Spliced steel arch frame and manufacturing method thereof

A steel arch and splicing technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve problems such as unsuitable support specifications, delays in construction period, and inappropriate arch radians, etc., so as to reduce the defective rate, Ease of transportation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

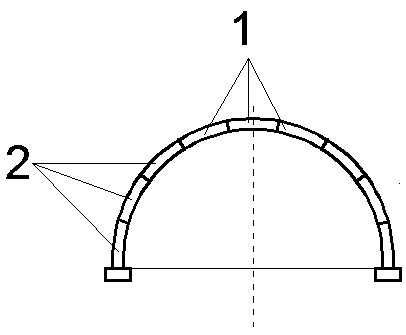

[0034] see figure 1 As shown, a spliced semicircular steel arch frame, arch support 1 and two mirror-symmetrical side wall supports 2, the center line between the center of the arch support 1 and the center of the tunnel is perpendicular to the tunnel ground, and the arch support 1 It is fixedly connected with the side wall bracket 2 by bolts.

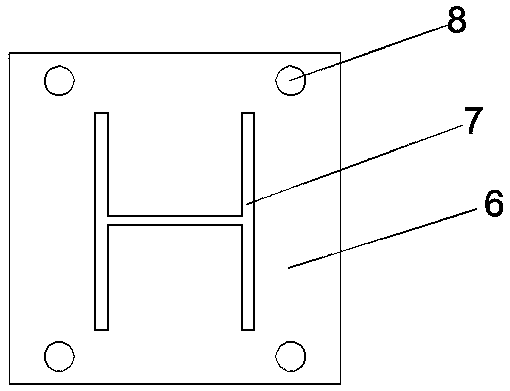

[0035] The first bracket and the second bracket have the same length and the same deformation arc, and are composed of section steel and connecting steel plate 6. The center of the connecting steel plate 6 coincides with the center of the end of the section steel. The section steel is preferably I-beam, and the connecting steel plate 6 is vertically welded Two sets of symmetrical connecting holes 8 are provided on the connecting steel plate 6 at the end of the I-beam, and each group of connecting holes 8 has two.

[0036] There are 9 first brackets and second brackets in total, including 1 first bracket as a vault bracket 1, and a s...

Embodiment 2

[0039] see figure 1 As shown, a spliced semicircular steel arch frame, arch support 1 and two mirror-symmetrical side wall supports 2, the center line between the center of the arch support 1 and the center of the tunnel is perpendicular to the tunnel ground, and the arch support 1 It is fixedly connected with the side wall bracket 2 by bolts.

[0040]The first bracket and the second bracket have the same length and the same deformation arc, and are composed of section steel and connecting steel plate 6. The center of the connecting steel plate 6 coincides with the center of the end of the section steel. The connecting steel plate 6 is vertically welded on the end of the section steel, and the connecting steel plate 6 There are two groups of symmetrical connection holes 8 on the top, each group of connection holes 8 has two.

[0041] There are 12 first brackets and second brackets in total, including the arch bracket 1 composed of 2 first brackets connected by high-strength...

Embodiment 3

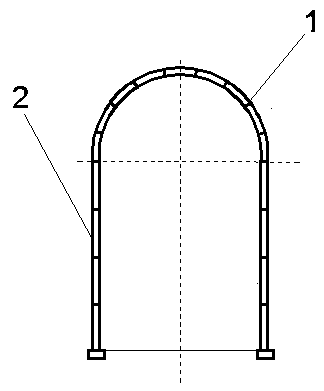

[0045] see figure 2 As shown, a spliced circular arch straight wall steel arch frame, the arch bracket 1 is a semicircular arch frame, the two side wall brackets 2 are vertical arch frames, and the center of the arch bracket center 1 is connected to the center of the tunnel Vertical to the tunnel ground, the vault support 1 and the side wall support 2 are fixedly connected by bolts.

[0046] Vault bracket 1 is composed of 5 first brackets fixedly connected by bolts. The deformation arc of the first brackets is 36°. Side wall arch frame 2 is composed of 8 second brackets connected by bolts. The second brackets are not deformed. The lengths of the shaped steel of the first bracket and the second bracket are the same or different.

[0047] Both the first bracket and the second bracket are made up of shaped steel and connecting steel plate 6, the center of connecting steel plate 6 coincides with the center of the end of shaped steel 3, connecting steel plate 6 is vertically we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com