Mosquito net support with struts and sliding locks

A technology of sliding locks and pillars, which is applied to other seating furniture, home appliances, insect nets, etc., can solve problems such as hindering activities, high rigidity requirements for pillars and top frames, and bending damage of components of mosquito net brackets that shake up and down, and achieve The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

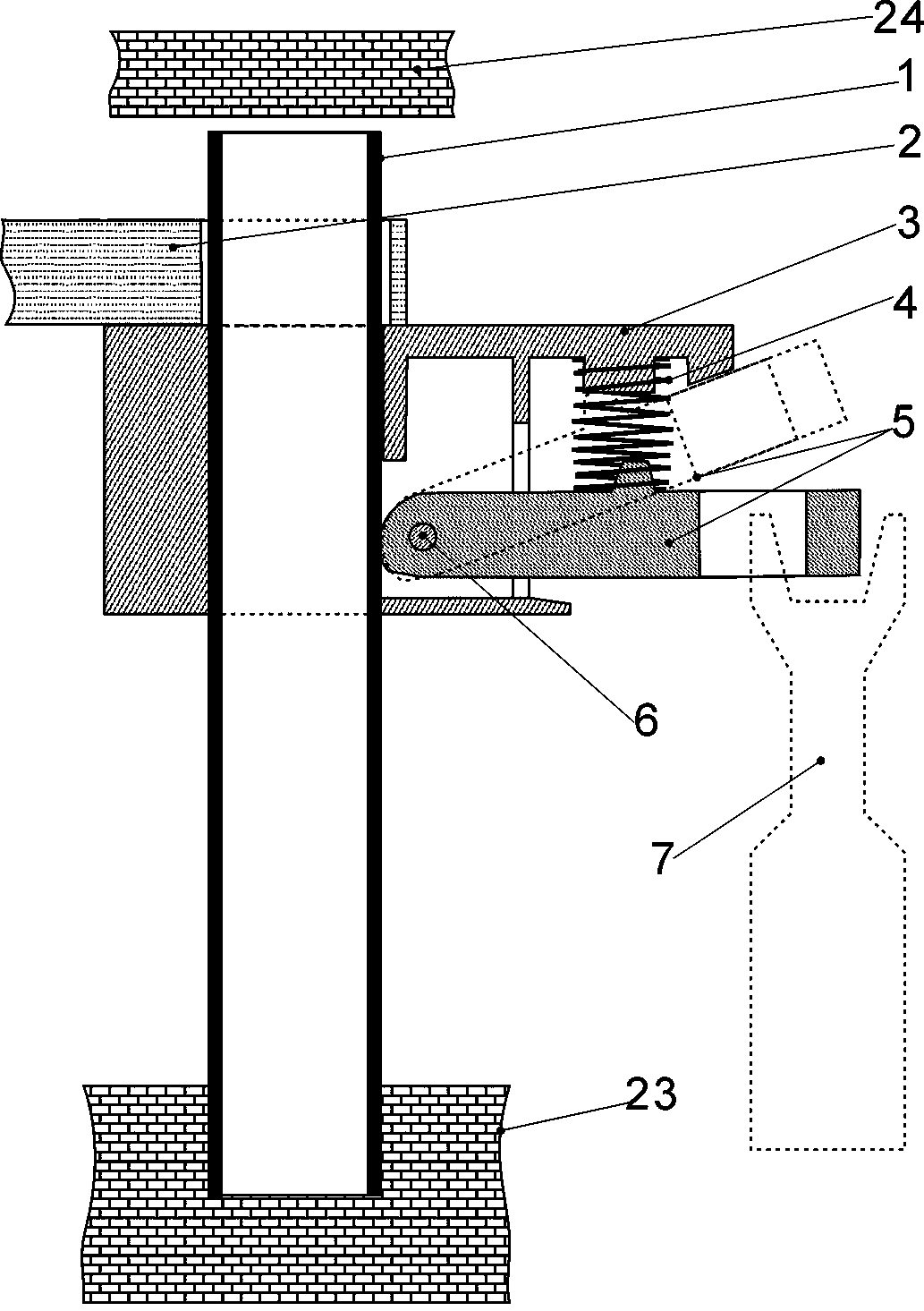

Embodiment 1

[0043] Embodiment one, see figure 1 and Figure 5 In this embodiment, the mosquito net bracket as a whole includes: a top frame 2, a column 1 and a slide lock 3S. Slide lock 3S is made up of lock case 3, pressure spring 4, lock handle 5, lock shaft 6. When the right end of the lock handle 5 of the slide lock (the position supported by the tool clothes fork 7 for applying external force) is at a high position, that is, when the lock handle 5 pushes against the lock housing 3 upwards, see figure 1 The middle dotted line draws the position and posture of the lock handle 5 with the contour line. The radius of the contact between the lock handle 5 and the column 1 should be 0.1 to 0.5 mm smaller than the distance from the lock shaft 6 to the surface of the column 1. When the lock handle 5 is horizontal, the lock The radius of the contact between the handle 5 and the column 1 is slightly larger than the distance from the lock shaft 6 to the surface of the column 1, and it is advis...

