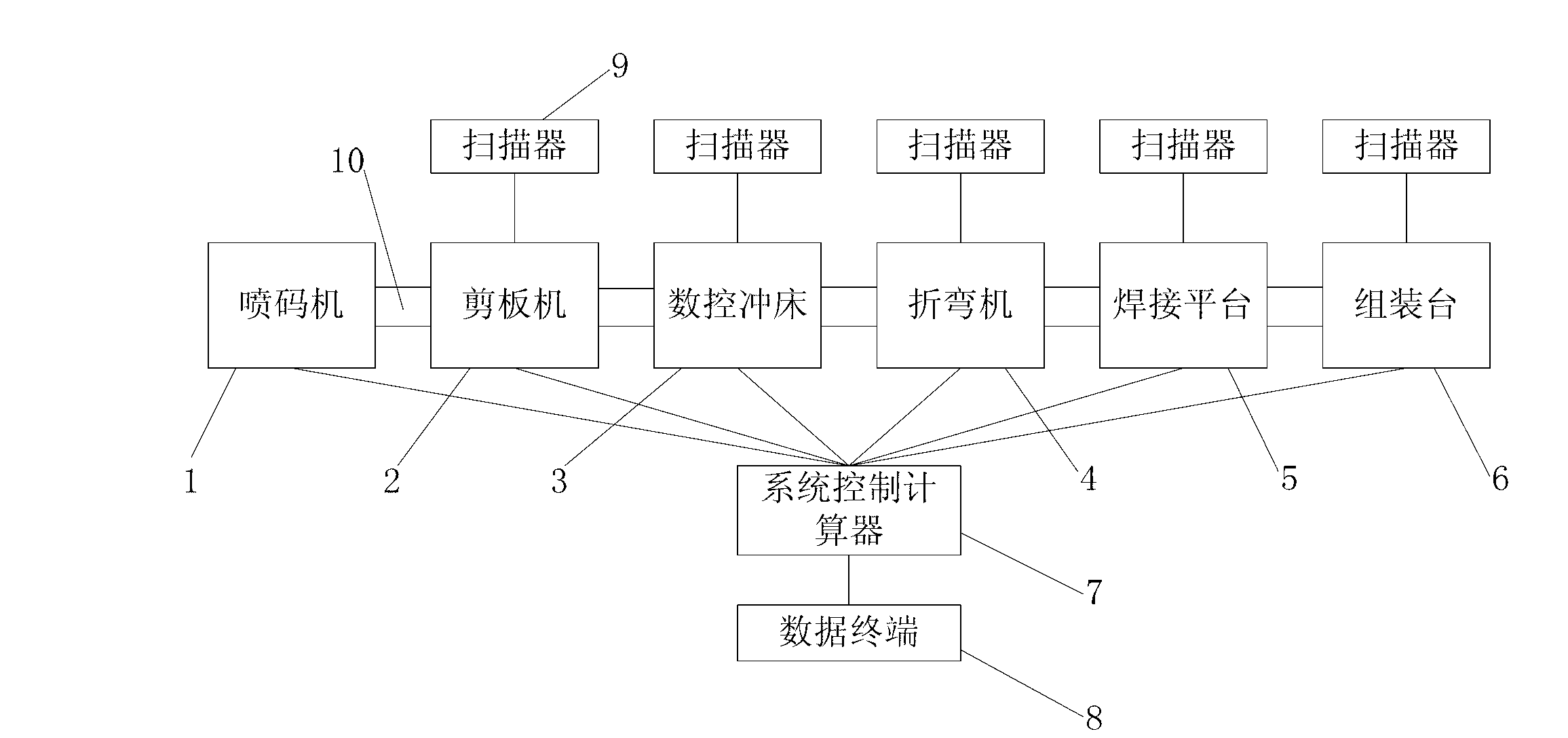

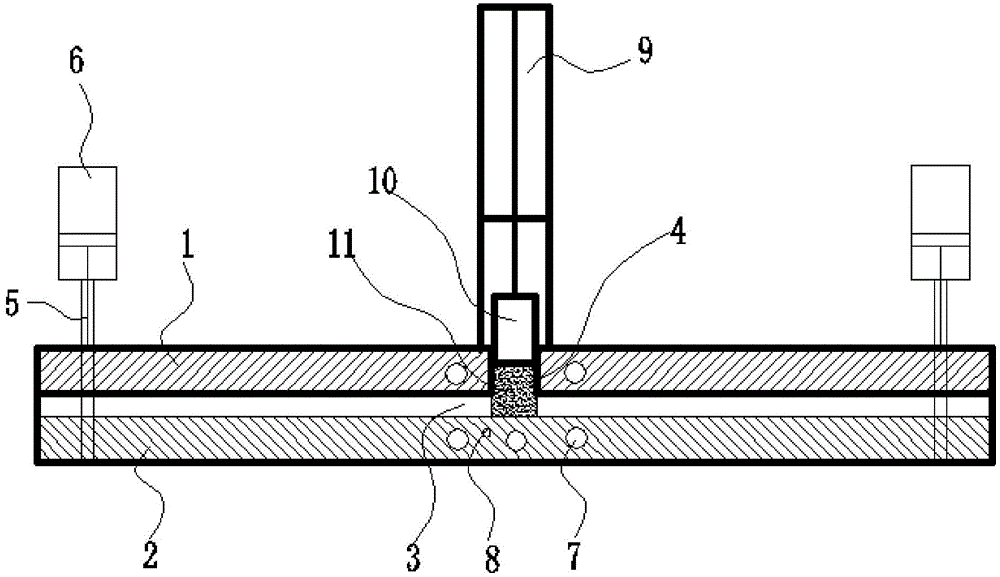

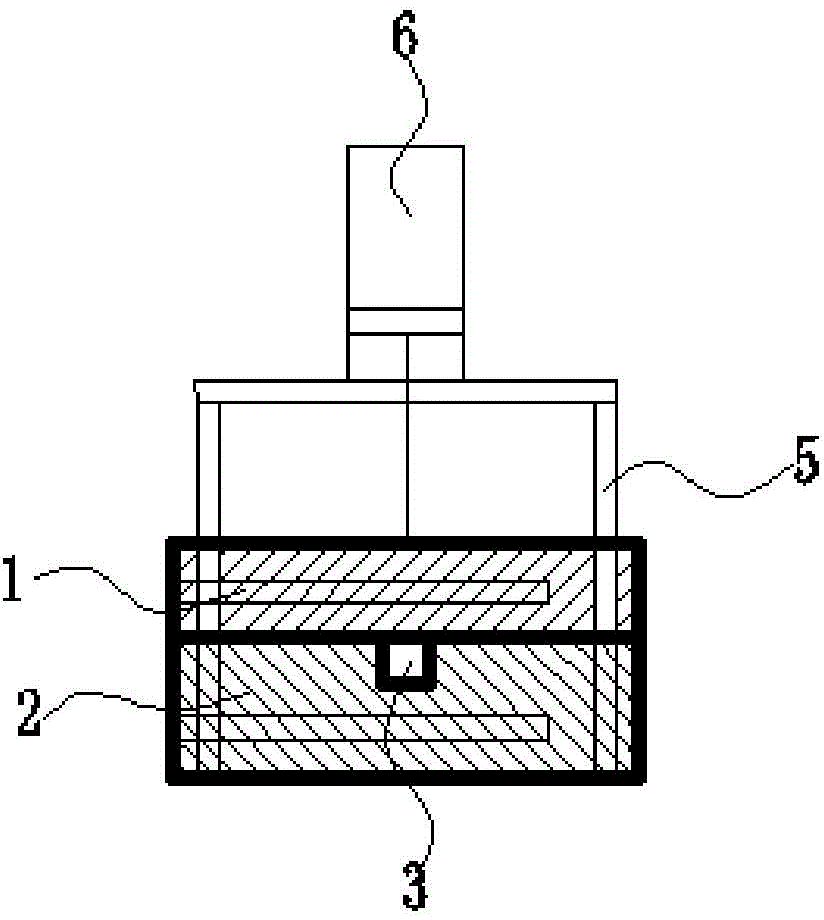

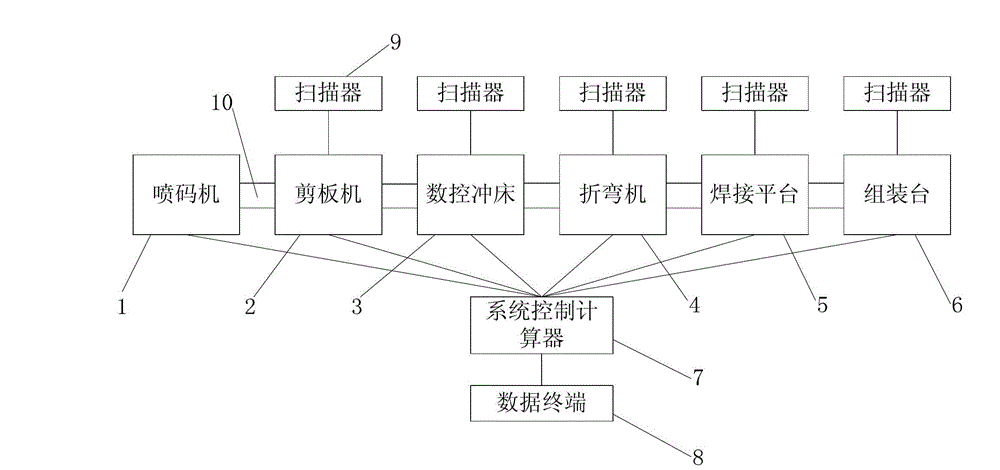

Automatic production device for cabinets

InactiveCN103056659AIncrease automatic handlingAdd automatic deliveryOther manufacturing equipments/toolsNumerical controlControl system

The invention discloses an automatic production device for cabinets. The automatic production device for the cabinets comprises a system control computer, an ink jet printer, a plate shear, a numerical control press, a bender, a welding platform, an assembly platform, scanners and a conveying belt. The ink jet printer, the plate shear, the numerical control press, the bender, the welding platform and the assembly platform are sequentially connected through the conveying belt; the plate shear, the numerical control press, the bender, the welding platform and the assembly platform are respectively connected with one scanner; and the ink jet printer, the plate sheer, the numerical control press, the bender, the welding platform and the assembly platform are connected with the system control computer respectively. According to the technical scheme, individual devices are combined together to form a production network control system, and production auxiliary equipment such as automatic transporting equipment, automatic conveying equipment, automatic checking equipment, automatic discriminating equipment and automatic operating equipment is added. The device has high automation degree, remarkably lowered labor costs, good promptness, simple and convenient data transmission, and high equipment utilization, and can reduce errors caused by manual transmission.

Owner:SHANGHAI CABA ELECTRIC

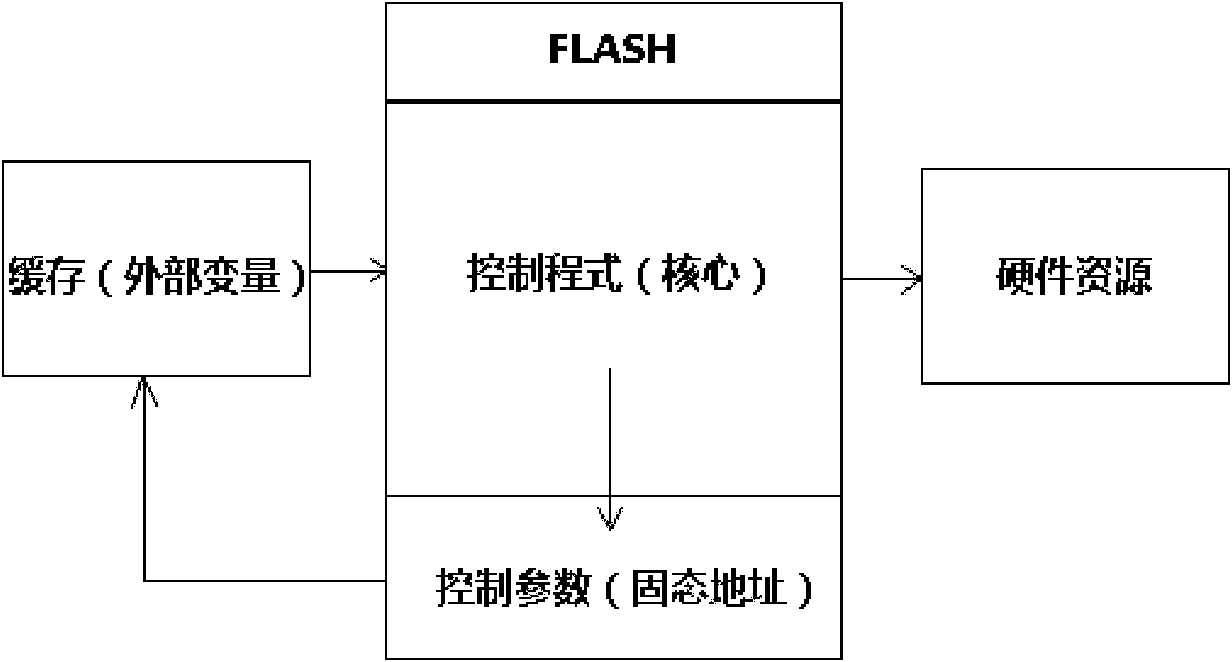

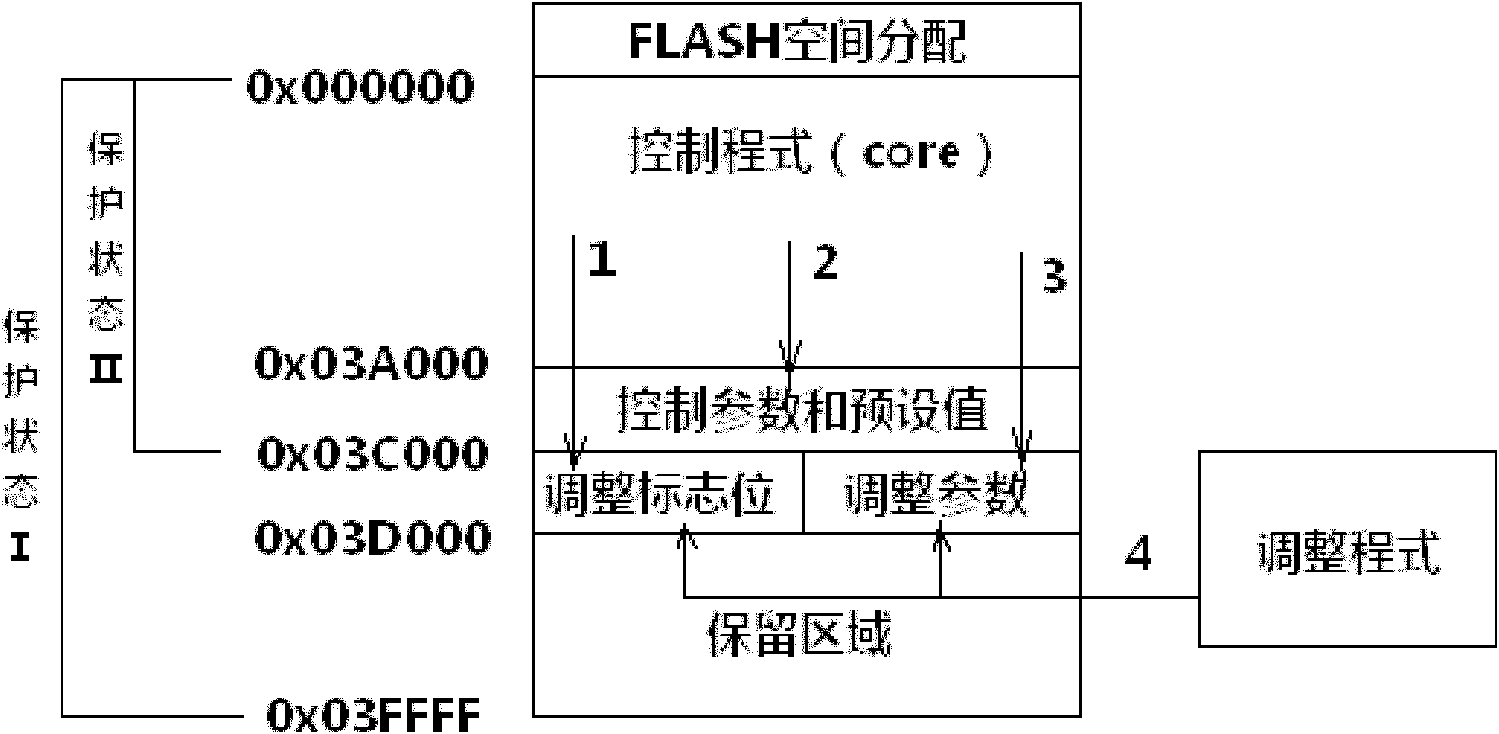

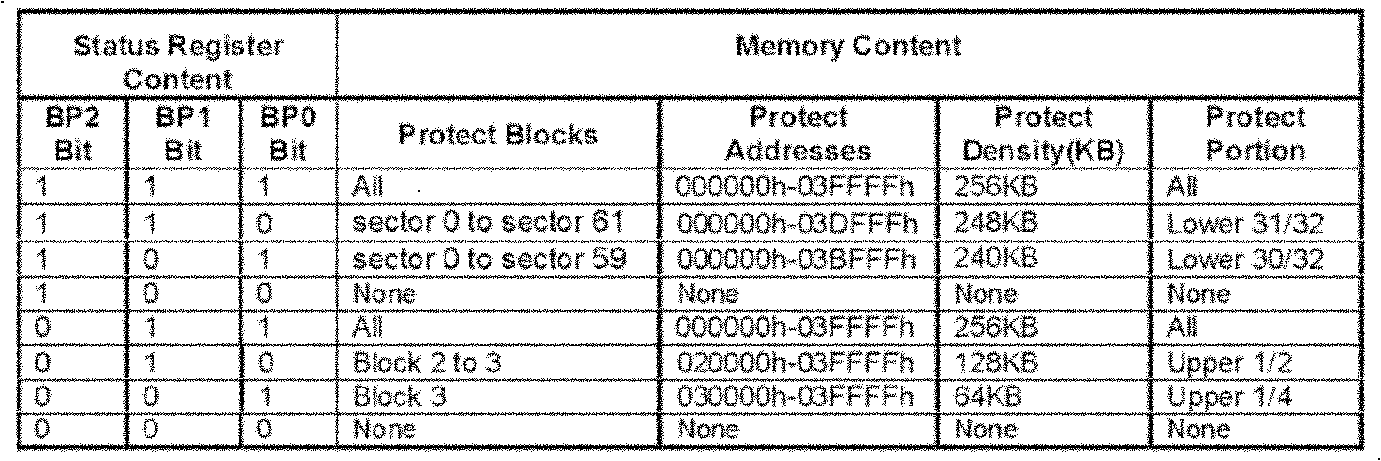

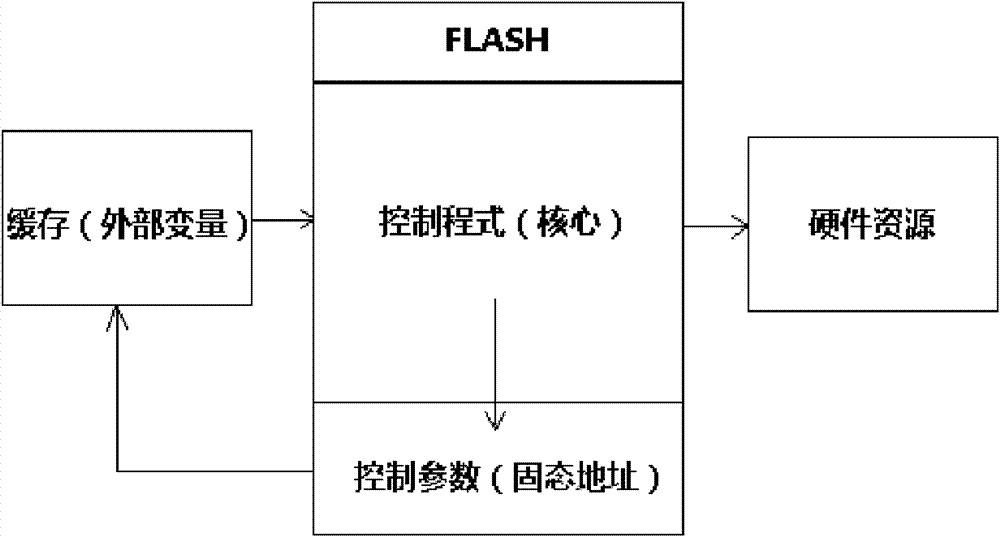

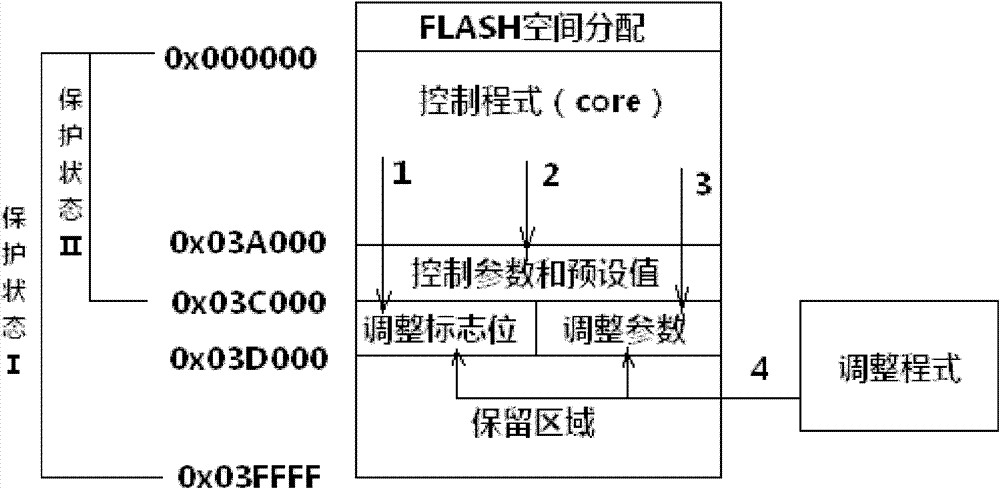

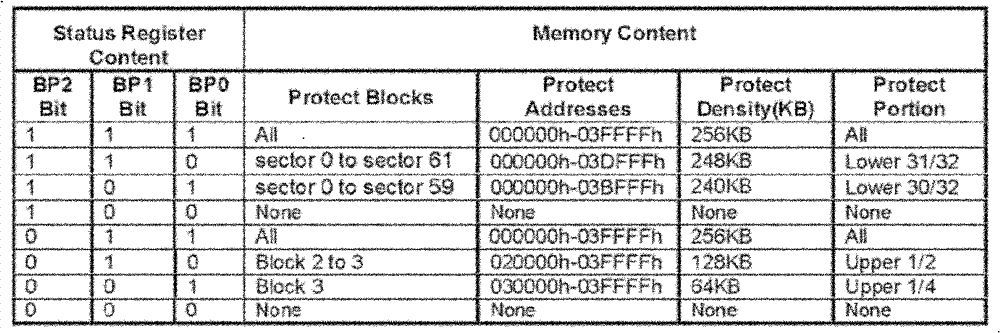

Method for arranging display equipment software and method for writing control parameters into FLASH

InactiveCN101976577AImprove design and development efficiencyReduce complexityRead-only memoriesElectricityPaper document

The invention discloses a method for arranging display equipment software and a method for writing control parameters into FLASH. A control program of the software is separated from the control parameters; a part of invariable control parameters and preset fixed values are stored in the FLASH (flash memory); and the FLASH is set in protected states for realizing read-only effect. The methods havethe advantages that: the control program and the control parameters are arranged separately, so that the setting complexity and risk of the control parameters can be lowered greatly, a large number of redundant verification processes are avoided and the development and design efficiencies of display equipment are improved; the writing opportunity of the control parameters is reduced, so that the risk of data loss caused by surge is lowered; simultaneously, an after-sales service department does not need to prepare for a large number of stock products; and once mechanism sizes are accordant, only the control parameters of the conventional product are set into a software document and are burnt, so that stock quantity can be reduced greatly and maintenance efficiency is improved.

