Intelligent vehicle quality inspection method and system

A vehicle quality and inspection method technology, applied in the field of vehicle quality intelligent inspection methods and systems, can solve the problems of poor real-time delivery of inspection tasks, inability to form associations, slow transmission speed, etc., to ensure reliability and traceability, avoid Data storage is troublesome, and the effect of process management is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

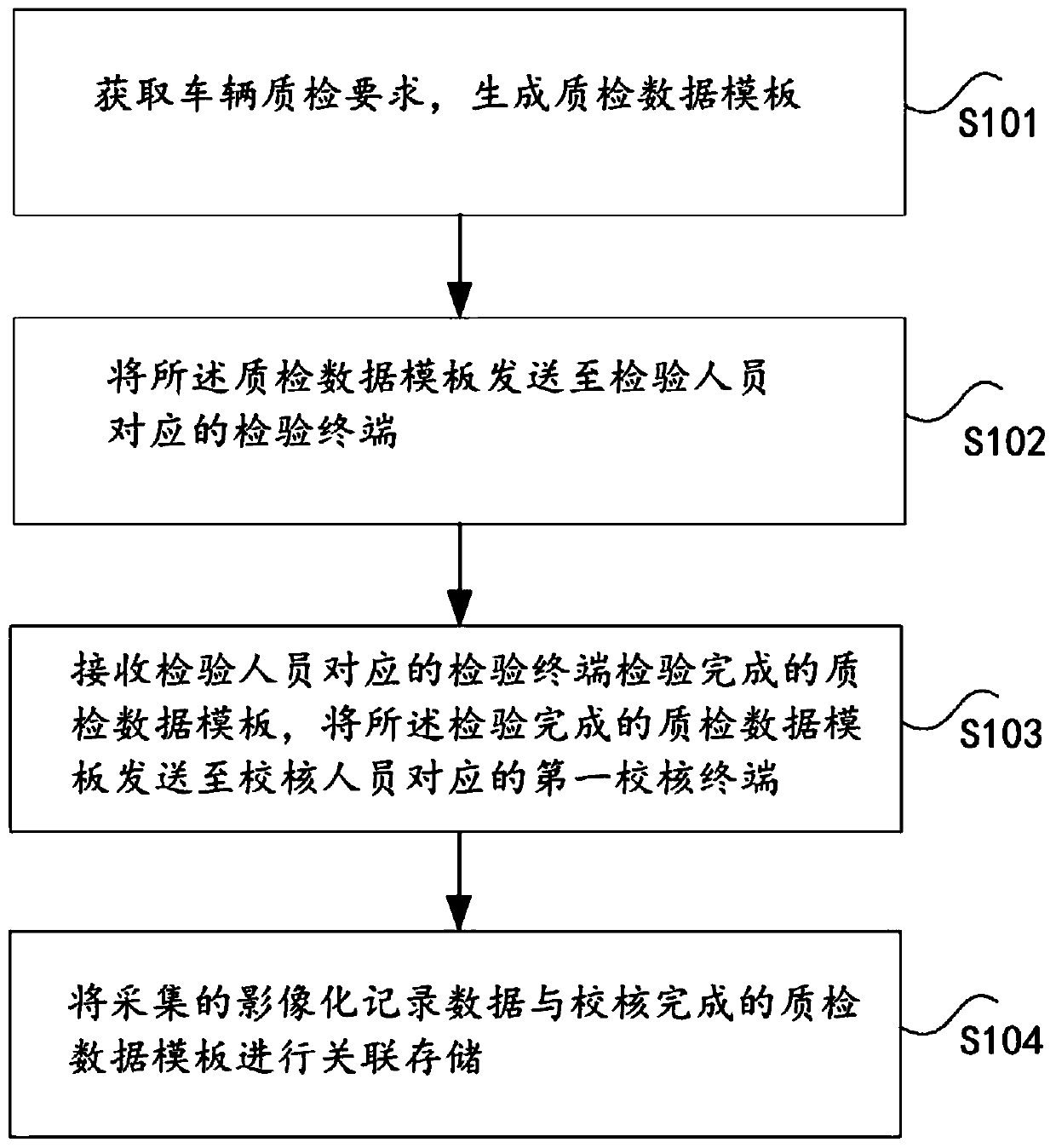

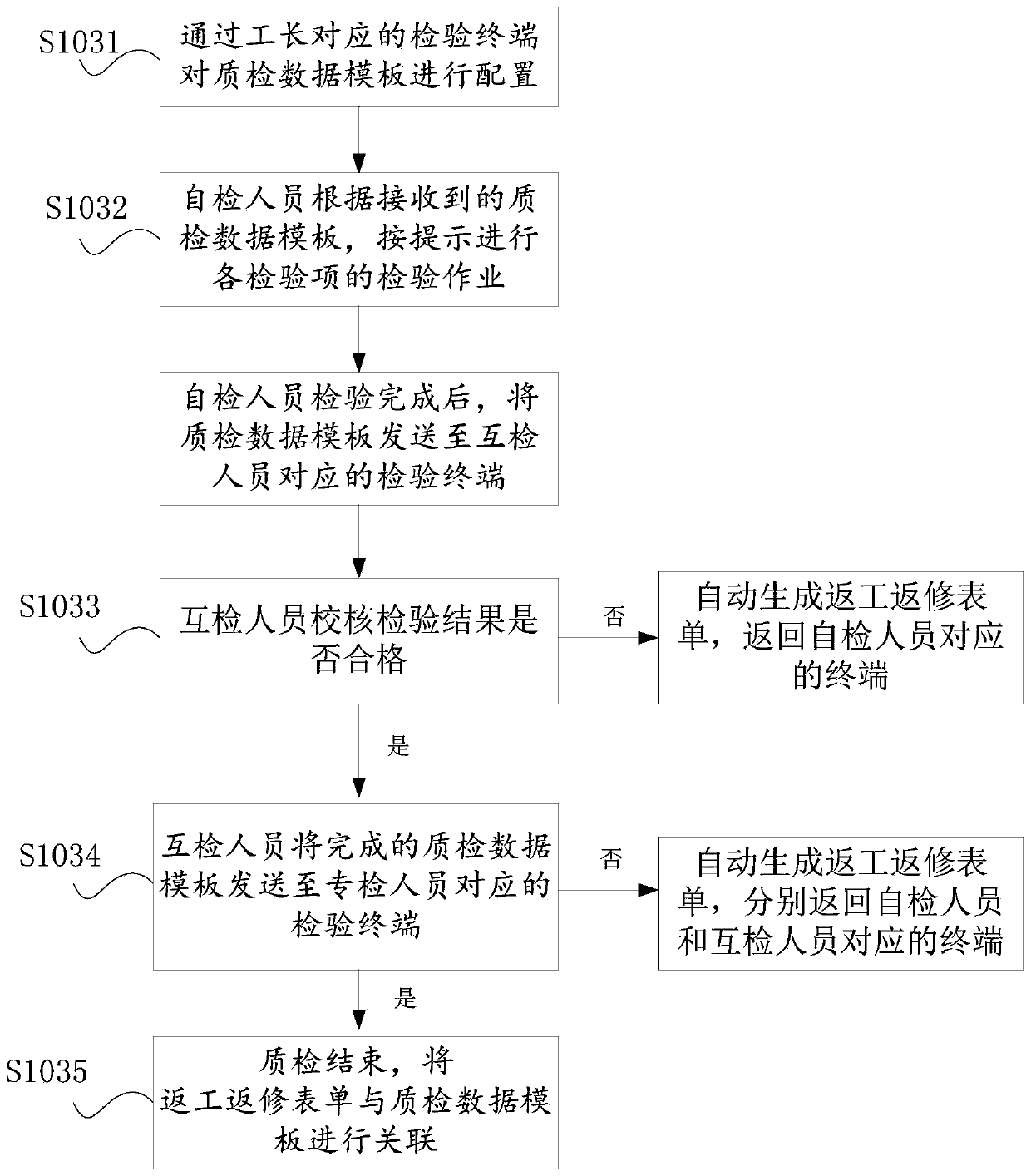

[0041] According to an embodiment of the present invention, an embodiment of a vehicle quality intelligent inspection method is provided, figure 1 It is a flowchart of a vehicle quality intelligent inspection method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0042] Step S101: Obtain vehicle quality inspection requirements, configure project information, quality inspection team information, vehicle quality inspection content, and quality inspection standard information, and generate a quality inspection data template.

[0043] Specifically, in the above steps, the vehicle quality inspection refers to the quality inspection of the vehicle as a whole, or the quality inspection of one or more parts or parts of the vehicle; the vehicle quality inspection requirements include: vehicle quality inspection standards; vehicle quality inspection scope (that is, the range of vehicle parts or parts that need q...