Embodiment 2

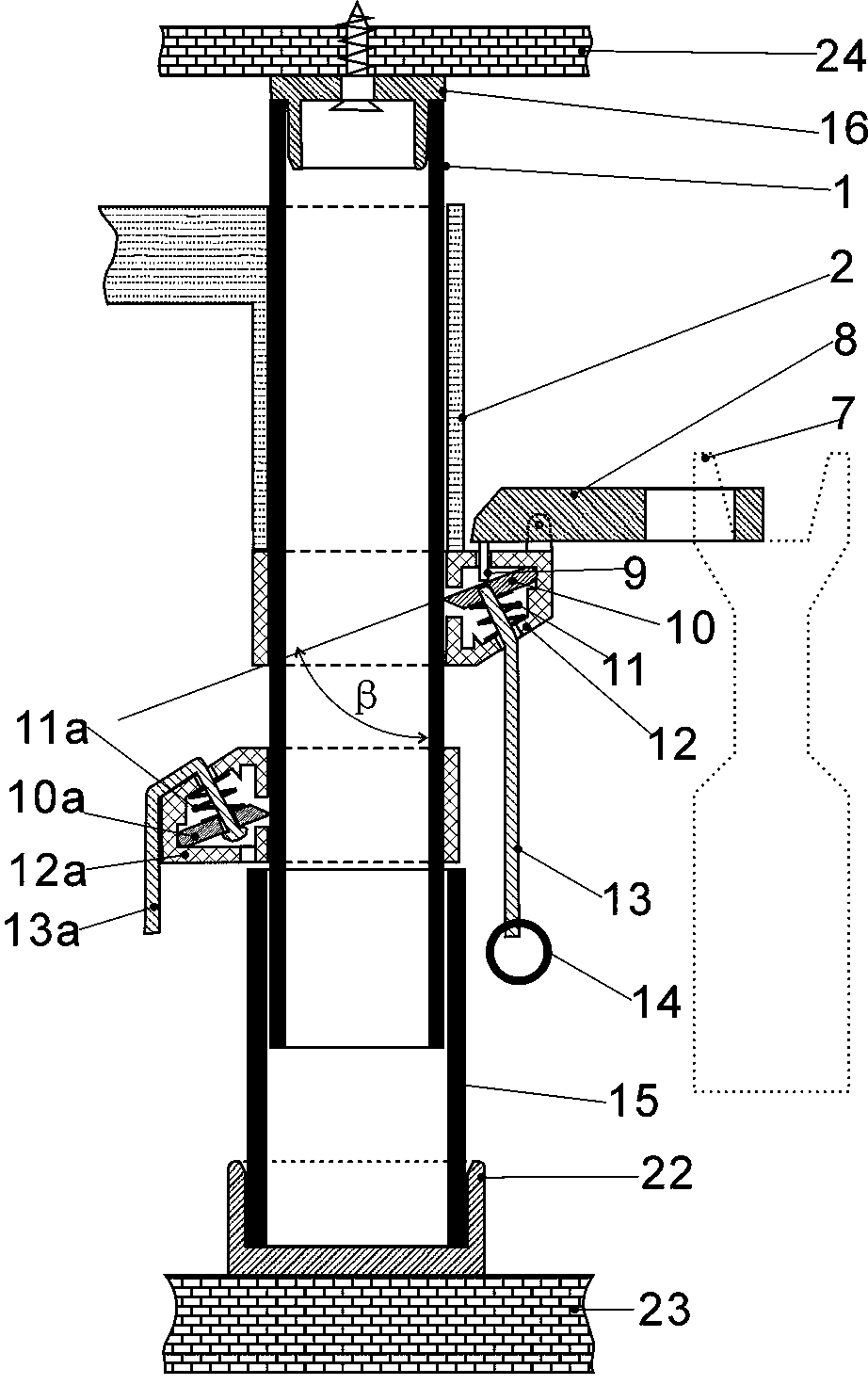

[0045] Embodiment two, see figure 2 , since no matter how many pillars the mosquito net support has, the details of each pillar and its connection with the top frame 2 are the same, so figure 2 Only draw a partial section view of a pillar and its connection with the top frame 2 in . In the present embodiment, the pillar includes parts such as column 1, pipe column 15, slide lock, two slide locks are altogether on every column 1 of mosquito net support, and top seat 16 can be fixed on ceiling 24 with screw, and base 22 can use double The face glue is glued on the floor 23 or fixed on the floor 23 with screws, figure 2 The central column 1 is a hollow pipe but can be solid in fact. If the column 1 is a solid top seat 12, it will be correspondingly changed into a structure like the base to constrain the column 1 from the outside.