Owner:TPV DISPLAY TECH WUHAN

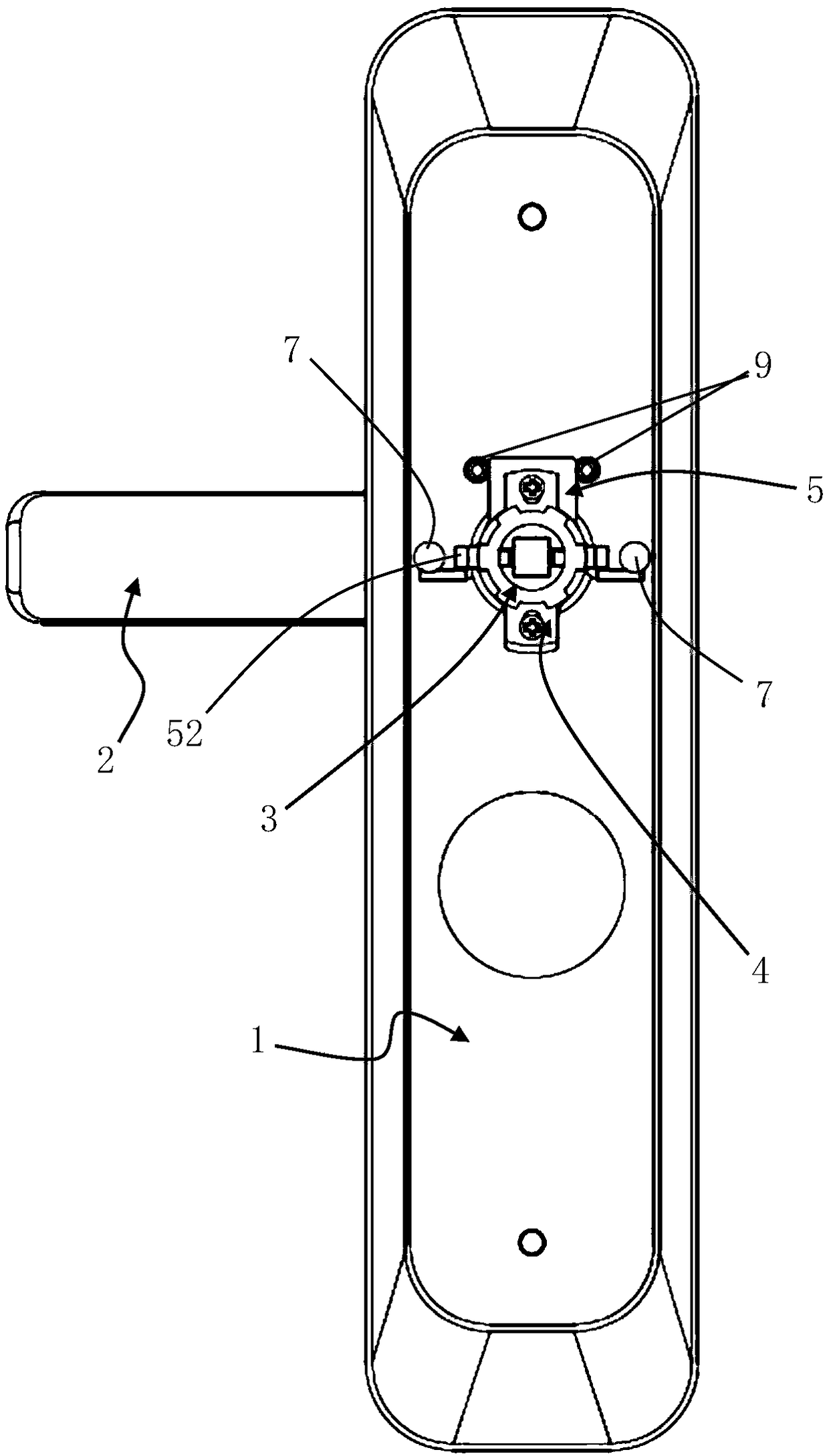

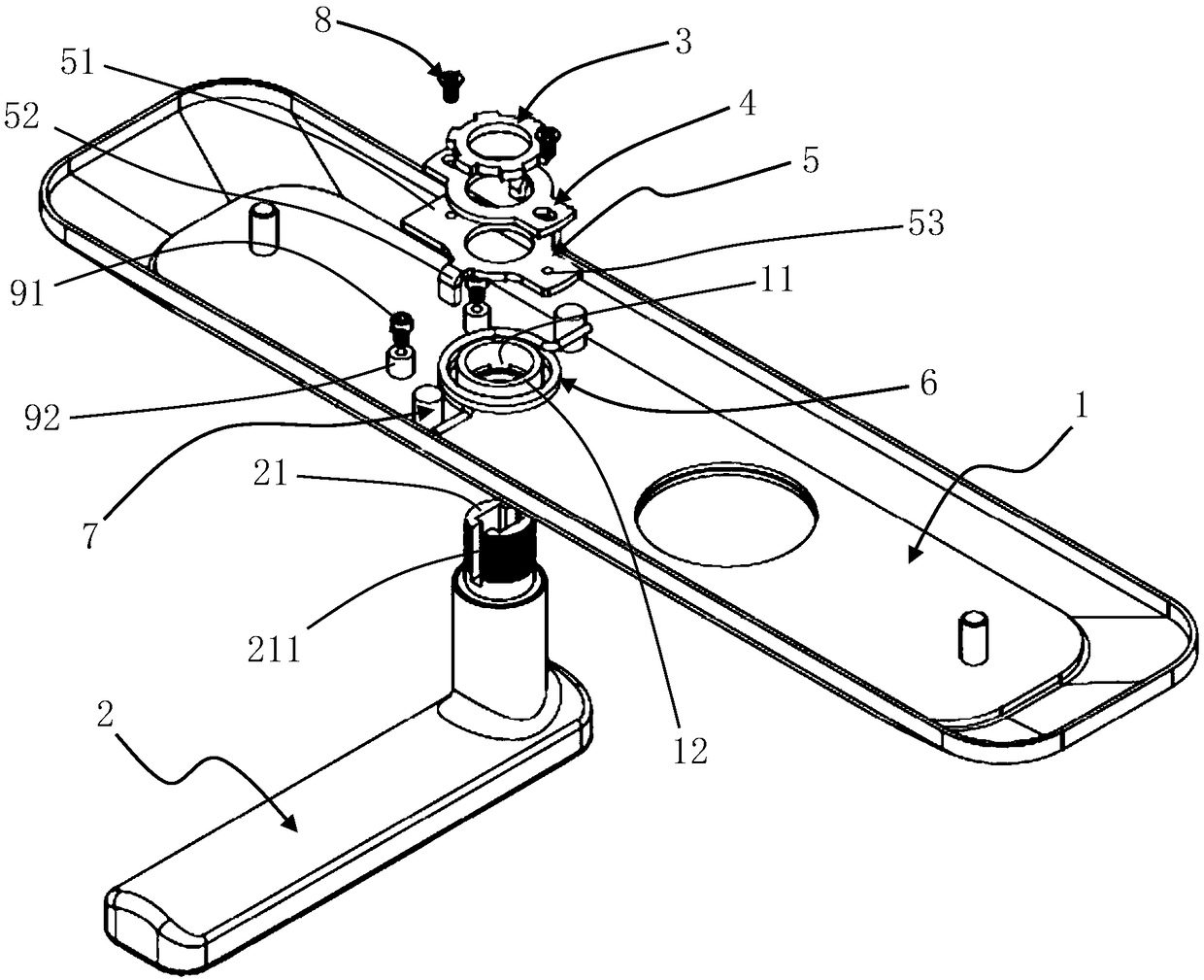

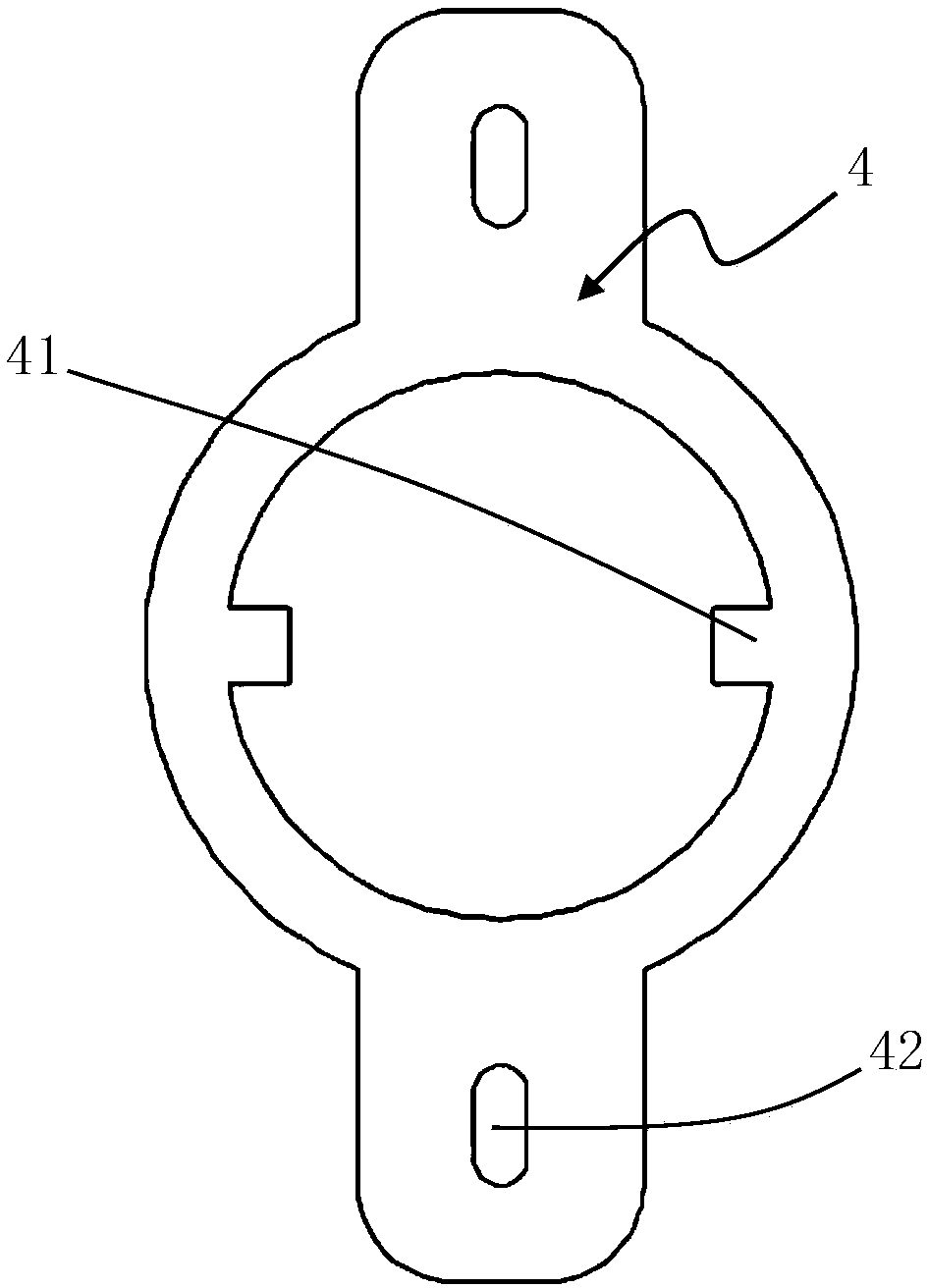

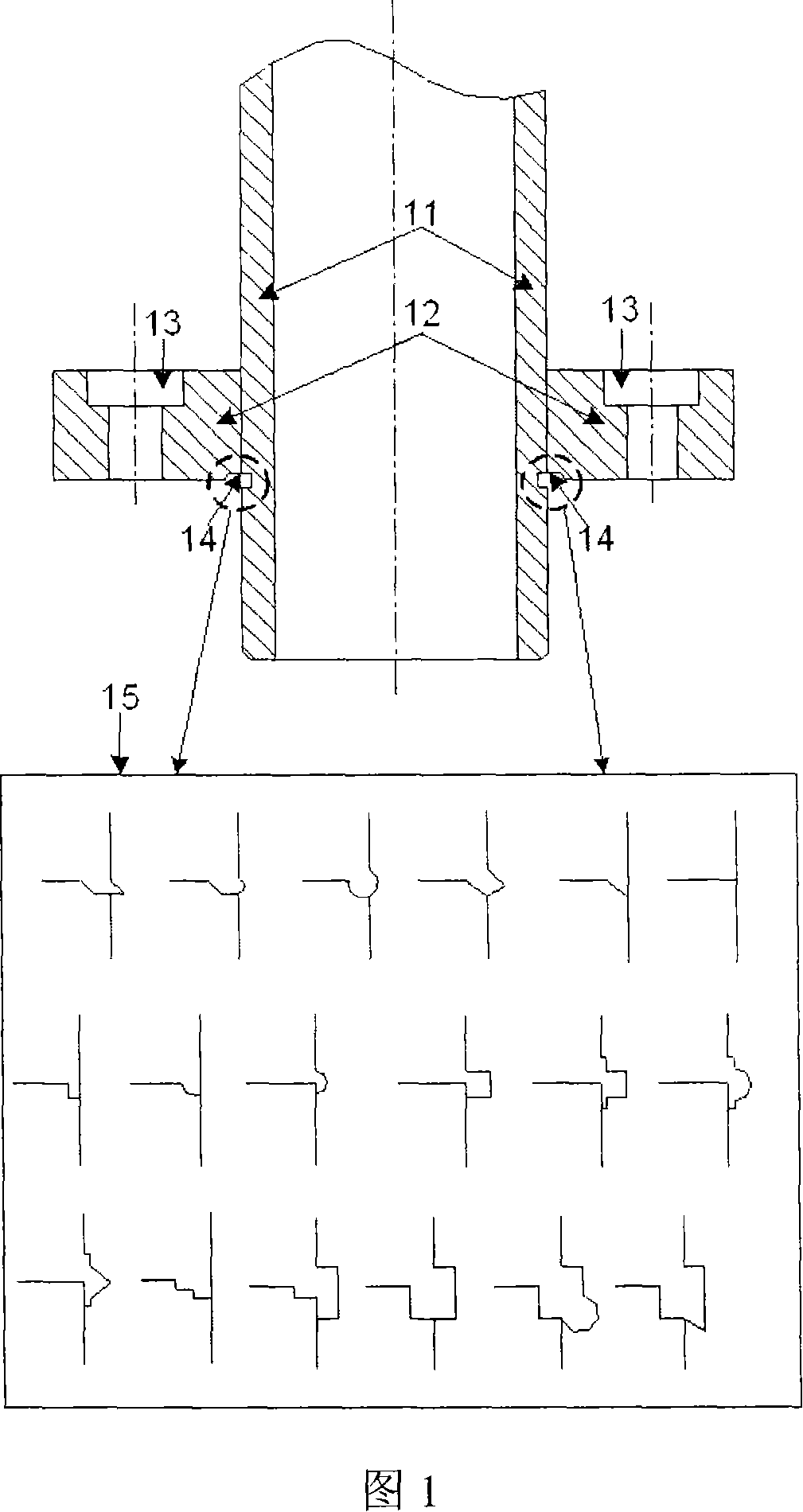

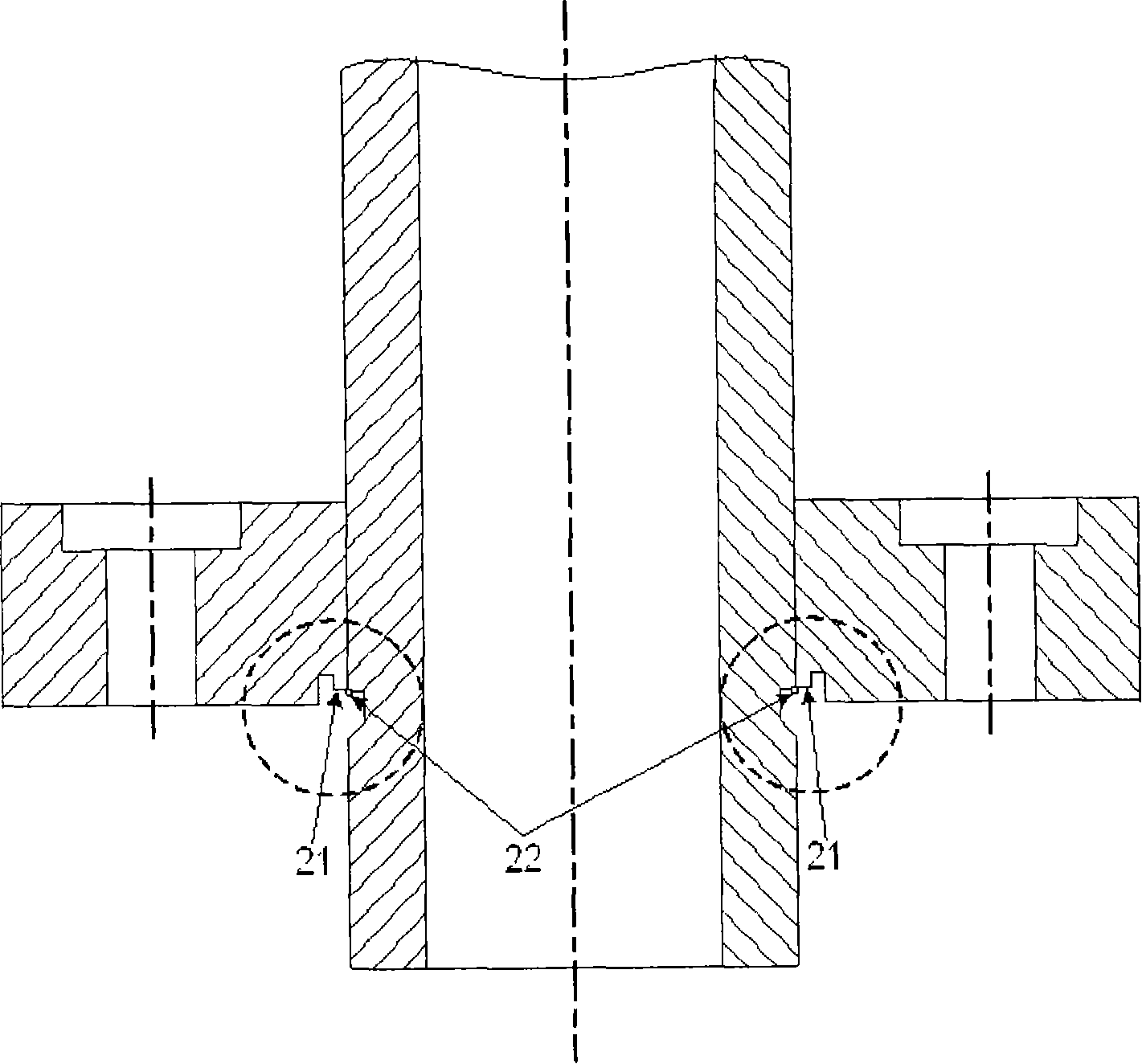

Panel handle structure with convenient and quick reversing function

The invention relates to a panel handle structure with a convenient and quick reversing function. The panel handle structure comprises a panel and a handle; a through hole is formed in the panel, a rotating shaft of the handle is arranged in the through hole in a penetrating mode, and outer threads are arranged on the outer circumference of the rotating shaft of the handle; the rotating shaft is sequentially sleeved with a nut, a reversing block and a limiting clamping ring from outside to inside; a clamping-connection structure is arranged between the outer circumference of the rotating shaftand the inner circumference of the reversing block and used for limiting the circumferential position of the reversing block relative to the rotating shaft; a certain gap is formed between the innercircumference of the limiting clamping ring and the outer circumference of the rotating shaft, and the limiting clamping ring and the reversing block are detachably and fixedly connected together; andthe panel handle structure further comprises a limiting structure, and the limiting structure is used for limiting the circumferential position of the limiting clamping ring. According to the panel handle structure, by additionally arranging the reversing block, the convenient and quick handle reversing function is achieved, feasibility of reversing operation of mounting personnel on a site can be greatly improved, and management and control of production materials in a factory are facilitated.

Owner:永康市锐安锁业有限公司

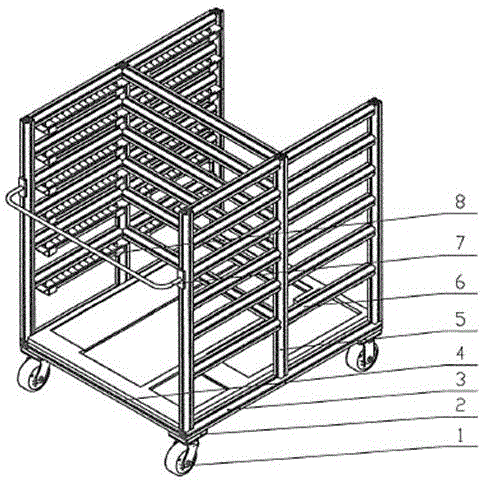

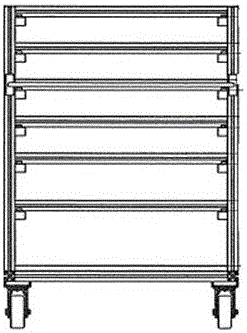

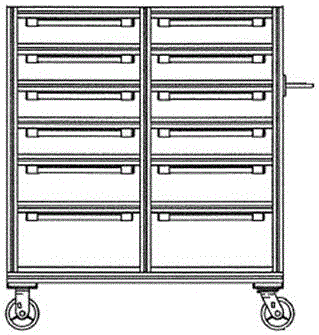

Fixed-position quantitative material delivery device and method

InactiveCN106240609ASafe storageGuaranteed QuantitativeOther workshop equipmentHand carts with multiple axesEngineeringFixed position

The invention discloses a fixed-position quantitative material delivery device and method. The fixed-position quantitative material delivery device comprises a bottom surface support rack, and a universal wheel, a strut beam, trays and a horizontal connecting beam mounted below the bottom surface support rack, wherein a plurality of storage areas are formed between the strut beam and the horizontal connecting beam, and each storage area is equipped with a tray. A plurality of layers of different trays are correspondingly arranged on a cart according to the difference of quantity, dimension and shape of materials, a plurality of difference storage areas can be arranged on the same tray and materials with different dimension, shape and preset quantity can be correspondingly stored in different tray storage areas, so as to realize the purpose of integration of storage and transportation. According to the invention, storage and transportation of material delivery can be combined into a whole, integration of storage and transportation can be realized, material sorting procedure can be reduced, visual management of fixed-position and quantitative material storage can be realized, and the operation efficiency can be greatly promoted.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

