Hydraulic clamping multipurpose tool with replaceable periphery blades

A hydraulic clamping and peripheral edge technology, applied in clamping, reamer, manufacturing tools, etc., can solve the problems of reducing processing efficiency and product accuracy, poor adaptability, etc., to improve processing accuracy and efficiency, long service life, reduce Effect of Inventory Quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

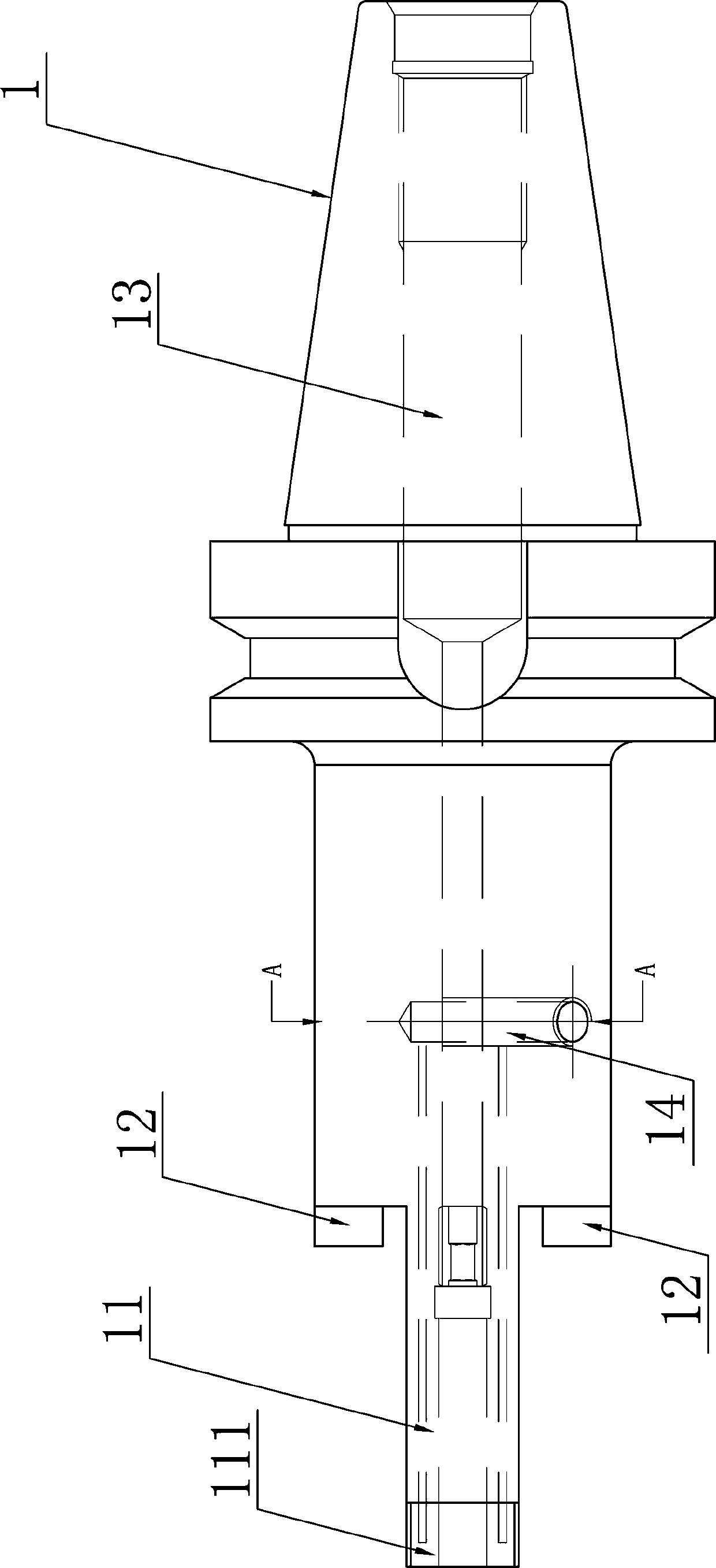

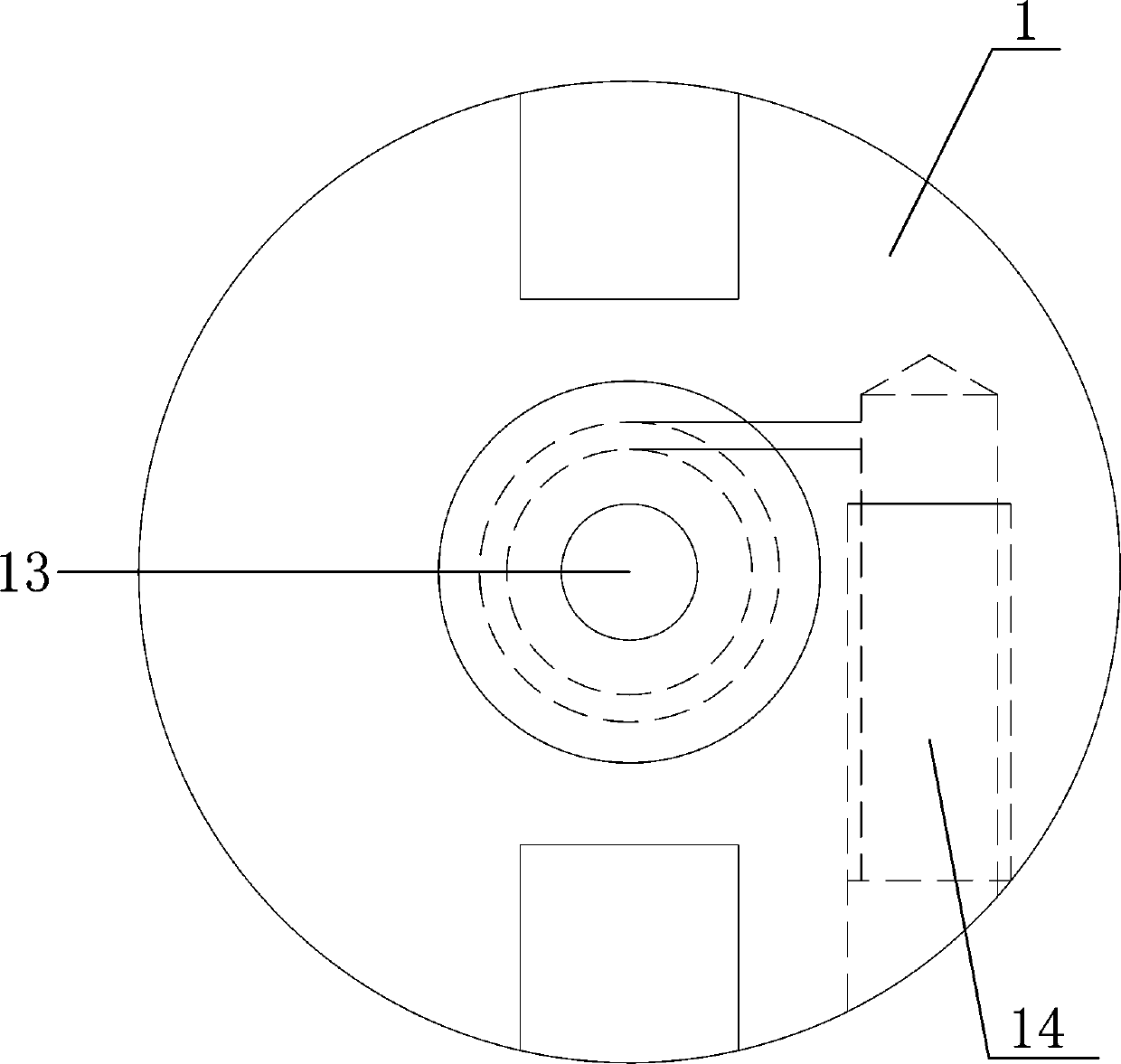

