A kind of frame suitable for assembling progressive multifocal lens and lens assembly method thereof

A progressive multi-focus and frame technology, applied in glasses/protective glasses, glasses/goggles, instruments, etc., can solve the problems of undefined temple length and opening width, small ear width, loss of corrective effect, etc. To achieve the effect of shortening the adaptation period, improving comfort and clear position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a spectacle frame suitable for assembling progressive multifocal lenses, and the material of the spectacle frame is titanium metal containing 80% or more of titanium.

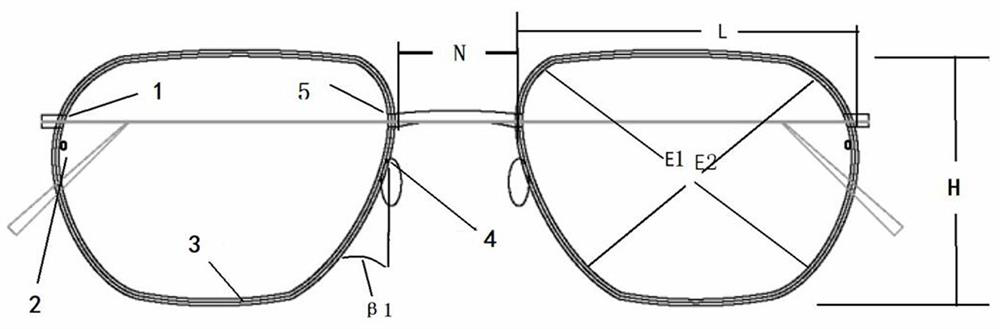

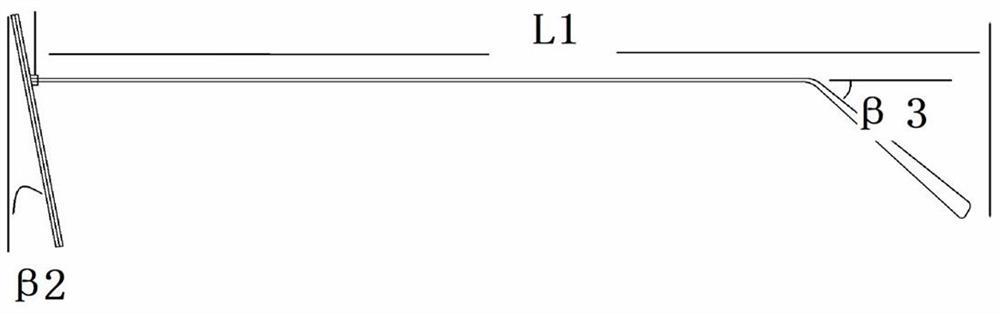

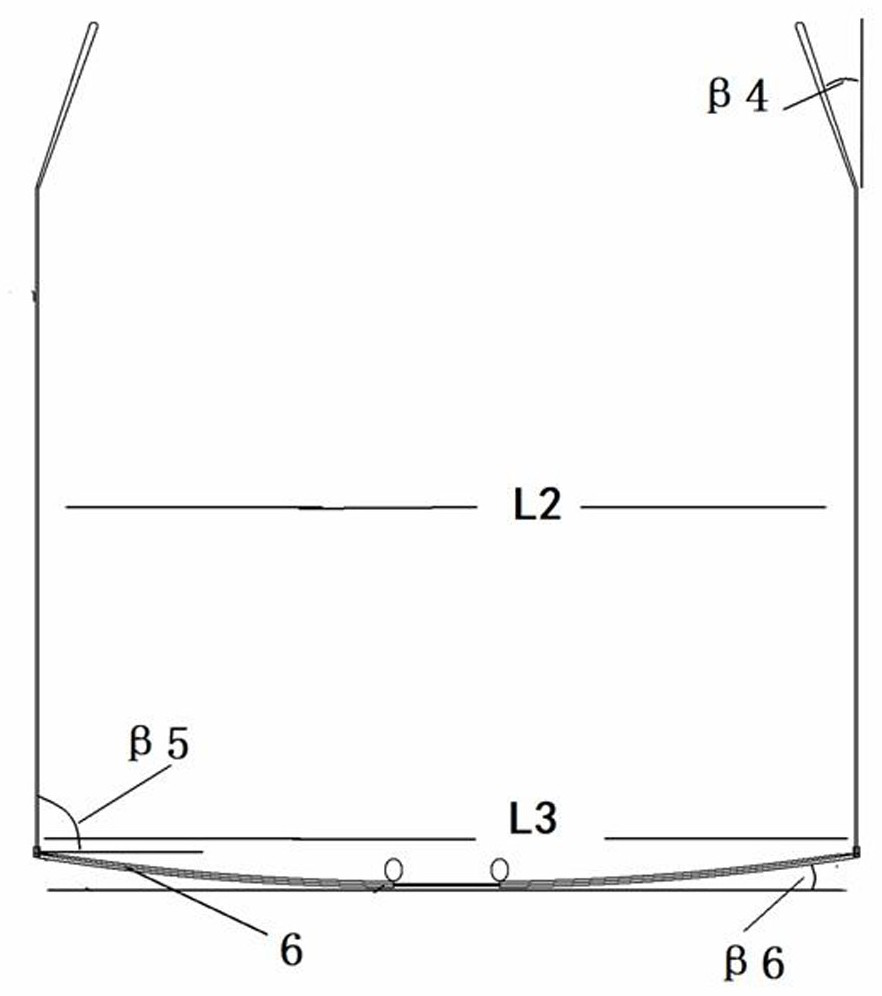

[0033] see figure 1 , 2 and 3 are respectively the structural schematic diagrams of the main view, side view and top view of a mirror frame suitable for assembling progressive multifocal lenses provided by this embodiment; its specific structure is:

[0034] The lens ring groove 3 is a 45° point-down V-shaped groove with a groove depth of 3mm and a single loop wire structure. The lens ring curvature 6 is 300 bends; the maximum horizontal width L of the lens ring is 50mm, the maximum vertical height H is 36mm, and the nose is up. The maximum distance E1 from the side to the outer temporal lower side is 46mm, the maximum distance E2 from the inner lower side of the nose to the outer temporal upper side is 47mm, the splay angle β1 below the midpoint of the nasal circle line is 20°,...

Embodiment 2