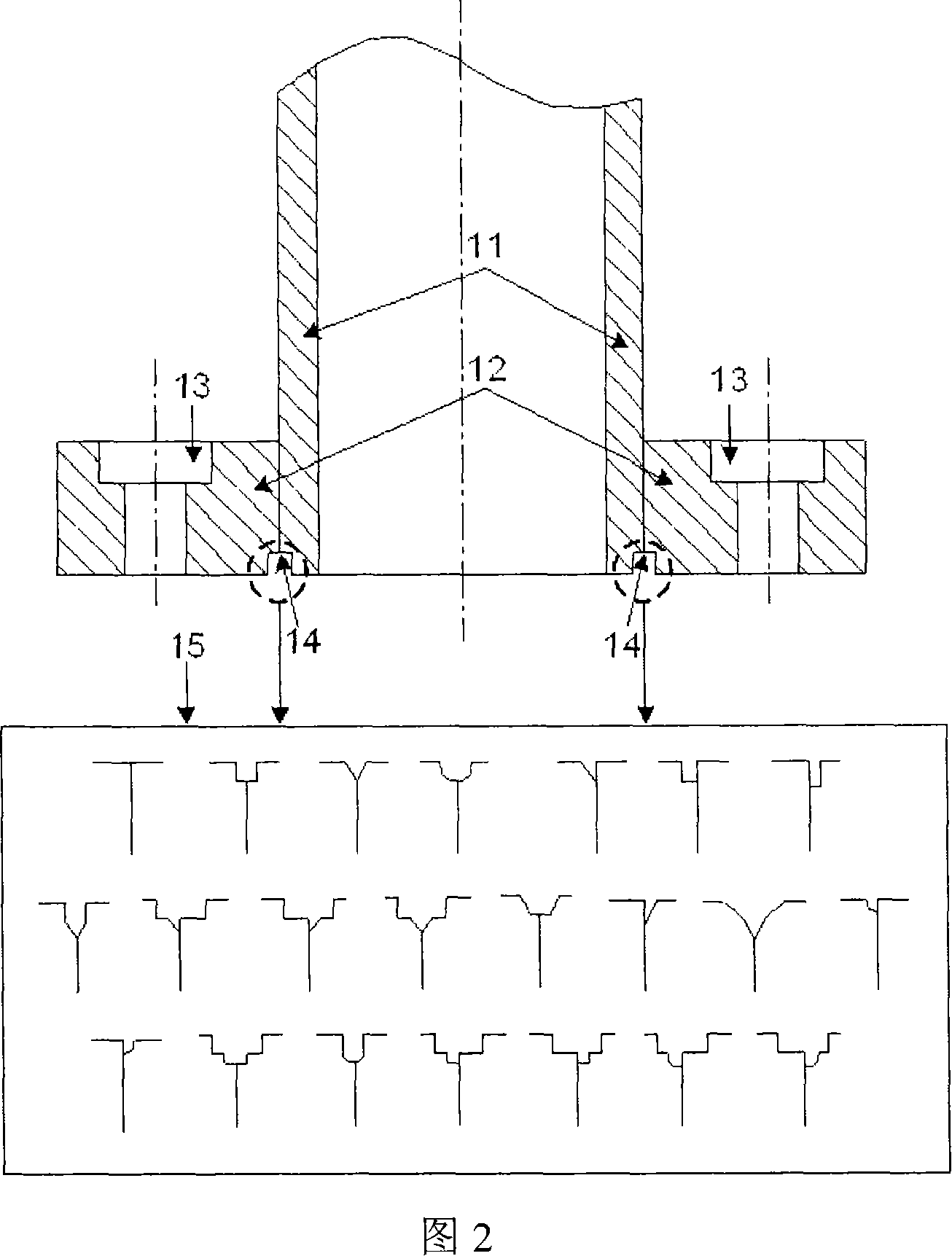

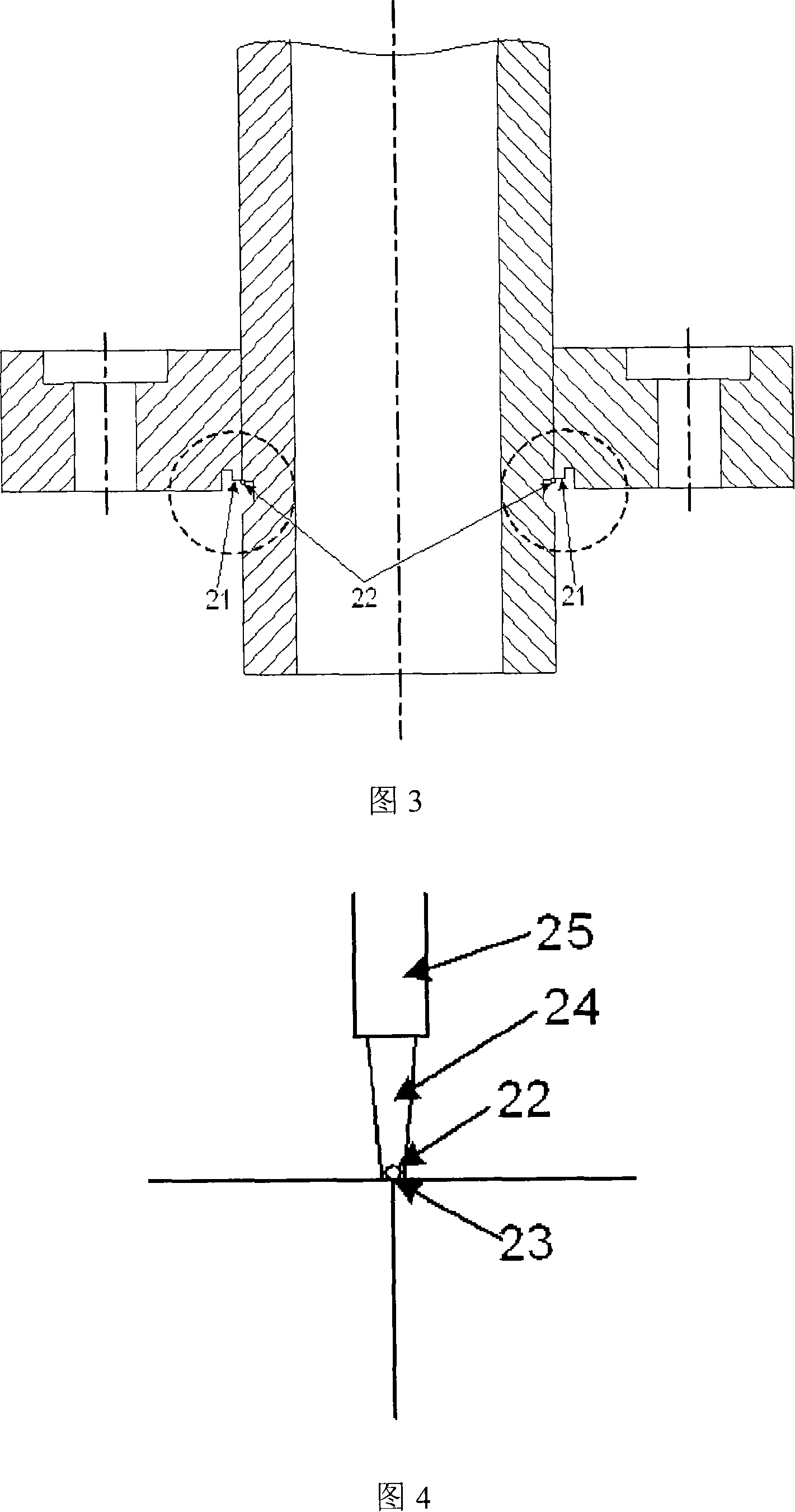

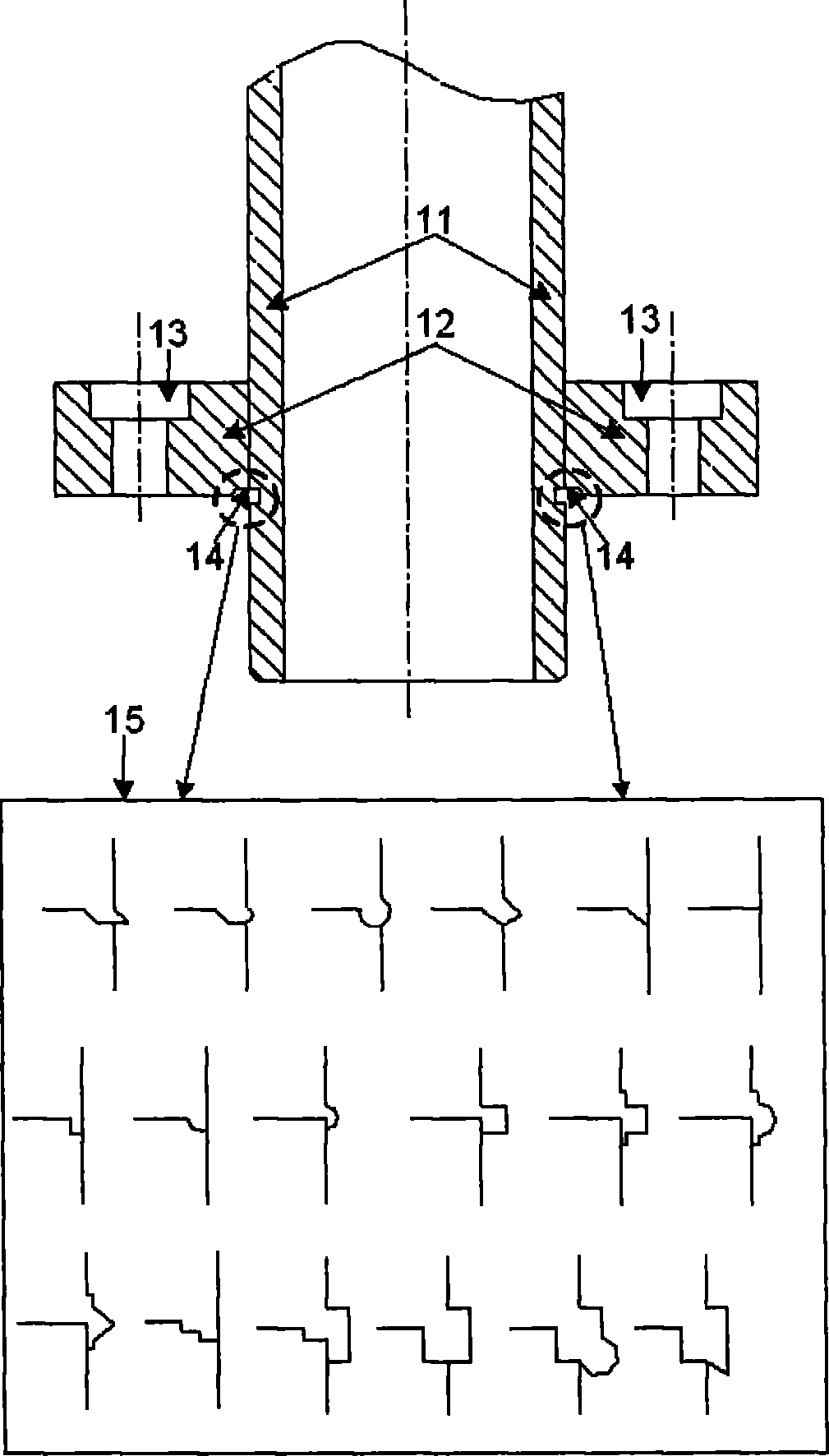

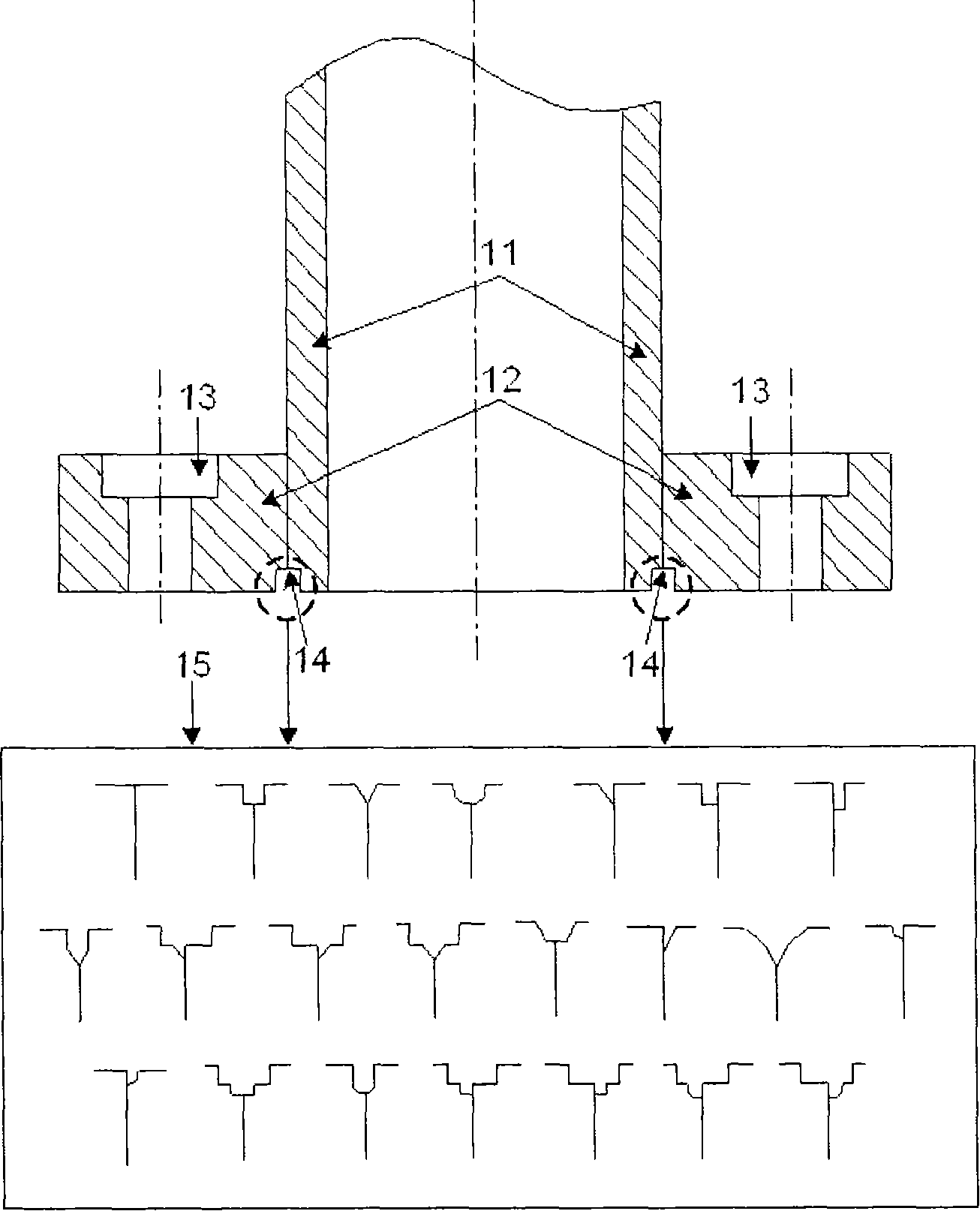

A manufacturing method of machinery parts for linear motion and linear bushing manufactured by the above method

ActiveCN101111345AReduce manufacturing costReduce inventory quantityLaser beam welding apparatusWorkpiece edge portionsFiller metalLinear motion

Disclosed are a flanged linear bushing formed by connecting an outer sleeve and a flange and a method of manufacturing the same. The manufacturing method includes the steps of: processing the edge of the outer sleeve at a predetermined angle to smoothly connect between the flange and the outer sleeve; after the flange and the outer sleeve are connected to each other, taking into account the the thickness of the outer sleeve, forming recesses on the outer surface of said outer sleeve at a uniform depth and width for simple laser welding; in a form corresponding to the recesses formed on said outer sleeve, machining the inner edge of the flange along the inner circumference of the flange to allow simple laser welding; connecting said flange and the outer sleeve manufactured through the above steps; and welding the notch formed on the outer sleeve using a high-energy beam A connection portion that is connected to each other with a structure formed on the flange, or the connection portion is welded with a high-energy beam having better linearity, while feeding a filler metal of a predetermined diameter to the connection at a predetermined speed. The invention can improve productivity through automatic processing, obtain dimensional stability and higher precision, and reduce manufacturing cost by reducing manufacturing processes.

Owner:SAMICK PRECISION IND

Method and equipment for processing polytetrafluoroethylene sealing ring

ActiveCN104527057AImprove processing efficiency and molding accuracyReduce manufacturing processButt jointPTFE - Polytetrafluoroethylene

The invention discloses a method for processing a polytetrafluoroethylene sealing ring. The method comprises the following steps: 1) setting a hot melting mold, wherein the hot melting mold comprises an upper mold and a lower mold, a segment of die cavity is formed between the upper mold and the lower mold, and the end face of the segment of die cavity is matched with the end face of a sealing ring needing to be welded; setting a welding mechanism on the hot melting mold, wherein the welding mechanism comprises a heating device corresponding to the die cavity, a filler area and a material pressing device; 2) putting both ends of a cut sealing strip in the die cavity of the hot melting mold according to the set specification of the sealing ring, and corresponding the butt joint sites at the both ends of the sealing strip to the welding mechanism; 3) putting corresponding modified fillers in the filler area of the welding mechanism, heating the filler area through the heating device, pressing the filler area through the material pressing device after reaching a set temperature, and maintaining the pressure for a period of time until the butt joint sites at the both ends of the sealing strip are fully fused with the modified fillers to form the sealing ring. The invention further discloses equipment for implementing the method.

Owner:广东科雷明斯智能科技有限公司

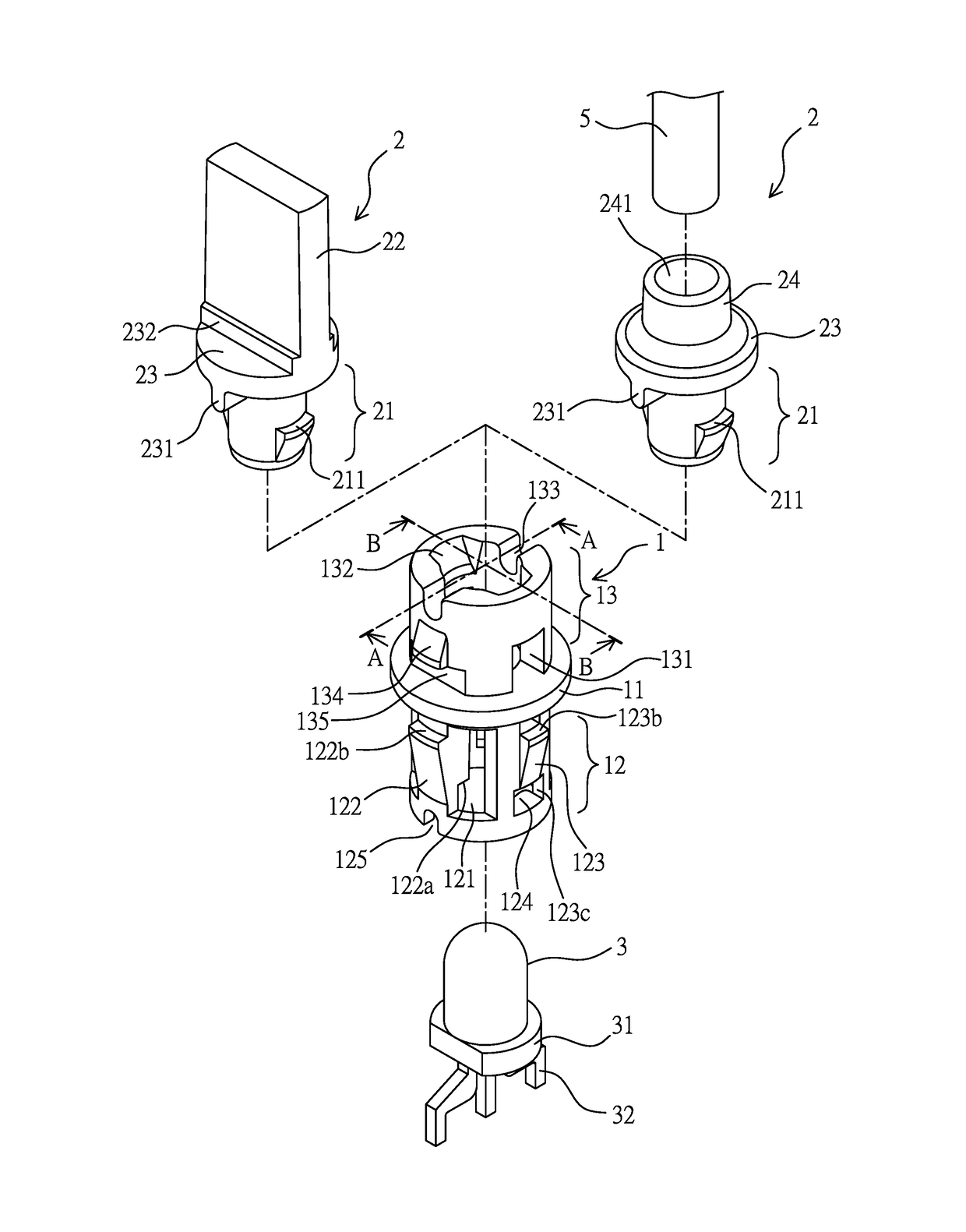

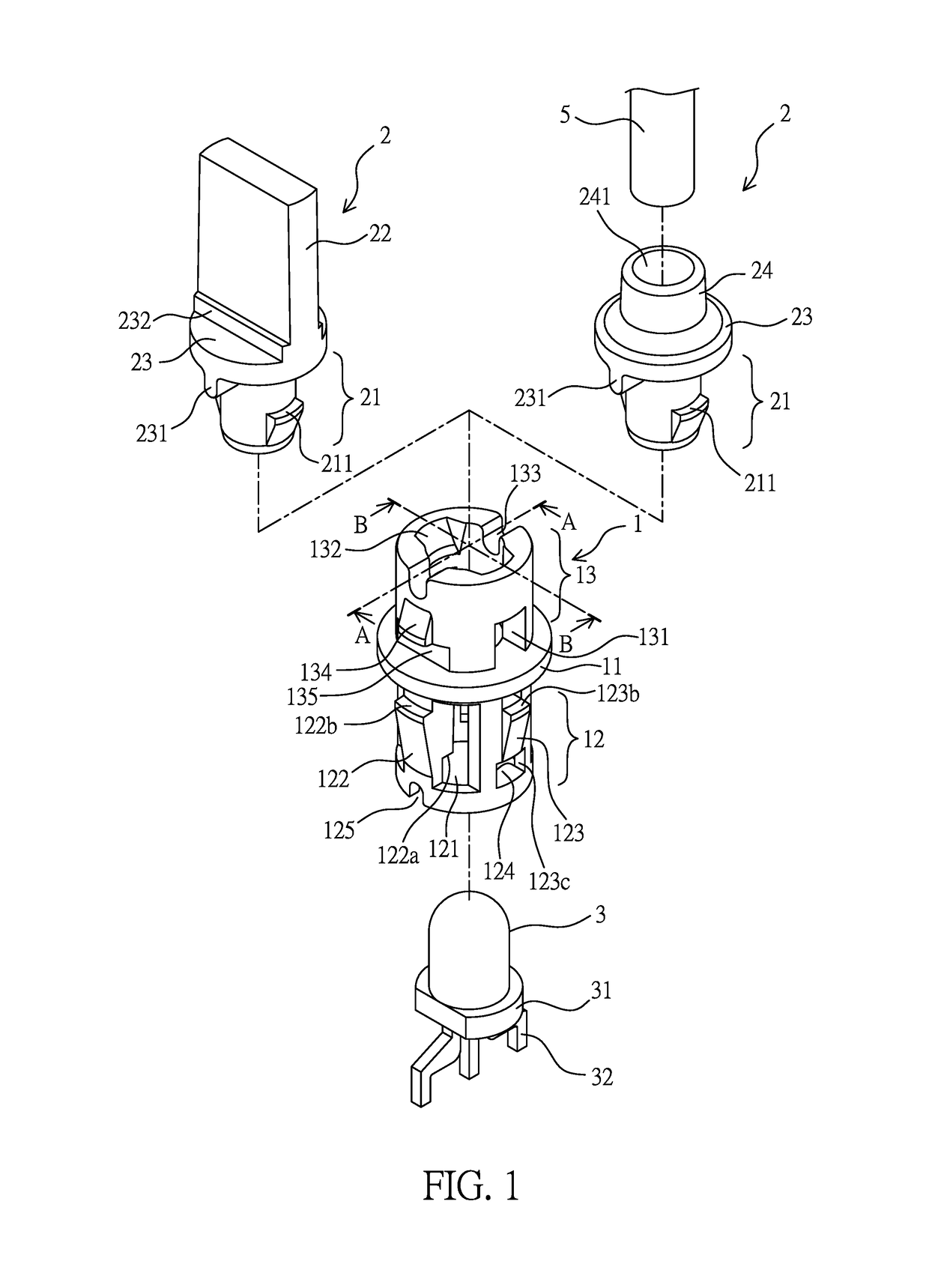

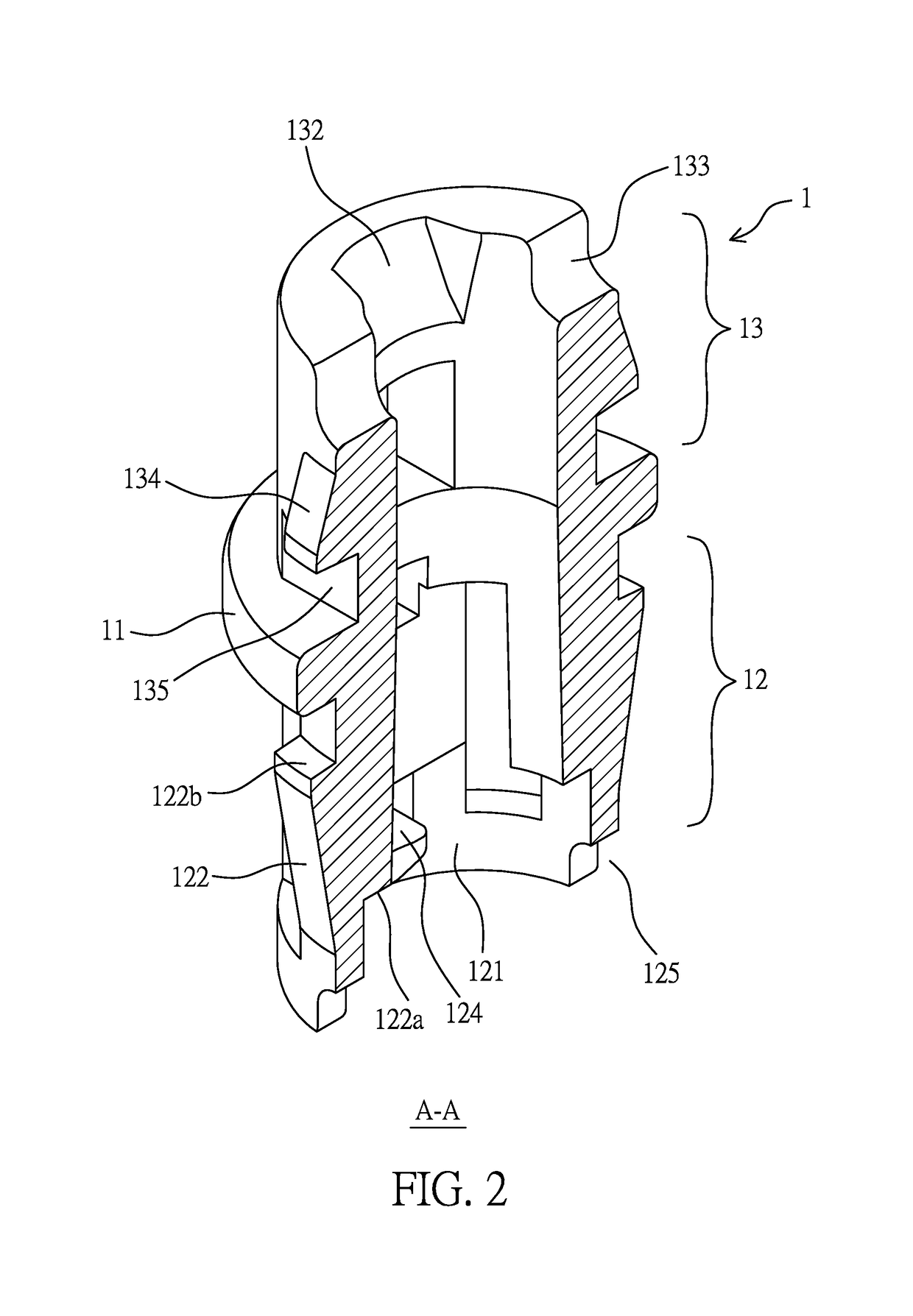

Multi-function light guide socket

ActiveUS10001606B1Reduce inventory quantityCost reductionMechanical apparatusFibre light guidesComponent fixationMultiple function

A multi-function light guide socket, including: a connecting tube, including a light source fixation part and a component fixation part, the light source fixation part having a pair of hollowed slots formed at two peripheral locations thereof, the pair of hollowed slots each having a first column therein along an axial direction, the first column having a first low-side stop edge on an inner surface thereof, at least two latching flaps protruding from an inner surface of a bottom opening of the connecting tube to cooperate with a pair of the first low-side stop edges to clamp a flange of a light emitting diode, and the component fixation part having at least two latching slots formed at at least two peripheral locations thereof; and an optical component including an engaging part for being plugged into and engaged with the component fixation part.