[0046] In order to avoid confusion, the first slide lock of the two slide locks in this embodiment is made up of parts: lock housing 12, dead bol...

Embodiment 3

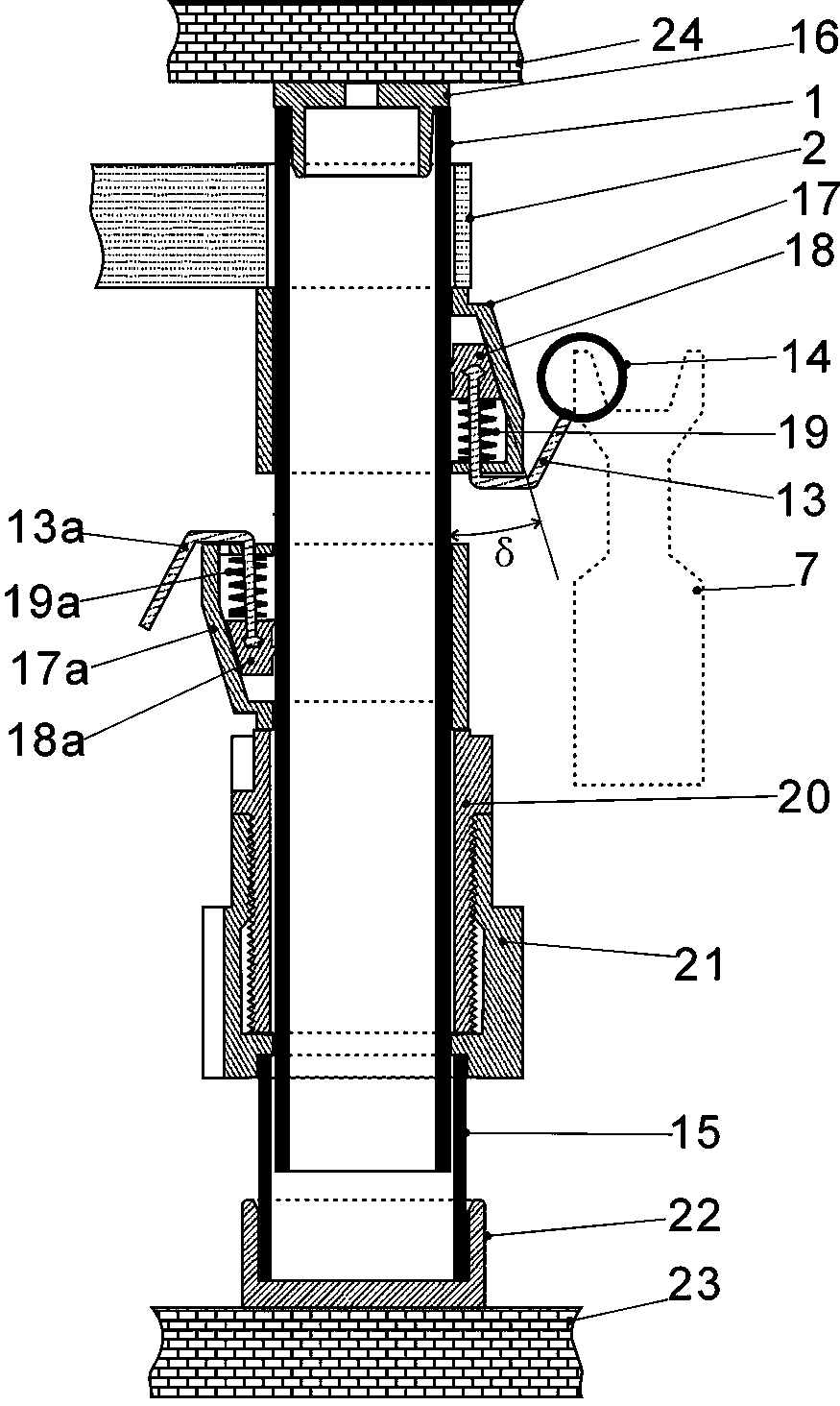

[0050] Embodiment three, see image 3 , since the details of each pillar and its connection to the top frame are the same no matter how many pillars the mosquito net support has, so image 3 Only draw a partial section view of a pillar and its connection with the top frame 2 in . The present embodiment is the specific embodiment that the structure of technical scheme 3 adopts the slide lock described in technical scheme 6 again. There are two slide locks on each column 1 of the mosquito net support, and the lifting of the top frame 2 is realized by the first slide lock. The purpose is to rely on the second sliding lock and the pipe column 15 to realize the purpose of the stepless height adjustment of the column 1, and to rely on the screw 20 and the nut 21 to make the column 1 press the ceiling and the floor up and down to avoid the construction and installation for restricting the horizontal movement of the column .

[0051] The first slide lock is made up of lock housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com