Brake master pump

A technology of brake master cylinder and pump body, which is applied in the field of hydraulic equipment, can solve the problems of increased types of semi-finished products and finished products, additional burden of production scheduling, increased management difficulty, etc., and achieves the effects of reasonable structure, simplified valve body processing, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and embodiments.

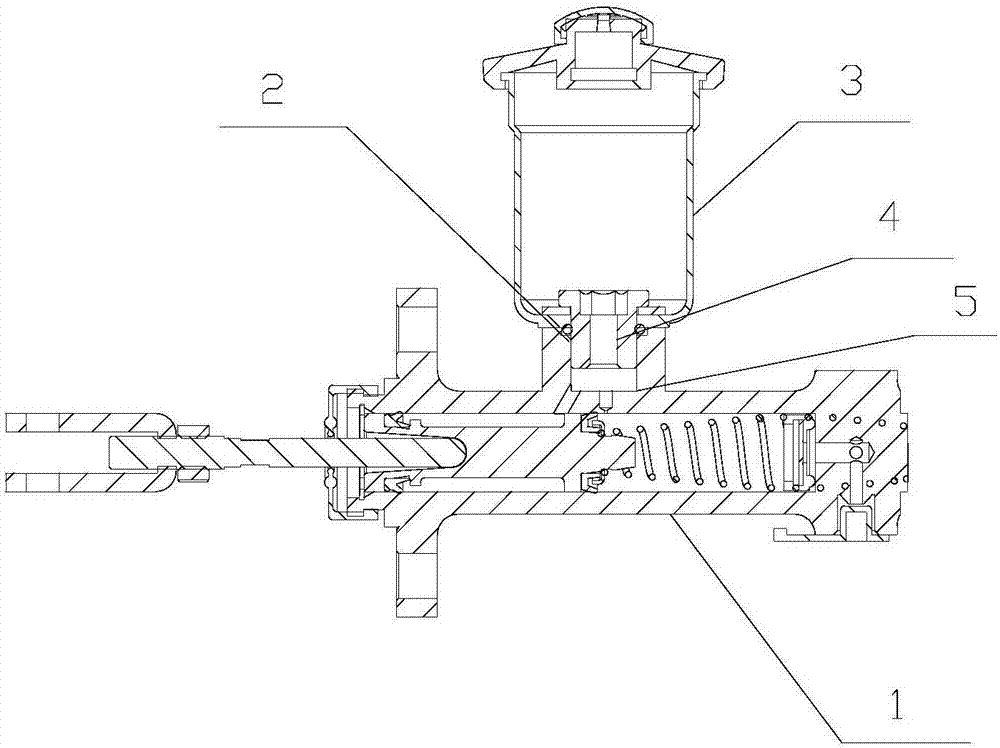

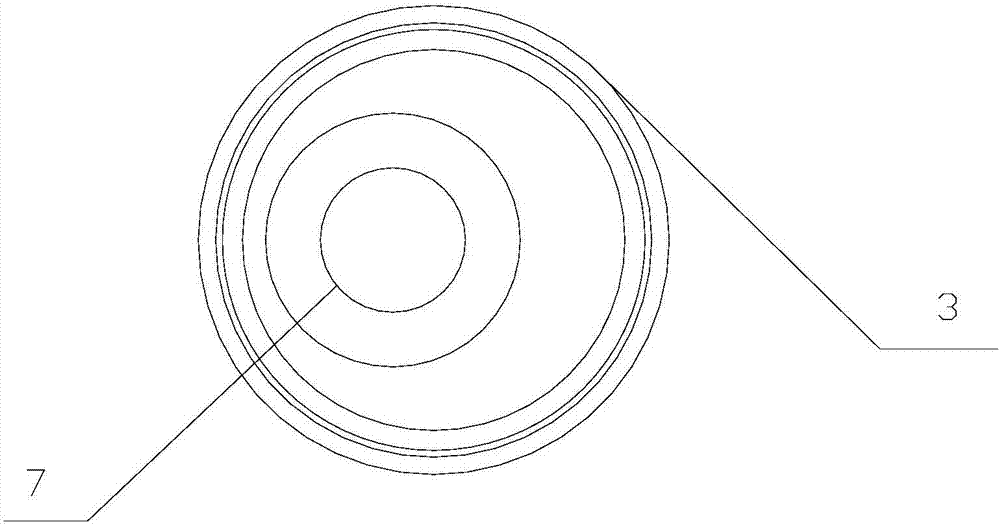

[0018] Such as Figure 1~3 As shown, a brake master cylinder includes: a pump body 1, the pump body 1 is provided with a master cylinder oiler interface 5, and the oiler assembly 3 is fixedly connected to the pump body 1 through the master cylinder oiler interface 5 Above, the oiler assembly 3 includes an oiler outlet 7 , and the oiler outlet 7 is an eccentric structure relative to the oiler assembly 3 .

[0019] An oiler sealing ring 2 is provided at the joint between the oiler assembly 3 and the master pump oiler interface 5 .

[0020] The oil pot assembly 3 is fixedly connected to the pump body 1 through oil pot pressing bolts 4 .

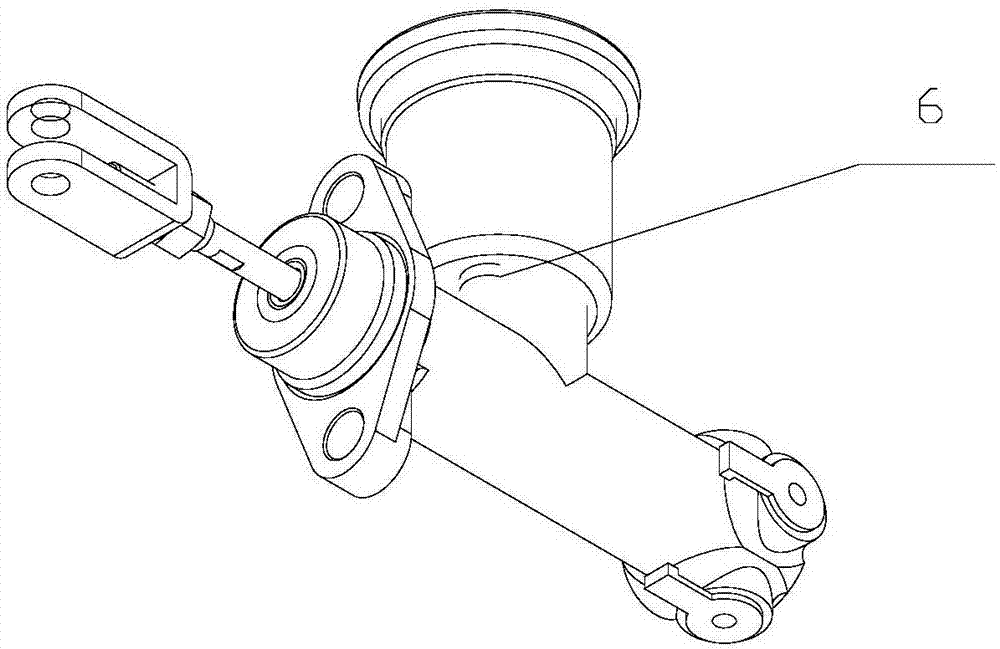

[0021] The oil pot assembly 3 is also provided with an oil pot stopper 6 .

[0022] The above-mentioned embodiments are only examples for clearly illustrating the present invention, rather than limiting the implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com