Owner:KANG YANG HARDWARE ENTERPRISES

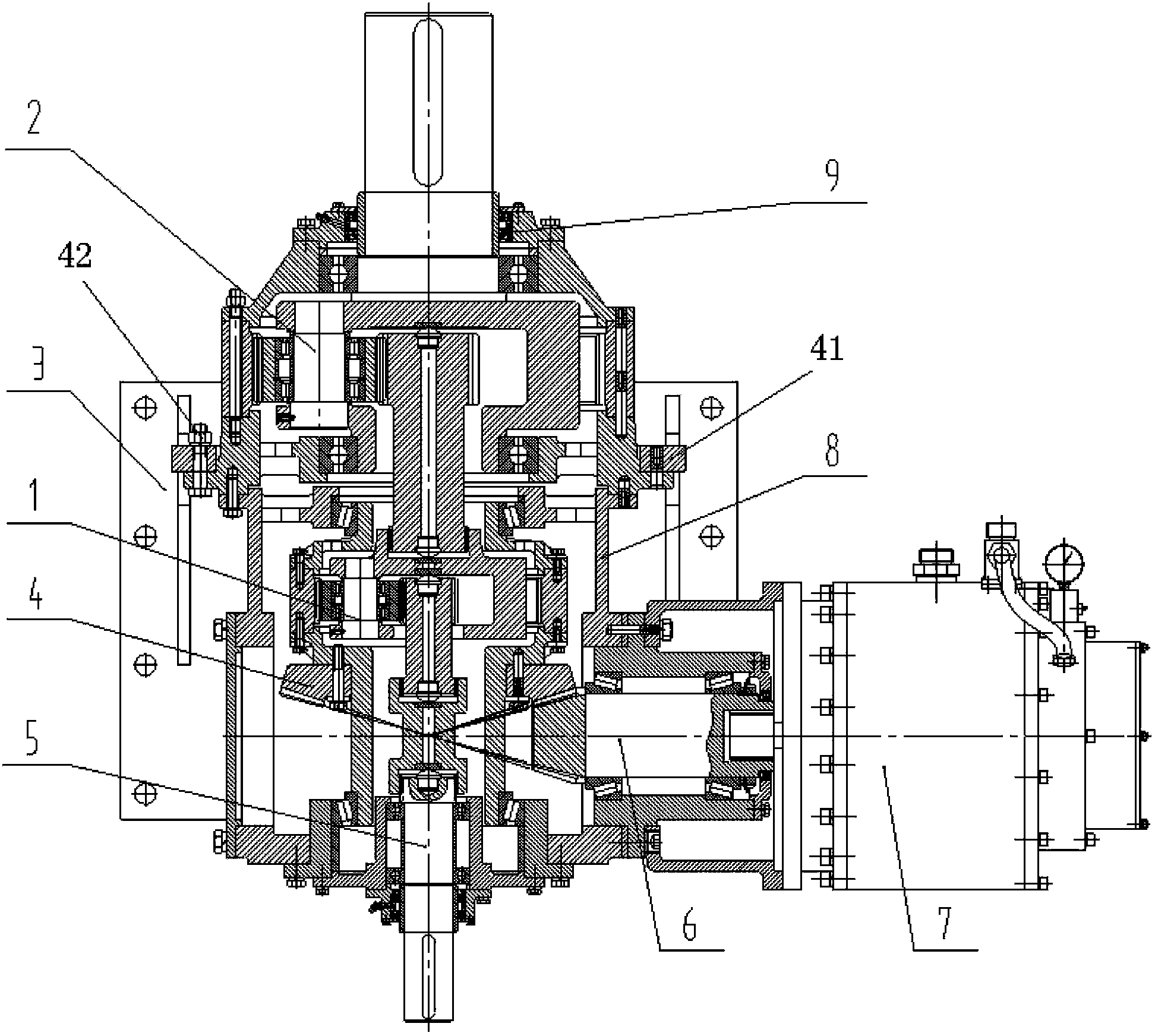

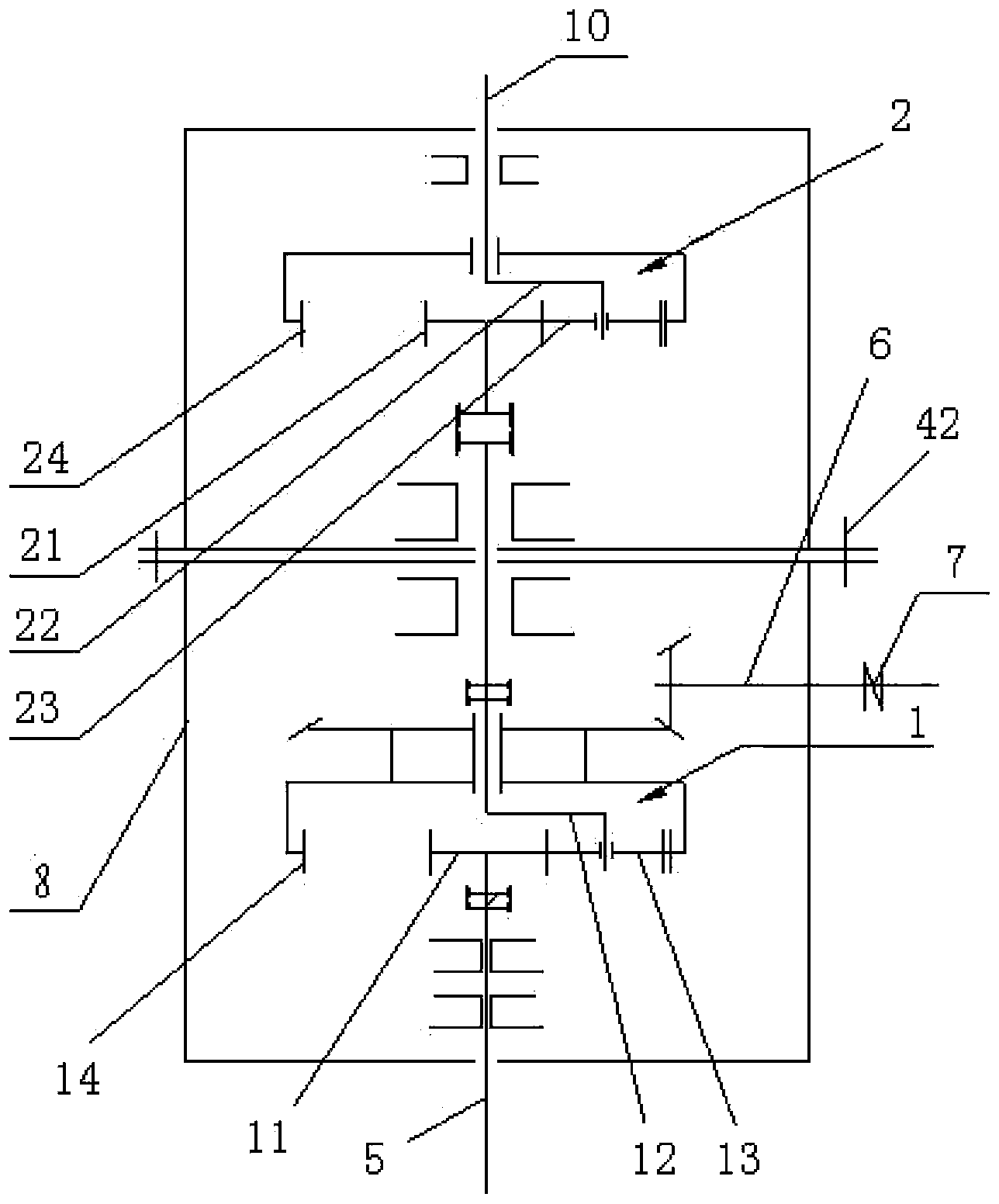

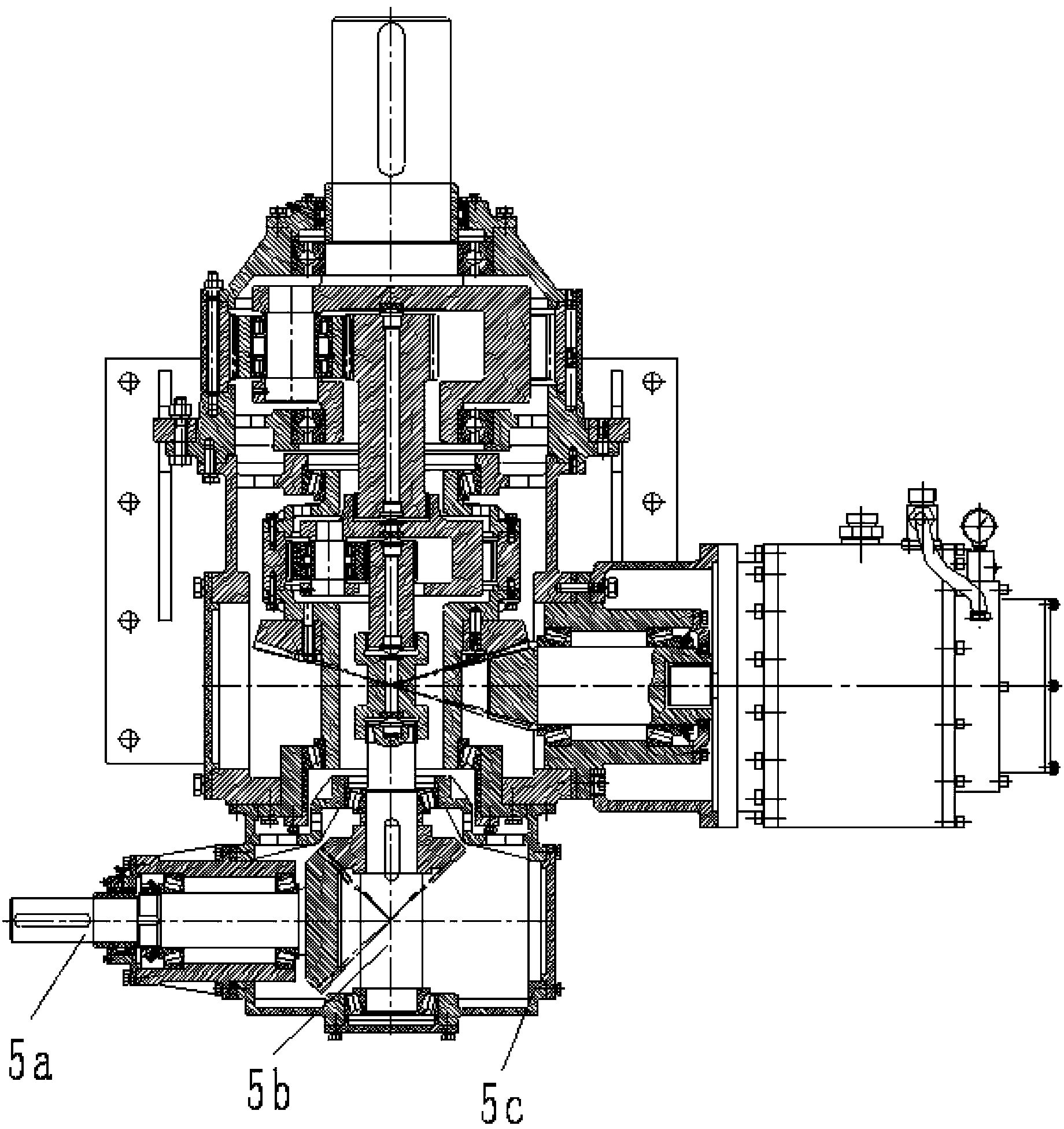

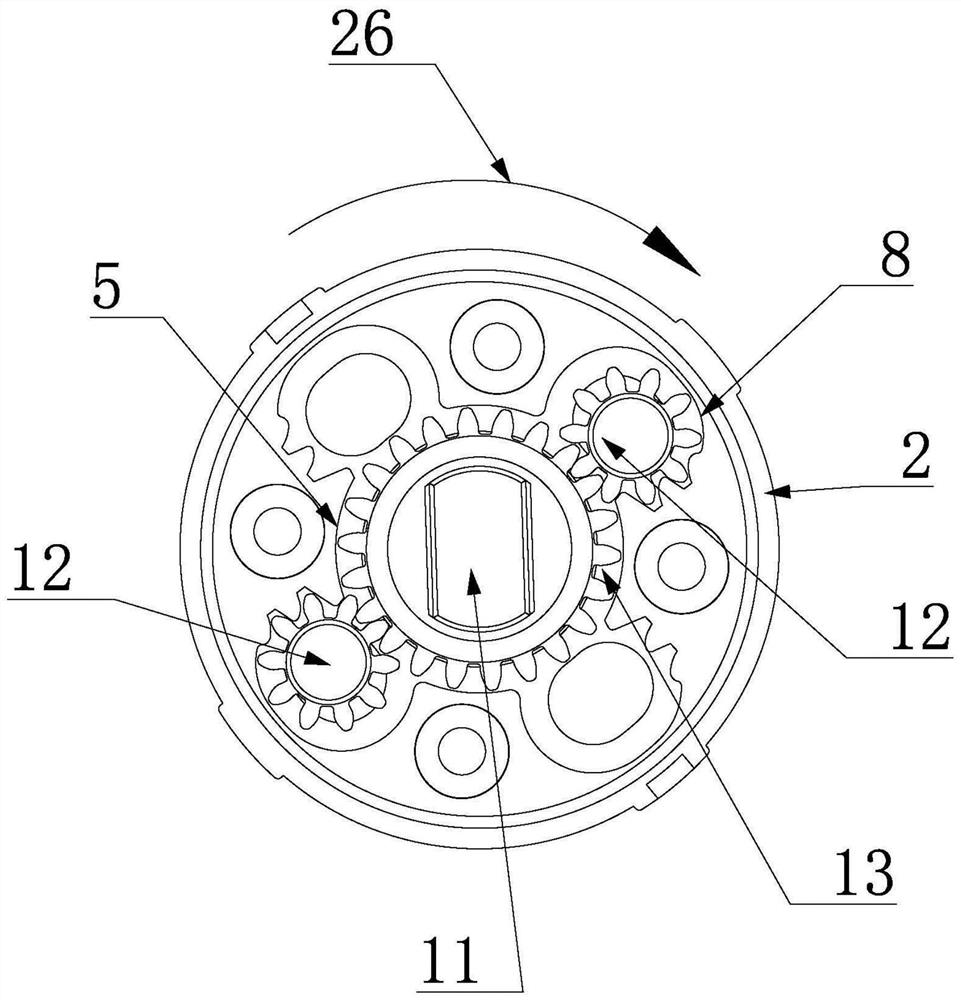

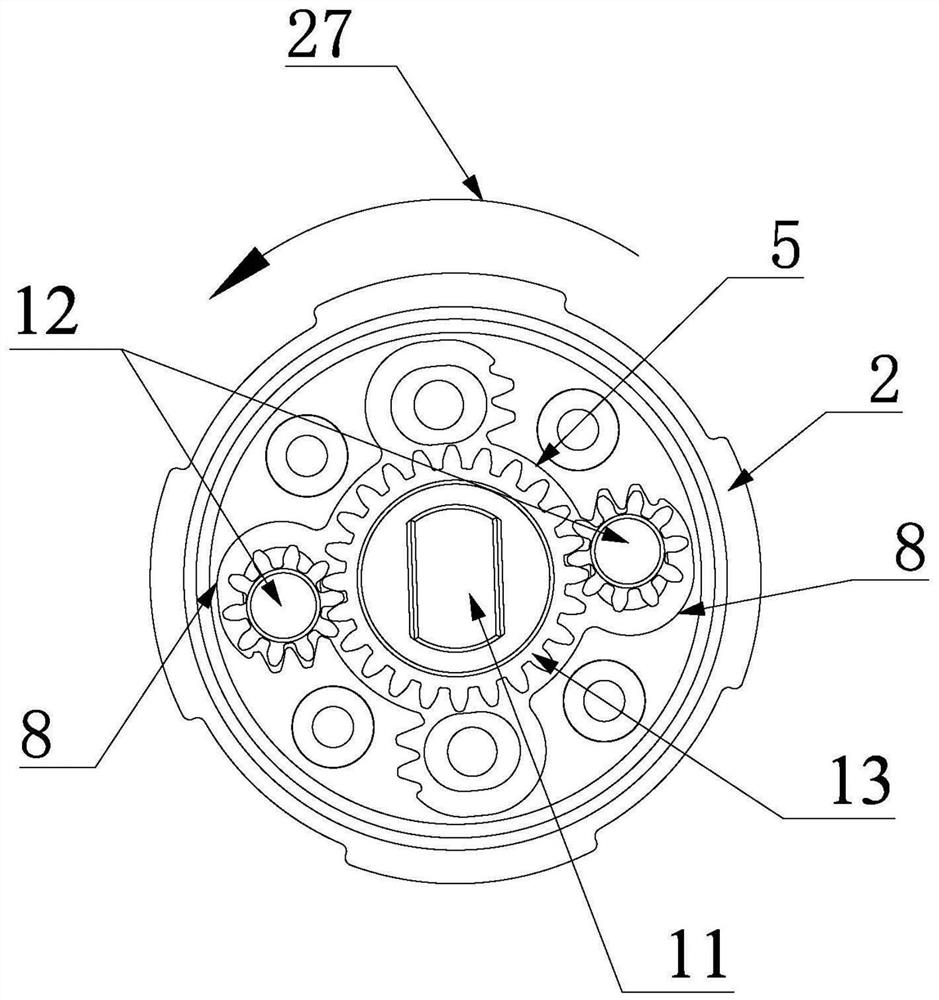

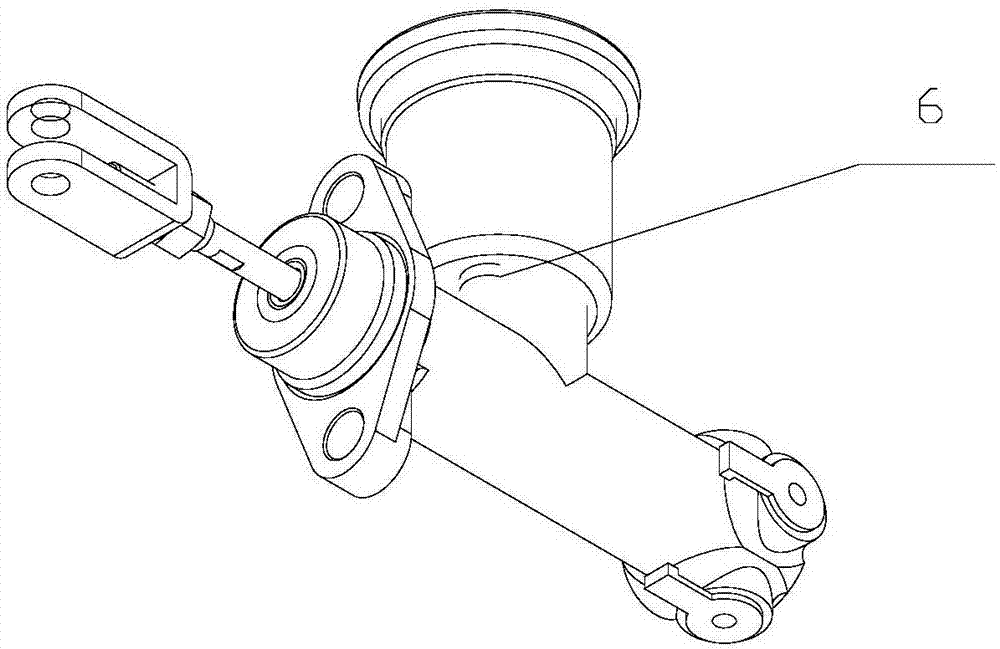

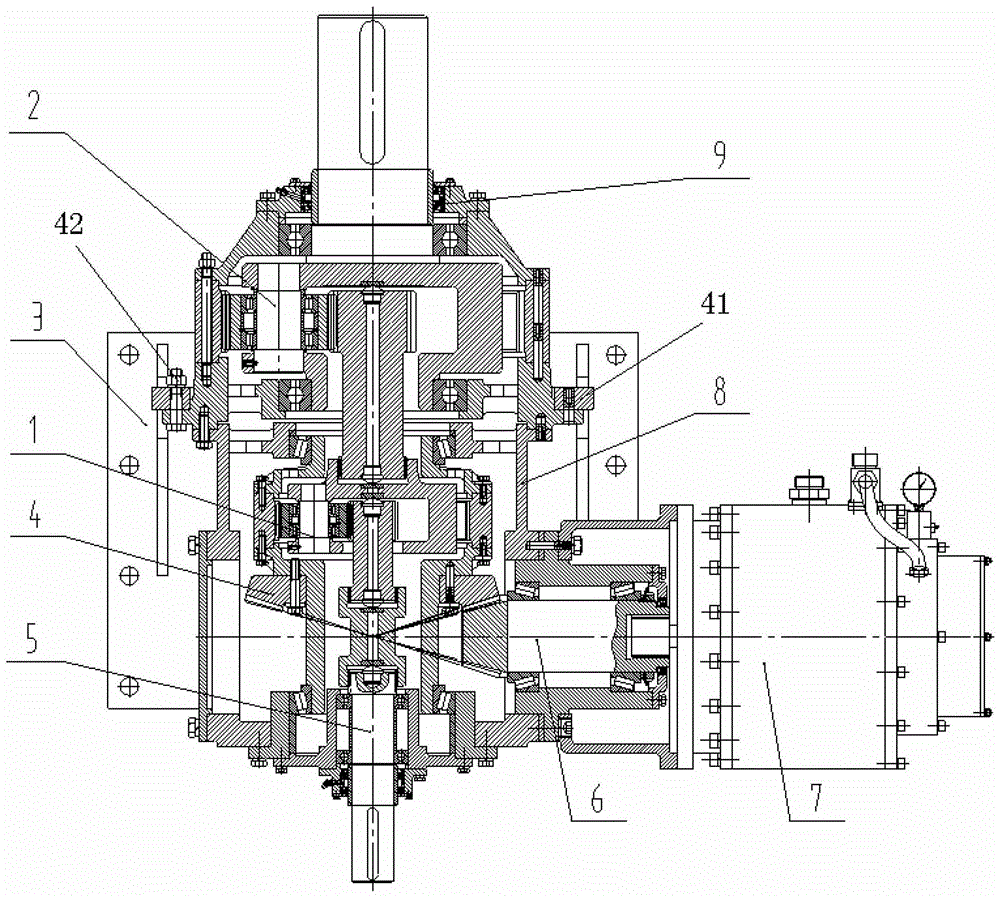

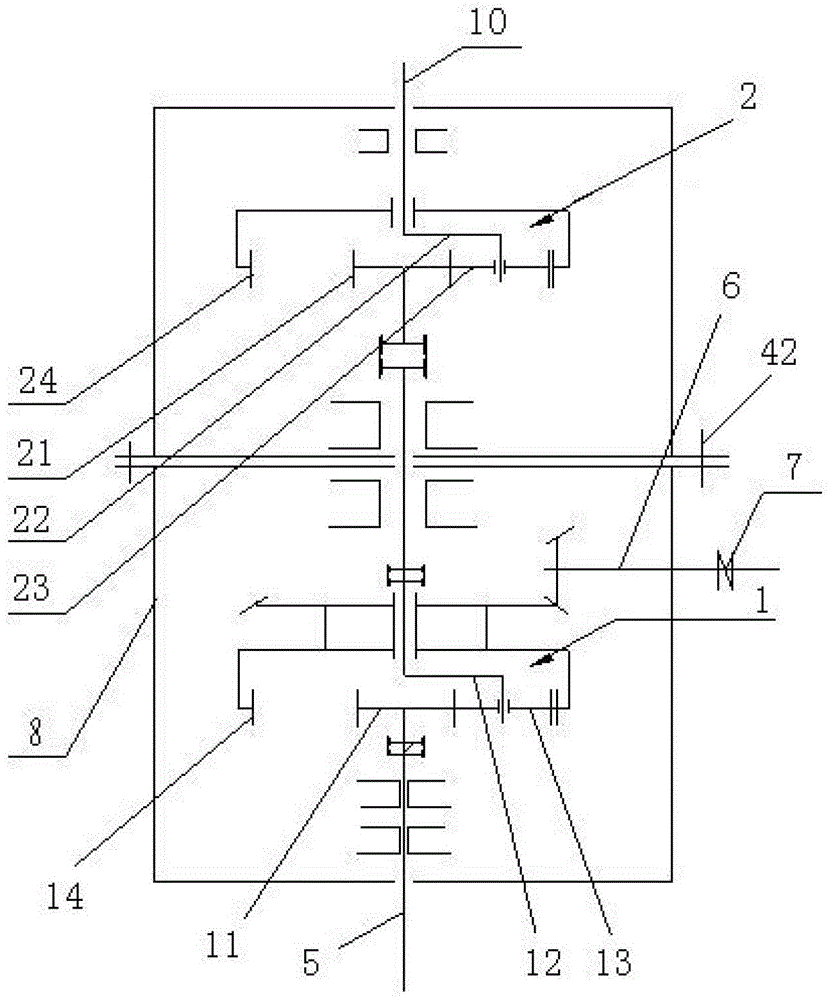

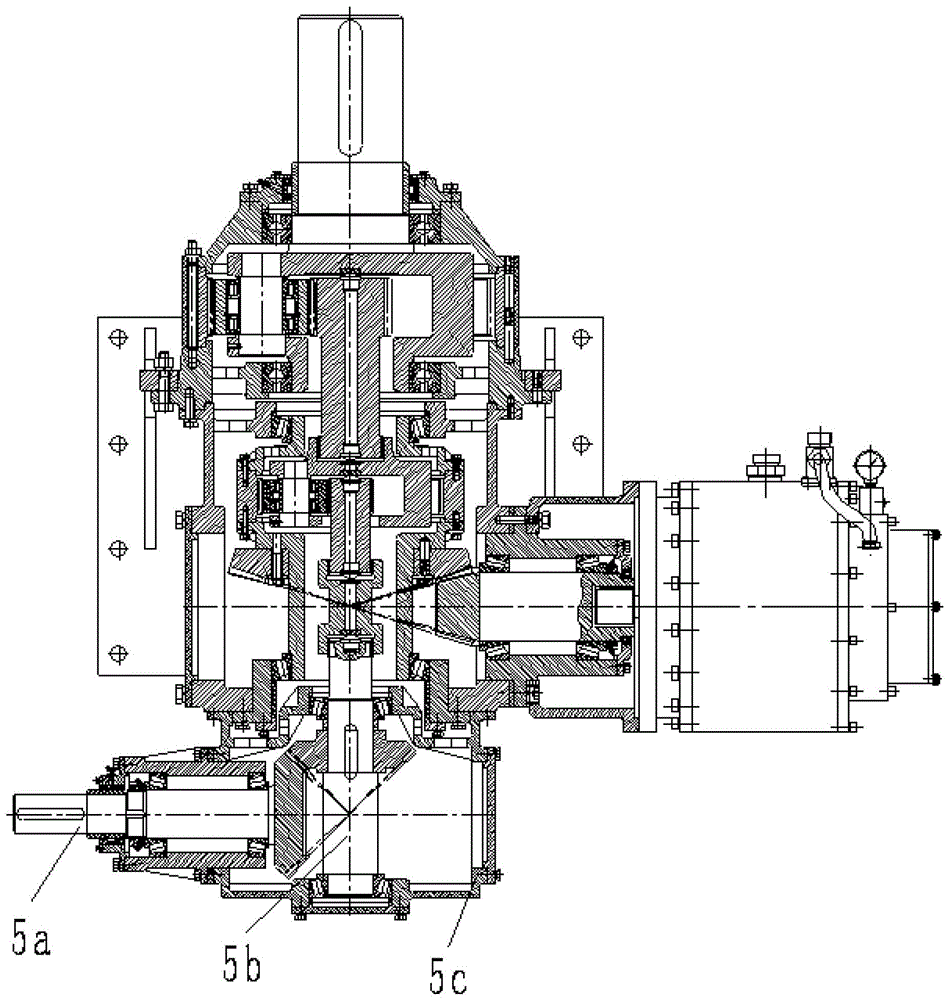

Mechanical soft start gear reducer for belt conveyor

ActiveCN103352962AReduce in quantityReduce investmentConveyorsToothed gearingsTransmitted powerReduction drive

The invention discloses a mechanical soft gear reducer for a belt conveyor. The mechanical soft gear reducer for the belt conveyor comprises an input shaft, an output shaft, a first planetary transmission mechanism, a second planetary transmission mechanism and a brake which are in transmission connection, wherein the input shaft, the first planetary transmission mechanism, the second planetary transmission mechanism and the output shaft form a main transmission line and transmit power from a motor and the like to a main machine of the belt conveyor, and the main machine is connected with the output shaft; and the brake and the first planetary transmission mechanism such as a first internal ring gear form an auxiliary transmission line, and the brake controls the first planetary transmission mechanism, so that soft start is realized. With the adoption of the two planetary transmission mechanisms, the bearing capacities of the transmission mechanisms are larger, and the speed adjusting range is wider.

Owner:BEIJING HAFORD SYST TECH

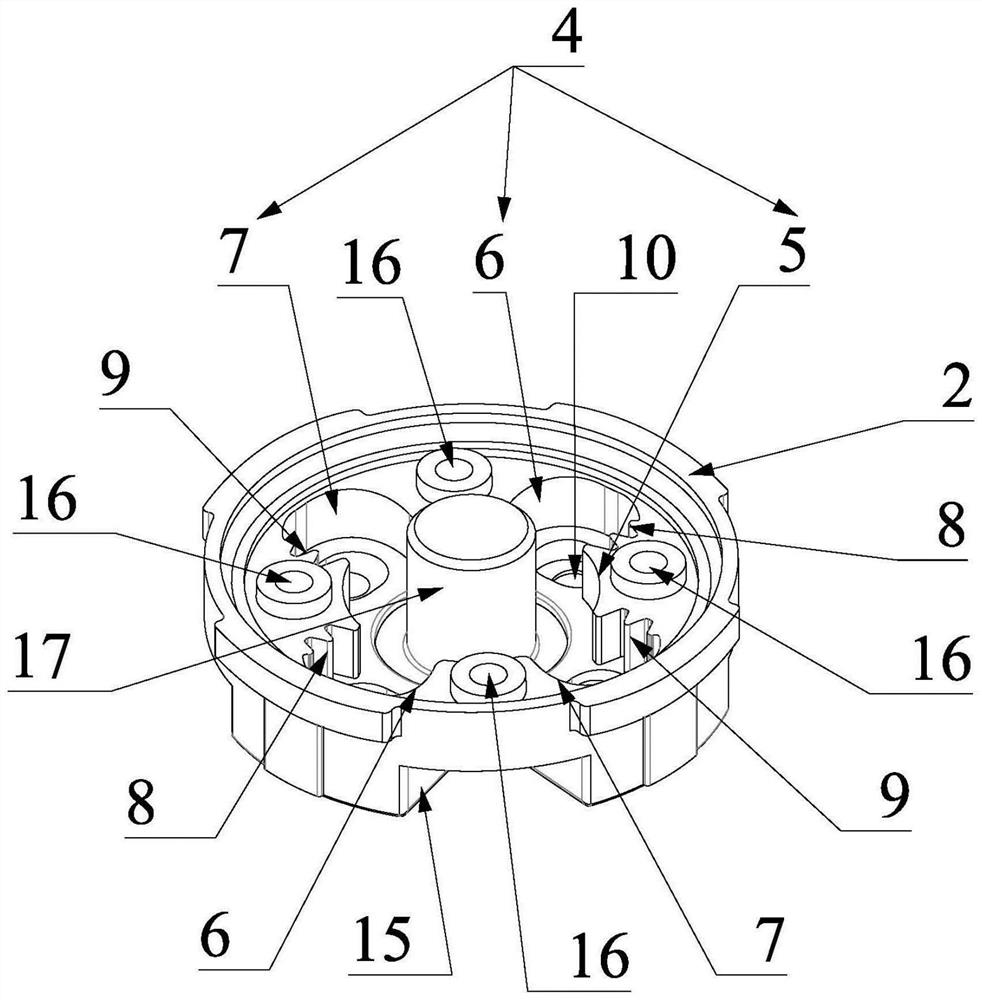

Damping rotating body and damper

The invention discloses a damping rotating body, and relates to the technical field of dampers. The damping rotating body comprises a rotating main body and a groove cover, and first gear grooves capable of being engaged with clamping gears are formed in the side wall faces, opposite to the clockwise direction around the axis of a positioning circular groove, of all clockwise arc-shaped grooves; second gear grooves capable of being engaged with the clamping gears are formed in the side wall surface, opposite to the anticlockwise direction around the axis of the positioning circular groove, of all anticlockwise arc-shaped grooves; first oil passing holes communicating gear containing grooves with the interior of a damper shell are formed in the rotating main body; and second oil passing holes communicating the gear containing grooves with the interior of the damper shell are formed in the groove cover. The invention further discloses a damper. The damper comprises a damper shell, a shell cover and the damping rotating body; the shell cover seals the damper shell; the shell cover and the damper shell form a containing cavity; the damping rotating body is arranged in the containing cavity; and the production cost can be reduced, and the damping performance of the damper is improved.