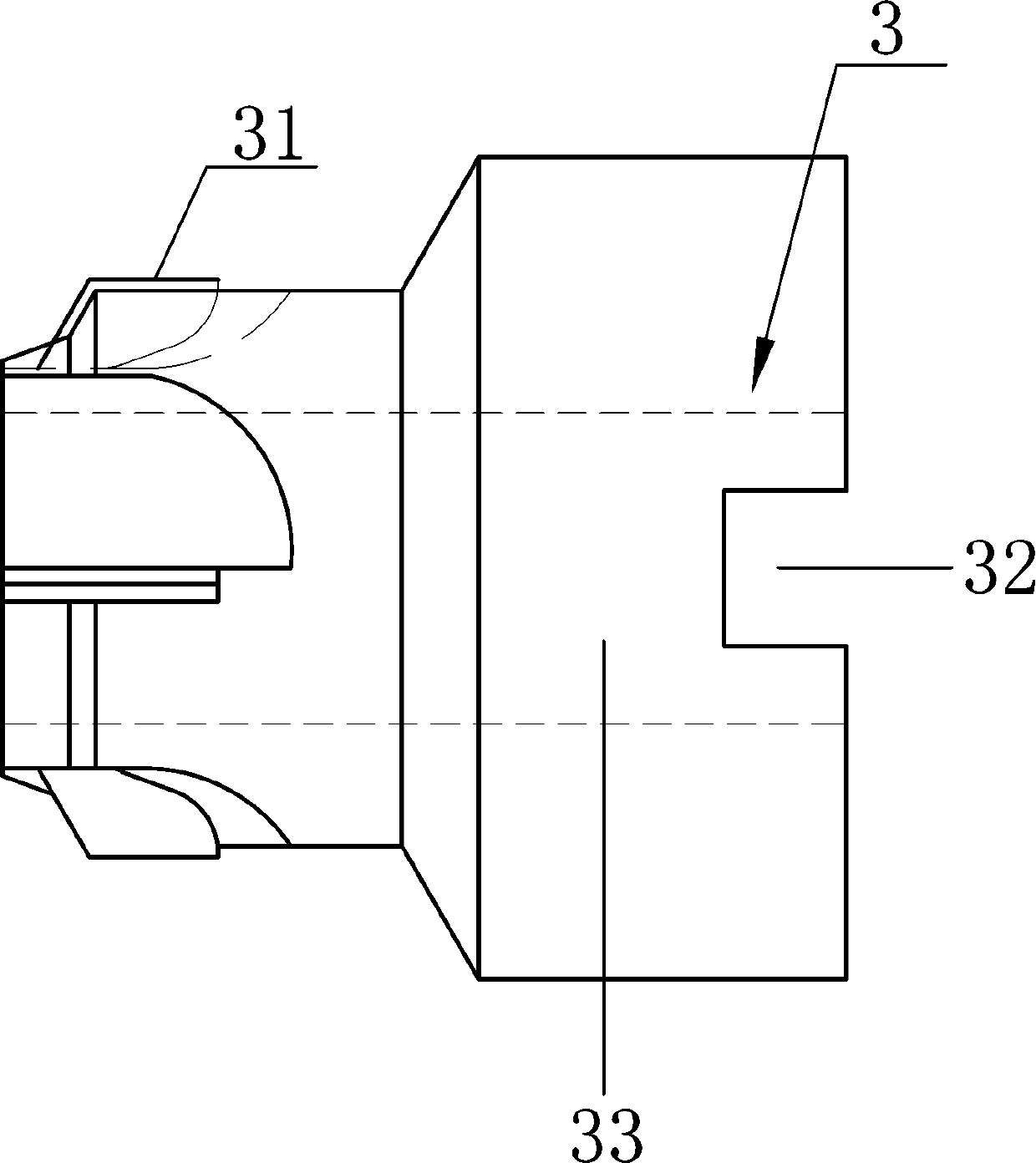

[0028] A hydraulically clamped multi-purpose tool with replaceable peripheral edges, including a hydraulic tool holder 1, a hydraulic locking bolt 2, a multi-edged chamfering knife 3, a lock nut 4 and a reamer 5, such as Figure 1 to Figure 7 As shown, the specific structure is:

[0029] The middle part of the front end of the hydraulic cutter bar 1 is provided with a positioning rod 11, and the front end of the positioning rod 11 is provided with at least three hydraulic oil flow passages 111. The outer surface of the hydraulic oil flow passages 111 is tapped with external threads that match the lock nut 4. Positioning teeth 12 are arranged on the outer edge of the front end of the tool bar 1, and the positioning teeth 12 are evenly distributed around the positioning bar 1. The middle part of the hydraulic tool bar 1 is provided with a tool bar cooling hole that passes through the front end surface of the positioning bar 11 and the rear end surface of the hydraulic tool bar 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com