A steel management system and method

A management system and steel technology, applied in the field of storage information management, can solve the problems of low practicability, inability to access information display users in the storage yard, complex information conversion, etc., to improve on-site management efficiency, solve information retention, and reduce inventory quantity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

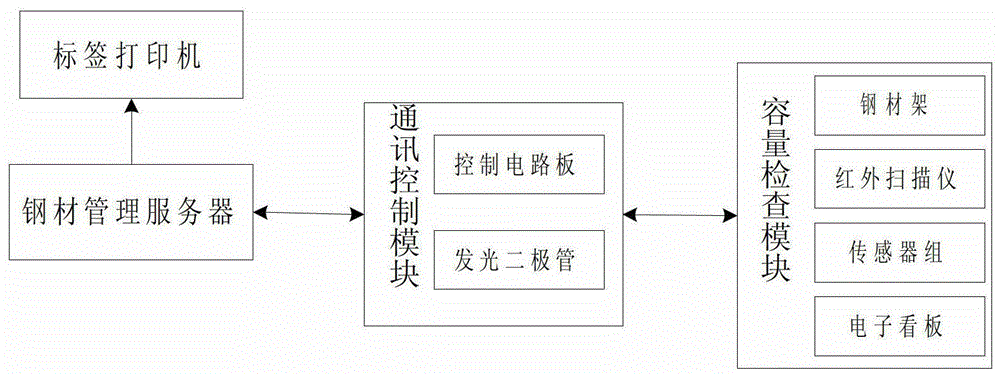

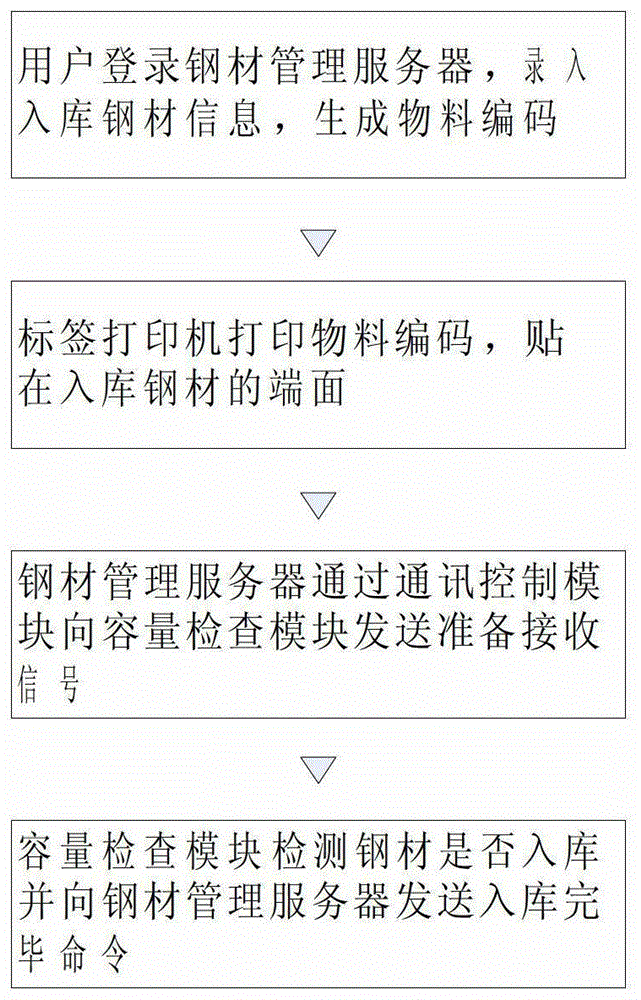

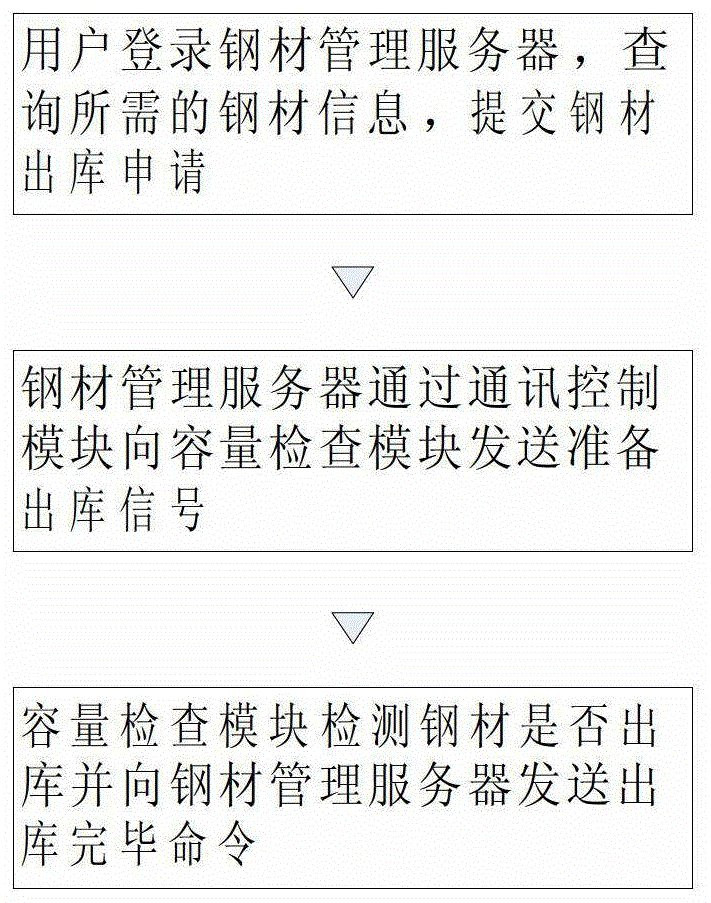

[0024] Such as figure 1 The schematic structural diagram of the steel management system of the present invention is shown. It can be seen from the figure that the present invention includes a steel management server, a label printer, a communication control module and a capacity inspection module, wherein the steel management server is used for users to query steel information, Retrieval, extraction, storage, allocation, movement and other operations and generation of material codes; the label printer is connected to the steel management server through a serial cable for printing the generated material codes; the communication control module is connected to the steel management server through a serial port connection , for the display of steel position information in the yard, and the signal conversion between the capacity inspection module and the steel management server; the capacity inspection module is connected to the communication control module through a serial port conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com