Owner:GANZHOU HEYING AUTO PARTS

Method for arranging display equipment software and method for writing control parameters into FLASH

InactiveCN101976577BImprove design and development efficiencyReduce complexityRead-only memoriesElectricityPaper document

The invention discloses a method for arranging display equipment software and a method for writing control parameters into FLASH. A control program of the software is separated from the control parameters; a part of invariable control parameters and preset fixed values are stored in the FLASH (flash memory); and the FLASH is set in protected states for realizing read-only effect. The methods havethe advantages that: the control program and the control parameters are arranged separately, so that the setting complexity and risk of the control parameters can be lowered greatly, a large number of redundant verification processes are avoided and the development and design efficiencies of display equipment are improved; the writing opportunity of the control parameters is reduced, so that the risk of data loss caused by surge is lowered; simultaneously, an after-sales service department does not need to prepare for a large number of stock products; and once mechanism sizes are accordant, only the control parameters of the conventional product are set into a software document and are burnt, so that stock quantity can be reduced greatly and maintenance efficiency is improved.

Owner:TPV DISPLAY TECH WUHAN

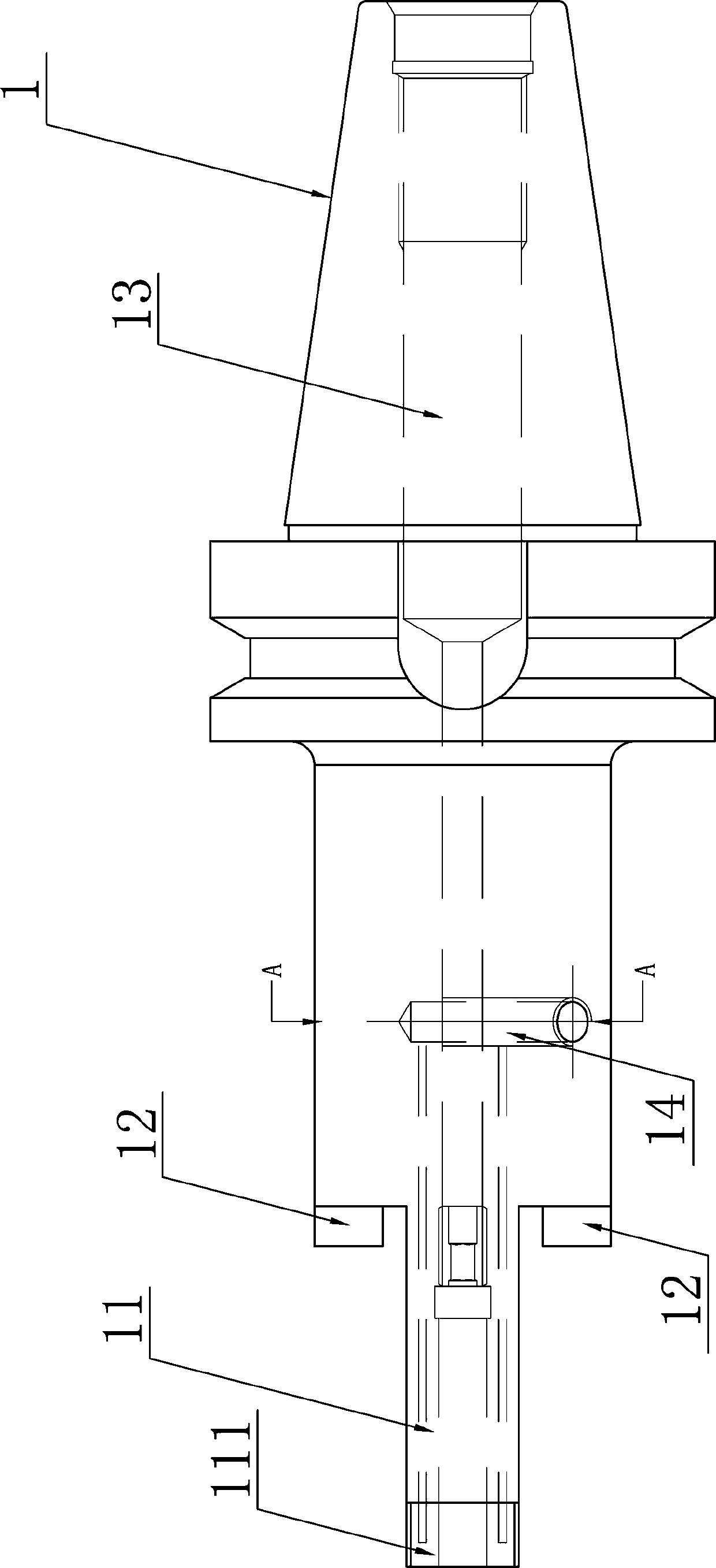

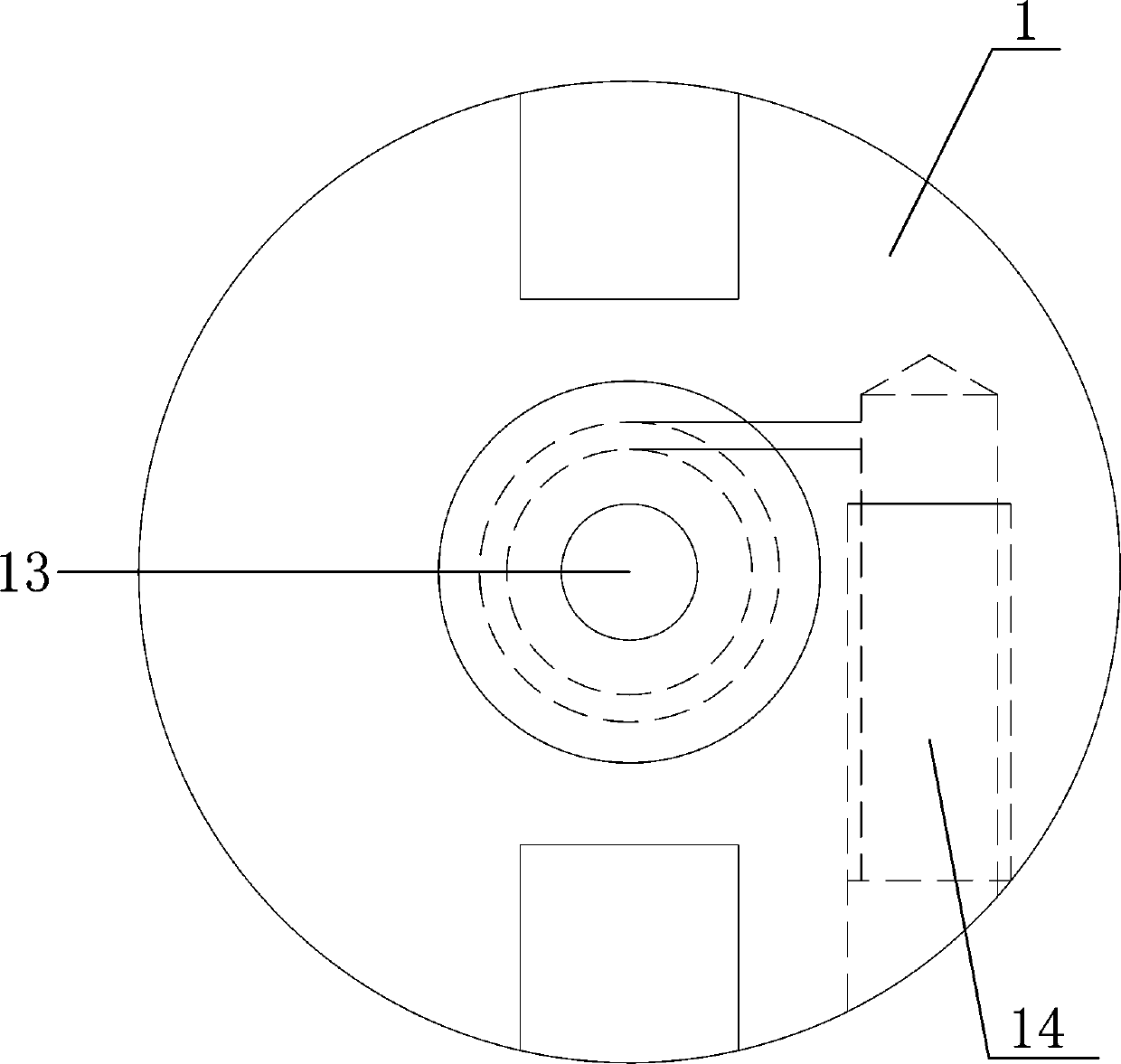

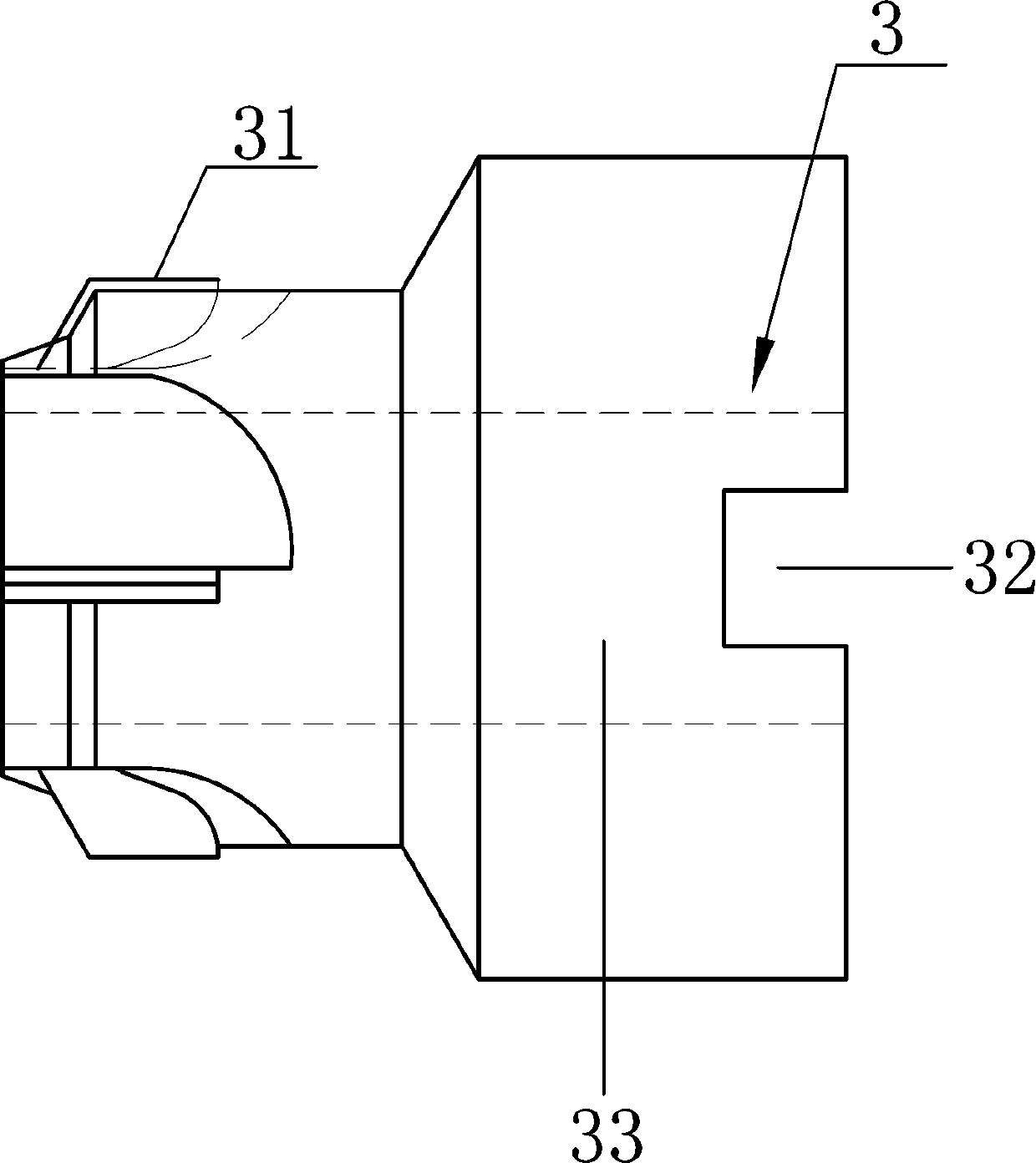

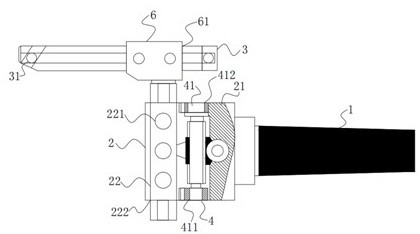

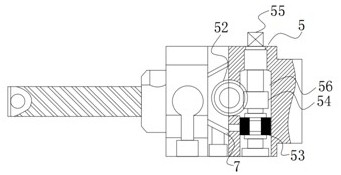

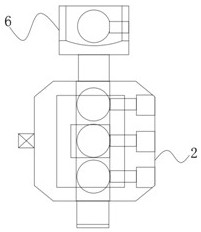

Hydraulic clamping multipurpose tool with replaceable periphery blades

PendingCN107552882AHigh clamping precisionEasy to operateReaming toolsPositioning apparatusTransducerEngineering

The invention relates to the field of tools of a machining center, in particular to a hydraulic clamping multipurpose tool with replaceable periphery blades. The hydraulic clamping multipurpose tool with the replaceable periphery blades comprises a hydraulic tool rod (1), and is characterized by further comprising a hydraulic locking bolt (2), a multi-blade chamfering tool (3), a locking nut (4) and a reamer (5); a positioning rod (11) is arranged at the middle portion of the front end of the hydraulic tool rod (1), at least three hydraulic oil runners (111) are arranged at the front end of the positioning rod (11), outer threads matched with the locking nut (4) are tapped on the outer side faces of the hydraulic oil runners (111), and a tool rod cooling hole (13) penetrating the front endface of the positioning rod (11) and the rear end face of the hydraulic tool rod (1) is formed in the middle portion of the hydraulic tool rod (1). The hydraulic clamping multipurpose tool with the replaceable periphery blades is simple in operation, convenient to use, convenient and fast to adjust, high in adaptability and high in precision.

Owner:上海新山田精密刀具有限公司

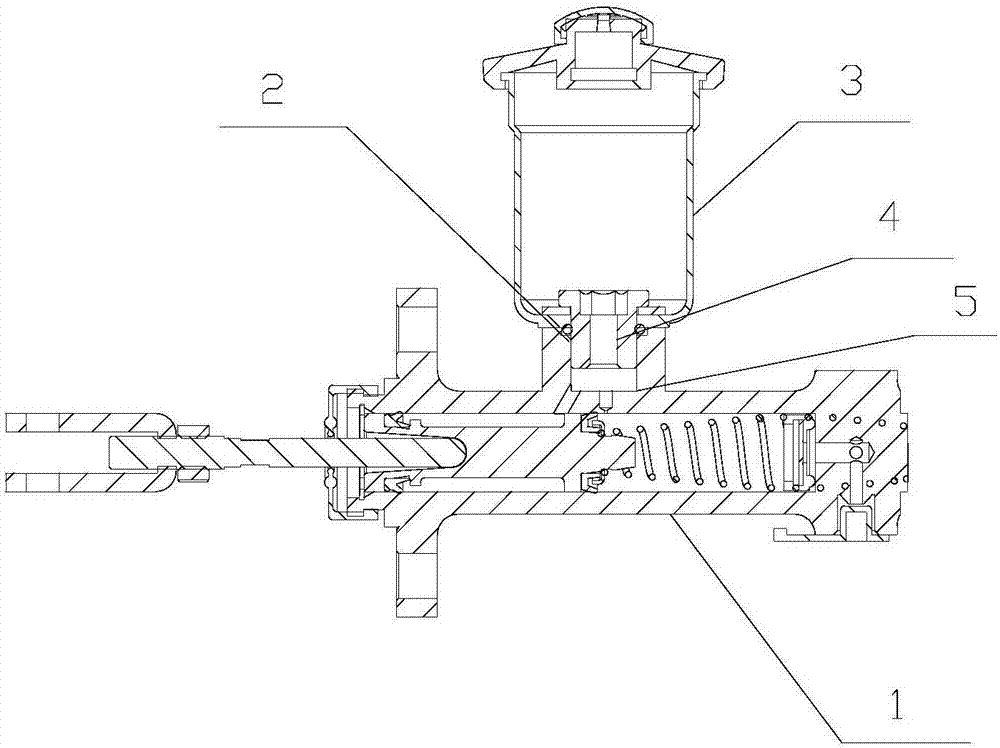

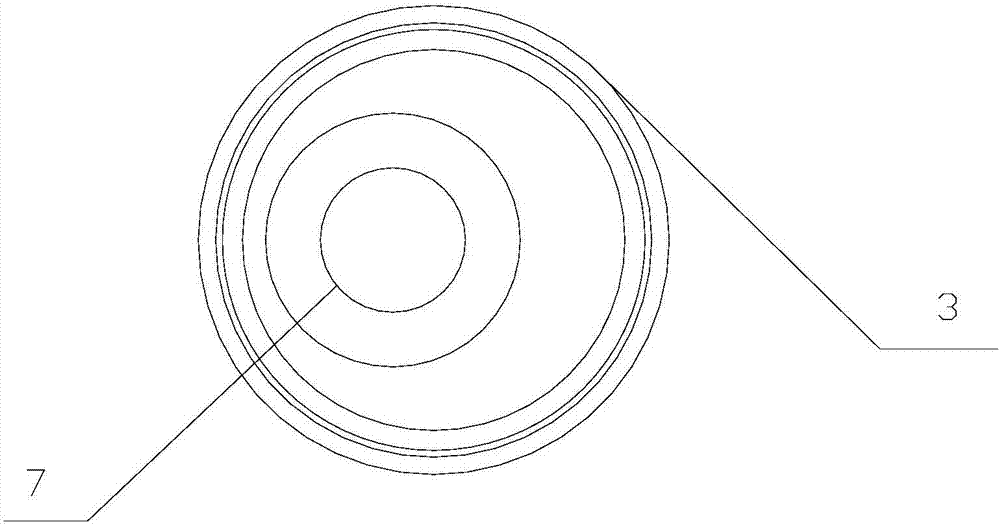

Brake master pump

PendingCN107499297ASimplified body machiningReduce inventory quantityFluid braking transmissionHydraulic equipmentPetroleum engineering

The invention belongs to the field of hydraulic equipment, and particularly relates to a brake master pump which comprises a pump. A master pump oil can connector is arranged on the pump, an oil can assembly is fixedly connected onto the pump by the master pump oil can connector and comprises an oil can outlet, and the oil can outlet is of an eccentric structure relative to the oil can assembly. The brake master pump has the advantages that the brake master pump is reasonable in structure and easy to machine, the eccentric location of an oil can is convenient to adjust relative to the pump, and accordingly requirements of different clients can be met.

Owner:镇江沃尔夫重工部件有限公司

Mechanical soft start reducer for belt conveyor

ActiveCN103352962BReduce in quantityReduce inventory quantityConveyorsToothed gearingsTransmitted powerReduction drive

The invention discloses a mechanical soft gear reducer for a belt conveyor. The mechanical soft gear reducer for the belt conveyor comprises an input shaft, an output shaft, a first planetary transmission mechanism, a second planetary transmission mechanism and a brake which are in transmission connection, wherein the input shaft, the first planetary transmission mechanism, the second planetary transmission mechanism and the output shaft form a main transmission line and transmit power from a motor and the like to a main machine of the belt conveyor, and the main machine is connected with the output shaft; and the brake and the first planetary transmission mechanism such as a first internal ring gear form an auxiliary transmission line, and the brake controls the first planetary transmission mechanism, so that soft start is realized. With the adoption of the two planetary transmission mechanisms, the bearing capacities of the transmission mechanisms are larger, and the speed adjusting range is wider.

Owner:BEIJING HAFORD SYST TECH

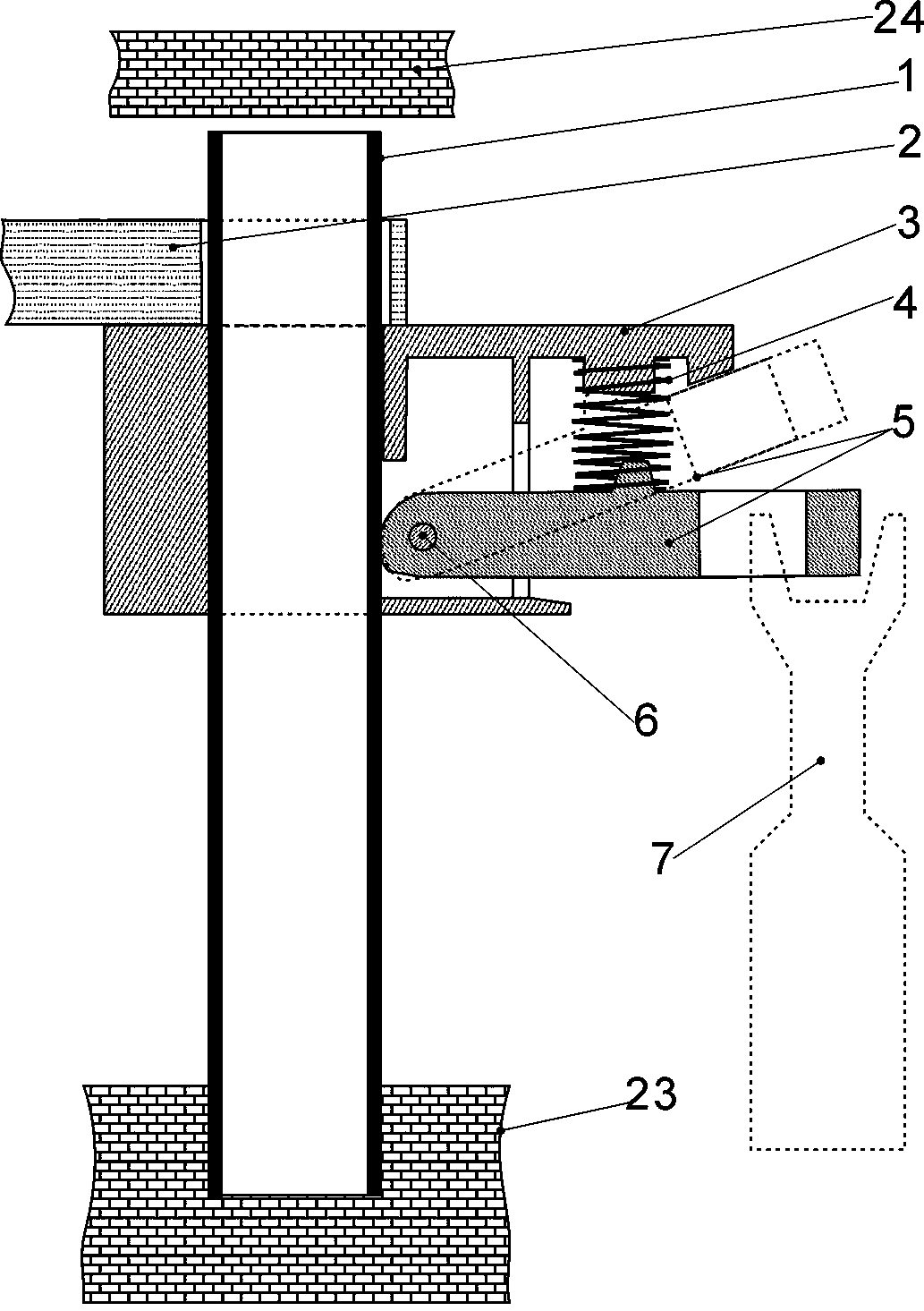

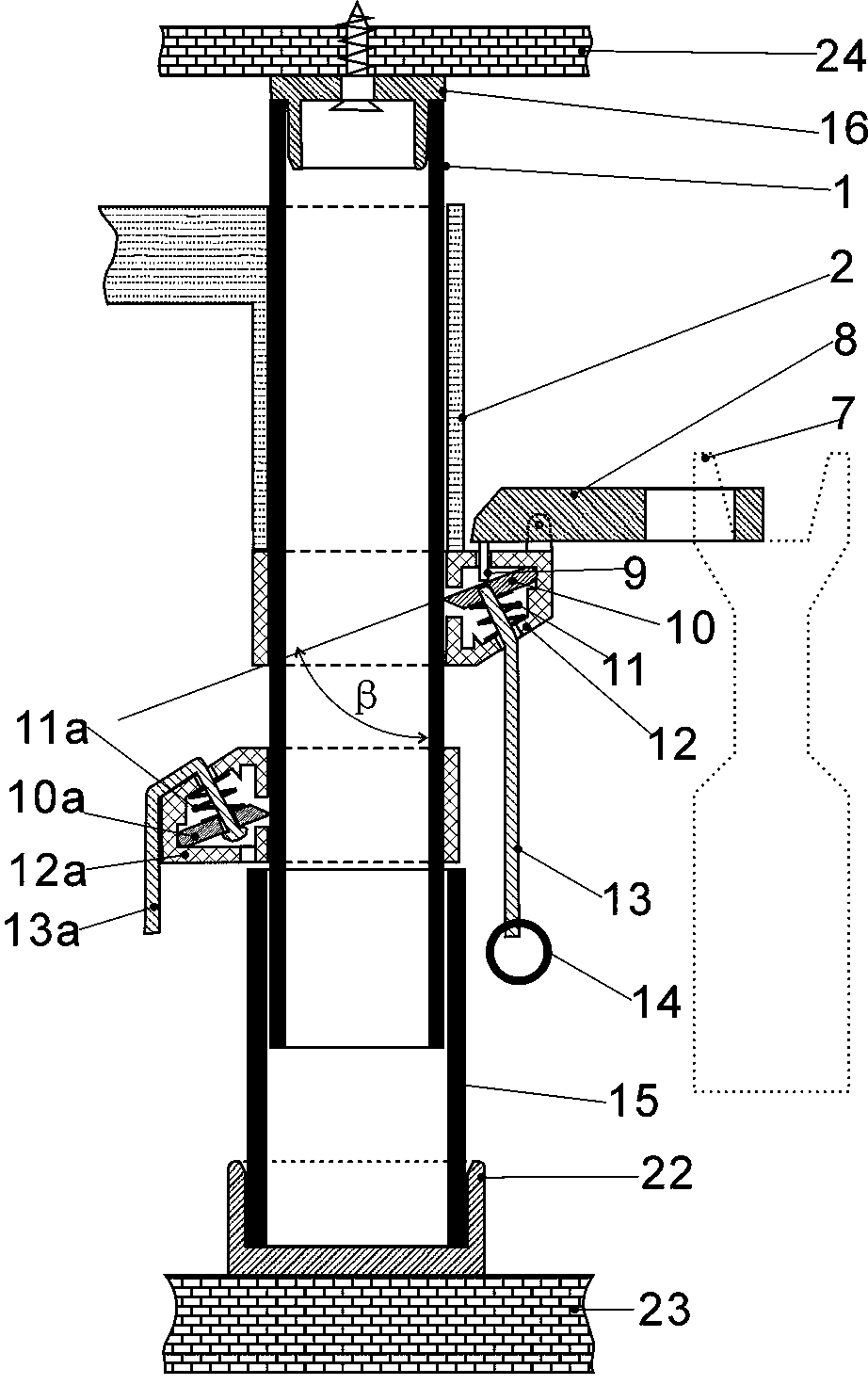

Mosquito net support with struts and sliding locks

The invention relates to a mosquito net support with struts and sliding locks. The mosquito net support comprises a top frame and at least one stand strut, the stand strut is provided with a sliding lock, the sliding lock is composed of a lock shell, a pressure spring, an unlocking mechanism and a friction lock cylinder, the posture or position of the friction lock cylinder in the lock shell determines that the sliding lock is in a locked or unlocked state, the top frame and the load of the top frame are transmitted to the stand strut through the sliding lock in the locked state, the top framecan move up and down along the stand strut in the unlocked state, the pressure spring presses the friction lock cylinder at a position where the sliding lock is in a locked state, people can push andpull the unlocking mechanism to drive the friction lock cylinder to be switched to the position where the sliding lock is in the unlocked state, after the hand is released, the locking is automatically recovered, the push-pull unlocking mechanism can also push up and lower down the sliding lock and the top frame, the mosquito net rises to a ceiling in daily use and falls down in disassembly, washing and maintenance, the push-pull unlocking mechanism has the advantages that the defect that an existing mosquito net with the top frame attached to the ceiling needs high-altitude operation in disassembly, washing and maintenance is overcome, and everyone can be qualified for disassembling and washing mosquito net cloth pieces.