Embodiment 2

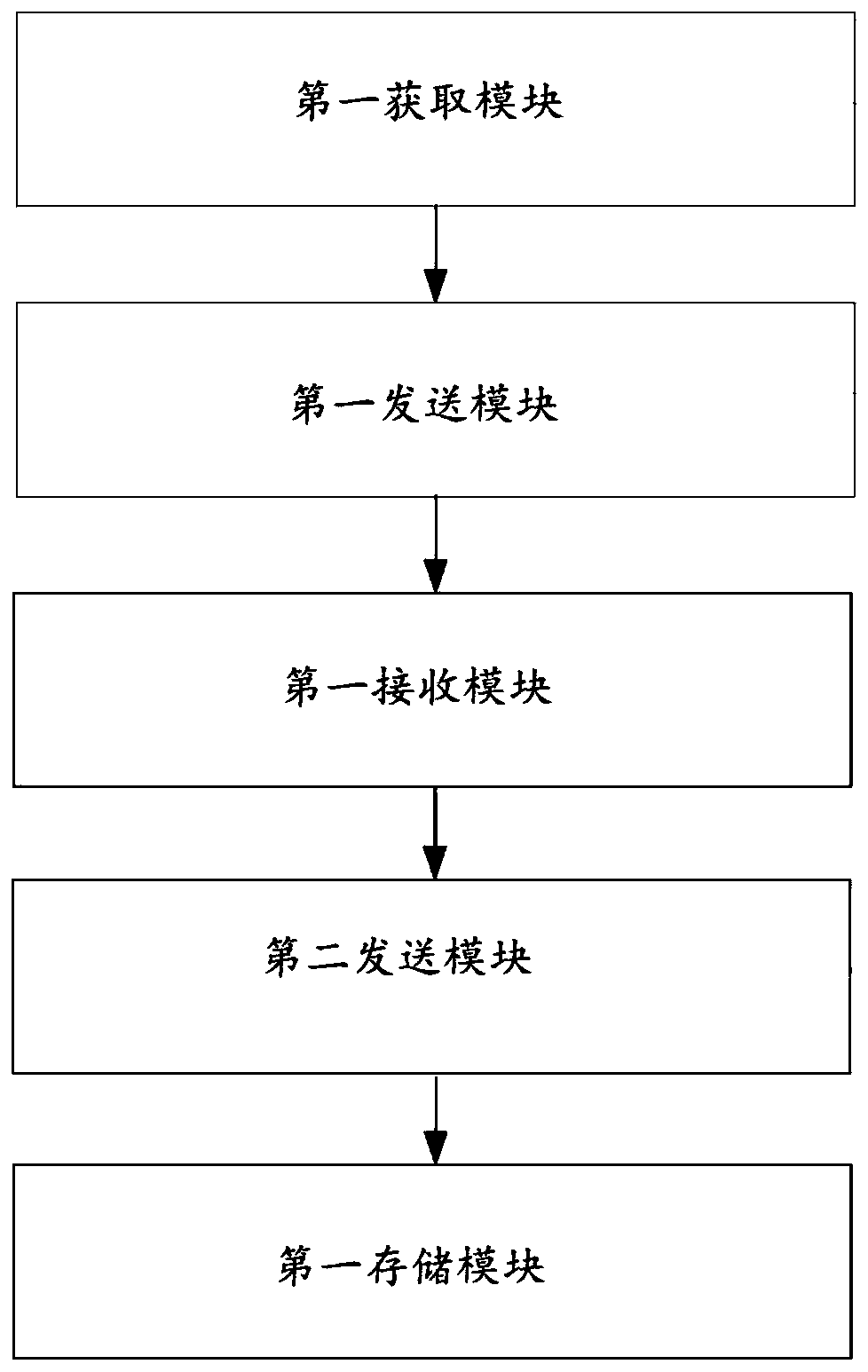

[0078] According to an embodiment of the present invention, an embodiment of a device for implementing the above-mentioned vehicle quality intelligent inspection method is also provided, image 3 It is a schematic diagram of a vehicle quality intelligent inspection system according to an embodiment of the present invention, refer to image 3 , the device consists of:

[0079] The first obtaining module is used to obtain vehicle quality inspection requirements and generate a quality inspection data template;

[0080] The first sending module is used to send the quality inspection data template to the inspection terminal corresponding to the inspector, so that the inspection terminal performs quality inspection or image data collection sequentially according to the inspection items in the quality inspection data template;

[0081] The first receiving module is used to receive the quality inspection data template of the inspection terminal corresponding to the inspection personn...

Embodiment 3

[0091] In one or more embodiments, a terminal device is disclosed, including a server, the server includes a memory, a processor, and a computer program stored on the memory and operable on the processor, and the processor executes the The program realizes the vehicle quality intelligent inspection method in the first embodiment. For the sake of brevity, details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com