[0043] Using the mirror frame provided by Embodiment 1 of the present invention, the lining is provided with an assembly reference point 7 and a measurement scale coordinate 8; the assembly reference point is set at the intersection of the mirror ring horizontal direction 22.5 mm and vertical direction 22 mm; the measurement scale coordinates are based on the assembly reference point The point is the origin, and the scales on the horizontal and vertical axes are within the range of ±2.5mm in the horizontal direction and ±2mm in the vertical direction of the assembly reference point, which can be used as a reference for lens cutting edge. If the pupillary distance and pupillary height of the wearer are unknown, they can be measured by means of the marks on the lining of the spectacle frame and the coordinates 8 of the measuring scale.

[0044] The spectacle wearer wears the spectacle frame provided in Example 1, and after properly adjusting the position of the nose pads to ensur...

Embodiment 3

[0047] The spectacle frame provided by Embodiment 1 of the present invention can assist in the measurement of pupil coordinates, and is suitable for the assembly of progressive multifocal lenses without pupil height measurement.

[0048] The spectacle wearer wears the spectacle frame provided by Example 1 of the present invention. After properly adjusting the position of the nose pads to ensure comfortable and stable position, the optometrist faces the wearer head-on and observes the pupil positions of the left and right eyes of the spectacle wearer respectively. The relative position relationship with the assembly reference point and the coordinates of the measurement scale shows that the horizontal optical center distance on the nasal side of the single lens is 20.5 mm, and the pupil is located 1 mm below the coordinates of the measurement scale. Calculated by (PD-N) / 2, (PD-18) / 2=25mm, the PD is 68mm, and the pupil height is 21mm, that is, the pupil distance of the wearer in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com