Owner:齐照雷

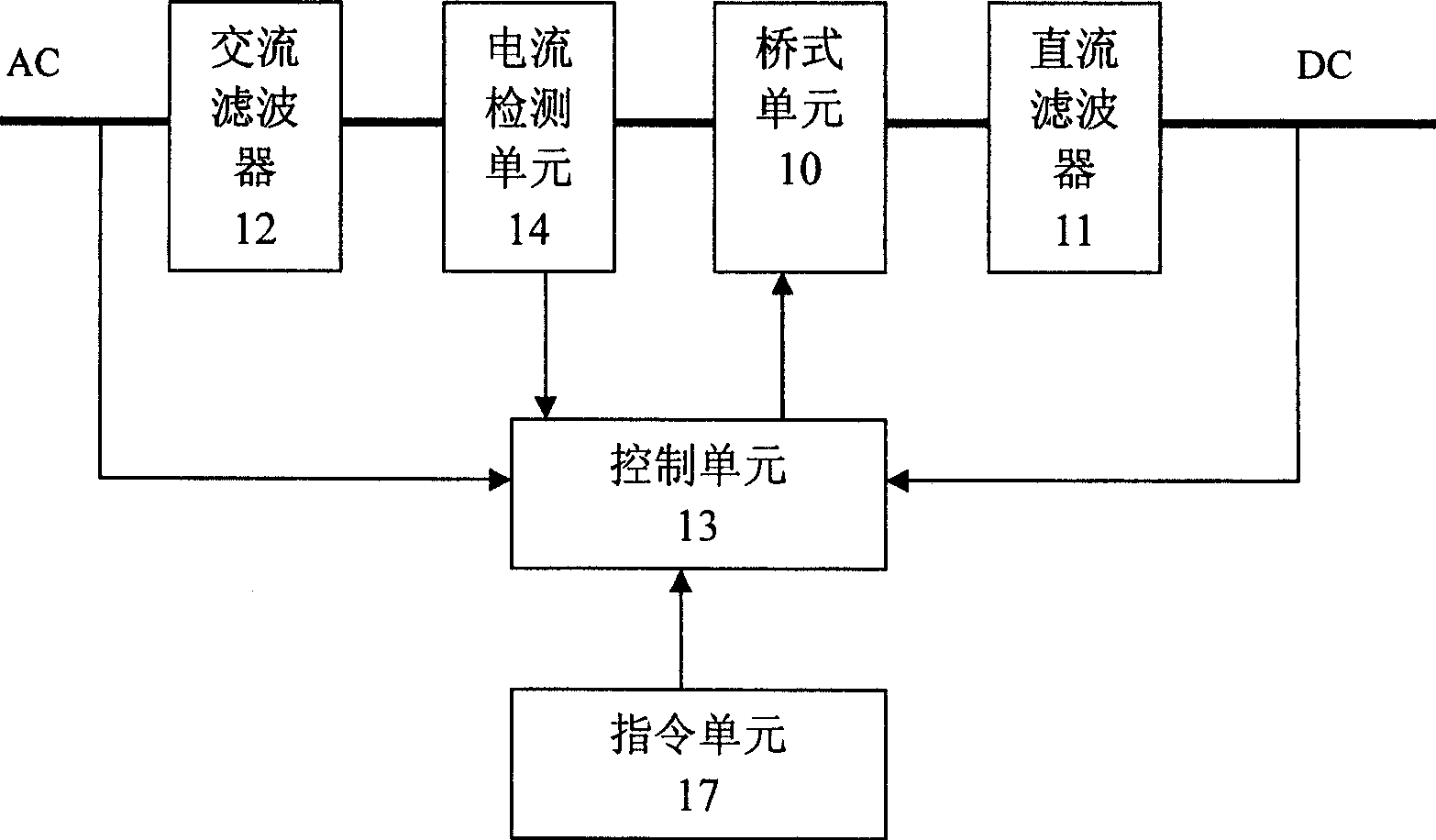

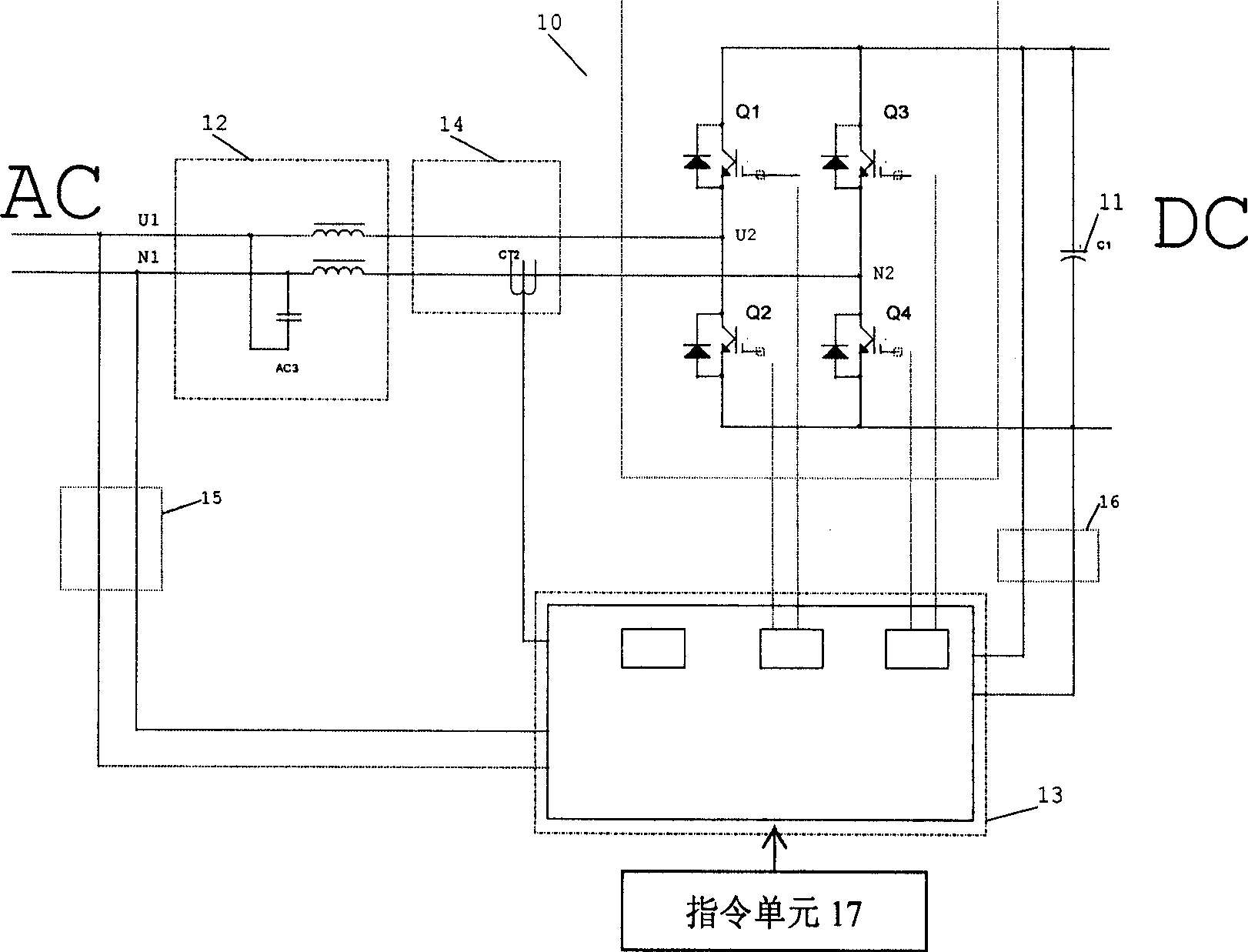

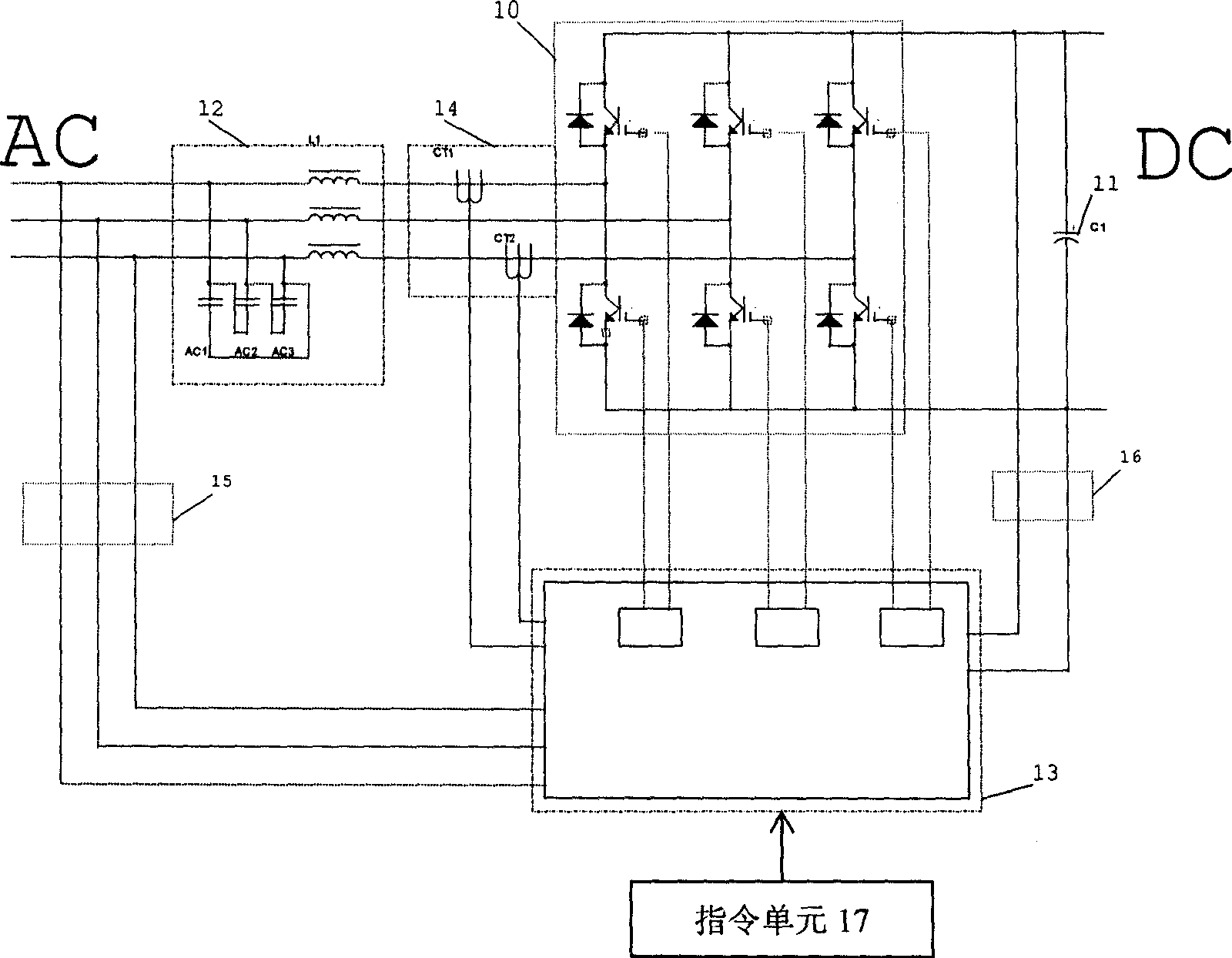

Power supply converter with rectification/inversion switching function

InactiveCN100481703CReduce inventory quantitySimple designConversion with reversalStorage cellEngineering

The present invention relates to a power supply conversion device, which can interchange the functions between rectification and inversaion. The device includes the instruction unit, the bridge type unit and the control unit. The instruction unit provides the rectification instruction and the inversaion instruction. Based on the provided instructions, the output relevant pulse signals control each switch part in the bridge type unit respectively. The control unit realizes the rectification function or the inversion function based on the instruction issued by the instruction unit. Only one device can provide the functions of rectification and inversion. The interchange of the functions can be realized by use of written in different instruction programs or different instruction cards inserted.

Owner:LIANYUNGANG DAFA ENVIRONMENTAL PROTECTION TECH CO LTD

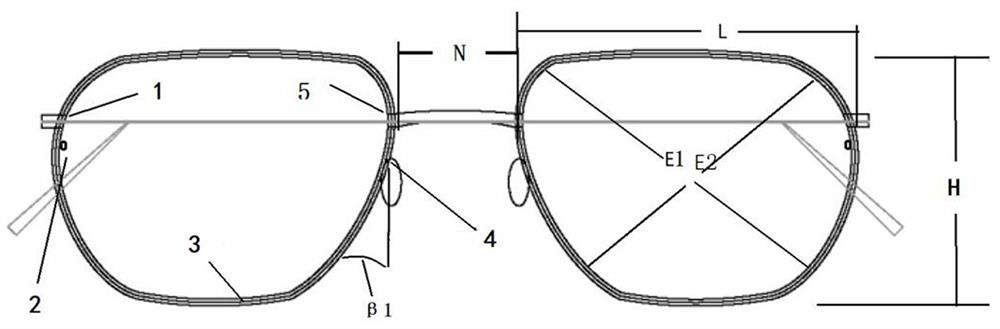

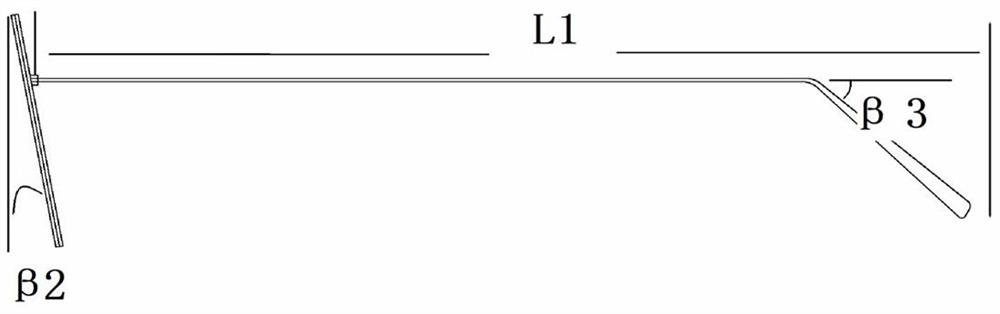

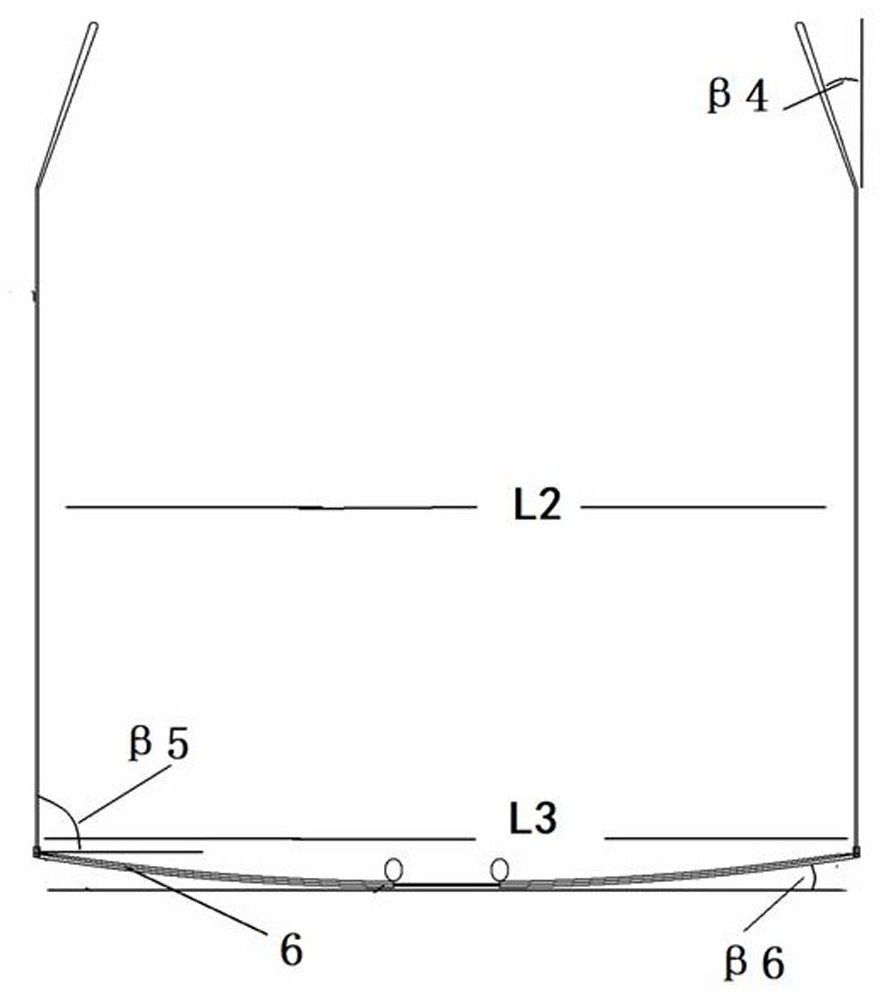

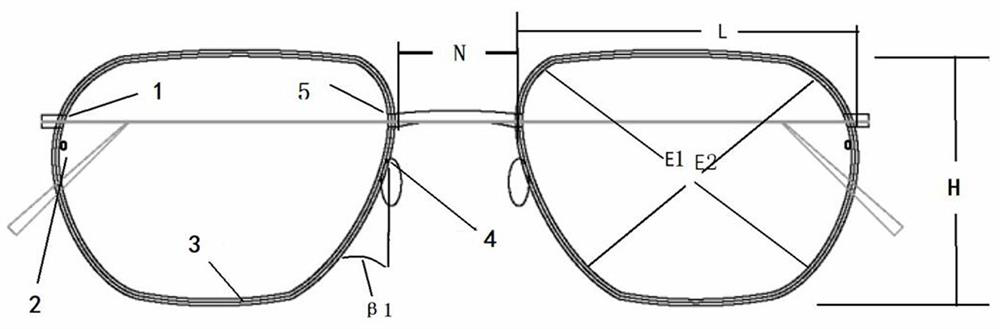

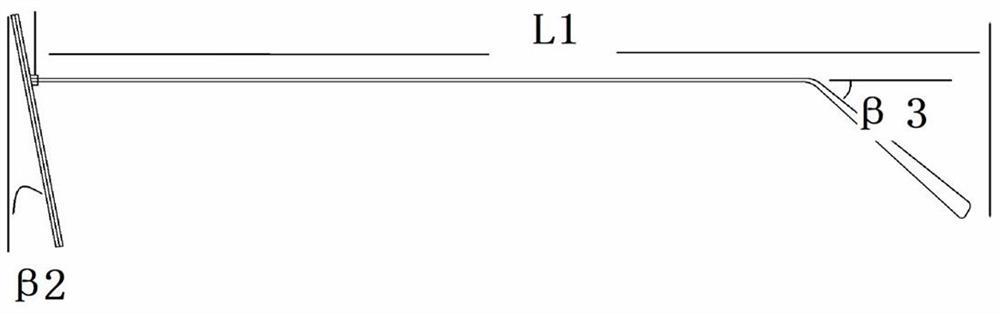

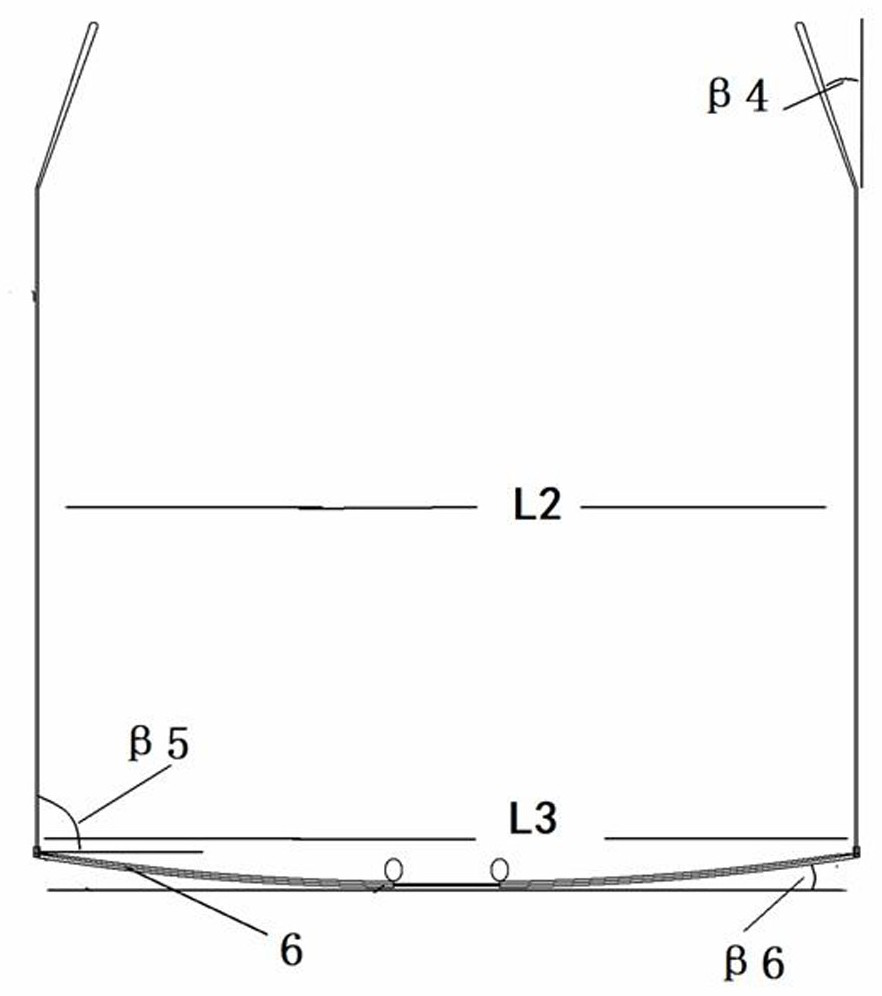

Spectacle frame suitable for assembling progressive multi-focus lenses and lens assembling method thereof

ActiveCN113126325AReduce inventory quantityAvoid blurred visionSpectales/gogglesNon-optical partsOphthalmologyPupillary distance

The invention relates to a spectacle frame suitable for assembling progressive addition lenses and a lens assembling method thereof. The spectacle frame adopts specific structural parameters of spectacle rings, pile heads and spectacle legs, and the shape characteristics of the spectacle frame are more suitable for assembling progressive addition lenses, so that a vision fuzzy area is avoided, the comfort is improved, and the adaptation period is shortened; the spectacle frame is provided with a lens ring lining sheet printed with a light black assembling reference point and a measuring scale coordinate, and the assembling reference point is arranged at an intersection point of 22.5 mm in the horizontal direction and 22mm in the vertical direction of the lens ring; the assembly reference point is used as an original point for the measuring scale coordinate, scales on the horizontal and vertical coordinate axes are within the range of + / -2.5 mm in the horizontal direction and + / -2 mm in the vertical direction of the assembly reference point, the spectacle frame can be used as a tool for accurately measuring the pupil distance and the pupil height, edge cutting assembly of the lens is facilitated, and the fitting success rate, precision and wearing comfort of the optical lens are effectively improved; and the assembly point, the far measurement point and the near measurement point of the progressive multi-focus lens after edge cutting can be restored by using the structural parameter characteristics of the spectacle frame.

Owner:SUZHOU MASON OPTICAL CO LTD +1

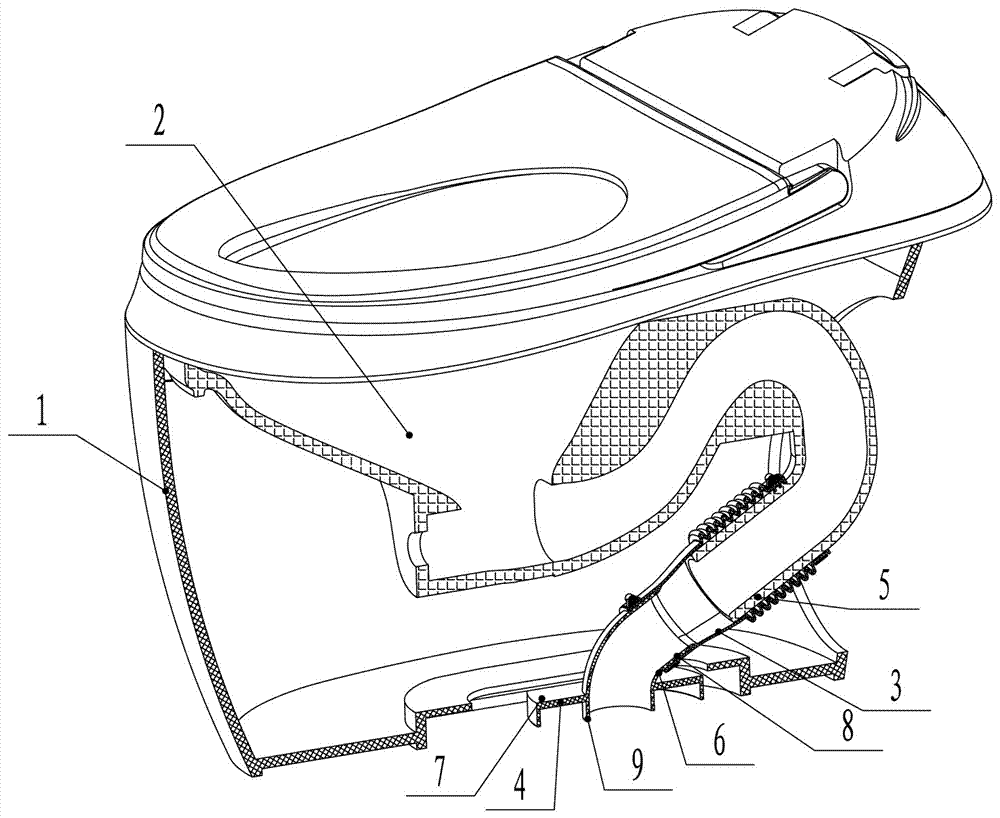

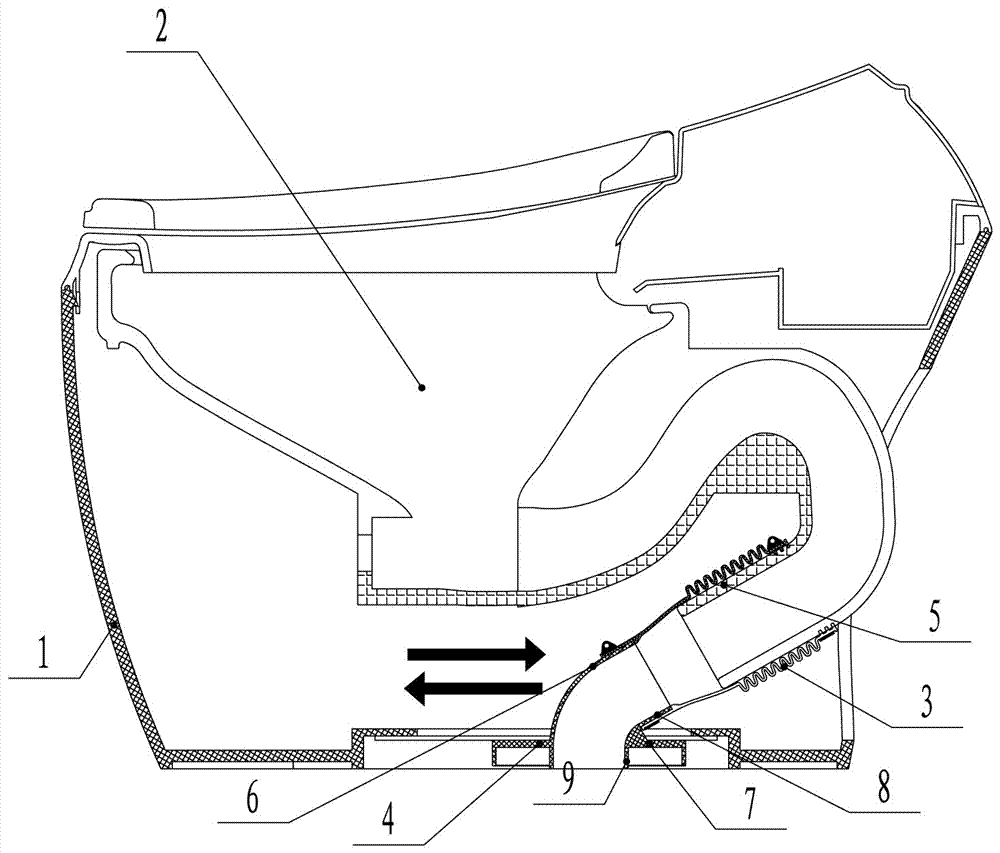

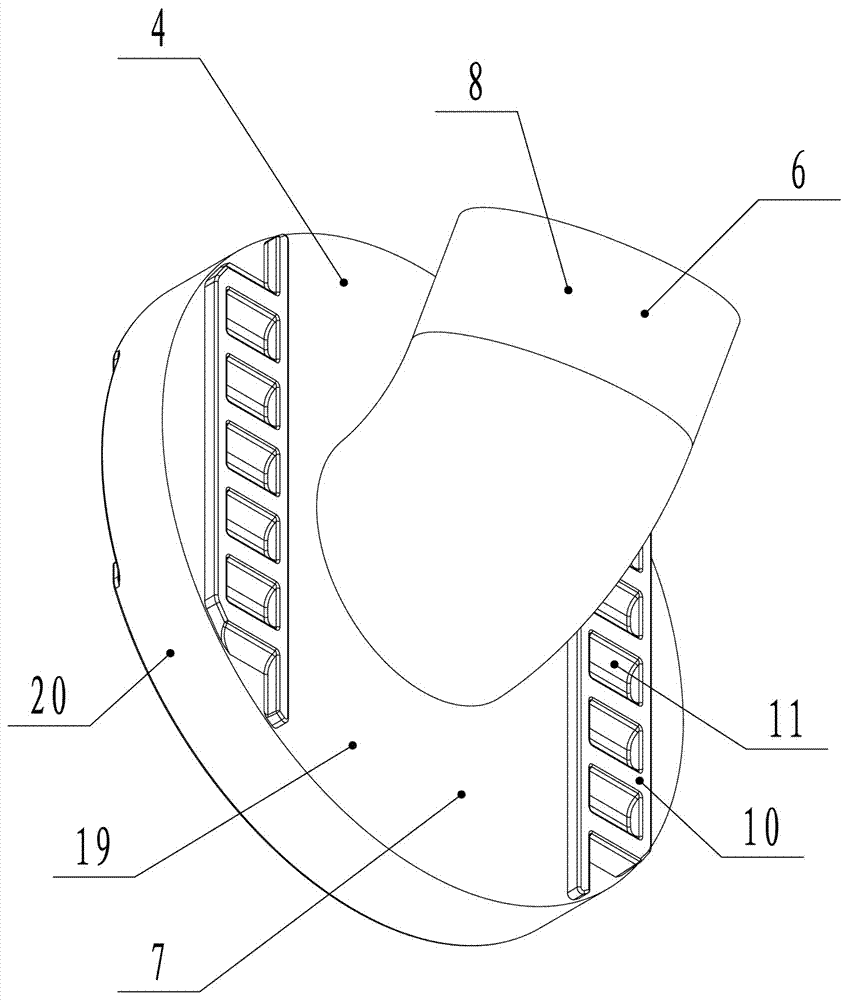

A toilet with adjustable installation pit distance

A closestool with the adjustable closestool pond installation pit distance comprises an outer shell, a closestool pond, a telescopic sewage discharge connection pipe and a closestool pond ground drainage part displacement device.The closestool pond comprises a closestool pond sewage discharge connector.The upper end of the sewage discharge connection pipe is connected with the closestool pond sewage discharge connector.The lower end of the sewage discharge connection pipe is connected with the closestool pond ground drainage part displacement device which is movably installed at the bottom of the outer shell.Therefore, when different closestool pond installation pit distances exist, the closestool pond installation pit distances can be adjusted by moving the closestool pond ground drainage part displacement device, and the outer shell does not need to be moved.In this way, the shell and a wall can be perfectly attached without forming gaps, the use space of toilets is greatly saved, space of toilets can be roomy, and cleanness and attractiveness are achieved; dealers do not need to prepare closestools of the specifications of 300 mm and 400 mm, and therefore the product stock number and the stock floor space are greatly decreased, and the closestool can be easily installed in houses with small reserved pit distances, for example, pit distances smaller than 300 mm.

Owner:ZHEJIANG LIANDE SCI & TECH

A manufacturing method of flange type linear bushing by laser and linear bushing manufactured by the above method

ActiveCN101111345BReduce inventory quantityReduce management costsLaser beam welding apparatusWorkpiece edge portionsManufacturing cost reductionCoupling

Disclosed herein are a flanged type linear bushing formed by coupling of an outer sleeve and a flange and a manufacturing method of the same. The manufacturing method includes the steps of: machining an edge of an outer sleeve at a predetermined angle for a smooth coupling between a flange and the outer sleeve; forming a recess on the outer periphery of the outer sleeve in uniform depth and widthin consideration of thickness of the outer sleeve for permitting an easy laser welding after coupling the flange and the outer sleeve with each other; machining an inside edge of flange along with inner circle of flange in a form corresponding to the recess formed on the outer sleeve to permit the easy laser welding; coupling the flange and the outer sleeve manufactured by the above steps; and welding the coupled portion, where the recess formed on the outer sleeve and the structure formed on the flange are coupled with each other, with high energy beam, or welding the coupled portion with high energy beam of good linearity while feeding filler metal of a predetermined diameter to the coupled site at a predetermined speed. The present invention can improve productivity through automation of process, obtain dimensional stability and precision, and reduce manufacturing costs by reducing the number of manufacturing processes.

Owner:SAMICK PRECISION IND

An Inventory Optimization Method Based on Probabilistic Demand Distribution

ActiveCN109740793BFaster turnaroundReduce occupancyDigital data information retrievalForecastingInformatizationNormal density

The invention discloses an inventory optimization method based on probability demand distribution. The method comprises the following steps of: an existing enterprise informatization management platform is relied on. inventory remainders of the commodities are extracted; warehouse entry and exit details, Sales order, purchasing multi-dimensional data such as advanced stage and the like; the methodcomprises the following steps: firstly, constructing probability distribution of warehouse-out quantity in a purchasing advance LT; if the warehouse-out quantity in the LT day is q (q is greater than0); historical warehouse-out frequency distribution is counted; according to the invention, a required probability density function f (q) can be obtained, so that an expected value corresponding to acertain probability value alpha is obtained, wherein 0 < =alpha < = 1. Therefore, a function relationship between the probability value and the demand prediction value is established. And then determining a target satisfaction rate Sopt, calculating a simulation satisfaction rate Si according to the F (alpha) traversal probability value alphai until Si is greater than or equal to the Sopt, and training an optimal probability and a corresponding demand prediction value. According to the method, the prediction idea of demand probability distribution is creatively introduced, and inventory optimization benefit maximization is achieved under the condition that the satisfaction rate is guaranteed for the pain point problems of large commodity demand fluctuation and high prediction difficulty of current enterprises.

Owner:杭州览众数据科技有限公司

Automatic production device for cabinets

InactiveCN103056659BIncrease automatic handlingAdd automatic deliveryOther manufacturing equipments/toolsNumerical controlAutomatic test equipment

Owner:SHANGHAI CABA ELECTRIC

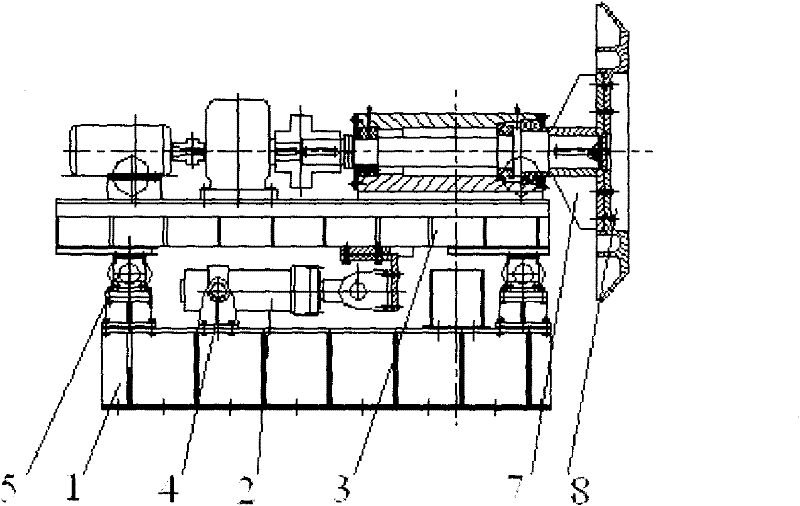

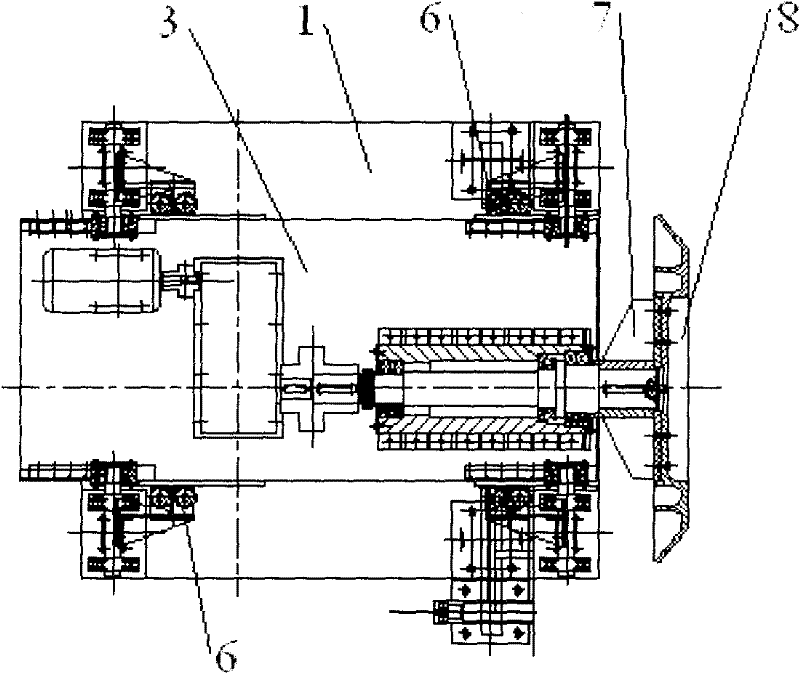

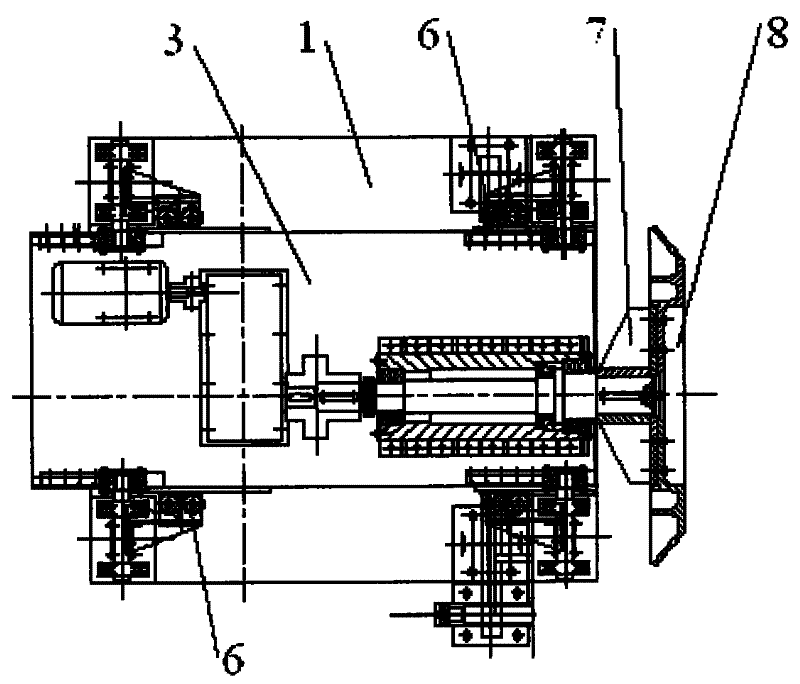

Guiding device of large diameter cast iron pipe external spraying machine

ActiveCN101722136BGuaranteed neutralityReliable neutralLiquid surface applicatorsSpraying apparatusMechanical engineeringCast iron pipe

The invention discloses a guiding device of a large diameter cast iron pipe external spraying machine. A supporting wheel (5) is arranged on a base (1); a middle supporting seat (3) is laid on the supporting wheel (5) through the bottom surface of the middle supporting seat (3); guiding wheel devices (6) are arranged on the base (1); the guiding wheel devices (6) are arranged on two sides of the middle supporting seat (3); and the guiding wheels of the guiding wheel devices (6) contact guiding surfaces fixed on the middle supporting seat (3) through rims. By adopting the technical scheme, thereliable centring performance of cast iron pipe products is ensured, the products are prevented from producing additional torsional forces, the damage to the guiding components of the guiding device of the cast iron pipe external spraying machine is small, the down time for abnormal overhaul and changing is reduced, and the labor intensity of workers is reduced, the spraying processing quality ofthe outer surface of the revolving body of the cast iron pipe is improved, and the purposes of production increasing and productivity improving, and energy saving and cost reducing are realized.

Owner:WUHU XINXING DUCTILE IRON PIPES

A kind of frame suitable for assembling progressive multifocal lens and lens assembly method thereof

ActiveCN113126325BReduce inventory quantityAvoid blurred visionSpectales/gogglesNon-optical partsOphthalmologyPupillary distance

The invention relates to a spectacle frame suitable for assembling progressive multi-focal lenses and a lens assembling method thereof. The frame adopts specific structural parameters of the lens ring, pile head and temple, and its shape characteristics are more suitable for the assembly of progressive multi-focal lenses, avoiding the blurred field of vision, improving comfort and shortening the adaptation period; the frame is printed with light black Assembling the reference point and measuring scale coordinates of the inner lining of the mirror ring, the assembly reference point is set at the intersection of the mirror ring’s horizontal 22.5mm and vertical 22mm; the measurement scale coordinates take the assembly reference point as the origin, and the horizontal and vertical axes The scale is in the range of ±2.5mm horizontally and ±2mm vertically at the assembly reference point, which can be used as a tool to accurately measure the pupillary distance and pupil height, facilitate the edge-cutting assembly of the lens, and effectively improve the success rate, accuracy and wearing comfort of optical lens fitting ; The structural parameter characteristics of the spectacle frame can also be used to restore the assembly point, distance measurement point and near measurement point of the progressive multi-focal lens after edge cutting.

Owner:SUZHOU MASON OPTICAL CO LTD +1

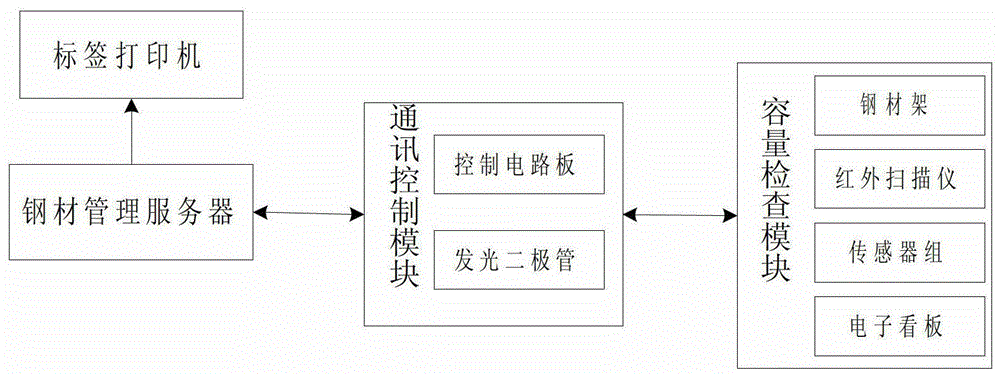

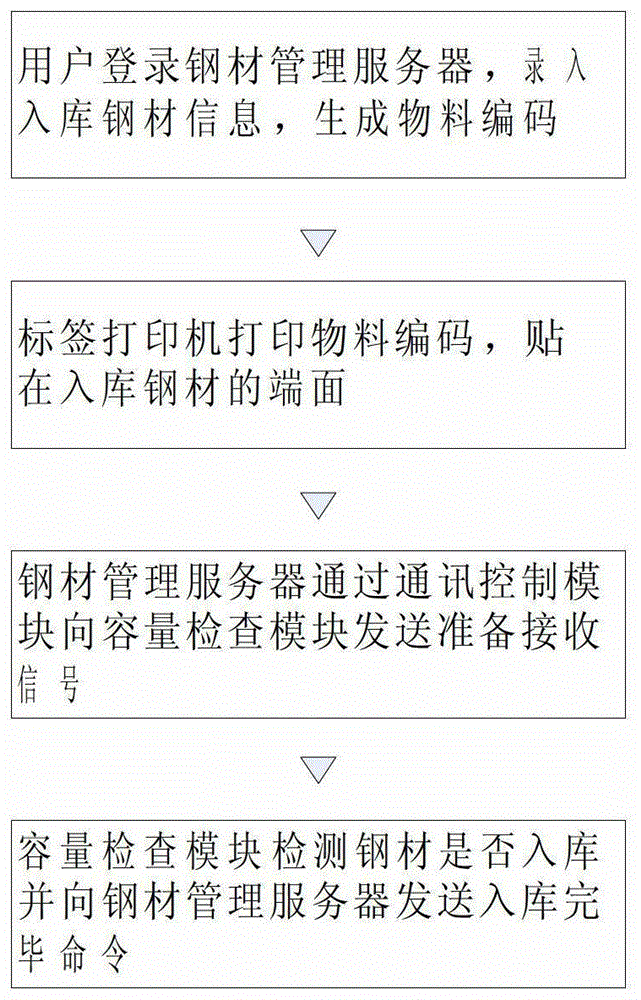

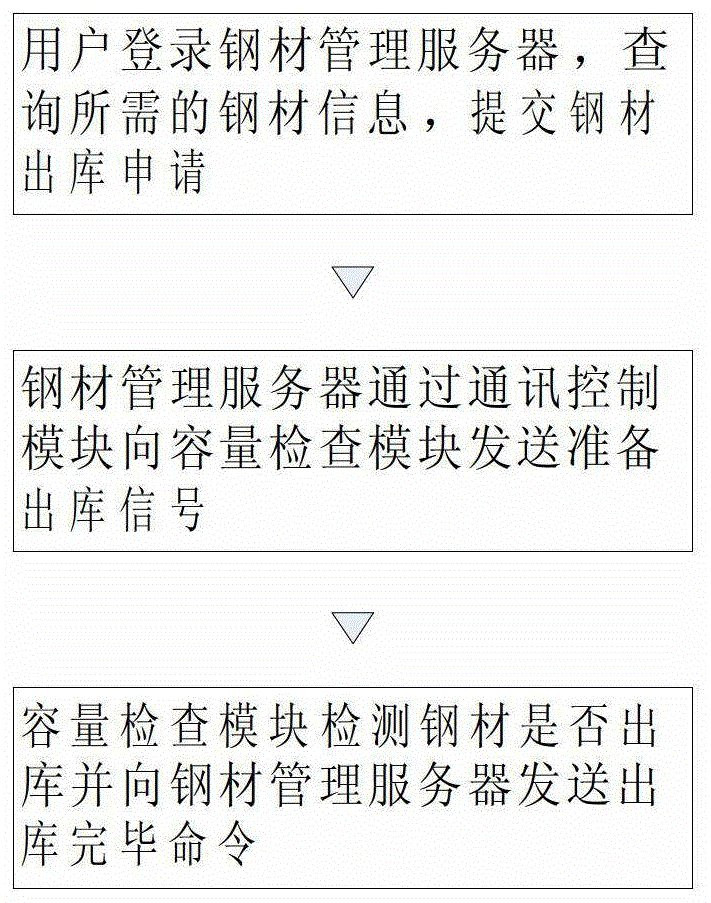

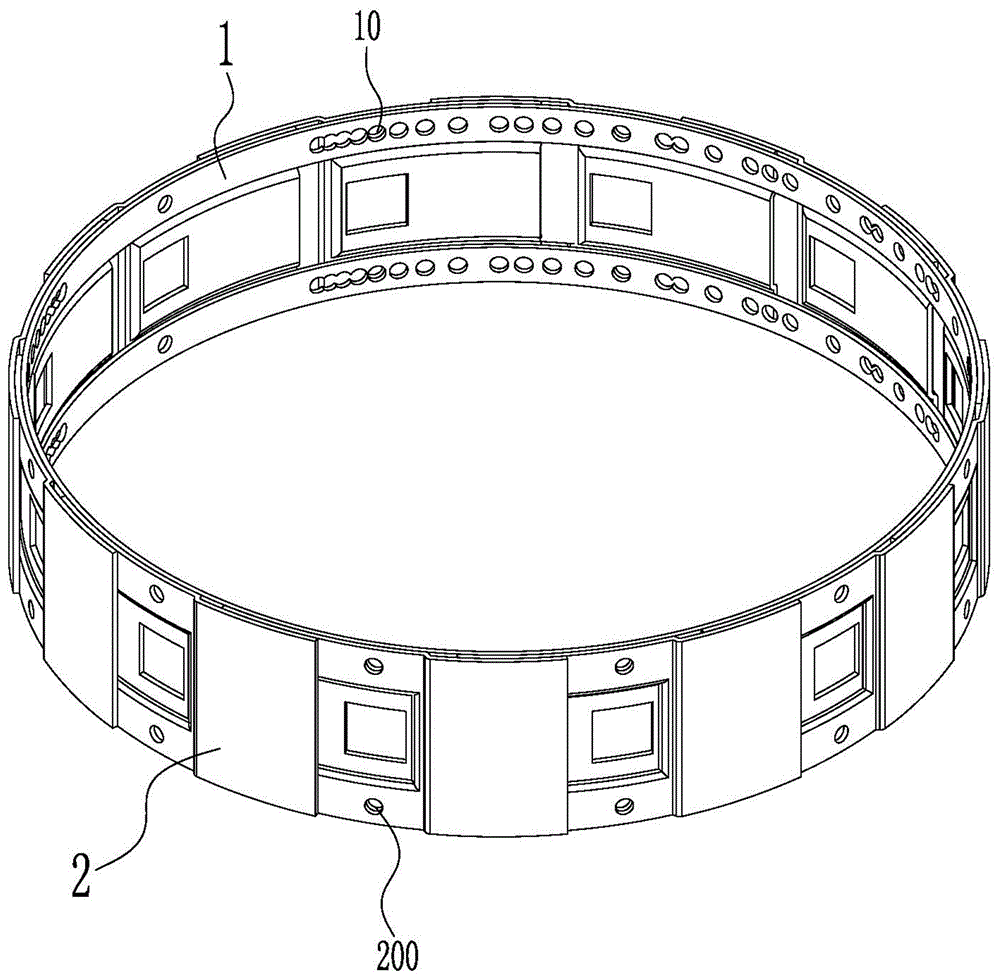

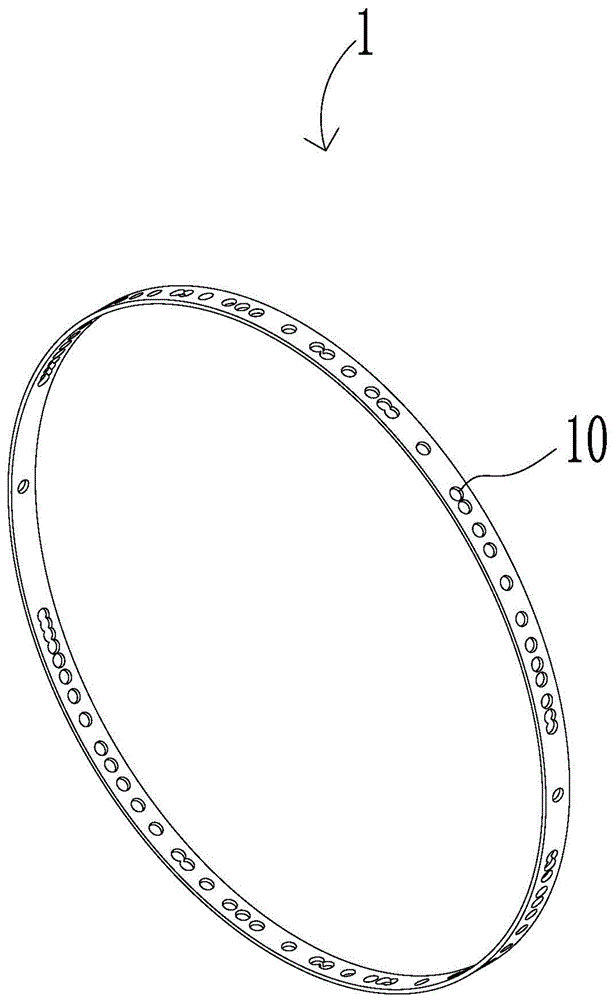

A steel management system and method

ActiveCN102945522BRealize the whole process managementAvoid Quality AccidentsLogisticsManufacturing computing systemsEngineeringCommunication control

The present invention belongs to the technical field of information storage and management, in particular to a management system and method of steel, particularly steel proposed a management system, a management server including steel, label printer, and a communication control module capacity check module, and the label printer management steel server via a serial cable connected to the communication control module and the management server are connected by steel serial cable, the communication capacity check module and control module are connected by serial cable, scan test case for storing yard in steel, and storing information steel passed the management server through the communication control module. The present invention realization of steel logistics timely, on-demand, accurate delivery and handling, to increase productivity, reduce costs, optimize the deployment of materials, shift and storage, to ensure the delivery of the ship is of great significance.

Owner:JIANGSU MODERN SHIPBUILDING TECH

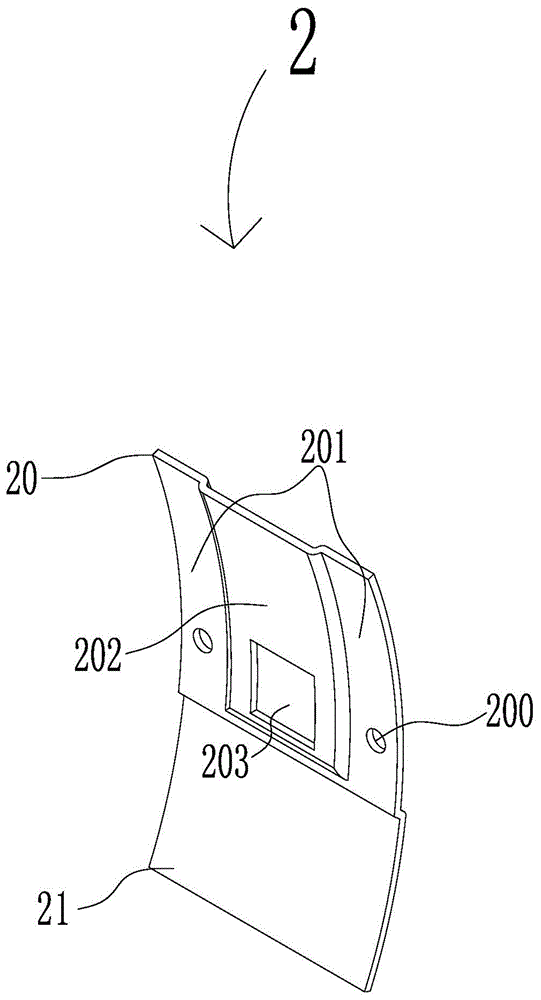

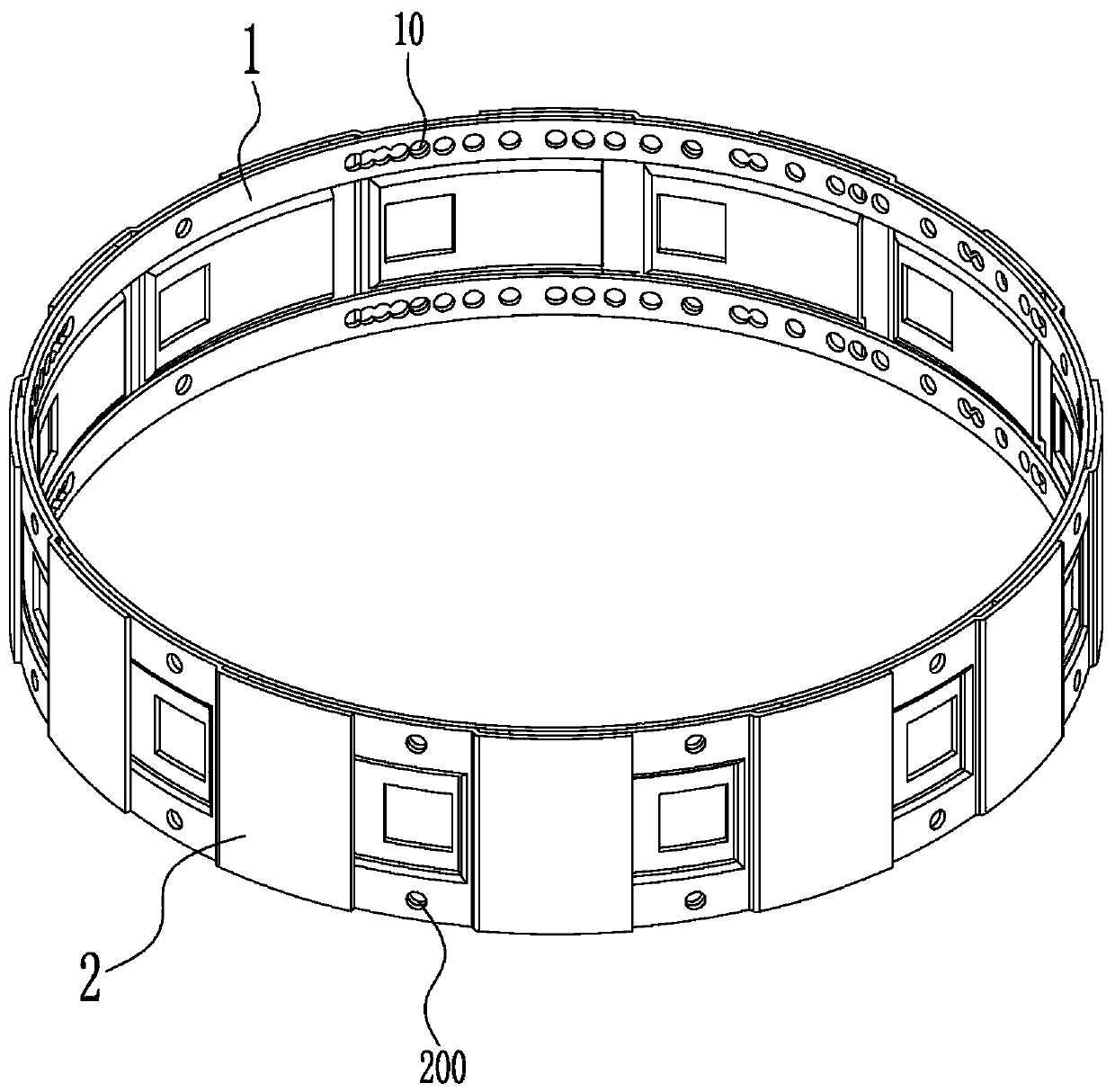

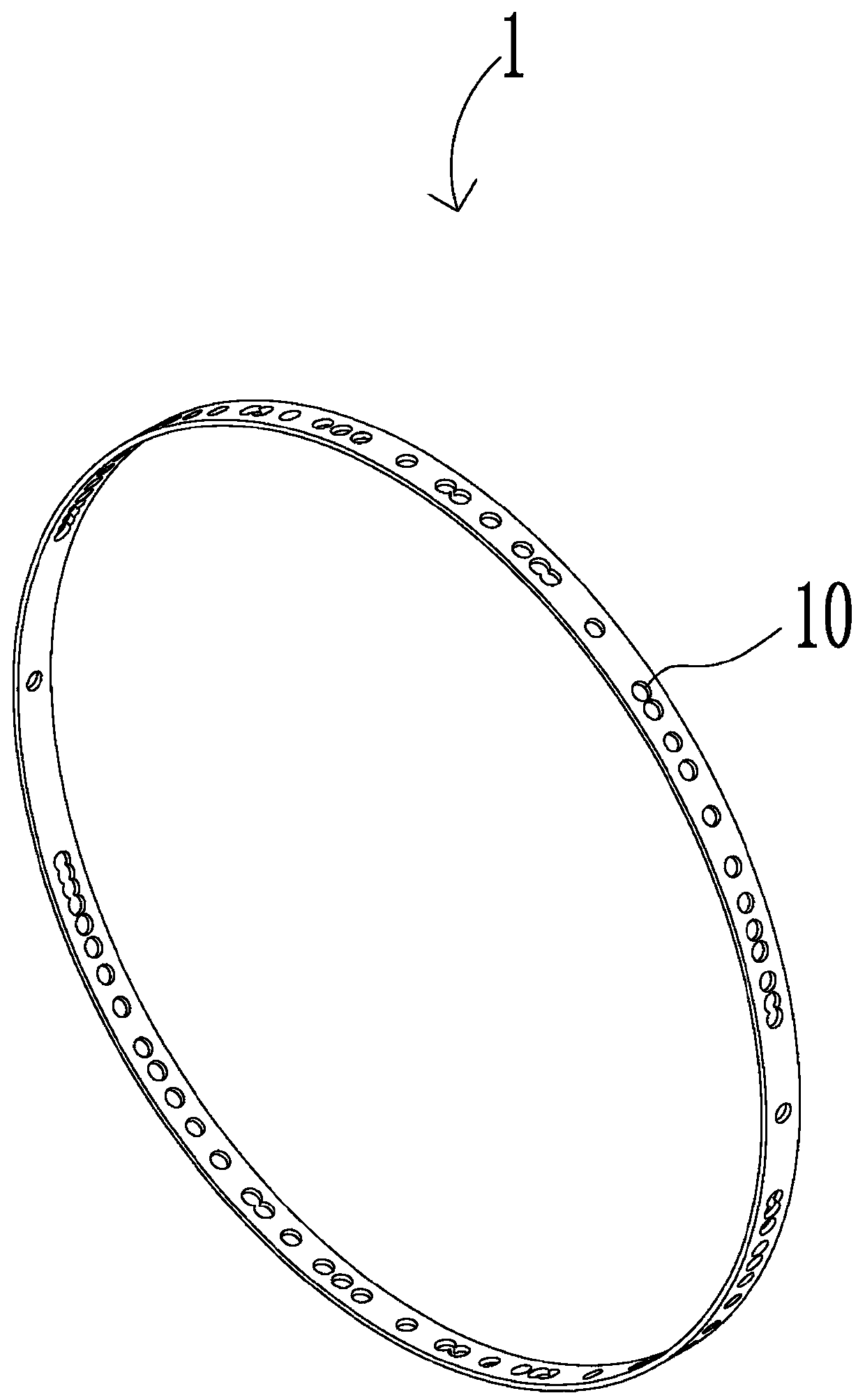

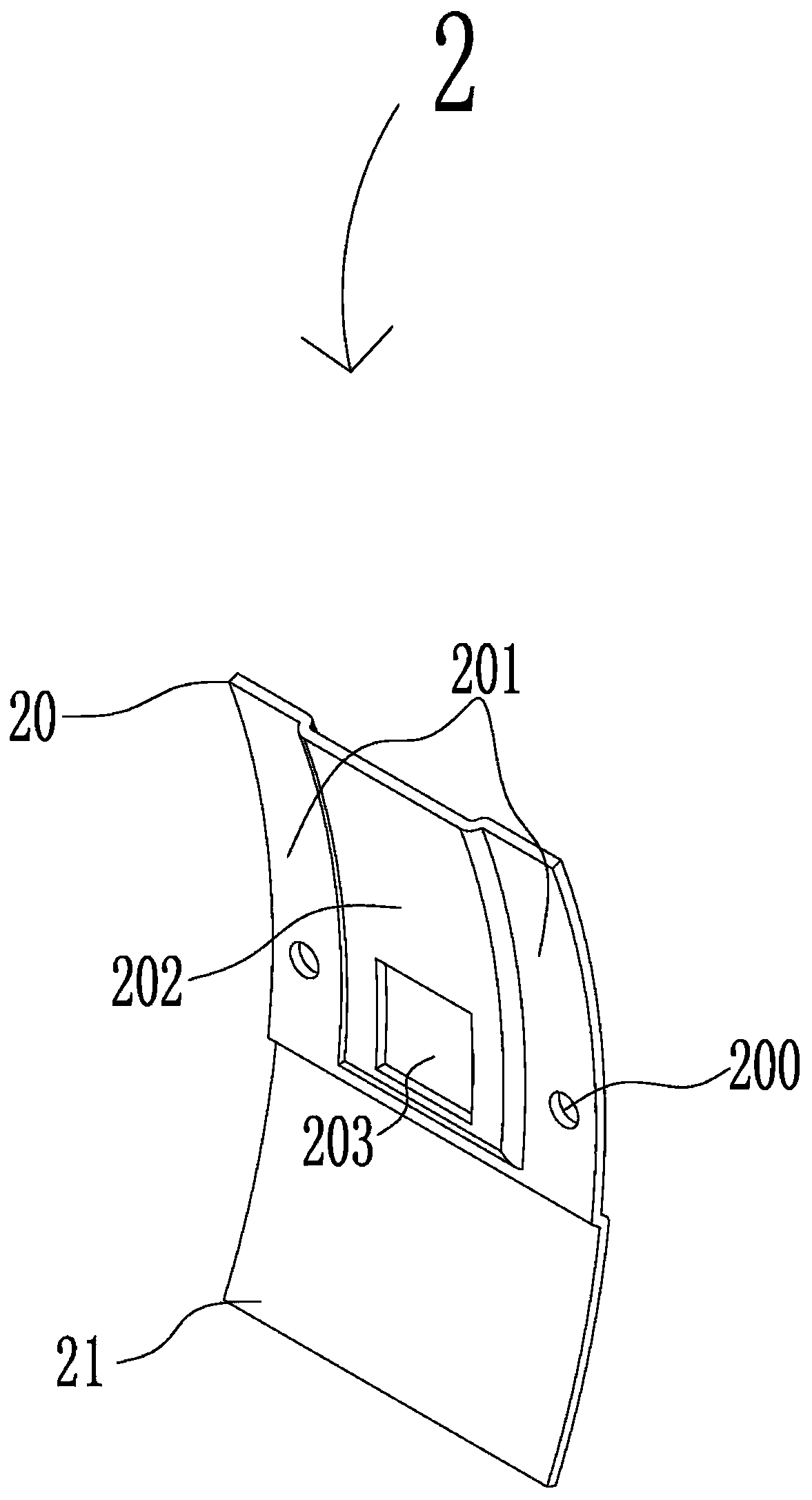

Seed circle belt assembly with adjustable hole sowing machine

ActiveCN106471963AReduce inventory quantityReduce manufacturing costDibble seedersSeed depositing seeder partsManufacturing technologyAgricultural engineering

The invention belongs to the technical field of design and manufacturing agricultural machinery, and particularly relates to a seed circle belt assembly with an adjustable hole sowing machine. The seed circle belt assembly comprises a belt supporting circle which supports and connects multiple fish scales, multiple location holes which are used for connecting the fish scales are formed in an annular supporting circle, each of the fish scales is composed of a fish scale working plate and a fish scale connecting plate, and a connecting part between the fish scale working plate and the fish scale connecting plate is arranged in a well-proportioned mode and presents an over-under position; the fish scale working plate is composed of a supporting circle connecting plate and a seed passing plate which is arranged in the middle part of the fish scale working plate, the seed passing plate is designed in a sunken mode, and a height difference exists between the seed passing plate and the supporting circle connecting plate; connecting holes matched with the location holes are formed in the supporting circle connecting plate, and seed passing holes are formed in the seed passing plate. The seed circle belt assembly has a better practicability, and the cost of use is reduced.

Owner:AKSU JINTIANCHENG MACHINERY EQUIP

A kind of hole planter adjustable seed ring belt assembly

ActiveCN106471963BReduce inventory quantityReduce manufacturing costDibble seedersSeed depositing seeder partsManufacturing technologyHeight difference

The invention belongs to the technical field of design and manufacturing agricultural machinery, and particularly relates to a seed circle belt assembly with an adjustable hole sowing machine. The seed circle belt assembly comprises a belt supporting circle which supports and connects multiple fish scales, multiple location holes which are used for connecting the fish scales are formed in an annular supporting circle, each of the fish scales is composed of a fish scale working plate and a fish scale connecting plate, and a connecting part between the fish scale working plate and the fish scale connecting plate is arranged in a well-proportioned mode and presents an over-under position; the fish scale working plate is composed of a supporting circle connecting plate and a seed passing plate which is arranged in the middle part of the fish scale working plate, the seed passing plate is designed in a sunken mode, and a height difference exists between the seed passing plate and the supporting circle connecting plate; connecting holes matched with the location holes are formed in the supporting circle connecting plate, and seed passing holes are formed in the seed passing plate. The seed circle belt assembly has a better practicability, and the cost of use is reduced.

Owner:AKSU JINTIANCHENG MACHINERY EQUIP

Fine adjustment type precision boring cutter

PendingCN113369513AReduce inventory quantityTo achieve the purpose of position adjustmentTurning toolsBoring headsStructural engineeringIndustrial engineering

The invention discloses a fine adjustment type precision boring cutter, and relates to the technical field of boring cutters. The fine adjustment type precision boring cutter comprises a cutter handle, a dovetail guide rail structure, a boring cutter rod, a screw rod mechanism and a worm and gear structure. The dovetail guide rail structure is arranged at one end of the cutter handle; the boring cutter rod is arranged at one side of the dovetail guide rail structure; the screw rod mechanism is arranged in the dovetail guide rail structure; the worm and gear structure is in meshed transmission connection with the lead screw mechanism; and the worm and gear structure drives the lead screw mechanism to act in a transmission manner, then the dovetail guide rail structure is driven to move, and the position of the boring cutter rod is adjusted. According to the boring cutter, the problem that the production efficiency is reduced due to the increase of the stock quantity of cutters and the cutter replacement time since boring cutters need to be replaced for many times during boring is solved.

Owner:苏州腾阳刀具科技有限公司

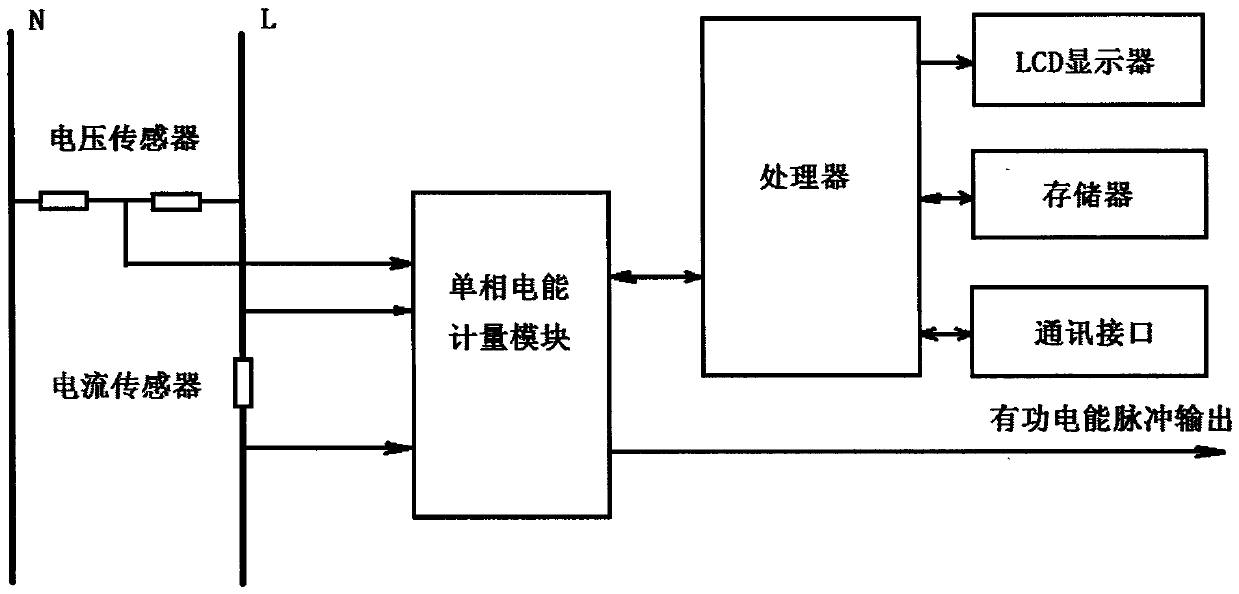

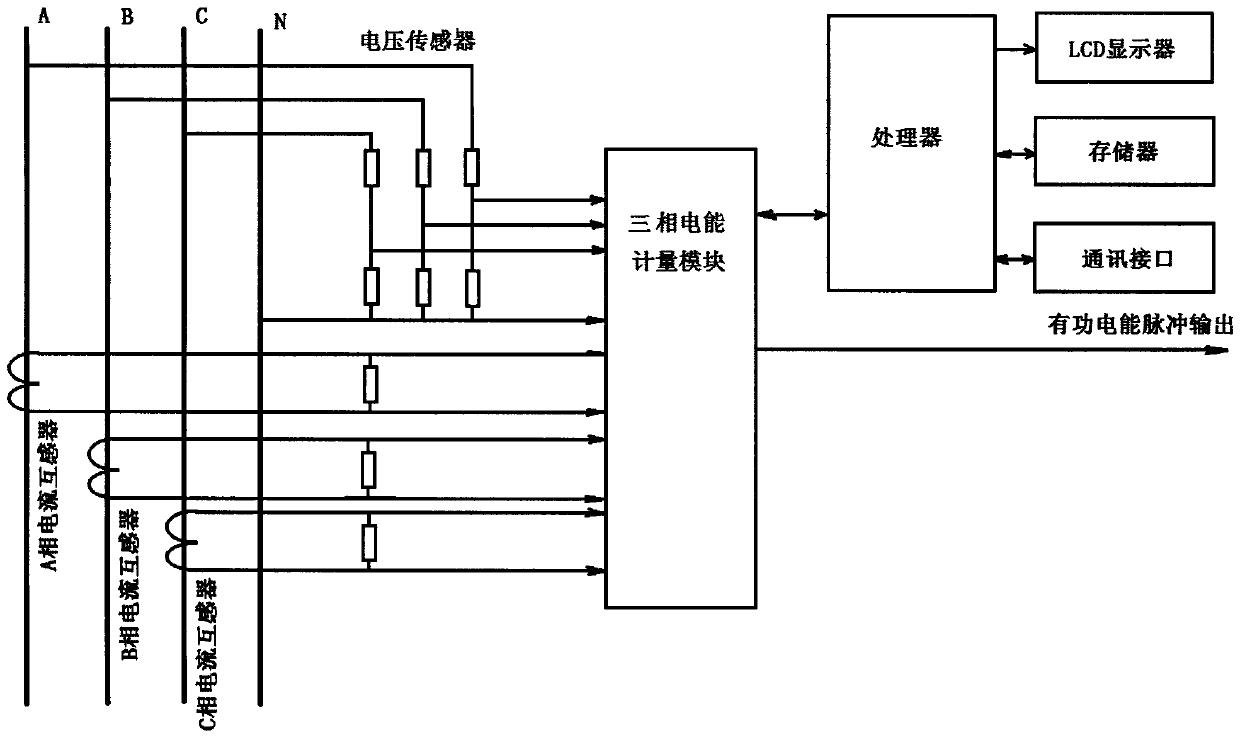

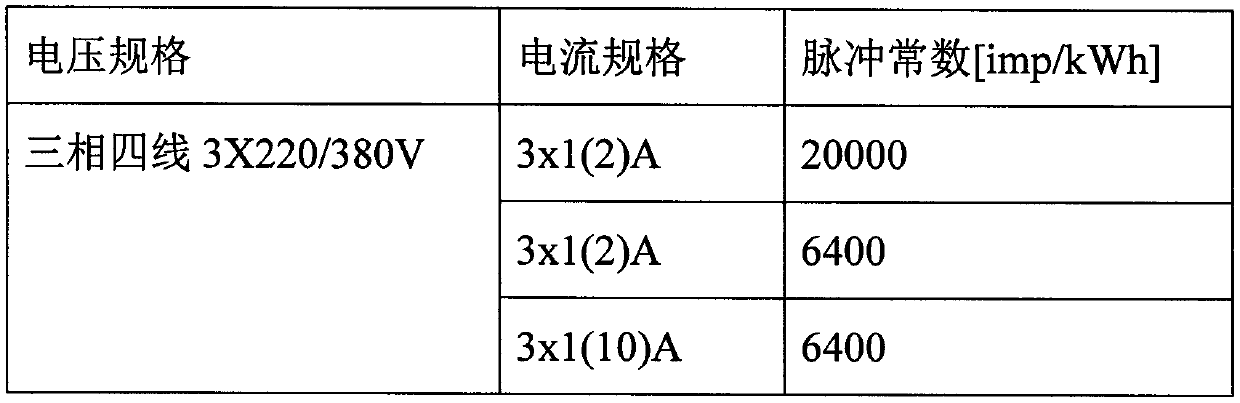

A method for setting specification parameters of a power meter

ActiveCN105891762BReduce inventory quantityReduce inventory costsElectrical measurementsElectric powerElectric energy

Owner:ZHEJIANG WELLSUN INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com